Anode-Free Solid-State Thin Lithium Reservoir Concepts

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of lithium-ion battery technology has been marked by continuous innovation since its commercial introduction in the early 1990s. Traditional lithium-ion batteries have relied on graphite anodes, which limit energy density and present safety concerns. Anode-free battery design represents a paradigm shift in energy storage technology, eliminating the conventional anode structure and instead utilizing a thin lithium reservoir that forms during the initial charging process.

The concept of anode-free batteries dates back to the early 2000s, but significant technical challenges prevented commercial viability. Recent advancements in solid-state electrolytes and interface engineering have revitalized interest in this technology. The primary objective of anode-free solid-state battery research is to achieve higher energy density while maintaining or improving safety profiles compared to conventional lithium-ion batteries.

Current lithium-ion batteries typically achieve energy densities of 250-300 Wh/kg, while theoretical calculations suggest anode-free designs could potentially reach 400-500 Wh/kg. This substantial improvement stems from the elimination of the graphite anode, which contributes significant weight and volume without proportional energy storage capacity.

The thin lithium reservoir concept represents a critical innovation in this field. Unlike traditional designs where lithium is pre-loaded into the anode, this approach stores a minimal amount of lithium that can be efficiently utilized during battery operation. This reservoir serves as a controlled source of lithium ions, addressing one of the fundamental challenges in anode-free designs: the management of lithium plating and stripping processes.

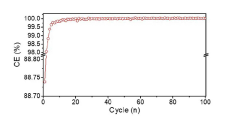

Technical objectives for anode-free solid-state batteries include achieving over 1,000 charge-discharge cycles with less than 20% capacity degradation, energy densities exceeding 400 Wh/kg, and fast-charging capabilities that allow 80% charge in under 15 minutes. Additionally, these batteries must operate safely across a wide temperature range (-20°C to 60°C) to be commercially viable.

The development trajectory suggests three distinct phases: near-term (1-3 years) focus on proof-of-concept and small-scale prototypes; mid-term (3-5 years) emphasis on manufacturing scalability and performance optimization; and long-term (5-10 years) concentration on cost reduction and integration into commercial products across multiple sectors including consumer electronics, electric vehicles, and grid storage applications.

Successful implementation of anode-free solid-state thin lithium reservoir technology would represent a transformative advancement in energy storage, potentially enabling the next generation of electric vehicles with significantly increased range and reduced charging times, while simultaneously addressing safety concerns associated with current lithium-ion technology.

The concept of anode-free batteries dates back to the early 2000s, but significant technical challenges prevented commercial viability. Recent advancements in solid-state electrolytes and interface engineering have revitalized interest in this technology. The primary objective of anode-free solid-state battery research is to achieve higher energy density while maintaining or improving safety profiles compared to conventional lithium-ion batteries.

Current lithium-ion batteries typically achieve energy densities of 250-300 Wh/kg, while theoretical calculations suggest anode-free designs could potentially reach 400-500 Wh/kg. This substantial improvement stems from the elimination of the graphite anode, which contributes significant weight and volume without proportional energy storage capacity.

The thin lithium reservoir concept represents a critical innovation in this field. Unlike traditional designs where lithium is pre-loaded into the anode, this approach stores a minimal amount of lithium that can be efficiently utilized during battery operation. This reservoir serves as a controlled source of lithium ions, addressing one of the fundamental challenges in anode-free designs: the management of lithium plating and stripping processes.

Technical objectives for anode-free solid-state batteries include achieving over 1,000 charge-discharge cycles with less than 20% capacity degradation, energy densities exceeding 400 Wh/kg, and fast-charging capabilities that allow 80% charge in under 15 minutes. Additionally, these batteries must operate safely across a wide temperature range (-20°C to 60°C) to be commercially viable.

