Anode-Free Solid-State SEI CEI Chemistry Analytics

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Anode-free solid-state battery (SSB) technology represents a revolutionary advancement in energy storage systems, emerging from decades of battery evolution that began with lithium-ion batteries in the early 1990s. This technology eliminates the traditional graphite or silicon anode, instead utilizing lithium metal formed in-situ during the initial charging process, directly on the current collector. The concept has gained significant momentum since 2015, with research intensifying dramatically after 2018 when several breakthrough papers demonstrated viable prototypes.

The fundamental appeal of anode-free SSBs lies in their theoretical energy density advantage, potentially reaching 450-500 Wh/kg at the cell level—approximately 70% higher than conventional lithium-ion batteries. This advancement directly addresses the growing demand for higher energy density power sources in electric vehicles, portable electronics, and renewable energy storage systems.

The evolution of this technology builds upon critical developments in solid electrolyte materials, including sulfide-based, oxide-based, and polymer-based systems. Each electrolyte family presents unique advantages and challenges in the anode-free configuration, particularly regarding interfacial stability and ion transport mechanisms. The absence of a pre-deposited anode creates distinctive technical challenges that differentiate this approach from conventional battery designs.

Current research objectives in anode-free SSB technology focus primarily on understanding and controlling the solid electrolyte interphase (SEI) and cathode electrolyte interphase (CEI) formation mechanisms. These interfaces critically determine battery performance, cycle life, and safety characteristics. Advanced analytical techniques including in-situ XPS, TOF-SIMS, and cryo-electron microscopy have become essential tools for investigating these interfacial phenomena at the molecular level.

The primary technical goals include achieving stable lithium deposition/stripping efficiency exceeding 99.9% over 1000+ cycles, reducing interfacial resistance to below 10 Ω·cm², and developing manufacturing processes compatible with existing battery production infrastructure. Additionally, researchers aim to operate these batteries at near-ambient temperatures (0-60°C) without external pressure requirements.

From a commercial perspective, anode-free SSB technology targets a 30% reduction in battery pack costs compared to conventional lithium-ion systems, primarily through material savings and energy density improvements. The elimination of the anode material and associated manufacturing steps presents significant economic advantages if the technical challenges can be overcome.

The convergence of solid-state electrolytes with anode-free design represents a synergistic approach that could potentially address the persistent challenges of energy density, safety, and cost that have limited battery technology advancement. Success in this field would enable transformative applications across multiple industries, particularly in transportation and renewable energy integration.

The fundamental appeal of anode-free SSBs lies in their theoretical energy density advantage, potentially reaching 450-500 Wh/kg at the cell level—approximately 70% higher than conventional lithium-ion batteries. This advancement directly addresses the growing demand for higher energy density power sources in electric vehicles, portable electronics, and renewable energy storage systems.

The evolution of this technology builds upon critical developments in solid electrolyte materials, including sulfide-based, oxide-based, and polymer-based systems. Each electrolyte family presents unique advantages and challenges in the anode-free configuration, particularly regarding interfacial stability and ion transport mechanisms. The absence of a pre-deposited anode creates distinctive technical challenges that differentiate this approach from conventional battery designs.

Current research objectives in anode-free SSB technology focus primarily on understanding and controlling the solid electrolyte interphase (SEI) and cathode electrolyte interphase (CEI) formation mechanisms. These interfaces critically determine battery performance, cycle life, and safety characteristics. Advanced analytical techniques including in-situ XPS, TOF-SIMS, and cryo-electron microscopy have become essential tools for investigating these interfacial phenomena at the molecular level.

The primary technical goals include achieving stable lithium deposition/stripping efficiency exceeding 99.9% over 1000+ cycles, reducing interfacial resistance to below 10 Ω·cm², and developing manufacturing processes compatible with existing battery production infrastructure. Additionally, researchers aim to operate these batteries at near-ambient temperatures (0-60°C) without external pressure requirements.

From a commercial perspective, anode-free SSB technology targets a 30% reduction in battery pack costs compared to conventional lithium-ion systems, primarily through material savings and energy density improvements. The elimination of the anode material and associated manufacturing steps presents significant economic advantages if the technical challenges can be overcome.

The convergence of solid-state electrolytes with anode-free design represents a synergistic approach that could potentially address the persistent challenges of energy density, safety, and cost that have limited battery technology advancement. Success in this field would enable transformative applications across multiple industries, particularly in transportation and renewable energy integration.

