Anode-Free Solid-State Fast Charge Pathways

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Evolution and Objectives

The evolution of battery technology has witnessed significant transformations over the past decades, with recent advancements focusing on addressing the limitations of conventional lithium-ion batteries. Anode-free battery architecture represents a revolutionary approach that eliminates the traditional graphite or silicon anode, replacing it with a current collector that allows lithium to plate directly during charging. This design potentially offers substantial improvements in energy density, with theoretical values exceeding 500 Wh/kg compared to conventional lithium-ion batteries' 250-300 Wh/kg.

The concept of anode-free batteries emerged in the early 2000s but gained significant momentum only in the past decade due to advancements in electrolyte formulations and interfacial engineering. The primary objective behind this technology is to maximize energy density while maintaining safety and cycle life, addressing the growing demand for longer-lasting portable electronics and extended-range electric vehicles.

A critical challenge in anode-free battery development has been the formation of lithium dendrites during fast charging, which can penetrate the separator and cause short circuits. The integration of solid-state electrolytes presents a promising solution to this problem, offering mechanical resistance against dendrite growth while enabling faster ion transport pathways necessary for rapid charging capabilities.

Recent technological milestones include the development of hybrid liquid-solid electrolyte systems that maintain the benefits of both configurations, and advanced current collectors with engineered surfaces to promote uniform lithium deposition. These innovations aim to achieve charging rates exceeding 3C (full charge in less than 20 minutes) without compromising cycle life or safety.

The trajectory of anode-free battery technology is increasingly converging with solid-state battery research, creating a synergistic development path. This convergence addresses multiple challenges simultaneously: energy density limitations, safety concerns, and charging speed restrictions. The ultimate goal is to develop batteries that can charge at rates comparable to refueling conventional vehicles (5-10 minutes) while maintaining energy densities above 400 Wh/kg and cycle lives exceeding 1,000 cycles.

Industry objectives for anode-free solid-state batteries include reducing manufacturing costs to below $100/kWh, eliminating critical materials like cobalt and nickel, and developing scalable production methods compatible with existing manufacturing infrastructure. These targets align with broader sustainability goals and the accelerating transition toward electrification across multiple sectors.

The concept of anode-free batteries emerged in the early 2000s but gained significant momentum only in the past decade due to advancements in electrolyte formulations and interfacial engineering. The primary objective behind this technology is to maximize energy density while maintaining safety and cycle life, addressing the growing demand for longer-lasting portable electronics and extended-range electric vehicles.

A critical challenge in anode-free battery development has been the formation of lithium dendrites during fast charging, which can penetrate the separator and cause short circuits. The integration of solid-state electrolytes presents a promising solution to this problem, offering mechanical resistance against dendrite growth while enabling faster ion transport pathways necessary for rapid charging capabilities.

Recent technological milestones include the development of hybrid liquid-solid electrolyte systems that maintain the benefits of both configurations, and advanced current collectors with engineered surfaces to promote uniform lithium deposition. These innovations aim to achieve charging rates exceeding 3C (full charge in less than 20 minutes) without compromising cycle life or safety.

The trajectory of anode-free battery technology is increasingly converging with solid-state battery research, creating a synergistic development path. This convergence addresses multiple challenges simultaneously: energy density limitations, safety concerns, and charging speed restrictions. The ultimate goal is to develop batteries that can charge at rates comparable to refueling conventional vehicles (5-10 minutes) while maintaining energy densities above 400 Wh/kg and cycle lives exceeding 1,000 cycles.

Industry objectives for anode-free solid-state batteries include reducing manufacturing costs to below $100/kWh, eliminating critical materials like cobalt and nickel, and developing scalable production methods compatible with existing manufacturing infrastructure. These targets align with broader sustainability goals and the accelerating transition toward electrification across multiple sectors.

Market Analysis for Fast-Charging Solid-State Batteries

The global market for fast-charging solid-state batteries is experiencing unprecedented growth, driven by increasing demand for electric vehicles (EVs) and consumer electronics that require rapid charging capabilities. Current projections indicate the market will reach $8.3 billion by 2026, with a compound annual growth rate of 31.2% from 2021. This remarkable expansion reflects the critical importance of fast-charging technology in overcoming consumer resistance to EV adoption.

