Inline Metrology And NDE For Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Metrology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with solid-state batteries (SSBs) emerging as a promising next-generation energy storage solution. Within this domain, anode-free solid-state batteries represent a cutting-edge approach that eliminates the traditional anode material, instead utilizing lithium metal that forms during the initial charging process. This configuration offers substantial benefits in energy density, safety, and form factor flexibility, making it particularly attractive for electric vehicles and portable electronics applications.

Inline metrology and non-destructive evaluation (NDE) techniques for anode-free SSBs have become increasingly critical as the technology progresses from laboratory research to commercial production. These measurement and evaluation methods enable real-time monitoring of battery components and performance parameters during manufacturing, without compromising the integrity of the battery structure. The historical development of these techniques has been closely tied to advances in materials science, sensor technology, and data analytics capabilities.

The primary objective of developing inline metrology and NDE for anode-free SSBs is to establish reliable, high-throughput quality control processes that can detect defects, inconsistencies, and performance limitations during production. This capability is essential for scaling up manufacturing while maintaining consistent product quality and safety standards. Current metrology approaches include ultrasonic testing, X-ray tomography, optical coherence tomography, and electrochemical impedance spectroscopy, each offering unique insights into different aspects of battery composition and performance.

Technical evolution in this field has been driven by the unique challenges presented by solid electrolytes and the absence of a pre-deposited anode. The lithium metal interface formation during initial charging creates distinctive measurement requirements that conventional battery testing protocols cannot adequately address. Industry trends indicate a growing emphasis on multi-modal measurement techniques that can simultaneously evaluate mechanical, chemical, and electrochemical properties of these complex energy storage systems.

The development trajectory of inline metrology for anode-free SSBs is increasingly focused on non-contact methods that can operate at production speeds while providing high-resolution data on critical parameters such as electrolyte uniformity, interfacial resistance, and lithium plating behavior. These technologies aim to predict battery performance and longevity based on manufacturing-stage measurements, potentially revolutionizing quality assurance approaches in advanced battery production.

Our technical objective is to comprehensively evaluate current inline metrology and NDE technologies applicable to anode-free SSBs, identify technological gaps, and outline potential innovation pathways that could address existing limitations while supporting industrial-scale manufacturing requirements.

Inline metrology and non-destructive evaluation (NDE) techniques for anode-free SSBs have become increasingly critical as the technology progresses from laboratory research to commercial production. These measurement and evaluation methods enable real-time monitoring of battery components and performance parameters during manufacturing, without compromising the integrity of the battery structure. The historical development of these techniques has been closely tied to advances in materials science, sensor technology, and data analytics capabilities.

The primary objective of developing inline metrology and NDE for anode-free SSBs is to establish reliable, high-throughput quality control processes that can detect defects, inconsistencies, and performance limitations during production. This capability is essential for scaling up manufacturing while maintaining consistent product quality and safety standards. Current metrology approaches include ultrasonic testing, X-ray tomography, optical coherence tomography, and electrochemical impedance spectroscopy, each offering unique insights into different aspects of battery composition and performance.

Technical evolution in this field has been driven by the unique challenges presented by solid electrolytes and the absence of a pre-deposited anode. The lithium metal interface formation during initial charging creates distinctive measurement requirements that conventional battery testing protocols cannot adequately address. Industry trends indicate a growing emphasis on multi-modal measurement techniques that can simultaneously evaluate mechanical, chemical, and electrochemical properties of these complex energy storage systems.

The development trajectory of inline metrology for anode-free SSBs is increasingly focused on non-contact methods that can operate at production speeds while providing high-resolution data on critical parameters such as electrolyte uniformity, interfacial resistance, and lithium plating behavior. These technologies aim to predict battery performance and longevity based on manufacturing-stage measurements, potentially revolutionizing quality assurance approaches in advanced battery production.

Our technical objective is to comprehensively evaluate current inline metrology and NDE technologies applicable to anode-free SSBs, identify technological gaps, and outline potential innovation pathways that could address existing limitations while supporting industrial-scale manufacturing requirements.

