Solid-Liquid Hybrid Concepts For Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the market since their commercial introduction in the early 1990s. However, conventional lithium-ion batteries face inherent limitations in energy density, safety, and charging speed. Solid-state batteries (SSBs) have emerged as a promising next-generation energy storage solution, offering potential improvements in safety, energy density, and lifespan compared to traditional liquid electrolyte systems.

Anode-free solid-state battery technology represents a revolutionary approach within the broader SSB landscape. By eliminating the traditional anode material and allowing lithium to plate directly onto a current collector during charging, anode-free designs theoretically enable significantly higher energy densities—potentially exceeding 500 Wh/kg at the cell level, compared to approximately 250-300 Wh/kg for conventional lithium-ion batteries.

The concept of solid-liquid hybrid electrolytes has gained traction as a transitional technology that combines the safety advantages of solid electrolytes with the superior ionic conductivity of liquid systems. This hybrid approach addresses one of the fundamental challenges in pure solid-state systems: the solid-solid interface impedance between the electrolyte and electrodes, which often limits power capability and cycle life.

Historical development of this technology can be traced back to early 2010s when researchers began exploring composite electrolyte systems. The field gained momentum around 2015-2018 when several research groups demonstrated proof-of-concept anode-free cells utilizing hybrid electrolyte architectures. Since then, development has accelerated with significant contributions from both academic institutions and industrial research centers.

The primary technical objectives for anode-free solid-state batteries with hybrid electrolytes include achieving stable lithium plating/stripping efficiency exceeding 99.9% over hundreds of cycles, maintaining high energy density advantages while ensuring safety, and developing manufacturing processes compatible with existing production infrastructure to enable cost-effective scaling.

Current research aims to understand and control the complex interfacial phenomena occurring during lithium plating and stripping, develop electrolyte formulations that maintain stability against lithium metal, and design cell architectures that accommodate volume changes during cycling while preventing dendrite formation.

The technology targets multiple applications, from portable electronics requiring high energy density to electric vehicles where both energy density and fast charging capabilities are crucial. Additionally, grid storage applications could benefit from the enhanced safety profile and potentially longer cycle life of these systems.

Anode-free solid-state battery technology represents a revolutionary approach within the broader SSB landscape. By eliminating the traditional anode material and allowing lithium to plate directly onto a current collector during charging, anode-free designs theoretically enable significantly higher energy densities—potentially exceeding 500 Wh/kg at the cell level, compared to approximately 250-300 Wh/kg for conventional lithium-ion batteries.

The concept of solid-liquid hybrid electrolytes has gained traction as a transitional technology that combines the safety advantages of solid electrolytes with the superior ionic conductivity of liquid systems. This hybrid approach addresses one of the fundamental challenges in pure solid-state systems: the solid-solid interface impedance between the electrolyte and electrodes, which often limits power capability and cycle life.

Historical development of this technology can be traced back to early 2010s when researchers began exploring composite electrolyte systems. The field gained momentum around 2015-2018 when several research groups demonstrated proof-of-concept anode-free cells utilizing hybrid electrolyte architectures. Since then, development has accelerated with significant contributions from both academic institutions and industrial research centers.

The primary technical objectives for anode-free solid-state batteries with hybrid electrolytes include achieving stable lithium plating/stripping efficiency exceeding 99.9% over hundreds of cycles, maintaining high energy density advantages while ensuring safety, and developing manufacturing processes compatible with existing production infrastructure to enable cost-effective scaling.

Current research aims to understand and control the complex interfacial phenomena occurring during lithium plating and stripping, develop electrolyte formulations that maintain stability against lithium metal, and design cell architectures that accommodate volume changes during cycling while preventing dendrite formation.

The technology targets multiple applications, from portable electronics requiring high energy density to electric vehicles where both energy density and fast charging capabilities are crucial. Additionally, grid storage applications could benefit from the enhanced safety profile and potentially longer cycle life of these systems.