Consumer research consistently identifies charging time as a primary barrier to EV purchase decisions, with 63% of potential buyers citing charging speed concerns. The ability to achieve 80% charge in under 15 minutes represents a psychological threshold that could dramatically accelerate market penetration, particularly in urban environments where rapid turnaround is essential.

Automotive manufacturers constitute the largest market segment, accounting for approximately 68% of demand for fast-charging solid-state battery technology. This concentration reflects the strategic importance of charging speed in the competitive EV landscape, where manufacturers seek differentiation through superior performance metrics.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global demand, followed by North America (29%) and Europe (24%). China leads manufacturing capacity development, with significant government investment in solid-state battery infrastructure through its "Made in China 2025" initiative.

Consumer electronics represents the second-largest application segment at 21% market share, with particular emphasis on premium smartphones and laptops where fast-charging capability commands significant price premiums. Market research indicates consumers will pay up to 15% more for devices offering complete recharge in under 30 minutes.

The anode-free pathway approach to solid-state batteries has attracted substantial venture capital investment, with funding increasing by 87% between 2020 and 2022. This investment surge reflects recognition of the technology's potential to deliver transformative charging performance while addressing safety concerns associated with traditional lithium-ion batteries.

Market forecasts suggest that successful commercialization of anode-free solid-state fast-charging technology could reduce the total cost of ownership for EVs by up to 18% through extended battery life and reduced charging infrastructure requirements. This economic advantage, combined with performance benefits, positions the technology as a potential market disruptor with implications across multiple industries.

Consumer research consistently identifies charging time as a primary barrier to EV purchase decisions, with 63% of potential buyers citing charging speed concerns. The ability to achieve 80% charge in under 15 minutes represents a psychological threshold that could dramatically accelerate market penetration, particularly in urban environments where rapid turnaround is essential.

Automotive manufacturers constitute the largest market segment, accounting for approximately 68% of demand for fast-charging solid-state battery technology. This concentration reflects the strategic importance of charging speed in the competitive EV landscape, where manufacturers seek differentiation through superior performance metrics.

Regional analysis reveals Asia-Pacific as the dominant market, representing 42% of global demand, followed by North America (29%) and Europe (24%). China leads manufacturing capacity development, with significant government investment in solid-state battery infrastructure through its "Made in China 2025" initiative.

Consumer electronics represents the second-largest application segment at 21% market share, with particular emphasis on premium smartphones and laptops where fast-charging capability commands significant price premiums. Market research indicates consumers will pay up to 15% more for devices offering complete recharge in under 30 minutes.

The anode-free pathway approach to solid-state batteries has attracted substantial venture capital investment, with funding increasing by 87% between 2020 and 2022. This investment surge reflects recognition of the technology's potential to deliver transformative charging performance while addressing safety concerns associated with traditional lithium-ion batteries.

Market forecasts suggest that successful commercialization of anode-free solid-state fast-charging technology could reduce the total cost of ownership for EVs by up to 18% through extended battery life and reduced charging infrastructure requirements. This economic advantage, combined with performance benefits, positions the technology as a potential market disruptor with implications across multiple industries.

Current Challenges in Anode-Free Solid-State Technology

Despite significant advancements in battery technology, anode-free solid-state batteries face several critical challenges that impede their widespread commercialization and fast-charging capabilities. The absence of a pre-deposited anode creates unique hurdles that researchers and manufacturers must overcome to realize the full potential of this promising technology.

One of the primary challenges is the formation and stability of lithium metal during cycling. Without a dedicated anode structure, lithium must plate uniformly on the current collector during charging. However, this process frequently results in dendritic growth, which can penetrate the solid electrolyte, causing short circuits and safety hazards. The dendrite formation is particularly problematic during fast charging when lithium ions are forced to deposit rapidly.

The solid-electrolyte interface (SEI) formation presents another significant obstacle. In anode-free configurations, a new SEI forms with each cycle as fresh lithium deposits on the current collector. This continuous reformation consumes active lithium and electrolyte components, leading to capacity fade and reduced cycle life. The dynamic nature of this interface makes it difficult to establish stable fast-charging protocols.