The development trajectory suggests three distinct phases: near-term (1-3 years) focus on proof-of-concept and small-scale prototypes; mid-term (3-5 years) emphasis on manufacturing scalability and performance optimization; and long-term (5-10 years) concentration on cost reduction and integration into commercial products across multiple sectors including consumer electronics, electric vehicles, and grid storage applications.

Successful implementation of anode-free solid-state thin lithium reservoir technology would represent a transformative advancement in energy storage, potentially enabling the next generation of electric vehicles with significantly increased range and reduced charging times, while simultaneously addressing safety concerns associated with current lithium-ion technology.

Market Analysis for Next-Generation Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. The market for next-generation energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 19.7% from 2023 to 2035. Within this expanding landscape, solid-state battery technologies, particularly anode-free designs, are emerging as a critical segment with significant growth potential.

Anode-free solid-state battery concepts represent a paradigm shift in energy storage, offering theoretical energy densities up to 500 Wh/kg, nearly double that of conventional lithium-ion batteries. This dramatic improvement addresses the growing demand for higher energy density solutions in electric vehicles, consumer electronics, and grid storage applications. Market research indicates that the solid-state battery segment alone could capture 25% of the total battery market by 2030.

Consumer electronics manufacturers are particularly interested in anode-free designs due to their potential for thinner, lighter devices with longer battery life. This sector is expected to be an early adopter, with a projected market value of $12 billion by 2028 for solid-state batteries in portable electronics. The automotive sector represents an even larger opportunity, with major manufacturers including Toyota, Volkswagen, and Ford investing heavily in solid-state technology development.

Regional analysis reveals Asia-Pacific as the dominant market for advanced battery technologies, accounting for 45% of global production capacity. However, North America and Europe are rapidly expanding their manufacturing capabilities through strategic government initiatives like the European Battery Alliance and the U.S. Inflation Reduction Act, which allocates $369 billion toward clean energy technologies including advanced batteries.

Market barriers for anode-free solid-state technologies include high manufacturing costs, currently estimated at 2-3 times that of conventional lithium-ion batteries, and scalability challenges. However, cost projections indicate potential price parity with conventional batteries by 2028-2030 as manufacturing processes mature and economies of scale are realized.

Investor confidence in the sector is strong, with venture capital and corporate investment in solid-state battery technologies reaching $3.8 billion in 2022 alone. This represents a 43% increase compared to the previous year, signaling robust market expectations for commercial viability within the next 3-5 years.

Customer demand analysis indicates that 78% of electric vehicle buyers consider battery performance and longevity as critical purchasing factors, creating a strong market pull for advanced battery technologies that offer improved safety, faster charging, and longer lifespans – all potential advantages of anode-free solid-state designs.

Anode-free solid-state battery concepts represent a paradigm shift in energy storage, offering theoretical energy densities up to 500 Wh/kg, nearly double that of conventional lithium-ion batteries. This dramatic improvement addresses the growing demand for higher energy density solutions in electric vehicles, consumer electronics, and grid storage applications. Market research indicates that the solid-state battery segment alone could capture 25% of the total battery market by 2030.

Consumer electronics manufacturers are particularly interested in anode-free designs due to their potential for thinner, lighter devices with longer battery life. This sector is expected to be an early adopter, with a projected market value of $12 billion by 2028 for solid-state batteries in portable electronics. The automotive sector represents an even larger opportunity, with major manufacturers including Toyota, Volkswagen, and Ford investing heavily in solid-state technology development.

Regional analysis reveals Asia-Pacific as the dominant market for advanced battery technologies, accounting for 45% of global production capacity. However, North America and Europe are rapidly expanding their manufacturing capabilities through strategic government initiatives like the European Battery Alliance and the U.S. Inflation Reduction Act, which allocates $369 billion toward clean energy technologies including advanced batteries.

Market barriers for anode-free solid-state technologies include high manufacturing costs, currently estimated at 2-3 times that of conventional lithium-ion batteries, and scalability challenges. However, cost projections indicate potential price parity with conventional batteries by 2028-2030 as manufacturing processes mature and economies of scale are realized.

