Reliability Qualification Matrix For Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Solid-state batteries (SSBs) represent a significant evolution in energy storage technology, promising enhanced safety, energy density, and longevity compared to conventional lithium-ion batteries. Among various SSB configurations, anode-free solid-state batteries have emerged as a particularly promising frontier, offering theoretical energy densities approaching the practical limits of lithium-based systems. The development of these batteries traces back to early research on solid electrolytes in the 1970s, with significant acceleration occurring in the past decade due to advances in materials science and manufacturing techniques.

The anode-free design eliminates the traditional anode material, instead utilizing lithium metal that plates directly onto the current collector during charging. This approach maximizes energy density by removing the weight and volume of a dedicated anode structure while leveraging the high theoretical capacity of lithium metal (3860 mAh/g). The evolution of this technology has been driven by the increasing demands of electric vehicles, portable electronics, and grid storage applications, where higher energy density and improved safety are paramount.

Current technological objectives for anode-free SSBs focus on addressing several critical challenges. Primary among these is the development of reliability qualification matrices that can accurately predict and evaluate battery performance over extended cycles and varied operating conditions. These matrices must account for unique failure modes specific to anode-free configurations, including dendrite formation at the electrolyte interface, volume changes during cycling, and potential chemical instabilities between the in-situ formed lithium and solid electrolytes.

The qualification framework aims to establish standardized testing protocols that can effectively assess cycle life, capacity retention, rate capability, and safety performance across different temperature ranges and usage scenarios. This standardization is essential for industry adoption and commercialization pathways, as it provides comparable metrics for evaluating different material combinations and cell designs.

Beyond performance validation, the technology objectives extend to manufacturing scalability and cost reduction. Current laboratory-scale demonstrations must transition to industrially viable production methods that maintain the integrity of interfaces between components while achieving economically competitive price points. This includes developing processes for large-area, defect-free solid electrolyte fabrication and ensuring consistent quality in the current collector preparation that will serve as the substrate for lithium plating.

The ultimate goal of anode-free SSB development is to create energy storage systems that exceed the performance of conventional lithium-ion batteries while eliminating their safety concerns, particularly those related to flammable liquid electrolytes. Success in this domain could revolutionize multiple industries and accelerate the transition toward electrification in transportation and renewable energy integration.

The anode-free design eliminates the traditional anode material, instead utilizing lithium metal that plates directly onto the current collector during charging. This approach maximizes energy density by removing the weight and volume of a dedicated anode structure while leveraging the high theoretical capacity of lithium metal (3860 mAh/g). The evolution of this technology has been driven by the increasing demands of electric vehicles, portable electronics, and grid storage applications, where higher energy density and improved safety are paramount.

Current technological objectives for anode-free SSBs focus on addressing several critical challenges. Primary among these is the development of reliability qualification matrices that can accurately predict and evaluate battery performance over extended cycles and varied operating conditions. These matrices must account for unique failure modes specific to anode-free configurations, including dendrite formation at the electrolyte interface, volume changes during cycling, and potential chemical instabilities between the in-situ formed lithium and solid electrolytes.

The qualification framework aims to establish standardized testing protocols that can effectively assess cycle life, capacity retention, rate capability, and safety performance across different temperature ranges and usage scenarios. This standardization is essential for industry adoption and commercialization pathways, as it provides comparable metrics for evaluating different material combinations and cell designs.

Beyond performance validation, the technology objectives extend to manufacturing scalability and cost reduction. Current laboratory-scale demonstrations must transition to industrially viable production methods that maintain the integrity of interfaces between components while achieving economically competitive price points. This includes developing processes for large-area, defect-free solid electrolyte fabrication and ensuring consistent quality in the current collector preparation that will serve as the substrate for lithium plating.

The ultimate goal of anode-free SSB development is to create energy storage systems that exceed the performance of conventional lithium-ion batteries while eliminating their safety concerns, particularly those related to flammable liquid electrolytes. Success in this domain could revolutionize multiple industries and accelerate the transition toward electrification in transportation and renewable energy integration.

Market Analysis for Next-Generation Battery Solutions

The global battery market is experiencing a significant shift towards advanced energy storage solutions, with solid-state batteries emerging as a promising technology to address the limitations of conventional lithium-ion batteries. The market for next-generation battery solutions is projected to reach $87.5 billion by 2027, growing at a CAGR of 18.3% from 2022. Anode-free solid-state batteries represent a particularly innovative segment within this market, offering potential advantages in energy density, safety, and longevity.