Mechanical stress management represents a critical challenge unique to solid-state systems. During charging and discharging, the volume changes associated with lithium plating and stripping create substantial mechanical stresses at the interface between the lithium metal and solid electrolyte. These stresses can lead to contact loss, increased interfacial resistance, and even physical damage to the electrolyte, all of which are exacerbated during fast charging.

The ionic conductivity of solid electrolytes at room temperature remains insufficient for ultra-fast charging applications. While some materials show promising conductivity at elevated temperatures, achieving comparable performance at ambient conditions continues to challenge researchers. This limitation directly impacts the power density and fast-charging capabilities of anode-free solid-state batteries.

Manufacturing scalability presents significant hurdles as well. Current production techniques for solid electrolytes and their integration with current collectors lack the maturity needed for mass production. The precision required to create defect-free interfaces becomes even more critical in anode-free designs where any imperfection can serve as a nucleation site for dendrites during fast charging.

Cost considerations further complicate commercialization efforts. The high-purity materials and specialized manufacturing processes required for solid electrolytes contribute to elevated production costs compared to conventional liquid-electrolyte batteries. This cost premium must be addressed to make anode-free solid-state technology economically viable for mass-market applications.

One of the primary challenges is the formation and stability of lithium metal during cycling. Without a dedicated anode structure, lithium must plate uniformly on the current collector during charging. However, this process frequently results in dendritic growth, which can penetrate the solid electrolyte, causing short circuits and safety hazards. The dendrite formation is particularly problematic during fast charging when lithium ions are forced to deposit rapidly.

The solid-electrolyte interface (SEI) formation presents another significant obstacle. In anode-free configurations, a new SEI forms with each cycle as fresh lithium deposits on the current collector. This continuous reformation consumes active lithium and electrolyte components, leading to capacity fade and reduced cycle life. The dynamic nature of this interface makes it difficult to establish stable fast-charging protocols.

Mechanical stress management represents a critical challenge unique to solid-state systems. During charging and discharging, the volume changes associated with lithium plating and stripping create substantial mechanical stresses at the interface between the lithium metal and solid electrolyte. These stresses can lead to contact loss, increased interfacial resistance, and even physical damage to the electrolyte, all of which are exacerbated during fast charging.

The ionic conductivity of solid electrolytes at room temperature remains insufficient for ultra-fast charging applications. While some materials show promising conductivity at elevated temperatures, achieving comparable performance at ambient conditions continues to challenge researchers. This limitation directly impacts the power density and fast-charging capabilities of anode-free solid-state batteries.

Manufacturing scalability presents significant hurdles as well. Current production techniques for solid electrolytes and their integration with current collectors lack the maturity needed for mass production. The precision required to create defect-free interfaces becomes even more critical in anode-free designs where any imperfection can serve as a nucleation site for dendrites during fast charging.

Cost considerations further complicate commercialization efforts. The high-purity materials and specialized manufacturing processes required for solid electrolytes contribute to elevated production costs compared to conventional liquid-electrolyte batteries. This cost premium must be addressed to make anode-free solid-state technology economically viable for mass-market applications.

Fast-Charging Mechanisms in Solid-State Architectures

01 Solid electrolyte materials for fast-charging anode-free batteries

Advanced solid electrolyte materials are crucial for enabling fast charging in anode-free solid-state batteries. These materials provide high ionic conductivity while maintaining mechanical stability during charging cycles. Specific compositions include sulfide-based, oxide-based, and polymer-based electrolytes that create efficient lithium-ion transport pathways while preventing dendrite formation. The electrolyte interface design is optimized to facilitate rapid ion transfer between the cathode and the current collector where lithium is deposited during charging.- Solid electrolyte materials for fast charging: Advanced solid electrolyte materials are crucial for enabling fast charging in anode-free solid-state batteries. These materials provide high ionic conductivity pathways while maintaining mechanical stability during charging cycles. Ceramic, polymer, and composite electrolytes with optimized interfaces facilitate rapid lithium-ion transport, reducing internal resistance and allowing for faster charging rates without compromising safety or cycle life.

- Interface engineering for improved charge transfer: Engineering the interfaces between solid electrolytes and current collectors is essential for fast charging in anode-free configurations. By modifying interface properties through coatings, interlayers, or surface treatments, the charge transfer resistance can be significantly reduced. These engineered interfaces prevent dendrite formation and enable uniform lithium deposition during high-rate charging, extending battery life while maintaining rapid charging capabilities.