Investor confidence in the sector is strong, with venture capital and corporate investment in solid-state battery technologies reaching $3.8 billion in 2022 alone. This represents a 43% increase compared to the previous year, signaling robust market expectations for commercial viability within the next 3-5 years.

Customer demand analysis indicates that 78% of electric vehicle buyers consider battery performance and longevity as critical purchasing factors, creating a strong market pull for advanced battery technologies that offer improved safety, faster charging, and longer lifespans – all potential advantages of anode-free solid-state designs.

Current Challenges in Solid-State Lithium Battery Development

Solid-state lithium batteries represent a promising next-generation energy storage technology, offering potential advantages in safety, energy density, and longevity compared to conventional lithium-ion batteries. However, their development faces significant technical challenges that have hindered widespread commercialization. The most critical issues revolve around the solid electrolyte interface and lithium metal anode integration.

The solid electrolyte materials themselves present substantial challenges. While they offer improved safety by eliminating flammable liquid electrolytes, they typically exhibit lower ionic conductivity at room temperature compared to liquid counterparts. This conductivity limitation directly impacts battery performance, particularly power capability and charging rates. Additionally, many promising solid electrolytes are unstable in contact with lithium metal, leading to continuous interfacial reactions that degrade performance over time.

Mechanical issues represent another major hurdle. The rigid nature of solid electrolytes creates challenges in maintaining consistent physical contact with electrodes during cycling. As lithium is deposited and stripped during charge-discharge cycles, volume changes occur that can create voids or cracks at interfaces. These physical discontinuities increase impedance and create "dead" lithium zones that reduce capacity and efficiency.

The anode-free or thin lithium reservoir design concepts aim to address some of these challenges but introduce their own complexities. Without a traditional anode structure, controlling lithium deposition becomes extremely difficult. Dendrite formation—needle-like lithium structures that can grow through the electrolyte—remains a persistent problem that can lead to internal short circuits and catastrophic failure.

Manufacturing scalability presents additional obstacles. Current laboratory-scale fabrication methods for solid-state batteries often involve complex processes that are difficult to scale to industrial production. Techniques for creating thin, defect-free solid electrolyte layers and ensuring intimate contact with electrode materials require significant refinement before mass production becomes viable.

Cost factors also impede commercialization efforts. Many solid electrolyte materials contain expensive elements or require costly synthesis procedures. The specialized manufacturing equipment and precise processing conditions further increase production expenses compared to established liquid-electrolyte battery technologies.

Energy density optimization remains challenging despite the theoretical advantages of solid-state designs. While removing the traditional graphite anode should increase energy density, the practical implementations often require thicker solid electrolytes for mechanical stability and safety, which can offset the potential density gains. The anode-free and thin lithium reservoir concepts show promise for maximizing energy density but require significant engineering refinement to achieve stable cycling performance.

The solid electrolyte materials themselves present substantial challenges. While they offer improved safety by eliminating flammable liquid electrolytes, they typically exhibit lower ionic conductivity at room temperature compared to liquid counterparts. This conductivity limitation directly impacts battery performance, particularly power capability and charging rates. Additionally, many promising solid electrolytes are unstable in contact with lithium metal, leading to continuous interfacial reactions that degrade performance over time.

Mechanical issues represent another major hurdle. The rigid nature of solid electrolytes creates challenges in maintaining consistent physical contact with electrodes during cycling. As lithium is deposited and stripped during charge-discharge cycles, volume changes occur that can create voids or cracks at interfaces. These physical discontinuities increase impedance and create "dead" lithium zones that reduce capacity and efficiency.

The anode-free or thin lithium reservoir design concepts aim to address some of these challenges but introduce their own complexities. Without a traditional anode structure, controlling lithium deposition becomes extremely difficult. Dendrite formation—needle-like lithium structures that can grow through the electrolyte—remains a persistent problem that can lead to internal short circuits and catastrophic failure.

