Nucleation And Plating Uniformity For Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Solid-state batteries represent a significant evolution in energy storage technology, promising enhanced safety, higher energy density, and longer lifespan compared to conventional lithium-ion batteries. Among these, anode-free solid-state batteries have emerged as a particularly promising frontier, offering theoretical energy densities approaching the practical limits of lithium-based systems.

The concept of anode-free batteries dates back to the early 2000s, but significant technological advancements have only materialized in the past decade. These batteries eliminate the traditional anode material, instead relying on lithium metal plating directly onto the current collector during charging. This configuration maximizes energy density by removing the weight and volume of a dedicated anode structure, potentially increasing energy density by 30-50% compared to conventional lithium-ion designs.

The evolution of this technology has been driven by the increasing demand for higher energy density power sources in electric vehicles, portable electronics, and grid storage applications. The global push toward electrification and renewable energy integration has accelerated research in this domain, with significant investments from both public and private sectors.

However, the path to commercialization faces substantial technical challenges, particularly regarding nucleation and plating uniformity. When lithium ions are reduced and deposited during charging, they tend to form non-uniform structures, including dendrites that can penetrate the solid electrolyte, causing short circuits and safety hazards. Additionally, uneven plating leads to capacity fade, reduced cycle life, and diminished performance.

The primary technical objectives in this field include achieving homogeneous lithium nucleation, controlling plating morphology, and maintaining uniform current distribution across the electrode-electrolyte interface. Researchers aim to develop strategies that promote even lithium deposition without dendrite formation while maintaining high coulombic efficiency over thousands of cycles.

Recent technological milestones include the development of novel solid electrolytes with high ionic conductivity, engineered current collectors with optimized surface properties, and advanced interface engineering techniques. These innovations have demonstrated promising results in laboratory settings, with some prototypes achieving over 300 cycles with minimal capacity degradation.

The ultimate goal of anode-free solid-state battery technology is to create commercially viable energy storage systems that combine the theoretical energy density advantages with practical cycle life, safety, and manufacturing scalability. Success in this domain could revolutionize multiple industries, enabling electric vehicles with ranges exceeding 500 miles, consumer electronics with week-long battery life, and more efficient integration of renewable energy sources into the grid.

The concept of anode-free batteries dates back to the early 2000s, but significant technological advancements have only materialized in the past decade. These batteries eliminate the traditional anode material, instead relying on lithium metal plating directly onto the current collector during charging. This configuration maximizes energy density by removing the weight and volume of a dedicated anode structure, potentially increasing energy density by 30-50% compared to conventional lithium-ion designs.

The evolution of this technology has been driven by the increasing demand for higher energy density power sources in electric vehicles, portable electronics, and grid storage applications. The global push toward electrification and renewable energy integration has accelerated research in this domain, with significant investments from both public and private sectors.

However, the path to commercialization faces substantial technical challenges, particularly regarding nucleation and plating uniformity. When lithium ions are reduced and deposited during charging, they tend to form non-uniform structures, including dendrites that can penetrate the solid electrolyte, causing short circuits and safety hazards. Additionally, uneven plating leads to capacity fade, reduced cycle life, and diminished performance.

The primary technical objectives in this field include achieving homogeneous lithium nucleation, controlling plating morphology, and maintaining uniform current distribution across the electrode-electrolyte interface. Researchers aim to develop strategies that promote even lithium deposition without dendrite formation while maintaining high coulombic efficiency over thousands of cycles.

Recent technological milestones include the development of novel solid electrolytes with high ionic conductivity, engineered current collectors with optimized surface properties, and advanced interface engineering techniques. These innovations have demonstrated promising results in laboratory settings, with some prototypes achieving over 300 cycles with minimal capacity degradation.

The ultimate goal of anode-free solid-state battery technology is to create commercially viable energy storage systems that combine the theoretical energy density advantages with practical cycle life, safety, and manufacturing scalability. Success in this domain could revolutionize multiple industries, enabling electric vehicles with ranges exceeding 500 miles, consumer electronics with week-long battery life, and more efficient integration of renewable energy sources into the grid.

Market Analysis for Solid-State Battery Demand

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for electric vehicles (EVs), consumer electronics, and renewable energy storage solutions. Current projections indicate the global solid-state battery market will reach $8.7 billion by 2030, with a compound annual growth rate of 34.2% from 2023 to 2030. This remarkable growth trajectory is primarily fueled by the automotive sector's transition toward electrification, with major manufacturers committing to electric vehicle production targets.