Market Analysis for Inline Battery Quality Control

The global market for inline battery quality control systems is experiencing robust growth, driven primarily by the rapid expansion of electric vehicle (EV) production and increasing adoption of energy storage solutions. Current market valuations indicate that the battery quality control segment reached approximately $1.2 billion in 2022, with projections suggesting a compound annual growth rate of 18-20% through 2030. This acceleration is particularly evident in regions with strong EV manufacturing bases, including East Asia, North America, and Europe.

For anode-free solid-state batteries specifically, the quality control market represents an emerging high-value segment. While currently smaller than traditional lithium-ion battery inspection systems, this specialized sector is anticipated to grow at a significantly faster rate due to the superior performance characteristics and safety advantages of solid-state technology.

Market demand is being shaped by several key factors. Battery manufacturers are facing increasing pressure to improve production yields while simultaneously enhancing product reliability and safety. Current data suggests that manufacturing defects account for approximately 5-8% of production costs in advanced battery manufacturing, creating strong economic incentives for improved inline metrology solutions.

Regulatory frameworks are also driving market growth. Safety standards for EV batteries have become more stringent in major markets, with particular emphasis on thermal runaway prevention and battery longevity assurance. These regulations directly increase demand for sophisticated non-destructive evaluation (NDE) technologies capable of detecting microscopic defects and interface irregularities in solid-state battery structures.

Customer requirements are evolving toward fully integrated inspection systems that can operate at production speeds exceeding 20 cells per minute while maintaining detection accuracy for defects smaller than 10 microns. This represents a significant technical challenge that is reshaping competitive dynamics within the market.

The competitive landscape features both established industrial automation companies expanding into battery inspection and specialized startups developing novel sensing technologies. Major industrial players like Keysight Technologies, Siemens, and Cognex have established market positions, while emerging companies focusing specifically on solid-state battery inspection are attracting significant venture capital investment.

Regional market distribution shows East Asia commanding approximately 60% of current market share, with particular strength in Japan and South Korea where solid-state battery development is most advanced. North American and European markets are growing rapidly as domestic battery production capacity expands in these regions to support local EV manufacturing.

For anode-free solid-state batteries specifically, the quality control market represents an emerging high-value segment. While currently smaller than traditional lithium-ion battery inspection systems, this specialized sector is anticipated to grow at a significantly faster rate due to the superior performance characteristics and safety advantages of solid-state technology.

Market demand is being shaped by several key factors. Battery manufacturers are facing increasing pressure to improve production yields while simultaneously enhancing product reliability and safety. Current data suggests that manufacturing defects account for approximately 5-8% of production costs in advanced battery manufacturing, creating strong economic incentives for improved inline metrology solutions.

Regulatory frameworks are also driving market growth. Safety standards for EV batteries have become more stringent in major markets, with particular emphasis on thermal runaway prevention and battery longevity assurance. These regulations directly increase demand for sophisticated non-destructive evaluation (NDE) technologies capable of detecting microscopic defects and interface irregularities in solid-state battery structures.

Customer requirements are evolving toward fully integrated inspection systems that can operate at production speeds exceeding 20 cells per minute while maintaining detection accuracy for defects smaller than 10 microns. This represents a significant technical challenge that is reshaping competitive dynamics within the market.

The competitive landscape features both established industrial automation companies expanding into battery inspection and specialized startups developing novel sensing technologies. Major industrial players like Keysight Technologies, Siemens, and Cognex have established market positions, while emerging companies focusing specifically on solid-state battery inspection are attracting significant venture capital investment.

Regional market distribution shows East Asia commanding approximately 60% of current market share, with particular strength in Japan and South Korea where solid-state battery development is most advanced. North American and European markets are growing rapidly as domestic battery production capacity expands in these regions to support local EV manufacturing.