Consumer electronics currently dominates the application landscape for advanced battery technologies, accounting for approximately 43% of market share. However, electric vehicles are rapidly becoming the primary growth driver, with demand expected to increase by 25% annually through 2030. This surge is fueled by stringent environmental regulations, government incentives, and increasing consumer acceptance of electric mobility solutions.

The market for solid-state batteries specifically is projected to grow from $1.2 billion in 2023 to $8.7 billion by 2030. Anode-free designs are gaining particular attention due to their theoretical energy density advantages of up to 70% compared to conventional lithium-ion batteries. This performance improvement addresses the range anxiety concerns that have historically limited EV adoption.

Regional analysis reveals Asia-Pacific as the dominant market for next-generation battery technologies, holding 52% of global market share. This is primarily due to the strong manufacturing base in countries like China, Japan, and South Korea. North America follows with 28% market share, driven by significant investments in battery research and electric vehicle production.

Customer demand patterns indicate a growing preference for batteries with enhanced safety profiles, faster charging capabilities, and longer cycle life. Anode-free solid-state batteries potentially address all these requirements, positioning them favorably in the competitive landscape. Market surveys indicate that 78% of potential EV buyers consider battery performance and safety as critical purchasing factors.

The reliability qualification matrix for anode-free solid-state batteries is becoming increasingly important as manufacturers seek to commercialize these technologies. Market acceptance hinges on demonstrable reliability metrics, with industry stakeholders establishing new testing protocols specific to solid-state architectures. This represents both a challenge and opportunity for market entrants, as standardized reliability benchmarks are still evolving.

Pricing trends suggest that while anode-free solid-state batteries currently command a premium of approximately 3.5 times that of conventional lithium-ion batteries, economies of scale and manufacturing innovations are expected to reduce this gap to 1.5 times by 2028, significantly expanding market accessibility.

Consumer electronics currently dominates the application landscape for advanced battery technologies, accounting for approximately 43% of market share. However, electric vehicles are rapidly becoming the primary growth driver, with demand expected to increase by 25% annually through 2030. This surge is fueled by stringent environmental regulations, government incentives, and increasing consumer acceptance of electric mobility solutions.

The market for solid-state batteries specifically is projected to grow from $1.2 billion in 2023 to $8.7 billion by 2030. Anode-free designs are gaining particular attention due to their theoretical energy density advantages of up to 70% compared to conventional lithium-ion batteries. This performance improvement addresses the range anxiety concerns that have historically limited EV adoption.

Regional analysis reveals Asia-Pacific as the dominant market for next-generation battery technologies, holding 52% of global market share. This is primarily due to the strong manufacturing base in countries like China, Japan, and South Korea. North America follows with 28% market share, driven by significant investments in battery research and electric vehicle production.

Customer demand patterns indicate a growing preference for batteries with enhanced safety profiles, faster charging capabilities, and longer cycle life. Anode-free solid-state batteries potentially address all these requirements, positioning them favorably in the competitive landscape. Market surveys indicate that 78% of potential EV buyers consider battery performance and safety as critical purchasing factors.

The reliability qualification matrix for anode-free solid-state batteries is becoming increasingly important as manufacturers seek to commercialize these technologies. Market acceptance hinges on demonstrable reliability metrics, with industry stakeholders establishing new testing protocols specific to solid-state architectures. This represents both a challenge and opportunity for market entrants, as standardized reliability benchmarks are still evolving.

Pricing trends suggest that while anode-free solid-state batteries currently command a premium of approximately 3.5 times that of conventional lithium-ion batteries, economies of scale and manufacturing innovations are expected to reduce this gap to 1.5 times by 2028, significantly expanding market accessibility.

Current Challenges in Anode-Free SSB Reliability Testing

Despite significant advancements in anode-free solid-state battery (SSB) technology, reliability testing remains a critical challenge that impedes commercial deployment. Current testing protocols designed for conventional lithium-ion batteries fail to address the unique failure mechanisms and performance characteristics of anode-free SSBs, creating a significant gap in qualification methodologies.

One primary challenge is the lack of standardized testing protocols specifically designed for anode-free SSBs. The absence of industry consensus on appropriate stress conditions, acceleration factors, and failure criteria makes it difficult to compare results across different research groups and manufacturers. This fragmentation hinders progress toward establishing reliable qualification matrices that can accurately predict battery lifetime and safety performance.

The dynamic interface evolution in anode-free SSBs presents another major testing challenge. Unlike conventional batteries with pre-formed anodes, the lithium metal anode in anode-free systems forms in-situ during the first charge cycle and continues to evolve throughout battery life. Current testing methodologies struggle to capture and characterize this dynamic behavior, particularly the formation of dendrites and interfacial resistance changes that occur over multiple cycles.