Anode-free solid-state battery technology represents a particularly promising segment within this market, offering theoretical energy density improvements of 30-50% compared to conventional lithium-ion batteries. The elimination of the traditional graphite anode creates significant advantages in terms of energy density, safety, and potentially cost, addressing key consumer concerns about electric vehicle adoption.

Regional market analysis reveals distinct patterns of demand development. Asia-Pacific currently dominates the solid-state battery market, with Japan and South Korea leading in patents and commercial development. However, North America and Europe are rapidly accelerating investments, particularly in anode-free technologies, with substantial government funding initiatives supporting research and development efforts.

Consumer electronics represents the current largest application segment for solid-state batteries, accounting for approximately 43% of market demand. However, the automotive sector is projected to become the dominant market driver by 2027, with annual growth rates exceeding 40% as major manufacturers integrate solid-state technology into production roadmaps.

Market research indicates that consumers are willing to pay a premium of 15-20% for electric vehicles featuring solid-state batteries, primarily due to expectations of improved range, faster charging capabilities, and enhanced safety profiles. This consumer acceptance is critical for market penetration as manufacturing scales and costs decrease.

Industrial stakeholders have identified uniform lithium plating in anode-free designs as a critical technical challenge that directly impacts market adoption timelines. Survey data from battery manufacturers indicates that solving nucleation and plating uniformity issues could accelerate market introduction by 2-3 years, representing a significant competitive advantage for companies that develop effective solutions.

The energy storage sector represents an emerging market opportunity for anode-free solid-state batteries, with grid storage applications projected to grow at 28% annually through 2030. This diversification beyond transportation applications provides additional market stability and investment incentives for companies developing nucleation and plating uniformity solutions.

Anode-free solid-state battery technology represents a particularly promising segment within this market, offering theoretical energy density improvements of 30-50% compared to conventional lithium-ion batteries. The elimination of the traditional graphite anode creates significant advantages in terms of energy density, safety, and potentially cost, addressing key consumer concerns about electric vehicle adoption.

Regional market analysis reveals distinct patterns of demand development. Asia-Pacific currently dominates the solid-state battery market, with Japan and South Korea leading in patents and commercial development. However, North America and Europe are rapidly accelerating investments, particularly in anode-free technologies, with substantial government funding initiatives supporting research and development efforts.

Consumer electronics represents the current largest application segment for solid-state batteries, accounting for approximately 43% of market demand. However, the automotive sector is projected to become the dominant market driver by 2027, with annual growth rates exceeding 40% as major manufacturers integrate solid-state technology into production roadmaps.

Market research indicates that consumers are willing to pay a premium of 15-20% for electric vehicles featuring solid-state batteries, primarily due to expectations of improved range, faster charging capabilities, and enhanced safety profiles. This consumer acceptance is critical for market penetration as manufacturing scales and costs decrease.

Industrial stakeholders have identified uniform lithium plating in anode-free designs as a critical technical challenge that directly impacts market adoption timelines. Survey data from battery manufacturers indicates that solving nucleation and plating uniformity issues could accelerate market introduction by 2-3 years, representing a significant competitive advantage for companies that develop effective solutions.

The energy storage sector represents an emerging market opportunity for anode-free solid-state batteries, with grid storage applications projected to grow at 28% annually through 2030. This diversification beyond transportation applications provides additional market stability and investment incentives for companies developing nucleation and plating uniformity solutions.

Nucleation Challenges in Anode-Free Solid-State Batteries

The nucleation process in anode-free solid-state batteries represents a critical challenge that significantly impacts battery performance and longevity. Unlike conventional lithium-ion batteries with pre-existing anodes, anode-free designs rely on lithium plating directly onto the current collector during the initial charging process. This nucleation step establishes the foundation for all subsequent lithium deposition and stripping cycles, making it a determinant factor in battery efficiency.

The primary nucleation challenge stems from the heterogeneous nature of solid electrolyte interfaces. Surface defects, impurities, and non-uniform current distribution create preferential nucleation sites that lead to uneven lithium deposition. This heterogeneity results in dendrite formation - finger-like lithium structures that can penetrate the solid electrolyte, causing short circuits and catastrophic battery failure.