Manufacturing scalability presents additional obstacles. Current laboratory-scale fabrication methods for solid-state batteries often involve complex processes that are difficult to scale to industrial production. Techniques for creating thin, defect-free solid electrolyte layers and ensuring intimate contact with electrode materials require significant refinement before mass production becomes viable.

Cost factors also impede commercialization efforts. Many solid electrolyte materials contain expensive elements or require costly synthesis procedures. The specialized manufacturing equipment and precise processing conditions further increase production expenses compared to established liquid-electrolyte battery technologies.

Energy density optimization remains challenging despite the theoretical advantages of solid-state designs. While removing the traditional graphite anode should increase energy density, the practical implementations often require thicker solid electrolytes for mechanical stability and safety, which can offset the potential density gains. The anode-free and thin lithium reservoir concepts show promise for maximizing energy density but require significant engineering refinement to achieve stable cycling performance.

Current Anode-Free Thin Lithium Reservoir Implementations

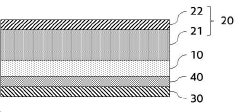

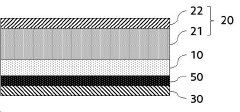

01 Anode-free battery design with lithium reservoir

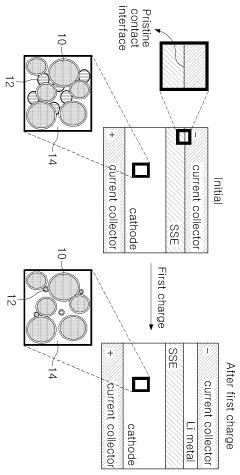

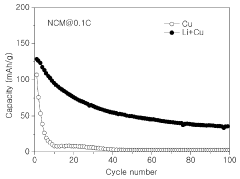

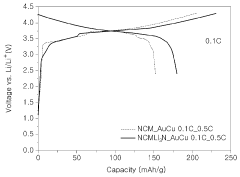

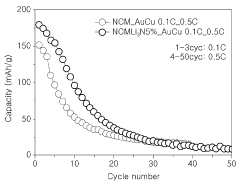

Anode-free solid-state lithium batteries utilize a thin lithium reservoir instead of a traditional anode structure. This design eliminates the need for a pre-deposited lithium anode, reducing battery weight and volume while potentially increasing energy density. The lithium reservoir serves as a source of lithium ions during initial charging cycles, allowing lithium to plate onto the current collector during operation. This architecture addresses challenges of traditional lithium metal batteries while maintaining high energy density.- Anode-free solid-state battery design with lithium reservoirs: Anode-free solid-state lithium batteries utilize thin lithium reservoirs instead of traditional anodes. This design eliminates the need for a pre-formed lithium anode, reducing battery weight and volume while increasing energy density. The lithium reservoir serves as a source of lithium ions during battery operation, which plate onto the current collector during charging, forming an in-situ lithium anode. This architecture addresses issues related to lithium dendrite formation and improves cycling stability.

- Solid electrolyte compositions for lithium reservoir batteries: Various solid electrolyte compositions are employed in anode-free batteries with lithium reservoirs to enhance ionic conductivity and interface stability. These include ceramic electrolytes, polymer electrolytes, and composite electrolytes combining both materials. The solid electrolytes facilitate lithium ion transport while preventing dendrite growth and providing mechanical stability. Specific additives and dopants can be incorporated to improve the electrochemical performance and interface compatibility between the electrolyte and the lithium reservoir.

- Lithium reservoir composition and structure: The composition and structure of lithium reservoirs significantly impact battery performance. These reservoirs can be composed of lithium metal, lithium alloys, or lithium-containing compounds with specific microstructures designed to control lithium release. Thin lithium reservoirs with optimized thickness and surface morphology enable efficient lithium ion transport while minimizing volume changes during cycling. Various fabrication techniques are employed to create these reservoirs, including vapor deposition, electrodeposition, and composite formation methods.