Market Analysis for Next-Generation Battery Solutions

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. The market for next-generation battery solutions is projected to reach $240 billion by 2030, with solid-state batteries representing one of the fastest-growing segments at a CAGR of 34.2% between 2023 and 2030.

Anode-free solid-state battery technology represents a significant advancement in the battery landscape, offering potential energy density improvements of 50-80% compared to conventional lithium-ion batteries. This technology addresses critical market demands for higher energy density, improved safety, faster charging capabilities, and extended cycle life - all key factors driving consumer and industrial adoption.

The EV sector constitutes the largest potential market for anode-free solid-state batteries, with automotive manufacturers actively seeking solutions that can deliver greater range, reduced charging times, and enhanced safety profiles. Major automakers including Toyota, Volkswagen, and GM have announced substantial investments in solid-state battery technology, signaling strong market confidence in this direction.

Energy storage systems represent another substantial market opportunity, particularly as renewable energy integration accelerates globally. The intermittent nature of renewable sources necessitates advanced storage solutions, with grid-scale applications demanding batteries that offer improved safety, longer lifespans, and reduced maintenance requirements - all potential advantages of anode-free solid-state technology.

Consumer electronics manufacturers are also expressing significant interest in next-generation battery solutions, seeking to differentiate their products through longer battery life and faster charging capabilities. This market segment values the potential size and weight reductions that anode-free designs could enable.

Market analysis reveals that SEI (Solid Electrolyte Interphase) and CEI (Cathode Electrolyte Interphase) chemistry analytics represent critical differentiators in the competitive landscape. Companies demonstrating superior capabilities in understanding and controlling these interfaces are positioned to capture premium market segments and establish technological leadership.

Regional analysis indicates Asia-Pacific currently leads in manufacturing capacity and R&D investment for next-generation batteries, with Japan, South Korea, and China dominating patent filings related to anode-free and solid-state technologies. However, significant research initiatives in North America and Europe are rapidly advancing, supported by government funding programs aimed at establishing domestic supply chains for critical battery technologies.

Market adoption barriers include current high production costs, manufacturing scalability challenges, and technical hurdles related to interface stability. However, industry forecasts suggest that with continued R&D investment and manufacturing optimization, anode-free solid-state batteries could reach price parity with conventional lithium-ion batteries by 2028, potentially triggering widespread market adoption.

Anode-free solid-state battery technology represents a significant advancement in the battery landscape, offering potential energy density improvements of 50-80% compared to conventional lithium-ion batteries. This technology addresses critical market demands for higher energy density, improved safety, faster charging capabilities, and extended cycle life - all key factors driving consumer and industrial adoption.

The EV sector constitutes the largest potential market for anode-free solid-state batteries, with automotive manufacturers actively seeking solutions that can deliver greater range, reduced charging times, and enhanced safety profiles. Major automakers including Toyota, Volkswagen, and GM have announced substantial investments in solid-state battery technology, signaling strong market confidence in this direction.

Energy storage systems represent another substantial market opportunity, particularly as renewable energy integration accelerates globally. The intermittent nature of renewable sources necessitates advanced storage solutions, with grid-scale applications demanding batteries that offer improved safety, longer lifespans, and reduced maintenance requirements - all potential advantages of anode-free solid-state technology.

Consumer electronics manufacturers are also expressing significant interest in next-generation battery solutions, seeking to differentiate their products through longer battery life and faster charging capabilities. This market segment values the potential size and weight reductions that anode-free designs could enable.

Market analysis reveals that SEI (Solid Electrolyte Interphase) and CEI (Cathode Electrolyte Interphase) chemistry analytics represent critical differentiators in the competitive landscape. Companies demonstrating superior capabilities in understanding and controlling these interfaces are positioned to capture premium market segments and establish technological leadership.

Regional analysis indicates Asia-Pacific currently leads in manufacturing capacity and R&D investment for next-generation batteries, with Japan, South Korea, and China dominating patent filings related to anode-free and solid-state technologies. However, significant research initiatives in North America and Europe are rapidly advancing, supported by government funding programs aimed at establishing domestic supply chains for critical battery technologies.

Market adoption barriers include current high production costs, manufacturing scalability challenges, and technical hurdles related to interface stability. However, industry forecasts suggest that with continued R&D investment and manufacturing optimization, anode-free solid-state batteries could reach price parity with conventional lithium-ion batteries by 2028, potentially triggering widespread market adoption.