Market Analysis for Next-Generation Battery Solutions

The global battery market is experiencing unprecedented growth, driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach $240 billion by 2027, with solid-state batteries potentially capturing 7-10% of this market within the next decade. This growth trajectory is particularly significant for anode-free solid-state battery technologies, which represent a revolutionary approach to energy storage.

Consumer demand for EVs continues to accelerate, with global sales increasing by 35% in 2023 compared to the previous year. This surge is creating substantial market pull for next-generation battery technologies that can overcome the limitations of conventional lithium-ion batteries. Range anxiety remains a primary concern for potential EV buyers, with 62% of consumers citing battery range as their top consideration when purchasing an electric vehicle.

The solid-liquid hybrid concepts for anode-free solid-state batteries address several critical market needs simultaneously. Energy density improvements of 70-100% compared to conventional lithium-ion batteries could extend EV ranges beyond 500 miles on a single charge, effectively eliminating range anxiety for most consumers. Additionally, the enhanced safety profile of these hybrid systems directly addresses the 28% of consumers who cite safety concerns as a barrier to EV adoption.

Commercial applications beyond automotive are equally promising. The grid storage market, valued at $4.7 billion in 2023, is projected to grow at a CAGR of 24% through 2030, creating significant opportunities for high-energy-density storage solutions. Solid-liquid hybrid battery concepts could potentially reduce grid storage costs by 30-40% on a per-kilowatt-hour basis compared to current technologies.

Regional market analysis reveals varying adoption potentials. Asia-Pacific currently dominates battery manufacturing with 75% of global capacity, but North America and Europe are rapidly expanding their battery ecosystems through substantial government investments. The European Battery Alliance has mobilized €6.1 billion to establish a competitive battery value chain, while the US Inflation Reduction Act allocates $369 billion toward clean energy initiatives, including advanced battery technologies.

Consumer electronics represents another significant market opportunity, with demand for longer-lasting, faster-charging devices growing at 18% annually. The compact form factor and high energy density of anode-free solid-state batteries could revolutionize portable device design, potentially extending smartphone battery life to 5-7 days on a single charge.

Market timing appears optimal for solid-liquid hybrid battery concepts, as manufacturing infrastructure for conventional lithium-ion batteries reaches maturity, creating natural transition points for next-generation technologies. Industry analysts predict the technology adoption curve will accelerate between 2025-2030, with early commercial applications emerging in premium market segments before expanding to mass-market applications.

Consumer demand for EVs continues to accelerate, with global sales increasing by 35% in 2023 compared to the previous year. This surge is creating substantial market pull for next-generation battery technologies that can overcome the limitations of conventional lithium-ion batteries. Range anxiety remains a primary concern for potential EV buyers, with 62% of consumers citing battery range as their top consideration when purchasing an electric vehicle.

The solid-liquid hybrid concepts for anode-free solid-state batteries address several critical market needs simultaneously. Energy density improvements of 70-100% compared to conventional lithium-ion batteries could extend EV ranges beyond 500 miles on a single charge, effectively eliminating range anxiety for most consumers. Additionally, the enhanced safety profile of these hybrid systems directly addresses the 28% of consumers who cite safety concerns as a barrier to EV adoption.

Commercial applications beyond automotive are equally promising. The grid storage market, valued at $4.7 billion in 2023, is projected to grow at a CAGR of 24% through 2030, creating significant opportunities for high-energy-density storage solutions. Solid-liquid hybrid battery concepts could potentially reduce grid storage costs by 30-40% on a per-kilowatt-hour basis compared to current technologies.

Regional market analysis reveals varying adoption potentials. Asia-Pacific currently dominates battery manufacturing with 75% of global capacity, but North America and Europe are rapidly expanding their battery ecosystems through substantial government investments. The European Battery Alliance has mobilized €6.1 billion to establish a competitive battery value chain, while the US Inflation Reduction Act allocates $369 billion toward clean energy initiatives, including advanced battery technologies.