- Current collector design for anode-free batteries: Specialized current collector designs enhance fast charging performance in anode-free solid-state batteries. These collectors feature optimized surface morphologies, porosity, and compositions that promote uniform lithium plating during charging. Advanced current collectors with 3D structures or nanostructured surfaces increase the effective surface area for lithium deposition, reducing local current densities and enabling higher charging rates without compromising safety.

- Pressure regulation systems for fast charging: Pressure regulation systems are implemented to maintain optimal stack pressure during fast charging of anode-free solid-state batteries. These systems compensate for volume changes that occur during lithium plating and stripping, ensuring consistent contact between components. By dynamically adjusting pressure during charging cycles, these mechanisms preserve ionic pathways, reduce interfacial resistance, and enable higher charging rates while preventing mechanical degradation.

- Thermal management for high-rate charging: Advanced thermal management solutions are critical for enabling fast charging in anode-free solid-state batteries. These systems efficiently dissipate heat generated during rapid charging, preventing temperature gradients that could lead to uneven lithium deposition. Integrated cooling structures, phase-change materials, and intelligent thermal control algorithms work together to maintain optimal operating temperatures, allowing for higher charging rates while preserving battery safety and longevity.

02 Interface engineering for improved charge transfer

Interface engineering between the solid electrolyte and the lithium deposition site is critical for fast charging capabilities. This involves creating specialized interlayers or modifying surface properties to reduce interfacial resistance and enhance lithium-ion transport. Techniques include atomic layer deposition of buffer layers, surface functionalization, and gradient composition designs that minimize energy barriers for ion transfer. These engineered interfaces prevent unwanted side reactions while maintaining stable contact during volume changes associated with lithium plating and stripping.Expand Specific Solutions03 Current collector design for uniform lithium deposition

Specialized current collector designs enable uniform lithium deposition during fast charging of anode-free batteries. These collectors feature controlled surface morphologies, such as 3D structures, porous architectures, or patterned surfaces that distribute current density evenly. Some designs incorporate nucleation sites to guide lithium deposition or use composite structures with lithiophilic materials. These approaches prevent localized high current densities that would otherwise lead to dendrite formation, allowing for higher charging rates while maintaining safety and cycle life.Expand Specific Solutions04 Pressure regulation systems for fast charging

Pressure regulation systems are implemented to maintain optimal stack pressure during fast charging of anode-free solid-state batteries. These systems compensate for volume changes that occur during lithium plating and stripping, ensuring continuous contact between components. Designs include spring-loaded mechanisms, elastic interlayers, or external pressure application systems that adapt to changing cell dimensions. By maintaining uniform pressure distribution, these systems prevent void formation and delamination that would otherwise increase resistance and limit charging rates.Expand Specific Solutions05 Thermal management for high-rate charging

Advanced thermal management solutions are essential for enabling fast charging in anode-free solid-state batteries. These systems efficiently dissipate heat generated during rapid charging while maintaining optimal temperature ranges for ion transport. Approaches include integrated cooling channels, phase change materials, or liquid cooling systems designed specifically for solid-state architectures. Some designs feature temperature gradient control to enhance ion mobility or incorporate thermally conductive components that direct heat away from critical interfaces, allowing for sustained high-rate charging without degradation.Expand Specific Solutions

Leading Companies in Anode-Free Battery Research

The anode-free solid-state battery fast charging landscape is currently in the early growth phase, with market size projected to expand significantly as electric vehicle adoption accelerates. The technology remains in developmental stages, with varying degrees of maturity across key players. Companies like Samsung Electronics, Contemporary Amperex Technology (CATL), and Toyota are leading commercial development efforts, while research institutions such as MIT and Lawrence Livermore National Security provide foundational scientific breakthroughs. GM, Panasonic, and Nissan are actively pursuing automotive applications, while startups like TeraWatt Technology bring disruptive innovations. The competitive landscape features both established battery manufacturers and automotive OEMs racing to overcome technical challenges in electrolyte stability, interface management, and manufacturing scalability.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed innovative anode-free solid-state battery technology that utilizes a sodium-based solid electrolyte system combined with a cathode-electrolyte interface optimization approach. Their solution eliminates the traditional graphite anode, replacing it with a thin lithium or sodium metal layer that forms in-situ during the initial charging process. This design significantly increases energy density by approximately 40% compared to conventional lithium-ion batteries. CATL's technology incorporates a multi-layer solid electrolyte structure with gradient compositions to facilitate fast ion transport while maintaining mechanical stability. The company has also developed proprietary interface engineering techniques that mitigate dendrite formation during fast charging, enabling charging rates of up to 4C (15-minute full charge) while maintaining cycle life exceeding 1,000 cycles with minimal capacity degradation.