Energy barriers for lithium nucleation at the solid electrolyte/current collector interface further complicate the process. These barriers are influenced by interfacial chemistry, surface energy, and wettability between lithium and the substrate. Higher nucleation energy barriers lead to larger overpotentials during initial charging, reducing energy efficiency and potentially causing side reactions that consume active lithium.

The mechanical stress generated during nucleation presents another significant challenge. As lithium deposits form, they create volume expansion that induces stress at the interface. This stress can propagate microcracks in the solid electrolyte, creating pathways for accelerated dendrite growth and compromising the mechanical integrity of the battery structure.

Interfacial resistance between the solid electrolyte and the current collector also impacts nucleation behavior. Higher resistance areas experience localized heating and altered electrochemical conditions, leading to non-uniform nucleation patterns. This resistance is often dynamic, changing throughout battery cycling as reaction products accumulate at interfaces.

Temperature sensitivity further complicates nucleation control. At lower temperatures, lithium ion mobility decreases, and nucleation becomes more difficult and less uniform. Conversely, elevated temperatures may accelerate nucleation but can also promote side reactions that deplete lithium inventory and form resistive interfacial layers.

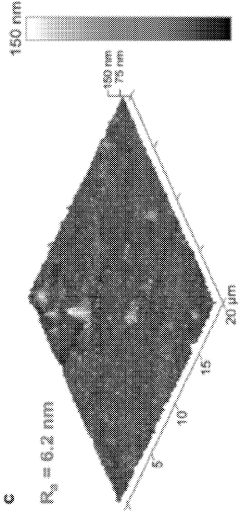

The current collector surface properties significantly influence nucleation patterns. Surface roughness, crystallographic orientation, and chemical composition all affect lithium adhesion and the spatial distribution of nucleation sites. Engineering these properties represents both a challenge and an opportunity for controlling uniform lithium deposition.

The primary nucleation challenge stems from the heterogeneous nature of solid electrolyte interfaces. Surface defects, impurities, and non-uniform current distribution create preferential nucleation sites that lead to uneven lithium deposition. This heterogeneity results in dendrite formation - finger-like lithium structures that can penetrate the solid electrolyte, causing short circuits and catastrophic battery failure.

Energy barriers for lithium nucleation at the solid electrolyte/current collector interface further complicate the process. These barriers are influenced by interfacial chemistry, surface energy, and wettability between lithium and the substrate. Higher nucleation energy barriers lead to larger overpotentials during initial charging, reducing energy efficiency and potentially causing side reactions that consume active lithium.

The mechanical stress generated during nucleation presents another significant challenge. As lithium deposits form, they create volume expansion that induces stress at the interface. This stress can propagate microcracks in the solid electrolyte, creating pathways for accelerated dendrite growth and compromising the mechanical integrity of the battery structure.

Interfacial resistance between the solid electrolyte and the current collector also impacts nucleation behavior. Higher resistance areas experience localized heating and altered electrochemical conditions, leading to non-uniform nucleation patterns. This resistance is often dynamic, changing throughout battery cycling as reaction products accumulate at interfaces.

Temperature sensitivity further complicates nucleation control. At lower temperatures, lithium ion mobility decreases, and nucleation becomes more difficult and less uniform. Conversely, elevated temperatures may accelerate nucleation but can also promote side reactions that deplete lithium inventory and form resistive interfacial layers.

The current collector surface properties significantly influence nucleation patterns. Surface roughness, crystallographic orientation, and chemical composition all affect lithium adhesion and the spatial distribution of nucleation sites. Engineering these properties represents both a challenge and an opportunity for controlling uniform lithium deposition.

Current Nucleation and Plating Uniformity Solutions

01 Electrolyte composition for uniform lithium plating

Specific electrolyte compositions can significantly improve lithium nucleation and plating uniformity in anode-free solid-state batteries. These compositions include optimized solid polymer electrolytes, composite electrolytes with ceramic fillers, and hybrid organic-inorganic electrolytes. The electrolyte formulations are designed to enhance ionic conductivity while maintaining mechanical stability, which helps to prevent dendrite formation and ensures uniform lithium deposition during charging cycles.- Electrolyte composition for uniform lithium plating: Specific electrolyte compositions can significantly improve lithium nucleation and plating uniformity in anode-free solid-state batteries. These compositions include optimized salt concentrations, solvent mixtures, and additives that promote homogeneous lithium deposition. The electrolyte formulations help control the solid electrolyte interphase (SEI) formation, reduce dendrite growth, and enhance the cycling stability of the battery by ensuring more uniform lithium plating during charging processes.

