Pouch Integration And BMS For Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Solid-state batteries (SSBs) represent a significant evolution in energy storage technology, with anode-free designs emerging as a particularly promising frontier. The development of anode-free solid-state batteries can be traced back to the early 2010s, when researchers began exploring ways to increase energy density while enhancing safety profiles of lithium-ion batteries. By eliminating the traditional graphite or silicon anode and allowing lithium to plate directly onto the current collector during charging, these batteries theoretically offer up to 70% higher energy density compared to conventional lithium-ion cells.

The technological evolution has been driven by increasing demands for higher energy density, improved safety, and longer cycle life in applications ranging from consumer electronics to electric vehicles and grid storage. Traditional lithium-ion batteries with liquid electrolytes face fundamental limitations in these areas, creating a strong impetus for solid-state alternatives. The anode-free configuration represents the ultimate optimization of lithium utilization within the battery architecture.

Current technical objectives for pouch integration and battery management systems (BMS) for anode-free SSBs focus on several critical areas. Primary among these is addressing the challenge of uniform lithium plating during charging to prevent dendrite formation, which can lead to short circuits and safety hazards. This requires sophisticated pressure management within the pouch cell format and advanced BMS algorithms capable of detecting early signs of non-uniform plating.

Another key objective involves the development of manufacturing processes that enable cost-effective, large-scale production of pouch-format anode-free SSBs. This includes innovations in solid electrolyte deposition, cathode formulation, and current collector treatments that facilitate reliable lithium plating and stripping over thousands of cycles.

Temperature management represents a third critical objective, as solid electrolytes typically require elevated temperatures to achieve ionic conductivity comparable to liquid systems. BMS development must therefore incorporate precise thermal management capabilities tailored to the specific solid electrolyte chemistry employed.

The integration of these batteries into practical applications further necessitates the development of state estimation algorithms that can accurately determine the state of charge, state of health, and remaining useful life of anode-free SSBs, which exhibit different voltage profiles and aging mechanisms compared to conventional batteries.

Looking forward, the technology trajectory aims toward commercialization in premium applications by mid-decade, with broader market penetration expected as manufacturing scales and costs decrease. The ultimate goal is to enable electric vehicles with 500+ mile ranges, consumer devices with multi-day battery life, and grid storage solutions with enhanced safety and longevity.

The technological evolution has been driven by increasing demands for higher energy density, improved safety, and longer cycle life in applications ranging from consumer electronics to electric vehicles and grid storage. Traditional lithium-ion batteries with liquid electrolytes face fundamental limitations in these areas, creating a strong impetus for solid-state alternatives. The anode-free configuration represents the ultimate optimization of lithium utilization within the battery architecture.

Current technical objectives for pouch integration and battery management systems (BMS) for anode-free SSBs focus on several critical areas. Primary among these is addressing the challenge of uniform lithium plating during charging to prevent dendrite formation, which can lead to short circuits and safety hazards. This requires sophisticated pressure management within the pouch cell format and advanced BMS algorithms capable of detecting early signs of non-uniform plating.

Another key objective involves the development of manufacturing processes that enable cost-effective, large-scale production of pouch-format anode-free SSBs. This includes innovations in solid electrolyte deposition, cathode formulation, and current collector treatments that facilitate reliable lithium plating and stripping over thousands of cycles.

Temperature management represents a third critical objective, as solid electrolytes typically require elevated temperatures to achieve ionic conductivity comparable to liquid systems. BMS development must therefore incorporate precise thermal management capabilities tailored to the specific solid electrolyte chemistry employed.

The integration of these batteries into practical applications further necessitates the development of state estimation algorithms that can accurately determine the state of charge, state of health, and remaining useful life of anode-free SSBs, which exhibit different voltage profiles and aging mechanisms compared to conventional batteries.

Looking forward, the technology trajectory aims toward commercialization in premium applications by mid-decade, with broader market penetration expected as manufacturing scales and costs decrease. The ultimate goal is to enable electric vehicles with 500+ mile ranges, consumer devices with multi-day battery life, and grid storage solutions with enhanced safety and longevity.