Consumer electronics represents another significant market opportunity, with demand for longer-lasting, faster-charging devices growing at 18% annually. The compact form factor and high energy density of anode-free solid-state batteries could revolutionize portable device design, potentially extending smartphone battery life to 5-7 days on a single charge.

Market timing appears optimal for solid-liquid hybrid battery concepts, as manufacturing infrastructure for conventional lithium-ion batteries reaches maturity, creating natural transition points for next-generation technologies. Industry analysts predict the technology adoption curve will accelerate between 2025-2030, with early commercial applications emerging in premium market segments before expanding to mass-market applications.

Current Challenges in Solid-Liquid Hybrid Electrolyte Systems

Despite the promising potential of solid-state batteries, hybrid solid-liquid electrolyte systems face several significant challenges that impede their widespread commercialization. The interface between solid electrolytes and electrodes represents one of the most critical issues, as poor contact leads to increased impedance and reduced ion transport efficiency. This interfacial resistance problem is particularly pronounced during cycling, where volume changes in electrode materials can create physical gaps that further deteriorate performance.

Chemical instability at the solid-liquid electrolyte interface presents another major hurdle. The liquid component often reacts with the solid electrolyte, forming degradation products that accumulate at interfaces and increase resistance over time. These reactions can lead to continuous capacity fading and shortened battery lifespan, especially at elevated temperatures or high voltage operations.

Lithium dendrite growth remains a persistent challenge in hybrid systems. While solid electrolytes theoretically should suppress dendrite formation, the presence of liquid components can create pathways for dendrite propagation, particularly at defect sites or grain boundaries in the solid electrolyte. This compromises the safety advantages that solid-state batteries are meant to provide.

Manufacturing complexity significantly hinders scalability of hybrid electrolyte systems. The integration of both solid and liquid components requires sophisticated production techniques to ensure uniform distribution and stable interfaces. Current manufacturing processes struggle to maintain consistency across larger formats, resulting in performance variations between cells and increased production costs.

Thermal management presents unique challenges in hybrid systems. The different thermal expansion coefficients between solid and liquid components can lead to mechanical stress during temperature fluctuations, potentially causing cracks in the solid electrolyte or delamination at interfaces. This thermal mismatch limits the operating temperature range and complicates battery management system design.

Long-term stability remains largely unproven for hybrid electrolyte systems. Accelerated aging tests show that the liquid component often degrades faster than the solid component, creating imbalances in ion transport properties over time. This differential aging process can lead to unpredictable performance degradation patterns that are difficult to model and compensate for in battery management systems.

The optimization of electrolyte composition faces competing requirements. Increasing the liquid component improves ion conductivity but compromises mechanical stability and safety. Conversely, maximizing the solid component enhances mechanical properties but may reduce overall ionic conductivity. Finding the optimal balance remains an ongoing research challenge that requires sophisticated characterization techniques and modeling approaches.

Chemical instability at the solid-liquid electrolyte interface presents another major hurdle. The liquid component often reacts with the solid electrolyte, forming degradation products that accumulate at interfaces and increase resistance over time. These reactions can lead to continuous capacity fading and shortened battery lifespan, especially at elevated temperatures or high voltage operations.

Lithium dendrite growth remains a persistent challenge in hybrid systems. While solid electrolytes theoretically should suppress dendrite formation, the presence of liquid components can create pathways for dendrite propagation, particularly at defect sites or grain boundaries in the solid electrolyte. This compromises the safety advantages that solid-state batteries are meant to provide.

Manufacturing complexity significantly hinders scalability of hybrid electrolyte systems. The integration of both solid and liquid components requires sophisticated production techniques to ensure uniform distribution and stable interfaces. Current manufacturing processes struggle to maintain consistency across larger formats, resulting in performance variations between cells and increased production costs.