- Interface engineering for improved nucleation: Engineering the interface between the solid electrolyte and the current collector is crucial for controlling lithium nucleation behavior. Various approaches include surface modification of current collectors, application of artificial interlayers, and gradient structures that can guide lithium deposition. These interface engineering techniques create preferential nucleation sites, reduce interfacial resistance, and promote uniform lithium growth, which is essential for preventing dendrite formation and extending battery life in anode-free configurations.

- Pressure and temperature control mechanisms: Controlling pressure and temperature during battery operation significantly impacts lithium plating behavior. Applied stack pressure helps maintain intimate contact between components and guides uniform lithium deposition. Temperature management systems can optimize the kinetics of lithium transport and deposition processes. These physical parameters can be dynamically adjusted during cycling to promote more uniform nucleation and growth of lithium, reducing the risk of dendrite formation and improving overall battery performance.

- Current density distribution optimization: Optimizing current density distribution across the electrode surface is essential for achieving uniform lithium plating. This can be accomplished through electrode design modifications, current collector patterning, and advanced cell architectures that distribute current more evenly. Controlled charging protocols that adjust current density based on state of charge can also promote more uniform nucleation. These approaches minimize local current hotspots that would otherwise lead to preferential lithium deposition and potential dendrite formation.

- Solid electrolyte composition and structure: The composition and structure of solid electrolytes play a critical role in lithium nucleation and plating uniformity. Materials with high ionic conductivity, good mechanical properties, and chemical stability against lithium metal are preferred. Composite solid electrolytes, ceramic-polymer hybrids, and nanostructured materials can be engineered to guide lithium ion transport pathways. The grain boundaries, crystallinity, and porosity of solid electrolytes can be tailored to promote uniform lithium deposition and suppress dendrite propagation.

02 Interface engineering for controlled nucleation

Engineering the interface between the solid electrolyte and current collector is crucial for controlling lithium nucleation in anode-free batteries. This includes surface modifications of the current collector, creation of artificial interphases, and gradient structures that promote uniform lithium deposition. These interface engineering approaches help to reduce local current density variations and provide uniform nucleation sites, resulting in more homogeneous lithium plating and improved cycling stability.Expand Specific Solutions03 Pressure and temperature control systems

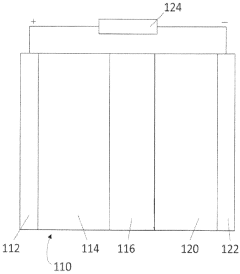

Implementing precise pressure and temperature control systems during battery operation can significantly improve plating uniformity in anode-free solid-state batteries. Controlled stack pressure helps maintain intimate contact between components, while temperature management systems ensure optimal operating conditions for uniform lithium deposition. These physical parameter controls help to minimize stress-induced defects and thermal gradients that could lead to non-uniform plating.Expand Specific Solutions04 Current collector design and materials

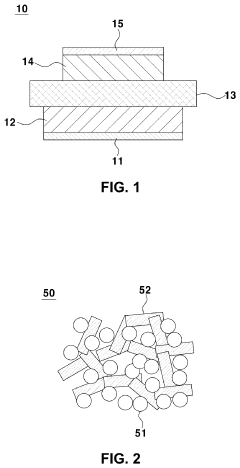

Advanced current collector designs and materials play a significant role in achieving uniform lithium nucleation and plating. This includes structured current collectors with engineered surface morphologies, composite current collectors with lithiophilic coatings, and three-dimensional architectures that provide uniform current distribution. These designs help to create homogeneous nucleation sites and reduce local current hotspots that could lead to dendrite formation.Expand Specific Solutions05 Additives and dopants for nucleation control

Incorporating specific additives and dopants into solid-state battery components can significantly improve lithium nucleation behavior and plating uniformity. These include nucleation-promoting additives, lithiophilic agents, and grain boundary modifiers that enhance ion transport pathways. The additives work by creating favorable nucleation sites, reducing energy barriers for lithium deposition, and improving the kinetics of the plating process, resulting in more uniform lithium distribution.Expand Specific Solutions