Market Analysis for Solid-State Battery Applications

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for electric vehicles (EVs), consumer electronics, and renewable energy storage solutions. Current market projections indicate that the global solid-state battery market will reach approximately $6.5 billion by 2026, with a compound annual growth rate of around 34% from 2021. This remarkable growth trajectory is primarily fueled by the superior performance characteristics of solid-state batteries, particularly anode-free designs, which offer higher energy density, improved safety, and longer cycle life compared to conventional lithium-ion batteries.

The automotive sector represents the largest application segment for solid-state batteries, accounting for over 40% of the total market share. Major automotive manufacturers including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery technology, recognizing its potential to overcome the range anxiety and safety concerns associated with traditional EV batteries. The integration of pouch-type anode-free solid-state batteries with advanced BMS (Battery Management Systems) is particularly attractive for this sector due to their flexible form factor and weight advantages.

Consumer electronics constitutes the second-largest application market, with approximately 30% market share. Manufacturers are increasingly seeking batteries with higher energy density and improved safety profiles for smartphones, laptops, and wearable devices. The thin profile of pouch-integrated anode-free solid-state batteries makes them especially suitable for next-generation portable electronic devices where space optimization is critical.

Geographically, Asia-Pacific dominates the solid-state battery market with approximately 45% share, led by Japan, South Korea, and China. These countries have established robust research and manufacturing ecosystems for advanced battery technologies. North America and Europe follow with approximately 30% and 20% market shares respectively, with significant growth potential as EV adoption accelerates in these regions.

Market challenges include high production costs, which currently position solid-state batteries at 2-3 times the price of conventional lithium-ion batteries. However, economies of scale and manufacturing innovations are expected to reduce this cost differential to less than 30% by 2028. Additionally, the integration of effective BMS with pouch-type anode-free solid-state batteries presents technical challenges that several specialized companies are addressing through innovative solutions.

Customer demand patterns indicate growing preference for batteries that offer fast charging capabilities, with over 80% of potential EV buyers citing charging time as a critical purchase factor. Anode-free solid-state batteries with appropriate BMS integration can potentially achieve charging rates 2-3 times faster than conventional lithium-ion batteries, positioning them favorably to meet this market requirement.

The automotive sector represents the largest application segment for solid-state batteries, accounting for over 40% of the total market share. Major automotive manufacturers including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery technology, recognizing its potential to overcome the range anxiety and safety concerns associated with traditional EV batteries. The integration of pouch-type anode-free solid-state batteries with advanced BMS (Battery Management Systems) is particularly attractive for this sector due to their flexible form factor and weight advantages.

Consumer electronics constitutes the second-largest application market, with approximately 30% market share. Manufacturers are increasingly seeking batteries with higher energy density and improved safety profiles for smartphones, laptops, and wearable devices. The thin profile of pouch-integrated anode-free solid-state batteries makes them especially suitable for next-generation portable electronic devices where space optimization is critical.

Geographically, Asia-Pacific dominates the solid-state battery market with approximately 45% share, led by Japan, South Korea, and China. These countries have established robust research and manufacturing ecosystems for advanced battery technologies. North America and Europe follow with approximately 30% and 20% market shares respectively, with significant growth potential as EV adoption accelerates in these regions.

Market challenges include high production costs, which currently position solid-state batteries at 2-3 times the price of conventional lithium-ion batteries. However, economies of scale and manufacturing innovations are expected to reduce this cost differential to less than 30% by 2028. Additionally, the integration of effective BMS with pouch-type anode-free solid-state batteries presents technical challenges that several specialized companies are addressing through innovative solutions.

Customer demand patterns indicate growing preference for batteries that offer fast charging capabilities, with over 80% of potential EV buyers citing charging time as a critical purchase factor. Anode-free solid-state batteries with appropriate BMS integration can potentially achieve charging rates 2-3 times faster than conventional lithium-ion batteries, positioning them favorably to meet this market requirement.

Current Challenges in Pouch Cell Integration

Despite the promising potential of anode-free solid-state batteries (AFSSBs), their integration into practical pouch cells presents significant challenges that impede commercial viability. The transition from coin cell laboratory demonstrations to larger format pouch cells introduces complex manufacturing hurdles that must be addressed systematically.