Thermal management presents unique challenges in hybrid systems. The different thermal expansion coefficients between solid and liquid components can lead to mechanical stress during temperature fluctuations, potentially causing cracks in the solid electrolyte or delamination at interfaces. This thermal mismatch limits the operating temperature range and complicates battery management system design.

Long-term stability remains largely unproven for hybrid electrolyte systems. Accelerated aging tests show that the liquid component often degrades faster than the solid component, creating imbalances in ion transport properties over time. This differential aging process can lead to unpredictable performance degradation patterns that are difficult to model and compensate for in battery management systems.

The optimization of electrolyte composition faces competing requirements. Increasing the liquid component improves ion conductivity but compromises mechanical stability and safety. Conversely, maximizing the solid component enhances mechanical properties but may reduce overall ionic conductivity. Finding the optimal balance remains an ongoing research challenge that requires sophisticated characterization techniques and modeling approaches.

Existing Solid-Liquid Hybrid Electrolyte Architectures

01 Hybrid electrolyte systems for anode-free solid-state batteries

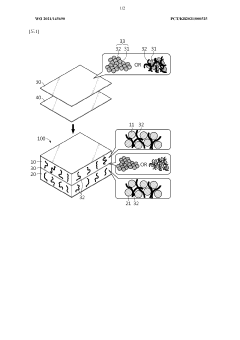

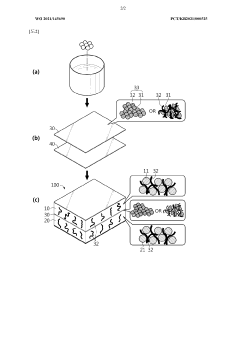

Hybrid electrolyte systems combine solid and liquid components to enhance ionic conductivity and interface stability in anode-free solid-state batteries. These systems typically consist of a solid electrolyte layer in contact with a liquid or gel electrolyte component, which helps to improve the contact between the solid electrolyte and the cathode material. The liquid component facilitates ion transport while the solid component provides mechanical stability and prevents dendrite formation.- Hybrid electrolyte systems for anode-free solid-state batteries: Hybrid electrolyte systems combine solid and liquid components to enhance ion conductivity and interface stability in anode-free solid-state batteries. These systems typically consist of a solid electrolyte layer in contact with a liquid or gel electrolyte component, which helps to improve the contact between the solid electrolyte and the cathode material. The liquid component facilitates lithium ion transport while the solid component provides mechanical stability and prevents dendrite formation.

- In-situ anode formation mechanisms in solid-liquid hybrid batteries: Anode-free solid-state batteries with hybrid electrolytes utilize in-situ anode formation during the initial charging process. Lithium ions from the cathode migrate through the electrolyte system and deposit directly onto a current collector, forming the anode during operation rather than during manufacturing. This approach eliminates the need for pre-lithiated anodes, reduces battery weight, and increases energy density while the hybrid electrolyte system helps control the morphology of the deposited lithium.

- Interface engineering for solid-liquid hybrid electrolytes: Interface engineering is crucial for solid-liquid hybrid electrolyte systems in anode-free batteries. Various approaches include the use of interlayers, surface coatings, and functional additives to improve the compatibility between solid and liquid components. These engineering solutions help reduce interfacial resistance, prevent unwanted side reactions, and enhance the stability of the electrochemical interfaces, resulting in improved cycling performance and battery longevity.

- Composite cathode structures for hybrid anode-free batteries: Specialized cathode structures are designed to work effectively with solid-liquid hybrid electrolytes in anode-free configurations. These composite cathodes often incorporate high-capacity active materials with conductive additives and binders optimized for ion transport across the hybrid electrolyte interface. Some designs include cathode coatings or gradient structures that facilitate ion movement between the cathode and the hybrid electrolyte system, enhancing overall battery performance and cycle life.