Current Challenges in Solid-State Battery Inspection

Solid-state batteries represent a significant advancement in energy storage technology, yet their manufacturing processes face critical inspection challenges. Current non-destructive evaluation (NDE) and metrology techniques struggle to adapt to the unique material properties and structural characteristics of anode-free solid-state batteries. Traditional inspection methods developed for liquid-electrolyte batteries prove inadequate for detecting defects in solid electrolytes and interfaces.

The primary challenge lies in the detection of microscopic defects at material interfaces. Solid-state batteries contain multiple layers with different material properties, creating complex interfaces where micro-cracks, delamination, and lithium dendrite formation can occur. These defects, often smaller than 1 μm, remain difficult to detect with conventional imaging techniques while maintaining production throughput.

Real-time monitoring presents another significant hurdle. Manufacturing solid-state batteries requires precise control of temperature, pressure, and environmental conditions. Current inline inspection tools lack the capability to provide immediate feedback on critical parameters during production, resulting in quality control issues that are only detected in final testing stages, increasing waste and production costs.

The heterogeneous nature of solid electrolytes creates additional inspection complexities. Unlike liquid electrolytes, solid electrolytes exhibit anisotropic properties and may contain grain boundaries that affect ion transport. Existing metrology tools struggle to characterize these variations accurately, particularly at production speeds, leading to inconsistent battery performance.

Thickness measurement and uniformity assessment of ultra-thin layers (often <10 μm) in anode-free designs demand exceptional precision. Current optical and mechanical measurement techniques introduce measurement uncertainties that exceed acceptable tolerances for these critical components, compromising quality assurance.

Temperature sensitivity further complicates inspection processes. Many solid-state materials undergo phase transitions or property changes at different temperatures, requiring inspection systems that can operate across varying thermal conditions while maintaining measurement accuracy. Most available systems are calibrated for narrow temperature ranges, limiting their effectiveness throughout the manufacturing process.

Integration challenges also exist between inspection systems and production lines. The high-speed, continuous nature of battery manufacturing requires seamless incorporation of inspection technologies without creating bottlenecks. Current NDE systems often require production slowdowns or sample extraction, disrupting manufacturing efficiency and increasing costs.

The primary challenge lies in the detection of microscopic defects at material interfaces. Solid-state batteries contain multiple layers with different material properties, creating complex interfaces where micro-cracks, delamination, and lithium dendrite formation can occur. These defects, often smaller than 1 μm, remain difficult to detect with conventional imaging techniques while maintaining production throughput.

Real-time monitoring presents another significant hurdle. Manufacturing solid-state batteries requires precise control of temperature, pressure, and environmental conditions. Current inline inspection tools lack the capability to provide immediate feedback on critical parameters during production, resulting in quality control issues that are only detected in final testing stages, increasing waste and production costs.

The heterogeneous nature of solid electrolytes creates additional inspection complexities. Unlike liquid electrolytes, solid electrolytes exhibit anisotropic properties and may contain grain boundaries that affect ion transport. Existing metrology tools struggle to characterize these variations accurately, particularly at production speeds, leading to inconsistent battery performance.

Thickness measurement and uniformity assessment of ultra-thin layers (often <10 μm) in anode-free designs demand exceptional precision. Current optical and mechanical measurement techniques introduce measurement uncertainties that exceed acceptable tolerances for these critical components, compromising quality assurance.

Temperature sensitivity further complicates inspection processes. Many solid-state materials undergo phase transitions or property changes at different temperatures, requiring inspection systems that can operate across varying thermal conditions while maintaining measurement accuracy. Most available systems are calibrated for narrow temperature ranges, limiting their effectiveness throughout the manufacturing process.

Integration challenges also exist between inspection systems and production lines. The high-speed, continuous nature of battery manufacturing requires seamless incorporation of inspection technologies without creating bottlenecks. Current NDE systems often require production slowdowns or sample extraction, disrupting manufacturing efficiency and increasing costs.