A primary challenge lies in the mechanical stability of the solid electrolyte layer during pouch cell assembly. Unlike liquid electrolytes that can easily conform to electrode surfaces, solid electrolytes require precise interface engineering to maintain consistent contact with the cathode while accommodating volume changes during cycling. The pressure distribution within pouch cells is often non-uniform, leading to localized stress concentrations that can fracture brittle solid electrolytes.

Stack pressure management represents another critical obstacle. AFSSBs typically require constant pressure to maintain intimate contact between components, but conventional pouch cell designs lack built-in pressure regulation mechanisms. External pressure fixtures add complexity, weight, and cost to the battery system, compromising the energy density advantages of the technology.

The sealing process for pouch cells containing moisture-sensitive solid electrolytes demands specialized techniques beyond standard production methods. Traditional heat-sealing approaches may introduce thermal gradients that damage the solid electrolyte interface. Additionally, even trace amounts of moisture ingress during assembly can trigger detrimental side reactions with lithium metal formed during charging, significantly degrading cell performance.

Current tab design and placement methodologies optimized for conventional lithium-ion batteries prove inadequate for AFSSBs. The higher interfacial resistance between solid components necessitates novel current collector configurations to ensure uniform current distribution across the cell area, preventing localized lithium plating and dendrite formation.

Manufacturing scalability remains perhaps the most formidable barrier. Existing roll-to-roll processes developed for liquid electrolyte systems cannot be directly applied to solid electrolyte layers without significant modification. The precise alignment and stacking of multiple solid layers without introducing defects or contamination requires new manufacturing paradigms and specialized equipment.

The integration of temperature management systems presents additional complexity, as solid-state electrolytes typically exhibit optimal ionic conductivity at elevated temperatures. This necessitates thermal management solutions that can maintain consistent operating temperatures while preventing thermal runaway events, further complicating pouch cell design and integration.

A primary challenge lies in the mechanical stability of the solid electrolyte layer during pouch cell assembly. Unlike liquid electrolytes that can easily conform to electrode surfaces, solid electrolytes require precise interface engineering to maintain consistent contact with the cathode while accommodating volume changes during cycling. The pressure distribution within pouch cells is often non-uniform, leading to localized stress concentrations that can fracture brittle solid electrolytes.

Stack pressure management represents another critical obstacle. AFSSBs typically require constant pressure to maintain intimate contact between components, but conventional pouch cell designs lack built-in pressure regulation mechanisms. External pressure fixtures add complexity, weight, and cost to the battery system, compromising the energy density advantages of the technology.

The sealing process for pouch cells containing moisture-sensitive solid electrolytes demands specialized techniques beyond standard production methods. Traditional heat-sealing approaches may introduce thermal gradients that damage the solid electrolyte interface. Additionally, even trace amounts of moisture ingress during assembly can trigger detrimental side reactions with lithium metal formed during charging, significantly degrading cell performance.

Current tab design and placement methodologies optimized for conventional lithium-ion batteries prove inadequate for AFSSBs. The higher interfacial resistance between solid components necessitates novel current collector configurations to ensure uniform current distribution across the cell area, preventing localized lithium plating and dendrite formation.

Manufacturing scalability remains perhaps the most formidable barrier. Existing roll-to-roll processes developed for liquid electrolyte systems cannot be directly applied to solid electrolyte layers without significant modification. The precise alignment and stacking of multiple solid layers without introducing defects or contamination requires new manufacturing paradigms and specialized equipment.

The integration of temperature management systems presents additional complexity, as solid-state electrolytes typically exhibit optimal ionic conductivity at elevated temperatures. This necessitates thermal management solutions that can maintain consistent operating temperatures while preventing thermal runaway events, further complicating pouch cell design and integration.

Existing Pouch Integration Solutions for SSBs

01 Anode-Free Battery Design and Architecture

Anode-free solid-state battery designs eliminate the traditional anode layer, instead allowing lithium to plate directly onto the current collector during charging. This architecture increases energy density by removing the weight and volume of a dedicated anode material. The design typically incorporates specialized current collectors and interfaces to manage lithium plating/stripping processes efficiently while preventing dendrite formation. These batteries require careful engineering of the solid electrolyte interface to maintain stability during cycling.- Anode-free solid-state battery design and materials: Anode-free solid-state batteries utilize lithium metal that forms during charging rather than having a pre-deposited anode. These designs incorporate specialized solid electrolytes that enable efficient lithium ion transport while preventing dendrite formation. Key materials include ceramic and polymer-based solid electrolytes with high ionic conductivity. The absence of a pre-deposited anode increases energy density and reduces manufacturing complexity, making these batteries promising for next-generation energy storage applications.