Leading Companies in Solid-State Battery Research

The solid-state battery market for anode-free technologies is in an early growth phase, characterized by intensive R&D efforts across automotive and energy sectors. Major automotive players like Hyundai, Toyota, GM, and Nissan are actively pursuing this technology to overcome lithium-ion battery limitations. Battery manufacturers including LG Energy Solution, Samsung SDI, and Svolt are competing to develop commercially viable solutions. The market is expected to expand significantly as companies address key technical challenges in nucleation and plating uniformity. Research institutions like Washington University and Zhejiang University collaborate with industry leaders to solve fundamental issues, while specialized companies like Ion Storage Systems focus exclusively on solid-state technology advancement. The competitive landscape reflects a strategic race to achieve uniform lithium plating for safer, higher-energy density batteries.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative approach to address nucleation and plating uniformity challenges in anode-free solid-state batteries. Their technology utilizes a gradient-structured solid electrolyte interface that promotes homogeneous lithium ion flux during charging. The company has engineered specialized ceramic-polymer composite electrolytes with precisely controlled surface morphology to create uniform nucleation sites for lithium deposition. Their proprietary "LiSEP" (Lithium Selective Plating) technology incorporates nano-engineered surface modifiers that preferentially direct lithium ions to deposit uniformly rather than forming dendrites. LG's solution also includes a thin artificial interlayer between the cathode and solid electrolyte that serves as a controlled nucleation template for lithium plating[2]. This layer contains carefully distributed conductive nanoparticles that act as nucleation centers, ensuring even distribution of lithium during charging. Their research shows that this approach reduces local current density variations by up to 85%, significantly improving plating uniformity and extending cycle life. LG has also implemented advanced pressure management systems that maintain optimal interfacial contact throughout battery operation, which is critical for uniform lithium deposition.

Strengths: LG's technology demonstrates exceptional plating uniformity with minimal dendrite formation even at fast charging rates. Their composite electrolyte design offers good mechanical stability while maintaining high ionic conductivity. Weaknesses: The complex manufacturing process for their gradient-structured interfaces may increase production costs, and the long-term stability of their artificial interlayers under repeated cycling still requires optimization.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to nucleation and plating uniformity for anode-free solid-state batteries through their advanced solid electrolyte technology. Their solution employs a multi-layer electrolyte architecture where a thin artificial SEI (Solid Electrolyte Interphase) layer is engineered between the lithium metal and solid electrolyte to promote uniform lithium deposition. Toyota's technique involves precise control of surface chemistry and microstructure at the electrolyte interface, creating preferential nucleation sites that guide lithium plating. They've implemented pressure-modulation systems during battery operation to maintain optimal contact at the lithium-electrolyte interface, which significantly improves plating uniformity. Their research demonstrates that controlling the current density distribution through specialized electrolyte designs with gradient ionic conductivity helps prevent dendrite formation and ensures homogeneous lithium deposition across the electrode surface[1][3]. Toyota has also pioneered the use of sulfide-based solid electrolytes with specific additives that enhance interfacial stability and promote uniform lithium nucleation.

Strengths: Toyota's approach demonstrates excellent cycling stability with over 1000 cycles at high capacity retention. Their technology effectively suppresses dendrite formation even at high current densities. Weaknesses: The manufacturing complexity of their multi-layer electrolyte system presents scaling challenges, and their sulfide-based electrolytes may have moisture sensitivity issues requiring stringent production environments.

Key Patents in Anode-Free Plating Technology

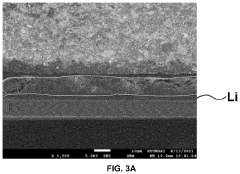

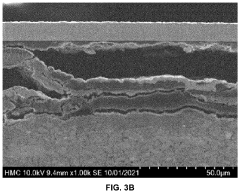

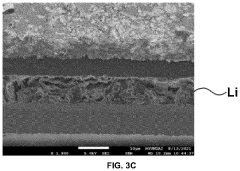

Stable metal plating in "anode-free" solid-state batteries enabled by seeded nucleation

PatentWO2024112751A1

Innovation

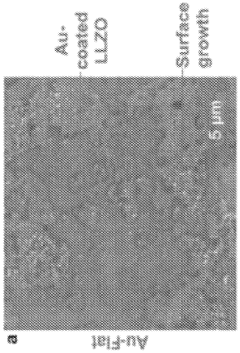

- The introduction of metal clusters on the solid-state electrolyte surface, such as gold clusters formed by sputtering and annealing, provides heterogeneous nucleation sites for homogeneous lithium plating, eliminating the need for high-pressure or high-temperature bonding between the current collector and solid-state electrolyte, and preventing current collector fracture.