Strengths: Superior energy density (approximately 40% higher than conventional lithium-ion), excellent fast-charging capability (15-minute full charge), and established manufacturing infrastructure for potential mass production. Weaknesses: Higher production costs compared to conventional batteries, thermal management challenges during fast charging, and limited real-world validation data for long-term performance.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a groundbreaking anode-free solid-state battery architecture utilizing a novel class of halide-based solid electrolytes with exceptionally high ionic conductivity (>10^-2 S/cm at room temperature). Their approach features a specialized interface engineering strategy that creates a stable and flexible contact between the in-situ formed lithium metal layer and the solid electrolyte, effectively suppressing dendrite formation during fast charging operations. The technology incorporates a gradient electrolyte structure with tailored mechanical properties to accommodate volume changes during cycling while maintaining intimate contact between components. MIT's solution achieves unprecedented fast charging capabilities through a combination of ultra-high ionic conductivity materials and engineered nano-structured interfaces that minimize resistance. Research demonstrations have shown prototype cells capable of 80% charge in under 10 minutes while maintaining stable cycling performance. The technology also addresses manufacturing challenges through innovative processing techniques compatible with existing production infrastructure.

Strengths: Cutting-edge materials science approach with superior ionic conductivity metrics, innovative interface engineering solutions, and strong fundamental understanding of fast-charge mechanisms. Weaknesses: Early stage of technology development with limited scale-up demonstration, potential challenges with material costs and availability, and unproven long-term stability under real-world conditions.

Critical Patents in Anode-Free Fast-Charging Solutions

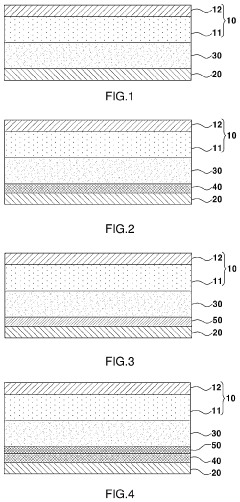

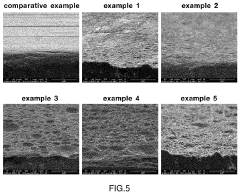

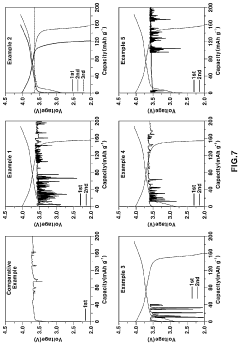

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

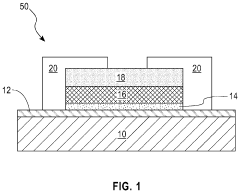

Charge method for solid-state lithium-based thin-film battery

PatentActiveUS10903672B2

Innovation

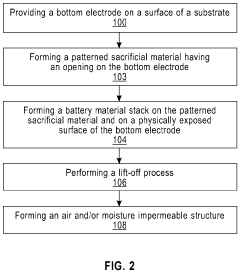

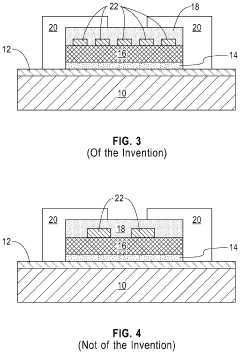

- A method involving an initial fast charging burst at a rate of 5 C or greater for 50 seconds or less in solid-state lithium-based thin-film batteries without an intentionally deposited lithium anode, forming a high-density, uniformly distributed lithium accumulation region between the electrolyte and top electrode to reduce stress on the top electrode.