Temperature sensitivity poses a significant reliability testing challenge. Solid electrolytes exhibit complex temperature-dependent behaviors that affect ionic conductivity, mechanical properties, and interfacial stability. Existing test protocols often fail to adequately characterize performance across the wide temperature range required for practical applications, from sub-zero to elevated temperatures that may approach the electrolyte's stability limits.

Mechanical stress testing represents another underdeveloped area. The solid-solid interfaces in anode-free SSBs are susceptible to mechanical failures from volume changes during cycling, external forces, and thermal expansion mismatches. Current testing methods inadequately address these mechanical reliability aspects, particularly under real-world conditions involving vibration, shock, and pressure variations.

Accelerated life testing (ALT) methodologies for anode-free SSBs remain largely unvalidated. The complex degradation mechanisms in these systems often do not follow simple Arrhenius relationships, making traditional acceleration factors unreliable for lifetime prediction. This creates uncertainty in translating laboratory test results to real-world performance expectations.

Finally, there is a critical need for non-destructive evaluation techniques that can monitor internal changes during reliability testing. Current methods often require post-mortem analysis, which provides limited insight into the progressive failure mechanisms that occur during operation. Advanced in-situ characterization methods are needed but remain technically challenging to implement in solid-state systems.

One primary challenge is the lack of standardized testing protocols specifically designed for anode-free SSBs. The absence of industry consensus on appropriate stress conditions, acceleration factors, and failure criteria makes it difficult to compare results across different research groups and manufacturers. This fragmentation hinders progress toward establishing reliable qualification matrices that can accurately predict battery lifetime and safety performance.

The dynamic interface evolution in anode-free SSBs presents another major testing challenge. Unlike conventional batteries with pre-formed anodes, the lithium metal anode in anode-free systems forms in-situ during the first charge cycle and continues to evolve throughout battery life. Current testing methodologies struggle to capture and characterize this dynamic behavior, particularly the formation of dendrites and interfacial resistance changes that occur over multiple cycles.

Temperature sensitivity poses a significant reliability testing challenge. Solid electrolytes exhibit complex temperature-dependent behaviors that affect ionic conductivity, mechanical properties, and interfacial stability. Existing test protocols often fail to adequately characterize performance across the wide temperature range required for practical applications, from sub-zero to elevated temperatures that may approach the electrolyte's stability limits.

Mechanical stress testing represents another underdeveloped area. The solid-solid interfaces in anode-free SSBs are susceptible to mechanical failures from volume changes during cycling, external forces, and thermal expansion mismatches. Current testing methods inadequately address these mechanical reliability aspects, particularly under real-world conditions involving vibration, shock, and pressure variations.

Accelerated life testing (ALT) methodologies for anode-free SSBs remain largely unvalidated. The complex degradation mechanisms in these systems often do not follow simple Arrhenius relationships, making traditional acceleration factors unreliable for lifetime prediction. This creates uncertainty in translating laboratory test results to real-world performance expectations.

Finally, there is a critical need for non-destructive evaluation techniques that can monitor internal changes during reliability testing. Current methods often require post-mortem analysis, which provides limited insight into the progressive failure mechanisms that occur during operation. Advanced in-situ characterization methods are needed but remain technically challenging to implement in solid-state systems.

Existing Reliability Qualification Methodologies for SSBs

01 Interface engineering for improved reliability

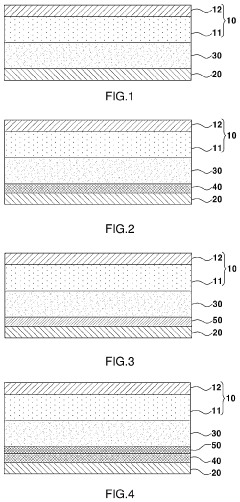

Interface engineering is crucial for enhancing the reliability of anode-free solid-state batteries. This involves developing specialized coatings and interlayers that stabilize the interface between the solid electrolyte and the lithium metal that forms during charging. These engineered interfaces help prevent dendrite formation, reduce interfacial resistance, and enhance cycling stability, which are critical factors affecting the long-term reliability of anode-free solid-state batteries.- Solid electrolyte materials for improved reliability: Specific solid electrolyte materials can significantly enhance the reliability of anode-free solid-state batteries. These materials include ceramic-based electrolytes, polymer electrolytes, and composite electrolytes that combine both. The key properties that contribute to reliability are high ionic conductivity, mechanical stability, and chemical compatibility with lithium metal. These electrolytes create a stable interface with the in-situ formed lithium anode, preventing dendrite formation and extending cycle life.