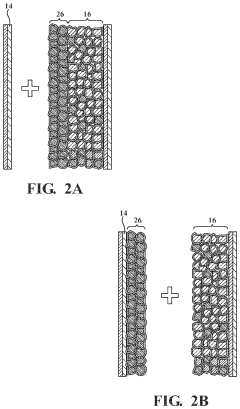

- Pouch cell integration for solid-state batteries: Pouch cell integration for anode-free solid-state batteries involves specialized packaging techniques to maintain pressure on the cell stack while accommodating volume changes during cycling. The pouch design includes multi-layer barrier films that prevent moisture ingress, which is critical for solid electrolyte stability. Manufacturing processes have been developed to ensure uniform stacking and sealing of components within the pouch format, addressing challenges related to interfacial contact between solid components and mechanical stability during battery operation.

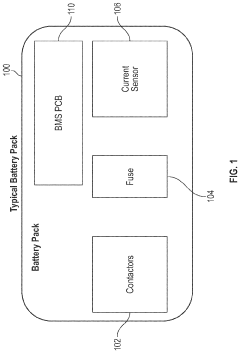

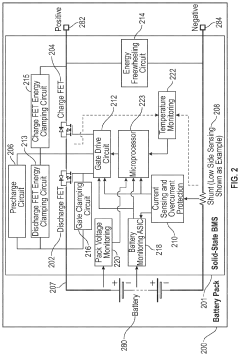

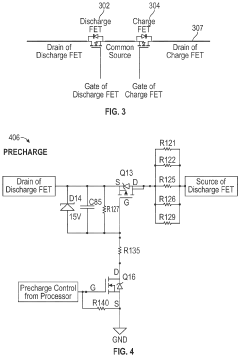

- Battery management systems for solid-state batteries: Battery management systems specifically designed for anode-free solid-state batteries incorporate algorithms that account for their unique electrochemical characteristics. These systems monitor critical parameters including temperature gradients, internal pressure, and state of charge with high precision to prevent lithium plating and dendrite formation. Advanced BMS solutions integrate predictive models that adapt to the changing internal resistance patterns of solid-state cells during cycling, extending battery life and enhancing safety through early detection of potential failure modes.

- Thermal management for anode-free solid-state batteries: Thermal management solutions for anode-free solid-state batteries address their specific temperature-dependent performance characteristics. These systems maintain optimal operating temperature ranges to ensure proper ionic conductivity of solid electrolytes while preventing overheating. Innovations include integrated heating elements for cold-start conditions and cooling systems that provide uniform temperature distribution across cell stacks. Advanced thermal management approaches incorporate phase change materials and liquid cooling circuits specifically designed for the thermal behavior of solid-state battery packs.

- Safety and failure detection mechanisms: Safety mechanisms for anode-free solid-state batteries include specialized sensors that detect mechanical deformation, pressure changes, and early signs of dendrite formation. These systems incorporate redundant monitoring circuits that can identify potential failure modes before they lead to thermal runaway. Advanced diagnostic algorithms analyze impedance signatures to detect internal short circuits or electrolyte degradation. Safety features also include physical protection elements such as pressure relief mechanisms and electrical isolation systems designed specifically for the failure modes of solid-state battery architectures.

02 Pouch Cell Integration for Solid-State Batteries

Integration of anode-free solid-state batteries into pouch cell formats presents unique challenges and opportunities. The pouch design must accommodate the mechanical stresses during lithium plating/stripping cycles while maintaining hermetic sealing. Specialized stacking and folding techniques are employed to optimize the internal space and ensure uniform pressure distribution across the cell layers. Manufacturing processes have been developed to address the sensitivity of solid electrolytes to moisture and air during pouch assembly and sealing operations.Expand Specific Solutions03 Battery Management Systems for Anode-Free Configurations