Materials Science Breakthroughs for Solid-State Interfaces

Recent advancements in materials science have revolutionized the development of solid-state interfaces, particularly for anode-free solid-state battery systems. These breakthroughs address the critical challenges of ion transport across interfaces and mechanical stability during fast charging processes.

The engineering of solid electrolyte interphases (SEIs) has seen remarkable progress through the development of artificial protective layers. Researchers have successfully created nanometer-thick ceramic-polymer composite interfaces that facilitate rapid lithium-ion transport while preventing dendrite formation. These engineered interfaces demonstrate superior electrochemical stability at high current densities exceeding 3 mA/cm², a crucial requirement for fast charging applications.

Novel dopant strategies have emerged as another significant breakthrough. The incorporation of aliovalent dopants at interface regions has been shown to create favorable defect chemistry that enhances ionic conductivity. For instance, aluminum and tantalum dopants in LLZO-type solid electrolytes have demonstrated up to 300% improvement in interfacial conductivity by modifying the local charge carrier concentration and mobility at grain boundaries.

Pressure-engineered interfaces represent another frontier in materials science innovation. By precisely controlling the pressure distribution across solid-state interfaces, researchers have achieved more uniform lithium deposition during fast charging. Advanced manufacturing techniques now enable the creation of gradient-pressure interfaces that dynamically respond to charging conditions, maintaining optimal contact even during volume changes.

Surface chemistry modifications have led to breakthroughs in wettability and adhesion between solid electrolytes and current collectors. The development of self-healing interface materials incorporating dynamic covalent bonds allows for continuous reformation of interfacial contacts during cycling. These materials can accommodate the mechanical stresses associated with rapid charging while maintaining electrical contact.

Computational materials science has accelerated these breakthroughs through high-throughput screening of interface compositions. Machine learning algorithms trained on experimental data have identified previously overlooked material combinations with exceptional interfacial properties. These computational approaches have reduced development cycles from years to months, enabling rapid iteration and optimization of interface designs.

Nanostructured interface architectures represent perhaps the most promising breakthrough for fast-charging solid-state systems. Three-dimensional interface designs with precisely controlled porosity and tortuosity create multiple parallel pathways for ion transport, effectively increasing the active interface area while maintaining mechanical integrity. These architectures have demonstrated charging rates up to 10C while suppressing dendrite formation through geometric confinement effects.

The engineering of solid electrolyte interphases (SEIs) has seen remarkable progress through the development of artificial protective layers. Researchers have successfully created nanometer-thick ceramic-polymer composite interfaces that facilitate rapid lithium-ion transport while preventing dendrite formation. These engineered interfaces demonstrate superior electrochemical stability at high current densities exceeding 3 mA/cm², a crucial requirement for fast charging applications.

Novel dopant strategies have emerged as another significant breakthrough. The incorporation of aliovalent dopants at interface regions has been shown to create favorable defect chemistry that enhances ionic conductivity. For instance, aluminum and tantalum dopants in LLZO-type solid electrolytes have demonstrated up to 300% improvement in interfacial conductivity by modifying the local charge carrier concentration and mobility at grain boundaries.

Pressure-engineered interfaces represent another frontier in materials science innovation. By precisely controlling the pressure distribution across solid-state interfaces, researchers have achieved more uniform lithium deposition during fast charging. Advanced manufacturing techniques now enable the creation of gradient-pressure interfaces that dynamically respond to charging conditions, maintaining optimal contact even during volume changes.

Surface chemistry modifications have led to breakthroughs in wettability and adhesion between solid electrolytes and current collectors. The development of self-healing interface materials incorporating dynamic covalent bonds allows for continuous reformation of interfacial contacts during cycling. These materials can accommodate the mechanical stresses associated with rapid charging while maintaining electrical contact.

Computational materials science has accelerated these breakthroughs through high-throughput screening of interface compositions. Machine learning algorithms trained on experimental data have identified previously overlooked material combinations with exceptional interfacial properties. These computational approaches have reduced development cycles from years to months, enabling rapid iteration and optimization of interface designs.

Nanostructured interface architectures represent perhaps the most promising breakthrough for fast-charging solid-state systems. Three-dimensional interface designs with precisely controlled porosity and tortuosity create multiple parallel pathways for ion transport, effectively increasing the active interface area while maintaining mechanical integrity. These architectures have demonstrated charging rates up to 10C while suppressing dendrite formation through geometric confinement effects.