Anodeless all-solid-state battery capable of achieving uniform deposition of lithium

PatentPendingUS20240079599A1

Innovation

- An anodeless all-solid-state battery design is proposed, featuring a bare anode current collector with a coating layer containing carbon and metal particles that induce lithium ion conduction, allowing uniform lithium deposition and controlling volume expansion, comprising a carbon particle mixture with spherical and linear shapes and metal particles like silver, to form a dense intermediate layer for efficient lithium precipitation.

Materials Science Advancements for Solid-State Interfaces

Recent advancements in materials science have significantly propelled the development of solid-state interfaces for anode-free solid-state batteries. These interfaces play a crucial role in addressing the challenges of nucleation and plating uniformity, which are essential for achieving stable and efficient battery performance.

The solid-electrolyte interface (SEI) has been revolutionized through innovative material compositions that enhance lithium ion conductivity while maintaining mechanical stability. Researchers have developed ceramic-polymer composite electrolytes that combine the high ionic conductivity of ceramics with the flexibility of polymers, creating interfaces that can accommodate volume changes during cycling while facilitating uniform lithium deposition.

Nanostructured interface engineering has emerged as a promising approach to control lithium nucleation sites. By introducing precisely designed surface textures at the nanoscale, researchers have demonstrated the ability to guide lithium deposition patterns, preventing dendritic growth that typically leads to short circuits and battery failure. These engineered interfaces provide preferential nucleation sites that promote homogeneous lithium plating.

Artificial interlayers composed of materials such as lithium phosphorous oxynitride (LiPON) have shown remarkable effectiveness in improving the wetting behavior of lithium on solid electrolytes. These interlayers modify the surface energy landscape, reducing the nucleation energy barrier and enabling more uniform lithium deposition across the electrode surface rather than concentrated growth at isolated sites.

Advanced coating technologies, including atomic layer deposition (ALD) and molecular layer deposition (MLD), have enabled the creation of ultrathin, conformal protective layers on solid electrolytes. These nanometer-scale coatings can significantly alter the interface chemistry, promoting favorable lithium nucleation kinetics while preventing parasitic reactions that lead to interface degradation and resistance growth.

The incorporation of two-dimensional materials such as graphene and MXenes at solid-state interfaces has demonstrated promising results in controlling lithium plating behavior. These materials provide unique electronic properties and physical barriers that guide ion transport pathways and nucleation processes, resulting in more uniform lithium deposition morphologies.

Computational materials science has accelerated interface design through atomistic modeling and machine learning approaches. These computational tools enable researchers to predict interface stability, ion transport mechanisms, and nucleation behaviors without extensive experimental iterations, significantly accelerating the discovery of optimal interface materials and structures for anode-free solid-state batteries.

The solid-electrolyte interface (SEI) has been revolutionized through innovative material compositions that enhance lithium ion conductivity while maintaining mechanical stability. Researchers have developed ceramic-polymer composite electrolytes that combine the high ionic conductivity of ceramics with the flexibility of polymers, creating interfaces that can accommodate volume changes during cycling while facilitating uniform lithium deposition.

Nanostructured interface engineering has emerged as a promising approach to control lithium nucleation sites. By introducing precisely designed surface textures at the nanoscale, researchers have demonstrated the ability to guide lithium deposition patterns, preventing dendritic growth that typically leads to short circuits and battery failure. These engineered interfaces provide preferential nucleation sites that promote homogeneous lithium plating.

Artificial interlayers composed of materials such as lithium phosphorous oxynitride (LiPON) have shown remarkable effectiveness in improving the wetting behavior of lithium on solid electrolytes. These interlayers modify the surface energy landscape, reducing the nucleation energy barrier and enabling more uniform lithium deposition across the electrode surface rather than concentrated growth at isolated sites.

Advanced coating technologies, including atomic layer deposition (ALD) and molecular layer deposition (MLD), have enabled the creation of ultrathin, conformal protective layers on solid electrolytes. These nanometer-scale coatings can significantly alter the interface chemistry, promoting favorable lithium nucleation kinetics while preventing parasitic reactions that lead to interface degradation and resistance growth.

The incorporation of two-dimensional materials such as graphene and MXenes at solid-state interfaces has demonstrated promising results in controlling lithium plating behavior. These materials provide unique electronic properties and physical barriers that guide ion transport pathways and nucleation processes, resulting in more uniform lithium deposition morphologies.