- Safety and stability enhancements for hybrid anode-free systems: Safety and stability improvements in solid-liquid hybrid anode-free batteries focus on preventing lithium dendrite growth and electrolyte degradation. Approaches include the use of mechanically robust solid electrolytes, flame-retardant liquid components, and advanced battery management systems. Some designs incorporate pressure regulation mechanisms or self-healing components that can respond to internal changes during cycling. These enhancements address the key challenges of thermal stability, mechanical integrity, and long-term cycling performance.

02 Interface engineering for solid-liquid hybrid batteries

Interface engineering techniques are employed to optimize the solid-liquid interfaces in hybrid anode-free batteries. These techniques include surface modifications, buffer layers, and specialized coatings that improve the wetting properties and reduce interfacial resistance. By carefully designing these interfaces, issues such as electrolyte decomposition and lithium dendrite formation can be mitigated, leading to improved cycling stability and battery performance.Expand Specific Solutions03 Novel electrode architectures for anode-free configurations

Innovative electrode designs are developed specifically for anode-free solid-state batteries with hybrid electrolytes. These architectures often feature porous or structured cathodes that accommodate volume changes during cycling and facilitate lithium plating/stripping. Some designs incorporate current collectors with specialized surface treatments or 3D structures that serve as preferential nucleation sites for lithium deposition, enhancing the uniformity of lithium plating and improving cycle life.Expand Specific Solutions04 Advanced materials for solid-liquid hybrid electrolytes

Novel materials are being developed for use in hybrid electrolyte systems, including polymer-ceramic composites, ionogels, and functionalized ionic liquids. These materials combine the advantages of solid electrolytes (mechanical stability, dendrite suppression) with those of liquid electrolytes (high ionic conductivity, good interfacial contact). Some approaches involve the use of solid electrolyte particles dispersed in liquid electrolytes or polymer matrices infused with ionic liquids to create hybrid systems with optimized properties.Expand Specific Solutions05 Manufacturing and scale-up methods for hybrid anode-free batteries

Specialized manufacturing techniques are being developed to produce anode-free solid-state batteries with hybrid electrolytes at scale. These methods address challenges such as precise control of layer thicknesses, interface quality, and electrolyte distribution. Approaches include advanced coating techniques, controlled atmosphere processing, and novel assembly methods that maintain the integrity of the hybrid electrolyte system while enabling cost-effective production of high-performance batteries.Expand Specific Solutions

Leading Companies and Research Institutions in SSB Development

The solid-liquid hybrid concept for anode-free solid-state batteries represents an emerging technology at the early commercialization stage, with the global market projected to reach $8-10 billion by 2030. The competitive landscape features established automotive manufacturers (Hyundai, Kia, GM, Nissan, Honda, Toyota) investing heavily alongside specialized battery developers like QuantumScape, Sion Power, and LG Energy Solution. Technical maturity varies significantly, with companies like QuantumScape and Livent Lithium leading in patent development while academic institutions (University of California, Chinese Academy of Sciences) contribute fundamental research. The technology addresses critical challenges in energy density and safety, with major players focusing on different hybrid approaches to overcome solid-electrolyte interface issues and lithium dendrite formation.

LG Energy Solution Ltd.

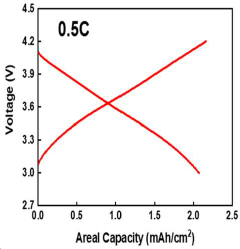

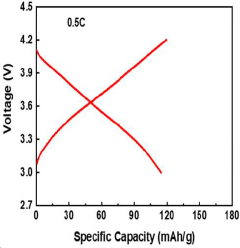

Technical Solution: LG Energy Solution has developed an innovative solid-liquid hybrid concept for anode-free solid-state batteries that combines a solid electrolyte with a liquid electrolyte interface layer. Their approach utilizes a lithium-ion conducting ceramic/polymer composite as the main solid electrolyte, while incorporating a thin liquid electrolyte layer at the cathode interface to improve contact and reduce interfacial resistance. This design enables direct lithium plating and stripping without a traditional graphite anode, significantly increasing energy density. Their proprietary composite solid electrolyte achieves ionic conductivity of 10^-3 S/cm at room temperature while maintaining mechanical stability. The liquid electrolyte component contains lithium salts in carefully selected organic solvents that are compatible with the solid electrolyte material, creating a stable solid-electrolyte interphase (SEI) that prevents continuous electrolyte decomposition during cycling.