Existing Inline NDE Solutions for SSB Manufacturing

01 Optical inspection methods for solid-state battery defect detection

Optical inspection techniques are employed for non-destructive evaluation of anode-free solid-state batteries. These methods utilize various light-based technologies such as infrared imaging, laser scanning, and optical coherence tomography to detect surface and subsurface defects. The techniques can identify issues like delamination, cracks, and uniformity problems in battery components without damaging the battery structure, making them suitable for inline quality control during manufacturing.- Optical inspection techniques for solid-state battery defect detection: Optical inspection methods are employed for non-destructive evaluation of anode-free solid-state batteries. These techniques use various light sources and imaging systems to detect surface and subsurface defects in battery components. Advanced image processing algorithms analyze the captured images to identify irregularities, delamination, or structural inconsistencies. These methods enable real-time quality control during manufacturing without compromising battery integrity.

- X-ray and tomographic analysis for internal battery structure evaluation: X-ray imaging and computed tomography techniques provide detailed insights into the internal structure of anode-free solid-state batteries without physical disassembly. These methods can detect internal defects, voids, cracks, and interface issues between different battery layers. Advanced algorithms process the tomographic data to create 3D visualizations of battery components, allowing for comprehensive quality assessment and identification of manufacturing defects that might affect battery performance and safety.

- Electrochemical impedance spectroscopy for battery quality monitoring: Electrochemical impedance spectroscopy (EIS) serves as a powerful non-destructive evaluation tool for assessing the quality and performance of anode-free solid-state batteries. By applying alternating current signals at different frequencies and measuring the battery's response, EIS can detect internal resistance issues, interface problems, and electrolyte defects. This technique enables inline monitoring of battery quality during production and can identify subtle defects that might lead to performance degradation or safety concerns.

- Ultrasonic and acoustic methods for defect identification: Ultrasonic and acoustic testing methods provide non-destructive evaluation of anode-free solid-state batteries by analyzing sound wave propagation through battery materials. These techniques can detect delamination, voids, cracks, and other structural defects that might compromise battery performance. Advanced signal processing algorithms interpret the acoustic responses to create detailed maps of internal battery structures, enabling inline quality control during manufacturing processes without damaging the battery components.

- Machine learning and AI-based defect detection systems: Artificial intelligence and machine learning algorithms enhance the effectiveness of inline metrology and non-destructive evaluation for anode-free solid-state batteries. These systems analyze data from multiple sensors to identify patterns associated with defects that might not be apparent through conventional analysis. By continuously learning from production data, these AI-based systems improve their defect detection capabilities over time, reducing false positives and increasing detection accuracy. This approach enables more efficient quality control processes and helps identify subtle manufacturing issues before they affect battery performance.

02 X-ray and tomographic imaging for internal battery structure analysis

Advanced X-ray techniques including computed tomography (CT) and radiography are utilized for non-destructive internal inspection of anode-free solid-state batteries. These methods provide detailed visualization of the internal structure, allowing detection of defects such as voids, inclusions, and interface irregularities that cannot be observed through surface inspection. The technology enables real-time monitoring of battery components during production, facilitating immediate quality control decisions.Expand Specific Solutions03 Electrochemical impedance spectroscopy for battery performance evaluation

Electrochemical impedance spectroscopy (EIS) serves as a non-destructive evaluation technique for assessing the performance and quality of anode-free solid-state batteries. This method measures the impedance response of batteries across a range of frequencies, providing insights into internal resistance, ion transport properties, and electrode-electrolyte interfaces. The technique can identify defects that affect electrochemical performance without disassembling the battery, making it valuable for inline quality control.Expand Specific Solutions04 Ultrasonic and acoustic methods for defect detection

Ultrasonic and acoustic testing methods are employed for non-destructive evaluation of anode-free solid-state batteries. These techniques use sound waves to detect internal defects such as delamination, cracks, and voids within battery components. By analyzing the reflection and transmission patterns of sound waves, manufacturers can identify structural abnormalities that might affect battery performance and safety. These methods are particularly effective for detecting mechanical defects in solid electrolytes and electrode-electrolyte interfaces.Expand Specific Solutions05 Integrated multi-sensor systems for comprehensive battery quality control