Computational materials science has accelerated interface design through atomistic modeling and machine learning approaches. These computational tools enable researchers to predict interface stability, ion transport mechanisms, and nucleation behaviors without extensive experimental iterations, significantly accelerating the discovery of optimal interface materials and structures for anode-free solid-state batteries.

Safety and Reliability Standards for Next-Gen Batteries

The evolution of battery technology has necessitated the development of comprehensive safety and reliability standards, particularly for next-generation systems like anode-free solid-state batteries. These standards must address the unique challenges posed by lithium nucleation and plating uniformity issues, which directly impact both performance and safety.

Current safety standards for conventional lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, provide foundational frameworks but require significant adaptation for solid-state technologies. The absence of liquid electrolytes in solid-state batteries eliminates certain risks while introducing new failure modes related to interfacial stability and lithium plating behavior.

Emerging standards specifically targeting solid-state batteries are beginning to incorporate testing protocols for evaluating nucleation behavior and plating uniformity. These include accelerated cycling tests under varying pressure conditions, temperature gradient evaluations, and advanced in-situ monitoring requirements to detect early signs of non-uniform lithium deposition.

Reliability metrics for anode-free designs must quantify the consistency of lithium nucleation sites across multiple charge-discharge cycles. Industry consensus is developing around acceptable variation thresholds, with proposed standards suggesting less than 15% deviation in plating distribution to ensure long-term stability and safety.

Thermal runaway risk assessment protocols are being redesigned to account for the different failure mechanisms in solid-state systems. While traditional batteries face thermal runaway primarily through electrolyte decomposition, anode-free solid-state batteries may experience localized heating due to current density concentrations at preferential nucleation sites.

Mechanical integrity standards are particularly critical for solid-state batteries, as interface delamination can lead to non-uniform plating. Proposed testing regimes include cyclic mechanical loading combined with electrochemical cycling to evaluate the resilience of interfaces under realistic operating conditions.

Accelerated aging protocols are being developed to predict long-term plating behavior, with emphasis on identifying conditions that might exacerbate non-uniform nucleation. These include rapid temperature fluctuations, partial state-of-charge cycling, and high-rate charging scenarios that stress the solid electrolyte interface.

International standardization bodies, including ISO and IEC, are currently forming specialized working groups to establish consensus on these emerging standards. The timeline for formal adoption is expected to be 2-3 years, though interim guidelines are already being implemented by industry leaders and research institutions to ensure safe development of this promising technology.

Current safety standards for conventional lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, provide foundational frameworks but require significant adaptation for solid-state technologies. The absence of liquid electrolytes in solid-state batteries eliminates certain risks while introducing new failure modes related to interfacial stability and lithium plating behavior.

Emerging standards specifically targeting solid-state batteries are beginning to incorporate testing protocols for evaluating nucleation behavior and plating uniformity. These include accelerated cycling tests under varying pressure conditions, temperature gradient evaluations, and advanced in-situ monitoring requirements to detect early signs of non-uniform lithium deposition.

Reliability metrics for anode-free designs must quantify the consistency of lithium nucleation sites across multiple charge-discharge cycles. Industry consensus is developing around acceptable variation thresholds, with proposed standards suggesting less than 15% deviation in plating distribution to ensure long-term stability and safety.

Thermal runaway risk assessment protocols are being redesigned to account for the different failure mechanisms in solid-state systems. While traditional batteries face thermal runaway primarily through electrolyte decomposition, anode-free solid-state batteries may experience localized heating due to current density concentrations at preferential nucleation sites.

Mechanical integrity standards are particularly critical for solid-state batteries, as interface delamination can lead to non-uniform plating. Proposed testing regimes include cyclic mechanical loading combined with electrochemical cycling to evaluate the resilience of interfaces under realistic operating conditions.

Accelerated aging protocols are being developed to predict long-term plating behavior, with emphasis on identifying conditions that might exacerbate non-uniform nucleation. These include rapid temperature fluctuations, partial state-of-charge cycling, and high-rate charging scenarios that stress the solid electrolyte interface.

International standardization bodies, including ISO and IEC, are currently forming specialized working groups to establish consensus on these emerging standards. The timeline for formal adoption is expected to be 2-3 years, though interim guidelines are already being implemented by industry leaders and research institutions to ensure safe development of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!