Strengths: Higher energy density than conventional lithium-ion batteries due to elimination of anode host material; improved interfacial contact reducing resistance; better cycle stability compared to pure solid-state designs. Weaknesses: Potential safety concerns from remaining liquid component; complex manufacturing process requiring precise control of liquid-solid interfaces; possible challenges with long-term stability of the hybrid interface.

GM Global Technology Operations LLC

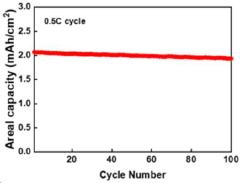

Technical Solution: GM Global Technology Operations has developed a hybrid solid-liquid electrolyte system for anode-free solid-state batteries that addresses key challenges in solid-state battery technology. Their approach utilizes a composite solid electrolyte consisting of a ceramic LLZO (lithium lanthanum zirconate) framework infused with a small amount of non-flammable ionic liquid electrolyte. This creates a continuous lithium-ion conduction network while maintaining mechanical stability. The liquid component is carefully confined within the ceramic structure, preventing leakage while enhancing interfacial contact with electrodes. GM's design enables in-situ formation of lithium metal during initial charging, eliminating the need for a pre-formed anode and increasing energy density. Their batteries have demonstrated stable cycling at practical current densities (3-5 mA/cm²) with minimal capacity fade over hundreds of cycles. The hybrid electrolyte achieves room temperature ionic conductivity exceeding 10^-4 S/cm while maintaining the mechanical properties needed to suppress lithium dendrite growth. GM has also developed specialized cathode coatings that protect high-nickel cathode materials from degradation when in contact with the hybrid electrolyte.

Strengths: Improved energy density through anode-free design; enhanced safety compared to conventional liquid electrolytes; better interfacial kinetics than pure solid electrolytes; compatibility with existing manufacturing infrastructure. Weaknesses: More complex electrolyte system requiring precise composition control; potential for performance degradation at extreme temperatures; challenges with scaling production while maintaining quality control.

Key Patents and Innovations in Anode-Free SSB Design

Hybrid anode free all solid lithium secondary battery and method of preparing same

PatentActiveKR1020230072827A

Innovation

- Incorporating a porous carbon layer between the negative electrode current collector and an organic-inorganic pseudo-solid electrolyte layer, which includes a carbon material and electrolyte solution, to stabilize the electrolyte against oxidation and inhibit lithium dendrite growth.

Method for manufacturing all-solid-state battery including solid-liquid hybrid electrolyte membrane, and solid-liquid hybrid electrolyte membrane

PatentWO2021145690A1

Innovation

- A method for manufacturing an all-solid-state battery using a solid-liquid hybrid electrolyte membrane, where a porous structure of solid polymer particles is impregnated with a controlled amount of liquid electrolyte, eliminating the need for a separate electrolyte injection process and enhancing ionic conductivity and mechanical strength.

Materials Science Advancements for Solid-Liquid Interfaces

Recent advancements in materials science have significantly accelerated the development of solid-liquid interfaces for anode-free solid-state batteries. These interfaces represent critical junctions where electrochemical reactions occur and energy transfer takes place, making them essential components for next-generation energy storage solutions.

The solid-liquid hybrid concept introduces a paradigm shift in battery design by combining the advantages of both solid electrolytes and liquid components. Solid electrolytes provide enhanced safety and stability, while liquid components facilitate better ion transport and interface contact. This synergistic approach addresses several limitations inherent to purely solid-state systems.