Current Challenges in Anode-Free SSB Development

Despite significant advancements in solid-state battery technology, anode-free solid-state batteries (AFSSBs) face several critical challenges that impede their commercial viability. The most prominent issue is the unstable solid electrolyte interface (SEI) formation during lithium plating and stripping cycles. Unlike conventional lithium-ion batteries with pre-formed SEI layers, AFSSBs develop these interfaces dynamically during operation, leading to unpredictable performance and accelerated degradation.

The cathode-electrolyte interface (CEI) presents equally significant challenges, particularly regarding chemical and mechanical compatibility. High-voltage cathode materials often react with solid electrolytes, forming resistive interlayers that impede lithium-ion transport. These reactions are exacerbated at elevated temperatures and higher states of charge, creating a moving target for interface engineering solutions.

Dendrite formation remains perhaps the most serious obstacle to AFSSB development. Without a traditional anode structure to guide lithium deposition, plated lithium tends to form irregular structures that can penetrate the solid electrolyte, causing internal short circuits. This phenomenon is particularly problematic at higher current densities, severely limiting fast-charging capabilities.

Volume changes during cycling represent another fundamental challenge. The absence of a host material for lithium storage means that the entire lithium inventory plates and strips directly at the current collector interface. This process causes significant volume fluctuations (up to 100%) that stress the solid electrolyte and compromise interfacial contact, leading to capacity fade and eventual cell failure.

Current analytical techniques for studying SEI and CEI chemistry in AFSSBs are insufficient. Traditional methods like X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM) provide only ex-situ snapshots of interface conditions, failing to capture the dynamic nature of these interfaces during operation. Advanced in-situ and operando techniques are needed but remain technically challenging to implement with solid-state systems.

Manufacturing scalability presents additional hurdles. The precise control required for interface formation in AFSSBs demands manufacturing processes that maintain exceptional cleanliness and uniformity. Current pilot-scale production methods struggle to achieve the necessary precision, resulting in high cell-to-cell variability and poor yield rates.

The combined challenges of interface stability, dendrite suppression, volume management, and analytical limitations create a complex technological landscape that requires interdisciplinary solutions spanning materials science, electrochemistry, and advanced manufacturing. Addressing these challenges will be essential for realizing the full potential of anode-free solid-state battery technology.

The cathode-electrolyte interface (CEI) presents equally significant challenges, particularly regarding chemical and mechanical compatibility. High-voltage cathode materials often react with solid electrolytes, forming resistive interlayers that impede lithium-ion transport. These reactions are exacerbated at elevated temperatures and higher states of charge, creating a moving target for interface engineering solutions.

Dendrite formation remains perhaps the most serious obstacle to AFSSB development. Without a traditional anode structure to guide lithium deposition, plated lithium tends to form irregular structures that can penetrate the solid electrolyte, causing internal short circuits. This phenomenon is particularly problematic at higher current densities, severely limiting fast-charging capabilities.

Volume changes during cycling represent another fundamental challenge. The absence of a host material for lithium storage means that the entire lithium inventory plates and strips directly at the current collector interface. This process causes significant volume fluctuations (up to 100%) that stress the solid electrolyte and compromise interfacial contact, leading to capacity fade and eventual cell failure.

Current analytical techniques for studying SEI and CEI chemistry in AFSSBs are insufficient. Traditional methods like X-ray photoelectron spectroscopy (XPS) and transmission electron microscopy (TEM) provide only ex-situ snapshots of interface conditions, failing to capture the dynamic nature of these interfaces during operation. Advanced in-situ and operando techniques are needed but remain technically challenging to implement with solid-state systems.

Manufacturing scalability presents additional hurdles. The precise control required for interface formation in AFSSBs demands manufacturing processes that maintain exceptional cleanliness and uniformity. Current pilot-scale production methods struggle to achieve the necessary precision, resulting in high cell-to-cell variability and poor yield rates.

The combined challenges of interface stability, dendrite suppression, volume management, and analytical limitations create a complex technological landscape that requires interdisciplinary solutions spanning materials science, electrochemistry, and advanced manufacturing. Addressing these challenges will be essential for realizing the full potential of anode-free solid-state battery technology.