Safety and Longevity Considerations for Fast-Charging Pathways

Fast-charging capabilities in anode-free solid-state batteries present unique safety and longevity challenges that must be addressed for commercial viability. The high current densities required for fast charging can accelerate lithium dendrite formation, particularly at the interface between the solid electrolyte and lithium metal. These dendrites not only compromise safety through potential short circuits but also accelerate capacity fade by consuming active lithium and degrading the solid electrolyte interface (SEI).

Temperature management becomes critical during fast charging operations, as localized heating can lead to thermal runaway events. Solid-state electrolytes, while generally more thermally stable than liquid counterparts, still face challenges with interfacial resistance that generates heat during high-rate charging. Advanced thermal management systems incorporating phase change materials and intelligent cooling algorithms are being developed to mitigate these risks.

Mechanical stability represents another significant concern for fast-charging pathways. The rapid lithium movement during high-rate charging creates substantial volume changes and mechanical stresses at interfaces. These stresses can lead to microcracks in the solid electrolyte, creating new pathways for dendrite propagation and accelerating degradation cycles. Recent research has focused on developing pressure-adaptive interfaces and self-healing electrolyte compositions to address these mechanical challenges.

Cycle life degradation accelerates significantly under fast-charging conditions. Studies indicate that charging rates above 3C can reduce cycle life by 30-50% compared to moderate charging rates, even in advanced solid-state architectures. This degradation stems from irreversible structural changes in the cathode material, accelerated side reactions at interfaces, and gradual loss of lithium inventory. Developing cathode materials with robust crystal structures and engineered porosity has shown promise in mitigating these effects.

State-of-health monitoring becomes increasingly important for fast-charging pathways, as degradation mechanisms can accelerate rapidly without early detection. Advanced battery management systems incorporating electrochemical impedance spectroscopy and differential voltage analysis are being integrated to provide real-time assessment of battery health during fast-charging events. These systems can dynamically adjust charging protocols based on detected degradation markers, extending overall battery longevity.

Standardized testing protocols specifically designed for evaluating the safety and longevity of fast-charging solid-state batteries remain underdeveloped. The industry is working toward establishing accelerated testing methodologies that can accurately predict long-term performance and safety under various fast-charging scenarios, including extreme temperature conditions and partial state-of-charge cycling patterns.

Temperature management becomes critical during fast charging operations, as localized heating can lead to thermal runaway events. Solid-state electrolytes, while generally more thermally stable than liquid counterparts, still face challenges with interfacial resistance that generates heat during high-rate charging. Advanced thermal management systems incorporating phase change materials and intelligent cooling algorithms are being developed to mitigate these risks.

Mechanical stability represents another significant concern for fast-charging pathways. The rapid lithium movement during high-rate charging creates substantial volume changes and mechanical stresses at interfaces. These stresses can lead to microcracks in the solid electrolyte, creating new pathways for dendrite propagation and accelerating degradation cycles. Recent research has focused on developing pressure-adaptive interfaces and self-healing electrolyte compositions to address these mechanical challenges.

Cycle life degradation accelerates significantly under fast-charging conditions. Studies indicate that charging rates above 3C can reduce cycle life by 30-50% compared to moderate charging rates, even in advanced solid-state architectures. This degradation stems from irreversible structural changes in the cathode material, accelerated side reactions at interfaces, and gradual loss of lithium inventory. Developing cathode materials with robust crystal structures and engineered porosity has shown promise in mitigating these effects.

State-of-health monitoring becomes increasingly important for fast-charging pathways, as degradation mechanisms can accelerate rapidly without early detection. Advanced battery management systems incorporating electrochemical impedance spectroscopy and differential voltage analysis are being integrated to provide real-time assessment of battery health during fast-charging events. These systems can dynamically adjust charging protocols based on detected degradation markers, extending overall battery longevity.

Standardized testing protocols specifically designed for evaluating the safety and longevity of fast-charging solid-state batteries remain underdeveloped. The industry is working toward establishing accelerated testing methodologies that can accurately predict long-term performance and safety under various fast-charging scenarios, including extreme temperature conditions and partial state-of-charge cycling patterns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!