Materials scientists have focused on developing novel composite materials that can maintain stable interfaces between solid and liquid phases. Polymer-ceramic hybrids have emerged as promising candidates, offering mechanical flexibility while maintaining high ionic conductivity. These materials typically incorporate nanoscale ceramic fillers within polymer matrices, creating pathways for efficient ion transport while preserving structural integrity.

Interface engineering has become a central focus, with researchers developing specialized coatings and interlayers to mitigate degradation mechanisms. Atomic layer deposition techniques have enabled precise control over interface properties, allowing for the creation of protective layers that prevent unwanted side reactions while facilitating desired ion transfer processes.

The development of self-healing interfaces represents another significant breakthrough. These innovative materials can autonomously repair microcracks and defects that naturally occur during battery cycling, extending operational lifetimes and improving overall performance metrics. Incorporation of dynamic chemical bonds and phase-change materials has been instrumental in achieving these self-healing properties.

Computational modeling and simulation tools have accelerated materials discovery by predicting interface behaviors under various operating conditions. Machine learning algorithms have been employed to identify promising material combinations and optimize interface properties without exhaustive experimental testing. These computational approaches have significantly reduced development timelines and resource requirements.

Characterization techniques have also evolved to provide unprecedented insights into solid-liquid interface dynamics. Advanced in-situ spectroscopy and microscopy methods now allow researchers to observe interface evolution during battery operation, capturing transient phenomena that were previously undetectable. These observations have led to fundamental understanding of degradation mechanisms and informed design improvements.

The integration of bioinspired materials represents an emerging frontier, with researchers drawing inspiration from natural systems that efficiently manage solid-liquid interfaces. Biomimetic approaches have yielded novel structures with enhanced stability and functionality, potentially revolutionizing how we conceptualize battery interfaces.

The solid-liquid hybrid concept introduces a paradigm shift in battery design by combining the advantages of both solid electrolytes and liquid components. Solid electrolytes provide enhanced safety and stability, while liquid components facilitate better ion transport and interface contact. This synergistic approach addresses several limitations inherent to purely solid-state systems.

Materials scientists have focused on developing novel composite materials that can maintain stable interfaces between solid and liquid phases. Polymer-ceramic hybrids have emerged as promising candidates, offering mechanical flexibility while maintaining high ionic conductivity. These materials typically incorporate nanoscale ceramic fillers within polymer matrices, creating pathways for efficient ion transport while preserving structural integrity.

Interface engineering has become a central focus, with researchers developing specialized coatings and interlayers to mitigate degradation mechanisms. Atomic layer deposition techniques have enabled precise control over interface properties, allowing for the creation of protective layers that prevent unwanted side reactions while facilitating desired ion transfer processes.

The development of self-healing interfaces represents another significant breakthrough. These innovative materials can autonomously repair microcracks and defects that naturally occur during battery cycling, extending operational lifetimes and improving overall performance metrics. Incorporation of dynamic chemical bonds and phase-change materials has been instrumental in achieving these self-healing properties.

Computational modeling and simulation tools have accelerated materials discovery by predicting interface behaviors under various operating conditions. Machine learning algorithms have been employed to identify promising material combinations and optimize interface properties without exhaustive experimental testing. These computational approaches have significantly reduced development timelines and resource requirements.

Characterization techniques have also evolved to provide unprecedented insights into solid-liquid interface dynamics. Advanced in-situ spectroscopy and microscopy methods now allow researchers to observe interface evolution during battery operation, capturing transient phenomena that were previously undetectable. These observations have led to fundamental understanding of degradation mechanisms and informed design improvements.

The integration of bioinspired materials represents an emerging frontier, with researchers drawing inspiration from natural systems that efficiently manage solid-liquid interfaces. Biomimetic approaches have yielded novel structures with enhanced stability and functionality, potentially revolutionizing how we conceptualize battery interfaces.