Existing SEI/CEI Interface Management Approaches

01 Interface engineering for anode-free solid-state batteries

Interface engineering is crucial for anode-free solid-state batteries to stabilize the solid electrolyte interphase (SEI) and cathode electrolyte interphase (CEI). Various coating materials and additives can be applied to modify these interfaces, reducing interfacial resistance and preventing unwanted side reactions. These engineering approaches help to control lithium deposition/dissolution processes and enhance the overall electrochemical performance and cycling stability of anode-free solid-state batteries.- SEI formation and stabilization in anode-free solid-state batteries: The formation and stabilization of the solid electrolyte interphase (SEI) is critical in anode-free solid-state batteries. Various approaches focus on controlling the SEI formation process to enhance battery performance and longevity. These include using specific electrolyte additives, protective coatings, and engineered interfaces that promote stable SEI formation. A well-formed SEI layer helps prevent continuous electrolyte decomposition and enables efficient lithium ion transport while protecting the electrode surface.

- CEI engineering for improved cathode-electrolyte interface stability: Engineering the cathode electrolyte interphase (CEI) is essential for enhancing the stability and performance of solid-state batteries. Various approaches include surface modifications of cathode materials, application of protective coatings, and incorporation of functional additives that promote the formation of a stable CEI. A well-designed CEI helps mitigate unwanted side reactions, reduces impedance at the cathode-electrolyte interface, and improves overall battery cycling performance.

- Advanced electrolyte compositions for interface stabilization: Specialized electrolyte compositions play a crucial role in stabilizing both SEI and CEI in anode-free solid-state batteries. These include novel solid electrolytes with tailored chemical compositions, hybrid electrolyte systems, and electrolyte additives specifically designed to form stable interfaces. The electrolyte compositions are engineered to minimize parasitic reactions at electrode interfaces while maintaining high ionic conductivity and mechanical stability throughout battery operation.

- Interface engineering strategies for anode-free configurations: Interface engineering strategies specific to anode-free configurations focus on controlling lithium deposition and preventing dendrite formation. These approaches include artificial interlayers, gradient interfaces, and three-dimensional architectures that guide uniform lithium plating. Such engineering techniques help maintain the integrity of the solid electrolyte interface during cycling, prevent short circuits, and extend battery lifespan by enabling more uniform current distribution and lithium deposition.

- In-situ and ex-situ characterization of interface phenomena: Advanced characterization techniques are employed to understand the formation and evolution of SEI and CEI layers in anode-free solid-state batteries. These include in-situ and ex-situ analytical methods such as spectroscopy, microscopy, and electrochemical analysis that provide insights into interface composition, morphology, and dynamics. Such characterization helps identify degradation mechanisms, optimize interface designs, and develop more effective strategies for stabilizing electrode-electrolyte interfaces in next-generation batteries.

02 Artificial SEI formation techniques

Artificial SEI layers can be created on electrode surfaces to protect against degradation in anode-free solid-state batteries. These engineered interfaces can be formed through various methods including pre-lithiation, ex-situ coating processes, or in-situ formation using electrolyte additives. Artificial SEI layers with optimized composition and structure can effectively suppress dendrite growth, reduce interfacial resistance, and improve the cycling performance of anode-free solid-state batteries.Expand Specific Solutions03 Advanced electrolyte compositions for interface stabilization

Specialized electrolyte compositions can be designed to form stable SEI and CEI layers in anode-free solid-state batteries. These electrolytes may incorporate functional additives, salt combinations, or polymer modifications that promote the formation of uniform and ion-conductive interfacial layers. The optimized electrolyte compositions help to minimize parasitic reactions at the electrode-electrolyte interfaces, leading to improved coulombic efficiency and extended battery lifespan.Expand Specific Solutions04 Cathode protection strategies and CEI optimization

Protecting the cathode and optimizing the cathode-electrolyte interphase (CEI) is essential for high-performance anode-free solid-state batteries. Various approaches include surface coatings, doping of cathode materials, and gradient composition designs to stabilize the cathode-electrolyte interface. These strategies aim to prevent cathode degradation, suppress transition metal dissolution, and maintain stable lithium-ion transport pathways at the CEI, ultimately enhancing the overall battery performance and durability.Expand Specific Solutions05 In-situ characterization and monitoring of interfacial phenomena