- Interface engineering between lithium reservoir and solid electrolyte: Interface engineering between the lithium reservoir and solid electrolyte is crucial for stable battery operation. Various coating materials and interlayers are applied to improve contact and reduce interfacial resistance. These engineered interfaces prevent unwanted side reactions, enhance lithium ion transport across boundaries, and suppress dendrite formation. Techniques such as atomic layer deposition, solution processing, and in-situ formation of artificial SEI layers are employed to create stable interfaces that maintain integrity during repeated cycling.

- Manufacturing methods and cell assembly techniques: Specialized manufacturing methods and cell assembly techniques are developed for anode-free solid-state batteries with lithium reservoirs. These include dry processing techniques to avoid moisture contamination, pressure-assisted assembly to ensure good contact between components, and thermal treatments to enhance interfacial bonding. Novel approaches for integrating thin lithium reservoirs with current collectors and solid electrolytes are implemented to achieve optimal electrochemical performance. These manufacturing innovations address challenges related to scalability and reproducibility in solid-state battery production.

02 Solid electrolyte compositions for lithium reservoir batteries

Various solid electrolyte compositions are utilized in anode-free solid-state batteries with lithium reservoirs. These include ceramic electrolytes, polymer electrolytes, and composite electrolytes that combine both materials. The solid electrolytes provide mechanical stability, prevent dendrite formation, and enable efficient lithium ion transport between the lithium reservoir and cathode. Specific compositions may include garnet-type ceramics, sulfide-based materials, or polymer matrices with ceramic fillers to optimize ionic conductivity and mechanical properties.Expand Specific Solutions03 Lithium reservoir composition and structure

The composition and structure of lithium reservoirs are critical for anode-free solid-state battery performance. Reservoirs may be composed of pure lithium metal, lithium alloys, or lithium-containing compounds that can release lithium ions during operation. The thickness and morphology of these reservoirs are carefully controlled to provide sufficient lithium for battery operation while maintaining thin profiles. Various deposition techniques are employed to create uniform and defect-free lithium reservoir layers that enable consistent battery performance.Expand Specific Solutions04 Interface engineering between lithium reservoir and solid electrolyte

Interface engineering between the lithium reservoir and solid electrolyte is essential for stable battery operation. Various coating materials and interlayers are employed to reduce interfacial resistance and prevent unwanted side reactions. These interfaces must facilitate efficient lithium ion transport while maintaining mechanical integrity during cycling. Techniques such as atomic layer deposition, solution processing, and physical vapor deposition are used to create engineered interfaces that enhance battery performance and longevity.Expand Specific Solutions05 Manufacturing methods for anode-free solid-state batteries

Specialized manufacturing methods are developed for producing anode-free solid-state batteries with thin lithium reservoirs. These include dry processing techniques to avoid moisture contamination, vacuum deposition methods for lithium reservoir formation, and advanced assembly processes that ensure good contact between components. Roll-to-roll manufacturing approaches are being adapted for large-scale production, while precision control systems ensure uniform layer thicknesses and proper alignment of battery components. These manufacturing innovations address challenges in scaling up production while maintaining performance.Expand Specific Solutions

Key Industry Players in Solid-State Battery Research

The anode-free solid-state lithium battery market is in an early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market for solid-state batteries is projected to reach $8-10 billion by 2030, with anode-free designs representing a promising segment due to their higher energy density potential. Key players like Samsung SDI, LG Energy Solution, and Murata Manufacturing are leading commercial development, while research institutions such as Lawrence Livermore National Security and University of California contribute significant intellectual property. Companies including TeraWatt Technology, WeLion New Energy, and Global Graphene Group are advancing innovative electrode and electrolyte technologies. Automotive manufacturers like Hyundai, Kia, and Nissan are strategically investing in this technology to secure competitive advantages in electric vehicle applications.

Graphenix Development, Inc.