Safety and Scalability Assessment of Anode-Free Technologies

The safety profile of anode-free solid-state batteries represents a significant advancement over conventional lithium-ion technologies. Without metallic lithium present in the initial state, these systems inherently reduce fire and explosion risks associated with thermal runaway events. However, as lithium plates during operation, safety concerns emerge that require careful assessment. Dendrite formation remains a critical challenge, potentially causing internal short circuits despite the mechanical strength of solid electrolytes.

Temperature sensitivity presents another safety consideration. Most solid-state electrolytes demonstrate optimal ionic conductivity at elevated temperatures, creating operational constraints that impact safety margins. Hybrid solid-liquid concepts introduce additional complexity to this safety profile, as the liquid component may reintroduce some flammability risks while potentially mitigating mechanical stress issues.

From a scalability perspective, anode-free technologies offer compelling advantages. The elimination of the anode material reduces cell thickness by approximately 10-20%, increasing energy density at the pack level. Manufacturing processes benefit from simplified assembly sequences with fewer components, potentially reducing production costs by an estimated 15-25% compared to conventional lithium-ion batteries.

However, significant scalability challenges persist. Current solid electrolyte production methods remain costly and difficult to scale, with material synthesis requiring precise control of atmospheric conditions and temperature profiles. The interface between solid electrolytes and current collectors demands novel manufacturing approaches that can maintain consistent contact across large surface areas.

The hybrid solid-liquid concept introduces both opportunities and challenges for mass production. While the liquid component can facilitate better interfacial contact, it complicates the manufacturing environment by requiring additional sealing and containment measures. Early production yield rates for these technologies remain below 70%, significantly lower than the 90%+ achieved in mature lithium-ion manufacturing.

Market adoption will depend on demonstrating safety performance across various abuse conditions while simultaneously developing cost-effective, high-volume manufacturing capabilities. Recent pilot production lines have shown promising results, with cycle life improvements of 30-40% compared to early prototypes, suggesting that manufacturing optimization is progressing. The path to gigawatt-scale production will require further innovations in materials processing and cell assembly techniques specific to these hybrid architectures.

Temperature sensitivity presents another safety consideration. Most solid-state electrolytes demonstrate optimal ionic conductivity at elevated temperatures, creating operational constraints that impact safety margins. Hybrid solid-liquid concepts introduce additional complexity to this safety profile, as the liquid component may reintroduce some flammability risks while potentially mitigating mechanical stress issues.

From a scalability perspective, anode-free technologies offer compelling advantages. The elimination of the anode material reduces cell thickness by approximately 10-20%, increasing energy density at the pack level. Manufacturing processes benefit from simplified assembly sequences with fewer components, potentially reducing production costs by an estimated 15-25% compared to conventional lithium-ion batteries.

However, significant scalability challenges persist. Current solid electrolyte production methods remain costly and difficult to scale, with material synthesis requiring precise control of atmospheric conditions and temperature profiles. The interface between solid electrolytes and current collectors demands novel manufacturing approaches that can maintain consistent contact across large surface areas.

The hybrid solid-liquid concept introduces both opportunities and challenges for mass production. While the liquid component can facilitate better interfacial contact, it complicates the manufacturing environment by requiring additional sealing and containment measures. Early production yield rates for these technologies remain below 70%, significantly lower than the 90%+ achieved in mature lithium-ion manufacturing.

Market adoption will depend on demonstrating safety performance across various abuse conditions while simultaneously developing cost-effective, high-volume manufacturing capabilities. Recent pilot production lines have shown promising results, with cycle life improvements of 30-40% compared to early prototypes, suggesting that manufacturing optimization is progressing. The path to gigawatt-scale production will require further innovations in materials processing and cell assembly techniques specific to these hybrid architectures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!