Advanced in-situ and operando characterization techniques are employed to monitor and understand the formation and evolution of SEI and CEI layers in anode-free solid-state batteries. These methods include spectroscopic, microscopic, and electrochemical techniques that provide real-time information about interfacial reactions and morphological changes during battery operation. The insights gained from these characterization approaches enable the rational design of interface engineering strategies to improve the performance and reliability of anode-free solid-state batteries.Expand Specific Solutions

Leading Companies and Research Institutions in SSB Field

Anode-Free Solid-State Battery Technology is currently in an early development phase, characterized by intensive research and limited commercial applications. The market is projected to grow significantly as this technology promises higher energy density and safety compared to conventional lithium-ion batteries. Key players demonstrate varying levels of technical maturity: established manufacturers like LG Energy Solution, Toyota, and Samsung Electronics are investing heavily in R&D while leveraging their manufacturing expertise; academic institutions including Penn State, Cornell, and Zhejiang University are pioneering fundamental research on SEI/CEI chemistry; and emerging specialists like Factorial and Northvolt are developing innovative approaches to solid-state electrolytes. The competitive landscape shows a blend of traditional battery manufacturers, automotive companies, and research-focused startups racing to overcome technical challenges in interface stability and manufacturing scalability.

LG Energy Solution Ltd.

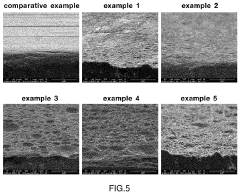

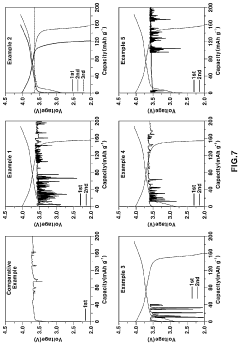

Technical Solution: LG Energy Solution has developed a pioneering anode-free solid-state battery technology that eliminates the traditional graphite anode, replacing it with a lithium metal anode that forms in-situ during the first charge cycle. Their approach focuses on advanced solid electrolyte interfaces (SEI) using a composite polymer-ceramic electrolyte system that enables stable lithium plating/stripping. The company has implemented sophisticated in-situ characterization techniques including X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (TOF-SIMS) to analyze the chemical composition and evolution of both SEI and cathode electrolyte interfaces (CEI) during cycling[1]. Their proprietary electrolyte formulation incorporates fluorinated additives that promote the formation of LiF-rich SEI layers, which significantly suppress dendrite growth and improve interfacial stability[2]. Recent advancements include a dual-layer protection strategy where a thin artificial SEI layer is pre-deposited on the current collector before cell assembly, working synergistically with the naturally formed SEI during operation.

Strengths: Superior energy density (>400 Wh/kg) due to elimination of anode host material; excellent cycle stability with >80% capacity retention after 500 cycles; reduced cell thickness enabling higher volumetric energy density. Weaknesses: Challenges with initial lithium plating uniformity; sensitivity to manufacturing conditions requiring precise control of moisture and oxygen levels; higher production costs compared to conventional lithium-ion batteries.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed a comprehensive anode-free solid-state battery technology centered around sulfide-based solid electrolytes with exceptional ionic conductivity (>5 mS/cm at room temperature). Their approach involves a direct lithium plating mechanism on a specially engineered current collector with nanoscale surface modifications to control nucleation sites. Toyota's research has particularly focused on the SEI chemistry at the lithium metal/solid electrolyte interface, employing advanced analytical techniques including cryogenic transmission electron microscopy (cryo-TEM) and synchrotron-based X-ray absorption spectroscopy to characterize interfacial phenomena at atomic resolution[3]. Their proprietary interface engineering strategy incorporates thin buffer layers composed of Li3N and Li2S-P2S5 mixtures that effectively mitigate interfacial resistance growth during cycling. Toyota has also developed novel in-situ analytical methods to monitor the real-time evolution of both SEI and CEI layers during battery operation, providing unprecedented insights into degradation mechanisms[4]. Their latest prototypes demonstrate stable cycling with minimal capacity fade over 1000+ cycles, achieved through precise control of lithium deposition morphology and interfacial chemistry.

Strengths: Industry-leading ionic conductivity in solid electrolytes; excellent thermal stability allowing operation at wider temperature ranges; superior safety characteristics with non-flammable components; demonstrated scalability in prototype production. Weaknesses: Higher manufacturing complexity requiring specialized equipment; challenges with mechanical stress management during lithium plating/stripping cycles; sensitivity to environmental contaminants during production.