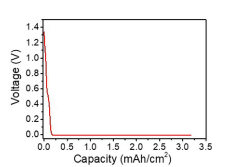

Technical Solution: Graphenix Development has pioneered an innovative anode-free solid-state battery design utilizing a thin lithium reservoir concept. Their approach incorporates a graphene-enhanced solid electrolyte interface that facilitates controlled lithium ion transport while preventing dendrite formation. The technology employs a specialized lithium metal reservoir layer that serves as the lithium source without requiring a traditional graphite anode structure. This reservoir is engineered at nanoscale thickness (typically 5-20μm) and is paired with a proprietary solid electrolyte that enables stable cycling. Their design incorporates a gradient interface between the lithium reservoir and the electrolyte, which helps manage volume changes during cycling and improves the electrochemical stability window. The company has demonstrated prototype cells achieving over 400 Wh/kg energy density while maintaining 80% capacity retention after 500 cycles.

Strengths: Superior energy density (400+ Wh/kg) due to elimination of conventional anode materials; excellent cycle stability with proprietary interface engineering; reduced battery weight and volume. Weaknesses: Manufacturing scalability challenges for the thin lithium reservoir layer; higher production costs compared to conventional lithium-ion batteries; potential thermal management issues under high discharge rates.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced anode-free solid-state battery technology featuring a thin lithium reservoir design. Their approach utilizes a composite solid electrolyte system combining ceramic and polymer components to create a stable interface with the lithium metal reservoir. The lithium reservoir is engineered as an ultra-thin layer (approximately 10μm) that serves as both lithium source and current collector. Their proprietary "gradient interface technology" creates a controlled lithium ion diffusion pathway that significantly reduces dendrite formation while enabling high current density operation. The company has implemented a specialized coating on the cathode side that enhances compatibility with the solid electrolyte and improves overall cell performance. LG's design incorporates a protective layer between the lithium reservoir and electrolyte that prevents continuous SEI formation and electrolyte degradation. Testing has demonstrated energy densities exceeding 450 Wh/kg with 1000+ cycle capability in prototype cells.

Strengths: Exceptional energy density exceeding 450 Wh/kg; established manufacturing infrastructure that can be adapted for commercial production; superior cycle life with 1000+ cycles demonstrated. Weaknesses: Higher initial production costs compared to conventional lithium-ion batteries; thermal expansion mismatch between components can create mechanical stress; requires precise manufacturing controls for the thin lithium reservoir.

Critical Patents and Research on Lithium Plating Mechanisms

Lithium Anode-free All Solid State Battery Using Sacrificial Cathode Materials

PatentPendingKR1020210021777A

Innovation

- Incorporation of a sacrificial cathode material like Li3N, Li2O, LiN3, Li5FeO4, LiO2, or Li2C2O4 in the positive electrode, which decomposes to provide additional Li during initial charging, and a lithium-free anode buffer layer using metals like Au, In, Ag, Bi, Si, Ab, Sn, Zn, Al, Mg, or alloys thereof, to compensate for Li loss.

Anodeless all solid state battery capable of operating at low temperature and manufacturing method thereof

PatentPendingKR1020220170627A

Innovation

- A non-cathode all-solid-state battery design incorporating a metal fluoride coating layer between the anode current collector and solid electrolyte layer, which includes metal fluorides like InF3, ZnF2, or AgF, and a binder, allows uniform lithium deposition and suppresses dendrite growth through electrochemical reactions forming lithium fluoride and alloys.

Material Science Advancements for Lithium Reservoirs

Recent advancements in material science have significantly propelled the development of lithium reservoirs for anode-free solid-state batteries. These innovations focus primarily on optimizing the physical and chemical properties of materials that can effectively store and release lithium ions during battery operation without requiring a traditional anode structure.