Battery Management Systems (BMS) for anode-free solid-state batteries require specialized algorithms to monitor and control the unique electrochemical processes involved. These systems incorporate advanced state-of-charge estimation methods that account for the absence of a traditional anode. The BMS must precisely control charging protocols to ensure uniform lithium plating and prevent dendrite formation. Additional safety features monitor mechanical stress, temperature gradients, and internal resistance changes specific to anode-free configurations.Expand Specific Solutions04 Solid Electrolyte Interfaces and Stability

The interface between the solid electrolyte and the lithium metal that forms during charging is critical for anode-free battery performance. Various coating technologies and interface engineering approaches have been developed to stabilize this boundary and prevent unwanted side reactions. Composite electrolytes combining different materials can create more stable interfaces while maintaining high ionic conductivity. These interfaces must accommodate volume changes during cycling while preventing electrolyte degradation and maintaining consistent lithium ion transport properties.Expand Specific Solutions05 Thermal Management and Safety Systems

Thermal management is crucial for anode-free solid-state batteries, particularly in pouch formats where heat distribution can be uneven. Specialized cooling systems have been developed to address hotspot formation during rapid charging. Safety mechanisms include pressure-sensitive switches that can detect mechanical deformation, thermal runaway prevention systems, and early detection of dendrite formation. These safety features are integrated with the BMS to enable real-time monitoring and preventive actions before critical failures occur.Expand Specific Solutions

Leading Companies in Solid-State Battery Development

The anode-free solid-state battery market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as this technology promises higher energy density and improved safety over conventional lithium-ion batteries. Major players like LG Energy Solution, LG Chem, and Factorial are advancing pouch integration and BMS technologies, while automotive companies including Hyundai, Kia, and GM are actively pursuing partnerships to secure future supply chains. Chinese manufacturers such as EVE Energy, WeLion, and Guoxuan are rapidly scaling their capabilities. The technology remains at TRL 5-7, with challenges in manufacturing scalability and system integration still being addressed before mass commercialization can occur.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive pouch integration system for anode-free solid-state batteries featuring a proprietary stacking technology that optimizes the interface between solid electrolyte and lithium metal. Their solution incorporates a multi-layer protection mechanism that prevents dendrite formation while maintaining high energy density. The BMS system employs advanced algorithms specifically designed for the unique charging/discharging characteristics of anode-free cells, with real-time impedance spectroscopy to monitor the solid-electrolyte interface. Their pouch design includes specialized pressure regulation mechanisms that accommodate volume changes during cycling while maintaining optimal contact between components. LG Chem's integration approach also features thermal management systems calibrated for the specific heat transfer properties of solid electrolytes.

Strengths: Industry-leading energy density (over 900 Wh/L); excellent thermal stability; sophisticated BMS algorithms specifically optimized for solid-state chemistry. Weaknesses: Higher manufacturing costs compared to conventional lithium-ion batteries; limited production scale; challenges with cycle life at extreme temperatures.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced pouch integration system for their Ultium platform, which includes provisions for anode-free solid-state battery configurations. Their approach features a modular design that allows for flexible adaptation to different cell chemistries while maintaining manufacturing compatibility with existing production lines. The pouch design incorporates specialized sealing techniques that ensure long-term stability of the moisture-sensitive solid electrolyte components. GM's BMS solution employs a multi-layered approach to battery management, with dedicated subsystems for thermal regulation, state-of-charge estimation, and safety monitoring. Their system features proprietary algorithms specifically calibrated for the unique characteristics of solid-state cells, including non-linear impedance responses and distinctive voltage signatures. The BMS incorporates wireless communication capabilities for over-the-air updates, allowing continuous improvement of battery management strategies as more operational data becomes available. Their integration approach also includes provisions for direct cooling of cells, addressing the thermal management challenges specific to solid-state batteries.

Strengths: Extensive integration experience with vehicle systems; sophisticated thermal management capabilities; robust safety systems with multiple redundancies. Weaknesses: Less specialized focus on solid-state technology compared to pure battery companies; challenges with optimizing energy density while maintaining automotive safety standards; higher system complexity.