Critical Patents and Research on Interface Chemistry

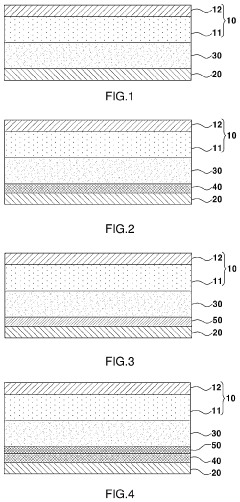

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

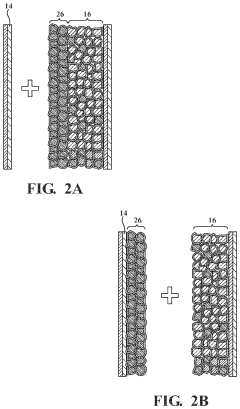

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

Materials Sustainability and Supply Chain Considerations

The sustainability of materials used in anode-free solid-state batteries represents a critical consideration for long-term technology viability. Unlike conventional lithium-ion batteries that rely heavily on graphite anodes, anode-free designs eliminate this component, reducing material requirements and potentially enhancing sustainability profiles. However, the specialized materials needed for solid electrolytes and cathode-electrolyte interfaces (CEI) present their own sustainability challenges.

Lithium metal, essential for anode-free battery operation, faces significant supply constraints with global reserves concentrated in South America, Australia, and China. Current extraction methods for lithium brine are water-intensive, raising environmental concerns in water-stressed regions. Alternative extraction technologies are under development but remain commercially unproven at scale.

Solid electrolyte materials, particularly those containing rare elements such as germanium, gallium, or lanthanum, face similar supply chain vulnerabilities. The geographic concentration of these materials in politically sensitive regions creates potential bottlenecks in manufacturing scale-up. Recycling infrastructure for these specialized materials remains underdeveloped, further complicating sustainability considerations.

The chemistry analytics focused on SEI and CEI formation introduces additional material considerations. High-purity precursors required for interface engineering often involve energy-intensive manufacturing processes with substantial carbon footprints. Life cycle assessments indicate that while operational benefits of anode-free designs are significant, manufacturing impacts may offset some environmental advantages without process optimization.

Supply chain resilience represents another critical dimension. The COVID-19 pandemic exposed vulnerabilities in global battery material supply chains, with disruptions affecting research timelines and commercial deployment schedules. Diversification of material sources and development of synthetic alternatives could mitigate these risks but require substantial investment in alternative material pathways.

Circular economy approaches offer promising solutions to sustainability challenges. Advanced recycling technologies specifically designed for solid-state battery components could recover critical materials from end-of-life batteries. However, the complex chemistry of SEI and CEI layers complicates separation and recovery processes, necessitating novel recycling methodologies tailored to these advanced battery architectures.

Regulatory frameworks worldwide are increasingly emphasizing responsible sourcing and environmental impact mitigation for battery materials. The European Battery Directive and similar initiatives in North America and Asia will likely influence material selection and supply chain development for anode-free solid-state battery technologies, potentially accelerating the transition toward more sustainable material pathways.

Lithium metal, essential for anode-free battery operation, faces significant supply constraints with global reserves concentrated in South America, Australia, and China. Current extraction methods for lithium brine are water-intensive, raising environmental concerns in water-stressed regions. Alternative extraction technologies are under development but remain commercially unproven at scale.

Solid electrolyte materials, particularly those containing rare elements such as germanium, gallium, or lanthanum, face similar supply chain vulnerabilities. The geographic concentration of these materials in politically sensitive regions creates potential bottlenecks in manufacturing scale-up. Recycling infrastructure for these specialized materials remains underdeveloped, further complicating sustainability considerations.

The chemistry analytics focused on SEI and CEI formation introduces additional material considerations. High-purity precursors required for interface engineering often involve energy-intensive manufacturing processes with substantial carbon footprints. Life cycle assessments indicate that while operational benefits of anode-free designs are significant, manufacturing impacts may offset some environmental advantages without process optimization.

Supply chain resilience represents another critical dimension. The COVID-19 pandemic exposed vulnerabilities in global battery material supply chains, with disruptions affecting research timelines and commercial deployment schedules. Diversification of material sources and development of synthetic alternatives could mitigate these risks but require substantial investment in alternative material pathways.