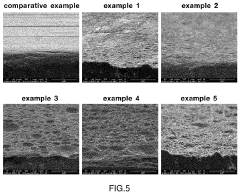

- Interface engineering for dendrite suppression: Interface engineering between the solid electrolyte and the in-situ formed lithium anode is crucial for preventing dendrite growth and improving reliability. Various approaches include applying protective coatings, creating artificial interphases, and introducing buffer layers that accommodate volume changes during cycling. These engineered interfaces help distribute lithium deposition more uniformly, reduce interfacial resistance, and prevent short circuits caused by dendrite penetration, thereby enhancing the overall reliability and safety of anode-free solid-state batteries.

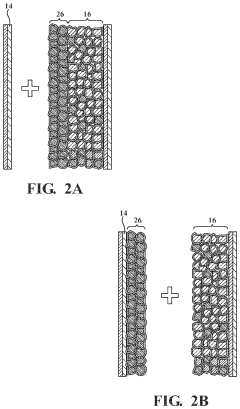

- Current collector modifications for uniform lithium plating: Modifications to the current collector design can significantly improve lithium plating uniformity in anode-free solid-state batteries. Techniques include surface texturing, applying functional coatings, and creating three-dimensional structures that provide nucleation sites for lithium deposition. These modifications help control the lithium plating process, prevent localized high current densities, and ensure more homogeneous lithium deposition, which directly enhances cycling stability and overall battery reliability.

- Pressure management systems for mechanical stability: Pressure management systems are essential for maintaining mechanical stability in anode-free solid-state batteries. These systems include specialized cell housings, compression mechanisms, and elastic components that apply consistent pressure during cycling. Proper pressure management helps maintain intimate contact between battery components, accommodates volume changes during lithium plating/stripping, and prevents delamination at interfaces. This approach significantly improves cycling performance and reliability by ensuring consistent ionic pathways throughout battery operation.

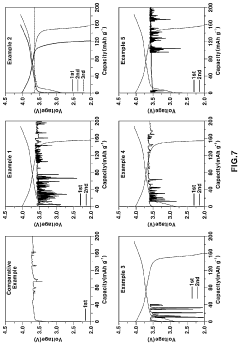

- Advanced testing protocols for reliability assessment: Advanced testing protocols have been developed specifically for evaluating the reliability of anode-free solid-state batteries. These include accelerated aging tests, temperature cycling, high-rate performance tests, and long-term cycling under various conditions. Non-destructive techniques such as in-situ microscopy and spectroscopy allow for real-time monitoring of lithium deposition behavior and interface evolution. These comprehensive testing methodologies help identify failure mechanisms, predict battery lifespan, and guide design improvements to enhance overall reliability.

02 Advanced solid electrolyte materials for reliability enhancement

The development of advanced solid electrolyte materials is essential for improving the reliability of anode-free solid-state batteries. These materials need to have high ionic conductivity, good mechanical strength, and excellent electrochemical stability. Ceramic, polymer, and composite electrolytes with these properties can effectively suppress lithium dendrite growth, maintain stable interfaces during cycling, and enhance the overall reliability and safety of anode-free solid-state batteries.Expand Specific Solutions03 Pressure management and mechanical stability solutions

Effective pressure management and mechanical stability are critical for the reliability of anode-free solid-state batteries. This involves designing battery structures that can accommodate volume changes during cycling while maintaining uniform pressure distribution. Solutions include specialized cell housings, pressure application systems, and flexible components that prevent delamination and cracking of the solid electrolyte, thereby enhancing the cycle life and reliability of these batteries.Expand Specific Solutions04 Temperature control and thermal management strategies

Temperature control and thermal management are essential for ensuring the reliability of anode-free solid-state batteries. These strategies involve developing systems that maintain optimal operating temperatures, prevent overheating, and ensure uniform temperature distribution across the battery. Effective thermal management helps preserve the integrity of the solid electrolyte, prevents unwanted side reactions, and enhances the overall reliability and safety of anode-free solid-state batteries.Expand Specific Solutions05 Novel cathode designs and current collector innovations

Innovative cathode designs and current collector technologies play a significant role in improving the reliability of anode-free solid-state batteries. These innovations include high-capacity cathode materials, specialized current collectors with enhanced adhesion properties, and novel architectures that facilitate efficient ion transport. Such designs help maintain stable interfaces, improve energy density, and enhance the overall reliability and performance of anode-free solid-state batteries during extended cycling.Expand Specific Solutions