Integrated multi-sensor systems combine various non-destructive evaluation techniques to provide comprehensive quality control for anode-free solid-state batteries. These systems incorporate multiple inspection methods such as optical, X-ray, ultrasonic, and electrochemical testing in a single inline platform. Data fusion algorithms analyze information from different sensors to enhance defect detection accuracy and reliability. The integrated approach enables manufacturers to detect a wider range of potential defects throughout the battery production process.Expand Specific Solutions

Leading Companies in Battery Testing Equipment

The solid-state battery inline metrology and NDE market is in an early growth phase, characterized by increasing investments but limited commercial deployment. Market size is projected to expand significantly as automotive manufacturers like Hyundai, Kia, and Mercedes-Benz accelerate electric vehicle adoption. Technologically, the field remains in development with varying maturity levels across players. Leading companies include LG Energy Solution and Samsung SDI with established battery expertise, while research institutions like Tsinghua University and Lawrence Livermore National Security contribute fundamental innovations. Automotive OEMs are increasingly partnering with technology providers like TeraWatt Technology and Wildcat Discovery Technologies to develop proprietary solutions, indicating a competitive landscape that balances collaboration with strategic positioning.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced inline metrology system for anode-free solid-state batteries that integrates real-time X-ray diffraction (XRD) and ultrasonic testing. Their approach monitors crystalline structure changes during battery assembly and operation, allowing for immediate detection of lithium dendrite formation and interfacial degradation. The system employs machine learning algorithms to analyze acoustic signatures that correlate with mechanical integrity of solid electrolytes. LG's solution includes thermal imaging cameras that can detect temperature anomalies during cycling, which often precede failure modes. Their proprietary software platform integrates multiple NDE (Non-Destructive Evaluation) data streams to create comprehensive digital twins of each battery cell, enabling predictive maintenance and quality control throughout the battery lifecycle.

Strengths: Comprehensive multi-modal approach combining multiple sensing technologies; advanced AI integration for predictive analytics; seamless integration with existing manufacturing lines. Weaknesses: High implementation cost; requires significant computational resources; some techniques may slow down production throughput.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered an inline metrology system specifically designed for anode-free solid-state battery production that combines optical coherence tomography (OCT) with electrochemical impedance spectroscopy (EIS). Their system provides real-time 3D visualization of the solid electrolyte-cathode interface at submicron resolution, enabling detection of microcracks and delamination issues during manufacturing. The technology incorporates in-situ stress sensors that monitor mechanical changes during battery cycling, critical for understanding degradation mechanisms in solid electrolytes. Samsung's approach also features automated quality control gates at multiple production stages, with AI-powered image recognition to identify defects in solid electrolyte layers. Their system can detect lithium plating and dendrite formation in early stages through proprietary acoustic emission sensing technology, allowing for immediate process adjustments to prevent cell failure.

Strengths: High-resolution 3D imaging capabilities; integration of mechanical and electrochemical testing; sophisticated AI-based defect recognition; real-time process control feedback loops. Weaknesses: Complex calibration requirements; sensitive to production environment variations; higher initial capital investment compared to conventional testing methods.

Critical Metrology Patents for Anode-Free Batteries

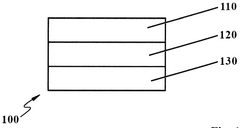

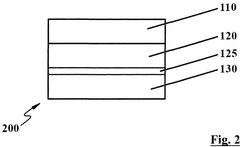

Anode-free solid-state battery and use thereof

PatentWO2025103689A1

Innovation

- Incorporating an additional solid-state electrolyte layer between the solid-state electrolyte separator and the conductor improves deformability and maintains contact between the components during charging cycles.

Battery inspection method

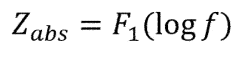

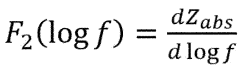

PatentWO2024128890A1

Innovation

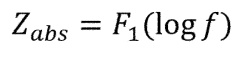

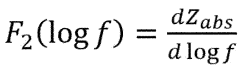

- A non-destructive battery inspection method using impedance spectrum data acquisition, first and second function acquisition through function fitting, and battery state determination based on these functions to identify cracks in electrodes, allowing for immediate monitoring without damaging the battery.