Ceramic-based materials have emerged as promising candidates for lithium reservoirs due to their excellent mechanical stability and ion conductivity. Particularly, lithium lanthanum zirconate (LLZO) and lithium lanthanum titanate (LLTO) demonstrate superior performance in maintaining structural integrity while facilitating rapid lithium ion transport. These materials exhibit minimal volume expansion during lithium plating and stripping cycles, addressing a critical challenge in anode-free battery designs.

Polymer-ceramic composite materials represent another breakthrough, combining the flexibility of polymers with the stability of ceramics. These composites, such as PEO-LLZO blends, create a synergistic effect that enhances both mechanical properties and ionic conductivity. The polymer matrix provides flexibility and processability, while ceramic fillers contribute to improved lithium ion transport and mechanical reinforcement.

Surface modification techniques have revolutionized the interface properties of lithium reservoirs. Atomic layer deposition (ALD) and molecular layer deposition (MLD) enable precise engineering of nanoscale protective layers that prevent unwanted side reactions while maintaining efficient lithium transport. These techniques have successfully mitigated dendrite formation, a persistent challenge in lithium metal batteries.

Nanostructured materials offer unprecedented control over lithium deposition behavior. Three-dimensional architectures with carefully designed porosity provide uniform lithium plating surfaces while accommodating volume changes. Carbon-based frameworks, including graphene and carbon nanotubes, have demonstrated exceptional capability as lithium hosts due to their electrical conductivity and mechanical flexibility.

Advanced characterization methods have been instrumental in understanding lithium reservoir behavior at atomic and molecular levels. In-situ transmission electron microscopy (TEM) and synchrotron-based X-ray techniques now allow researchers to observe lithium plating/stripping processes in real-time, providing crucial insights for material optimization. Computational modeling approaches complement experimental work by predicting material properties and guiding rational design of next-generation lithium reservoirs.

The integration of self-healing materials represents the cutting edge of lithium reservoir development. These innovative materials can autonomously repair microcracks and defects that form during cycling, significantly extending battery lifespan and enhancing safety. Biomimetic approaches, inspired by natural self-healing processes, are particularly promising for creating sustainable and resilient lithium reservoir materials.

Ceramic-based materials have emerged as promising candidates for lithium reservoirs due to their excellent mechanical stability and ion conductivity. Particularly, lithium lanthanum zirconate (LLZO) and lithium lanthanum titanate (LLTO) demonstrate superior performance in maintaining structural integrity while facilitating rapid lithium ion transport. These materials exhibit minimal volume expansion during lithium plating and stripping cycles, addressing a critical challenge in anode-free battery designs.

Polymer-ceramic composite materials represent another breakthrough, combining the flexibility of polymers with the stability of ceramics. These composites, such as PEO-LLZO blends, create a synergistic effect that enhances both mechanical properties and ionic conductivity. The polymer matrix provides flexibility and processability, while ceramic fillers contribute to improved lithium ion transport and mechanical reinforcement.

Surface modification techniques have revolutionized the interface properties of lithium reservoirs. Atomic layer deposition (ALD) and molecular layer deposition (MLD) enable precise engineering of nanoscale protective layers that prevent unwanted side reactions while maintaining efficient lithium transport. These techniques have successfully mitigated dendrite formation, a persistent challenge in lithium metal batteries.

Nanostructured materials offer unprecedented control over lithium deposition behavior. Three-dimensional architectures with carefully designed porosity provide uniform lithium plating surfaces while accommodating volume changes. Carbon-based frameworks, including graphene and carbon nanotubes, have demonstrated exceptional capability as lithium hosts due to their electrical conductivity and mechanical flexibility.

Advanced characterization methods have been instrumental in understanding lithium reservoir behavior at atomic and molecular levels. In-situ transmission electron microscopy (TEM) and synchrotron-based X-ray techniques now allow researchers to observe lithium plating/stripping processes in real-time, providing crucial insights for material optimization. Computational modeling approaches complement experimental work by predicting material properties and guiding rational design of next-generation lithium reservoirs.