Key Patents in Anode-Free Battery Technology

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

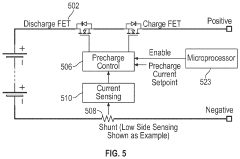

Solid-State Battery Management System for High Current Applications

PatentPendingUS20230395876A1

Innovation

- Integration of solid-state FETs, current sensing, and other battery management components onto a single printed circuit board assembly (PCBA) with advanced monitoring, driving, protection, and thermal management systems, including solid-state precharge circuits, fast gate turn-off circuits, energy clamping, and redundant overcharge/overvoltage detection, to enhance efficiency, reliability, and safety.

Safety Standards for Solid-State Battery Systems

The development of safety standards for solid-state battery systems represents a critical component in the advancement and commercialization of anode-free solid-state battery technologies. Current safety standards for lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, provide a foundation but require significant adaptation to address the unique characteristics and failure modes of solid-state systems, particularly those utilizing pouch cell configurations.

Safety standards for anode-free solid-state batteries must account for their distinctive material properties and potential failure mechanisms. The absence of a traditional anode introduces novel safety considerations related to lithium plating behavior, interface stability, and mechanical stress distribution within the pouch cell structure. These factors necessitate specialized testing protocols beyond those established for conventional lithium-ion technologies.

Thermal runaway prevention remains paramount in safety standard development, though solid-state electrolytes offer inherent advantages through their non-flammable nature. Standards must evaluate thermal stability across wider operating temperature ranges, as solid electrolytes enable operation in conditions that would be hazardous for liquid-electrolyte systems. Mechanical integrity testing becomes increasingly important, as solid-state pouch cells may respond differently to physical deformation, puncture, or external pressure.

Battery Management System (BMS) integration presents unique challenges for anode-free solid-state batteries. Safety standards must address the specialized voltage profiles, impedance characteristics, and state-of-charge estimation methods required for these systems. The BMS must be capable of detecting early indicators of potential failure modes specific to solid-state architectures, such as dendrite formation or electrolyte fracturing, which differ significantly from conventional battery failure mechanisms.

International standardization bodies, including ISO, IEC, and UL, are actively developing frameworks specifically for solid-state battery technologies. These emerging standards emphasize abuse testing under extreme conditions, long-term reliability assessment, and accelerated aging protocols tailored to solid-state chemistry. The pouch cell format introduces additional considerations regarding edge sealing integrity, uniform pressure distribution, and terminal connection stability.

Regulatory compliance pathways for anode-free solid-state batteries remain in development, with transportation regulations requiring particular attention. The UN Manual of Tests and Criteria is evolving to incorporate provisions for solid-state technologies, though interim guidance often requires case-by-case safety assessments for novel battery architectures. This regulatory uncertainty presents both challenges and opportunities for early market entrants developing pouch-format solid-state systems.

Safety standards for anode-free solid-state batteries must account for their distinctive material properties and potential failure mechanisms. The absence of a traditional anode introduces novel safety considerations related to lithium plating behavior, interface stability, and mechanical stress distribution within the pouch cell structure. These factors necessitate specialized testing protocols beyond those established for conventional lithium-ion technologies.

Thermal runaway prevention remains paramount in safety standard development, though solid-state electrolytes offer inherent advantages through their non-flammable nature. Standards must evaluate thermal stability across wider operating temperature ranges, as solid electrolytes enable operation in conditions that would be hazardous for liquid-electrolyte systems. Mechanical integrity testing becomes increasingly important, as solid-state pouch cells may respond differently to physical deformation, puncture, or external pressure.

Battery Management System (BMS) integration presents unique challenges for anode-free solid-state batteries. Safety standards must address the specialized voltage profiles, impedance characteristics, and state-of-charge estimation methods required for these systems. The BMS must be capable of detecting early indicators of potential failure modes specific to solid-state architectures, such as dendrite formation or electrolyte fracturing, which differ significantly from conventional battery failure mechanisms.

International standardization bodies, including ISO, IEC, and UL, are actively developing frameworks specifically for solid-state battery technologies. These emerging standards emphasize abuse testing under extreme conditions, long-term reliability assessment, and accelerated aging protocols tailored to solid-state chemistry. The pouch cell format introduces additional considerations regarding edge sealing integrity, uniform pressure distribution, and terminal connection stability.