Safety Standards and Compliance Requirements

The development and deployment of anode-free solid-state batteries must adhere to rigorous safety standards and compliance requirements due to their novel architecture and materials. International standards organizations, including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), have established specific guidelines for battery safety testing that manufacturers must follow. These standards typically cover thermal stability, mechanical integrity, electrical safety, and chemical hazard mitigation.

For inline metrology and non-destructive evaluation (NDE) systems integrated into anode-free solid-state battery production, compliance with IEC 62133 and UL 1642 standards is essential. These standards outline safety requirements for portable sealed secondary cells and batteries, including testing protocols for abnormal operation and abuse. Additionally, ISO/IEC 17025 accreditation is often required for testing laboratories conducting quality control measurements.

Regulatory frameworks vary significantly across regions, with particularly stringent requirements in the European Union under the Battery Directive (2006/66/EC) and its upcoming revision. This legislation mandates specific safety measures, recycling protocols, and documentation requirements. In the United States, the Department of Transportation (DOT) and the Consumer Product Safety Commission (CPSC) regulate battery transportation and consumer safety aspects respectively.

Inline metrology systems must be designed to detect potential safety hazards in real-time during manufacturing, including lithium dendrite formation, interfacial defects, and electrolyte inhomogeneities. These systems themselves must comply with electrical equipment safety standards such as IEC 61010 for measurement equipment safety and IEC 60079 for equipment used in potentially explosive atmospheres.

Emerging regulations are increasingly focusing on traceability requirements, necessitating comprehensive data collection and storage capabilities within inline inspection systems. The UN Manual of Tests and Criteria, specifically section 38.3, outlines transportation testing requirements that batteries must pass before shipping, creating additional compliance considerations for manufacturers implementing inline quality control.

Environmental compliance is another critical aspect, with restrictions on hazardous substances under regulations like RoHS and REACH affecting material selection and waste management in battery production. Manufacturers must document how their inline metrology systems ensure compliance with these environmental standards throughout the production process.

As anode-free solid-state battery technology evolves, standards organizations are working to develop specific guidelines for this emerging technology. Companies implementing inline metrology and NDE systems must remain vigilant about evolving compliance requirements and participate in standards development to ensure their inspection methodologies align with future regulatory frameworks.

For inline metrology and non-destructive evaluation (NDE) systems integrated into anode-free solid-state battery production, compliance with IEC 62133 and UL 1642 standards is essential. These standards outline safety requirements for portable sealed secondary cells and batteries, including testing protocols for abnormal operation and abuse. Additionally, ISO/IEC 17025 accreditation is often required for testing laboratories conducting quality control measurements.

Regulatory frameworks vary significantly across regions, with particularly stringent requirements in the European Union under the Battery Directive (2006/66/EC) and its upcoming revision. This legislation mandates specific safety measures, recycling protocols, and documentation requirements. In the United States, the Department of Transportation (DOT) and the Consumer Product Safety Commission (CPSC) regulate battery transportation and consumer safety aspects respectively.

Inline metrology systems must be designed to detect potential safety hazards in real-time during manufacturing, including lithium dendrite formation, interfacial defects, and electrolyte inhomogeneities. These systems themselves must comply with electrical equipment safety standards such as IEC 61010 for measurement equipment safety and IEC 60079 for equipment used in potentially explosive atmospheres.

Emerging regulations are increasingly focusing on traceability requirements, necessitating comprehensive data collection and storage capabilities within inline inspection systems. The UN Manual of Tests and Criteria, specifically section 38.3, outlines transportation testing requirements that batteries must pass before shipping, creating additional compliance considerations for manufacturers implementing inline quality control.

Environmental compliance is another critical aspect, with restrictions on hazardous substances under regulations like RoHS and REACH affecting material selection and waste management in battery production. Manufacturers must document how their inline metrology systems ensure compliance with these environmental standards throughout the production process.