The integration of self-healing materials represents the cutting edge of lithium reservoir development. These innovative materials can autonomously repair microcracks and defects that form during cycling, significantly extending battery lifespan and enhancing safety. Biomimetic approaches, inspired by natural self-healing processes, are particularly promising for creating sustainable and resilient lithium reservoir materials.

Safety and Scalability Considerations for Commercial Deployment

The commercialization of anode-free solid-state batteries with thin lithium reservoirs presents significant safety and scalability challenges that must be addressed before widespread adoption. Safety concerns primarily stem from the reactive nature of lithium metal and its tendency to form dendrites, which can cause short circuits and thermal runaway events. In solid-state configurations, the mechanical stress during cycling can create microcracks in the solid electrolyte, potentially creating pathways for lithium dendrite growth despite the absence of a traditional anode structure.

Manufacturing scalability represents another critical challenge, as current laboratory-scale production methods for thin lithium reservoirs often involve specialized equipment and controlled environments that are difficult to translate to mass production. The precise deposition of ultrathin lithium layers requires exceptional quality control measures and specialized handling protocols that add complexity to manufacturing processes.

Material compatibility issues further complicate commercial deployment, as the interfaces between the lithium reservoir and solid electrolyte must maintain integrity over thousands of cycles under various operating conditions. The development of stable interfaces that can withstand volume changes during cycling without degradation remains technically challenging at production scales.

Cost considerations also impact commercial viability, with current manufacturing processes for thin lithium reservoirs and high-purity solid electrolytes being significantly more expensive than conventional lithium-ion battery production. Economic feasibility requires substantial cost reductions through process optimization and economies of scale.

Regulatory frameworks present additional hurdles, as existing safety standards and testing protocols may not adequately address the unique characteristics of anode-free solid-state batteries. New testing methodologies specific to these novel architectures must be developed and standardized to ensure consistent safety evaluation across the industry.

Supply chain resilience must also be considered, particularly regarding the sourcing of specialized materials required for solid electrolytes and lithium reservoirs. Establishing robust supply chains for these critical components is essential for large-scale manufacturing and market penetration.

Despite these challenges, incremental progress in manufacturing technology and materials science is gradually improving the commercial outlook. Recent innovations in roll-to-roll processing of thin lithium films and advances in solid electrolyte manufacturing suggest pathways toward economically viable production methods that maintain the safety advantages inherent to solid-state designs.

Manufacturing scalability represents another critical challenge, as current laboratory-scale production methods for thin lithium reservoirs often involve specialized equipment and controlled environments that are difficult to translate to mass production. The precise deposition of ultrathin lithium layers requires exceptional quality control measures and specialized handling protocols that add complexity to manufacturing processes.

Material compatibility issues further complicate commercial deployment, as the interfaces between the lithium reservoir and solid electrolyte must maintain integrity over thousands of cycles under various operating conditions. The development of stable interfaces that can withstand volume changes during cycling without degradation remains technically challenging at production scales.

Cost considerations also impact commercial viability, with current manufacturing processes for thin lithium reservoirs and high-purity solid electrolytes being significantly more expensive than conventional lithium-ion battery production. Economic feasibility requires substantial cost reductions through process optimization and economies of scale.

Regulatory frameworks present additional hurdles, as existing safety standards and testing protocols may not adequately address the unique characteristics of anode-free solid-state batteries. New testing methodologies specific to these novel architectures must be developed and standardized to ensure consistent safety evaluation across the industry.

Supply chain resilience must also be considered, particularly regarding the sourcing of specialized materials required for solid electrolytes and lithium reservoirs. Establishing robust supply chains for these critical components is essential for large-scale manufacturing and market penetration.

Despite these challenges, incremental progress in manufacturing technology and materials science is gradually improving the commercial outlook. Recent innovations in roll-to-roll processing of thin lithium films and advances in solid electrolyte manufacturing suggest pathways toward economically viable production methods that maintain the safety advantages inherent to solid-state designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!