Regulatory compliance pathways for anode-free solid-state batteries remain in development, with transportation regulations requiring particular attention. The UN Manual of Tests and Criteria is evolving to incorporate provisions for solid-state technologies, though interim guidance often requires case-by-case safety assessments for novel battery architectures. This regulatory uncertainty presents both challenges and opportunities for early market entrants developing pouch-format solid-state systems.

Manufacturing Scalability Considerations

The scalability of manufacturing processes for anode-free solid-state batteries presents significant challenges that must be addressed for commercial viability. Current pouch cell integration techniques developed for conventional lithium-ion batteries require substantial modification to accommodate the unique properties of solid electrolytes and the absence of a pre-deposited anode. The transition from laboratory-scale production to industrial manufacturing necessitates the development of specialized equipment capable of handling sensitive solid electrolyte materials while maintaining precise environmental controls.

A critical manufacturing consideration is the interface formation between the solid electrolyte and the current collectors. Without a pre-deposited anode, ensuring uniform lithium plating during initial charging cycles requires exceptionally clean and controlled assembly environments. Contamination levels that might be acceptable in conventional battery production can lead to catastrophic failure in anode-free designs, necessitating cleanroom conditions that significantly increase production costs.

The integration of battery management systems (BMS) with anode-free solid-state batteries introduces additional manufacturing complexities. Sensors must be strategically positioned to monitor the electrochemical deposition of lithium during operation, requiring precise placement during the assembly process. This demands advanced automation systems capable of maintaining positional accuracy while handling delicate solid electrolyte components.

Roll-to-roll processing, a cornerstone of cost-effective battery manufacturing, faces particular challenges with solid electrolytes. The mechanical properties of these materials often preclude traditional handling methods, necessitating the development of specialized transfer mechanisms and processing equipment. Current pilot-scale production typically achieves throughput rates of only 0.5-2 m²/hour, compared to 50-100 m²/hour for conventional lithium-ion battery components.

Thermal management during manufacturing represents another significant hurdle. Many solid electrolytes require specific temperature profiles during assembly to achieve optimal interfacial contact and minimize internal resistance. Scaling these thermal processes while maintaining uniformity across larger pouch cells demands sophisticated heating and cooling systems integrated directly into production lines.

Cost modeling indicates that current manufacturing approaches for anode-free solid-state batteries result in production expenses 3-5 times higher than conventional lithium-ion technologies. Achieving cost parity will require not only process optimization but fundamental redesigns of manufacturing equipment and facility layouts. Industry projections suggest that economies of scale could reduce this premium to approximately 1.5 times by 2028, contingent upon significant investment in manufacturing technology development.

A critical manufacturing consideration is the interface formation between the solid electrolyte and the current collectors. Without a pre-deposited anode, ensuring uniform lithium plating during initial charging cycles requires exceptionally clean and controlled assembly environments. Contamination levels that might be acceptable in conventional battery production can lead to catastrophic failure in anode-free designs, necessitating cleanroom conditions that significantly increase production costs.

The integration of battery management systems (BMS) with anode-free solid-state batteries introduces additional manufacturing complexities. Sensors must be strategically positioned to monitor the electrochemical deposition of lithium during operation, requiring precise placement during the assembly process. This demands advanced automation systems capable of maintaining positional accuracy while handling delicate solid electrolyte components.

Roll-to-roll processing, a cornerstone of cost-effective battery manufacturing, faces particular challenges with solid electrolytes. The mechanical properties of these materials often preclude traditional handling methods, necessitating the development of specialized transfer mechanisms and processing equipment. Current pilot-scale production typically achieves throughput rates of only 0.5-2 m²/hour, compared to 50-100 m²/hour for conventional lithium-ion battery components.

Thermal management during manufacturing represents another significant hurdle. Many solid electrolytes require specific temperature profiles during assembly to achieve optimal interfacial contact and minimize internal resistance. Scaling these thermal processes while maintaining uniformity across larger pouch cells demands sophisticated heating and cooling systems integrated directly into production lines.

Cost modeling indicates that current manufacturing approaches for anode-free solid-state batteries result in production expenses 3-5 times higher than conventional lithium-ion technologies. Achieving cost parity will require not only process optimization but fundamental redesigns of manufacturing equipment and facility layouts. Industry projections suggest that economies of scale could reduce this premium to approximately 1.5 times by 2028, contingent upon significant investment in manufacturing technology development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!