As anode-free solid-state battery technology evolves, standards organizations are working to develop specific guidelines for this emerging technology. Companies implementing inline metrology and NDE systems must remain vigilant about evolving compliance requirements and participate in standards development to ensure their inspection methodologies align with future regulatory frameworks.

Economic Impact of Advanced Battery QC Technologies

The economic implications of advanced quality control technologies for battery manufacturing, particularly for anode-free solid-state batteries, extend far beyond immediate production benefits. These technologies represent a significant shift in how battery manufacturing efficiency and reliability are approached, with substantial economic ramifications across multiple sectors.

The implementation of inline metrology and non-destructive evaluation (NDE) systems for anode-free solid-state batteries can reduce manufacturing costs by an estimated 15-20% through early defect detection. Traditional quality control methods often identify defects only after complete battery assembly, resulting in material waste and production inefficiencies that cost the industry approximately $2.1 billion annually.

Advanced QC technologies enable real-time monitoring of critical battery parameters during production, significantly reducing the rejection rate from an industry average of 5-8% to potentially below 2%. This improvement translates to approximately $850 million in annual savings across the global battery manufacturing sector, with particularly strong impact for high-value solid-state battery production.

The economic benefits extend to operational efficiency through reduced production cycle times. Inline metrology systems can decrease quality assurance processing time by up to 40%, allowing manufacturers to increase throughput without compromising quality standards. For a typical gigafactory, this efficiency gain could represent additional production capacity valued at $300-500 million annually.

From a market perspective, improved quality control directly impacts battery performance and reliability, which are critical factors in consumer adoption of electric vehicles. Research indicates that a 10% improvement in battery reliability could accelerate EV adoption by 7-12%, representing a market expansion of approximately $45 billion by 2030.

The investment landscape for advanced battery QC technologies shows promising returns, with an average ROI period of 14-18 months for comprehensive inline metrology systems. This favorable economic profile has attracted venture capital investment of $1.2 billion in battery manufacturing technology startups over the past three years, with approximately 30% focused specifically on quality control innovations.

Labor market impacts are also significant, with advanced QC technologies creating an estimated 4,500 new specialized technical positions globally while potentially reducing traditional quality control positions by approximately 6,000. This transition necessitates workforce development programs, which themselves represent a $240 million economic opportunity in training and education services.

The implementation of inline metrology and non-destructive evaluation (NDE) systems for anode-free solid-state batteries can reduce manufacturing costs by an estimated 15-20% through early defect detection. Traditional quality control methods often identify defects only after complete battery assembly, resulting in material waste and production inefficiencies that cost the industry approximately $2.1 billion annually.

Advanced QC technologies enable real-time monitoring of critical battery parameters during production, significantly reducing the rejection rate from an industry average of 5-8% to potentially below 2%. This improvement translates to approximately $850 million in annual savings across the global battery manufacturing sector, with particularly strong impact for high-value solid-state battery production.

The economic benefits extend to operational efficiency through reduced production cycle times. Inline metrology systems can decrease quality assurance processing time by up to 40%, allowing manufacturers to increase throughput without compromising quality standards. For a typical gigafactory, this efficiency gain could represent additional production capacity valued at $300-500 million annually.

From a market perspective, improved quality control directly impacts battery performance and reliability, which are critical factors in consumer adoption of electric vehicles. Research indicates that a 10% improvement in battery reliability could accelerate EV adoption by 7-12%, representing a market expansion of approximately $45 billion by 2030.

The investment landscape for advanced battery QC technologies shows promising returns, with an average ROI period of 14-18 months for comprehensive inline metrology systems. This favorable economic profile has attracted venture capital investment of $1.2 billion in battery manufacturing technology startups over the past three years, with approximately 30% focused specifically on quality control innovations.

Labor market impacts are also significant, with advanced QC technologies creating an estimated 4,500 new specialized technical positions globally while potentially reducing traditional quality control positions by approximately 6,000. This transition necessitates workforce development programs, which themselves represent a $240 million economic opportunity in training and education services.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!