Circular economy approaches offer promising solutions to sustainability challenges. Advanced recycling technologies specifically designed for solid-state battery components could recover critical materials from end-of-life batteries. However, the complex chemistry of SEI and CEI layers complicates separation and recovery processes, necessitating novel recycling methodologies tailored to these advanced battery architectures.

Regulatory frameworks worldwide are increasingly emphasizing responsible sourcing and environmental impact mitigation for battery materials. The European Battery Directive and similar initiatives in North America and Asia will likely influence material selection and supply chain development for anode-free solid-state battery technologies, potentially accelerating the transition toward more sustainable material pathways.

Safety Standards and Performance Benchmarking

Safety standards for anode-free solid-state batteries represent a critical framework for ensuring these advanced energy storage systems meet rigorous requirements before commercial deployment. Current safety protocols primarily focus on thermal runaway prevention, mechanical integrity during physical stress, and chemical stability under various operating conditions. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established preliminary guidelines, though these require significant adaptation to address the unique characteristics of anode-free architectures and solid electrolyte interfaces.

Performance benchmarking methodologies for anode-free solid-state batteries emphasize several key metrics that differ from conventional lithium-ion evaluations. Energy density measurements typically show theoretical values exceeding 400 Wh/kg, substantially higher than commercial lithium-ion cells. Cycle life assessment protocols must account for the dynamic nature of the SEI/CEI formation in anode-free configurations, with current laboratory prototypes demonstrating 200-500 cycles before capacity degradation below 80%.

Rate capability testing presents particular challenges for solid-state systems due to interfacial resistance limitations. Standard protocols now incorporate pulse power testing at various states of charge to evaluate the electrochemical performance of the interfaces. Temperature performance evaluation ranges have expanded to -40°C to 80°C, reflecting the wider operational window potentially offered by solid electrolytes compared to liquid systems.

Analytical techniques for SEI/CEI characterization during performance testing have evolved significantly, with in-situ X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) becoming standard tools for interface composition monitoring during cycling. These techniques enable correlation between interface chemistry evolution and performance metrics, providing crucial insights for optimization.

Harmonization efforts between different testing standards remain ongoing, with the Battery Standards Testing Council working to establish unified protocols specifically for solid-state technologies. The development of accelerated testing methodologies represents another frontier, as traditional calendar aging protocols may not accurately predict the long-term stability of anode-free systems where interfacial chemistry continuously evolves.

Industry benchmarks currently position anode-free solid-state batteries as promising but still developing technology, with performance targets including energy densities above 500 Wh/kg, cycle life exceeding 1000 cycles, and fast-charging capabilities of 80% in under 15 minutes—all while maintaining stringent safety standards under abuse conditions.

Performance benchmarking methodologies for anode-free solid-state batteries emphasize several key metrics that differ from conventional lithium-ion evaluations. Energy density measurements typically show theoretical values exceeding 400 Wh/kg, substantially higher than commercial lithium-ion cells. Cycle life assessment protocols must account for the dynamic nature of the SEI/CEI formation in anode-free configurations, with current laboratory prototypes demonstrating 200-500 cycles before capacity degradation below 80%.

Rate capability testing presents particular challenges for solid-state systems due to interfacial resistance limitations. Standard protocols now incorporate pulse power testing at various states of charge to evaluate the electrochemical performance of the interfaces. Temperature performance evaluation ranges have expanded to -40°C to 80°C, reflecting the wider operational window potentially offered by solid electrolytes compared to liquid systems.

Analytical techniques for SEI/CEI characterization during performance testing have evolved significantly, with in-situ X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) becoming standard tools for interface composition monitoring during cycling. These techniques enable correlation between interface chemistry evolution and performance metrics, providing crucial insights for optimization.

Harmonization efforts between different testing standards remain ongoing, with the Battery Standards Testing Council working to establish unified protocols specifically for solid-state technologies. The development of accelerated testing methodologies represents another frontier, as traditional calendar aging protocols may not accurately predict the long-term stability of anode-free systems where interfacial chemistry continuously evolves.

Industry benchmarks currently position anode-free solid-state batteries as promising but still developing technology, with performance targets including energy densities above 500 Wh/kg, cycle life exceeding 1000 cycles, and fast-charging capabilities of 80% in under 15 minutes—all while maintaining stringent safety standards under abuse conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!