Leading Companies and Research Institutions in SSB Development

The anode-free solid-state battery reliability qualification landscape is currently in an early development stage, with market projections showing significant growth potential as the technology addresses key EV adoption barriers. Major automotive manufacturers including Toyota, GM, Hyundai, and Kia are leading development efforts alongside specialized battery companies like LG Energy Solution and SVOLT. Academic-industry partnerships involving institutions such as Washington University and University of Maryland are accelerating innovation. The technology maturity varies significantly across players, with Toyota demonstrating the most advanced capabilities through extensive patent portfolios and prototype demonstrations, while companies like Panasonic, NGK Insulators, and TDK contribute specialized materials expertise essential for overcoming current reliability challenges in solid electrolytes and interfaces.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive reliability qualification matrix for anode-free solid-state batteries that focuses on electrochemical stability and mechanical integrity. Their approach involves multi-scale testing protocols that evaluate battery performance under various operational conditions including temperature extremes (-30°C to 80°C), high charging rates, and mechanical stress scenarios. Toyota's matrix incorporates accelerated aging tests that simulate years of usage within months, allowing for rapid iteration and improvement. Their qualification system particularly emphasizes dendrite formation prevention and interface stability monitoring through advanced in-situ characterization techniques. Toyota has invested over $13.5 billion in battery technology development and maintains over 1,000 patents related to solid-state battery technology, positioning them as industry leaders in anode-free solid-state battery reliability assessment.

Strengths: Extensive experience in battery integration for automotive applications; comprehensive testing infrastructure; strong focus on safety and longevity. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; challenges in scaling manufacturing processes for mass production.

GM Global Technology Operations LLC

Technical Solution: GM has established a comprehensive reliability qualification matrix for anode-free solid-state batteries focused on automotive-grade durability standards and safety performance. Their matrix incorporates extensive thermal cycling tests (-40°C to 85°C) combined with mechanical stress evaluations that simulate real-world driving conditions. GM's approach features specialized protocols for evaluating solid electrolyte stability during fast charging scenarios, with particular attention to interface degradation mechanisms. Their qualification system employs advanced neutron imaging techniques to visualize lithium transport phenomena non-destructively during operation. GM has developed proprietary computational models that predict long-term reliability based on accelerated testing data, allowing for rapid screening of material combinations. Their matrix particularly excels at evaluating cell performance under abuse conditions including overcharge, external short circuit, and mechanical deformation—critical safety factors for automotive applications where GM aims to deploy this technology in their Ultium platform.

Strengths: Deep integration with vehicle design requirements; extensive real-world testing capabilities; strong focus on safety standards compliance. Weaknesses: Relatively conservative approach to new battery technologies; challenges in balancing performance with cost requirements for mass-market vehicles.

Critical Patents and Research on Anode-Free SSB Testing

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

Safety Standards and Certification Requirements for SSBs

The development of anode-free solid-state batteries (SSBs) necessitates comprehensive safety standards and certification requirements to ensure market acceptance and regulatory compliance. Currently, the safety certification landscape for SSBs is evolving, with traditional lithium-ion battery standards being adapted to address the unique characteristics of solid-state technology.

International standards organizations including IEC, ISO, and UL have begun developing specific protocols for SSB safety evaluation. IEC 62660 series and UL 1642 standards are being modified to incorporate solid-state specific considerations, particularly focusing on thermal stability, mechanical integrity, and electrochemical performance under various conditions.

For anode-free SSBs specifically, certification requirements must address the distinctive failure modes associated with lithium plating/stripping processes. These include dendrite formation risks, interface stability during cycling, and potential mechanical stress at the electrolyte-electrode interfaces. The UN38.3 transportation safety requirements are particularly relevant, requiring modifications to test protocols for pressure differentials, vibration resistance, and thermal cycling.

Regulatory bodies in major markets have established different certification pathways. The European Union requires compliance with Battery Directive 2006/66/EC and upcoming Battery Regulation, with additional requirements under REACH and RoHS directives. In the United States, UL certification combined with CPSC and DOT regulations form the regulatory framework, while Japan follows JIS standards with specific METI guidelines for new battery technologies.

Automotive applications of anode-free SSBs face particularly stringent requirements under ISO 26262 for functional safety and upcoming UN GTR regulations specific to electric vehicle batteries. These standards emphasize abuse tolerance testing, including nail penetration, crush resistance, and thermal propagation control.

Emerging certification considerations specific to anode-free SSBs include protocols for evaluating long-term interface stability, lithium inventory management, and performance degradation mechanisms. Testing methodologies must account for the absence of a pre-deposited anode and the dynamics of lithium movement during battery operation.

Companies developing anode-free SSBs should implement a staged certification strategy, beginning with laboratory safety validation, progressing through third-party preliminary testing, and culminating in full certification processes. This approach allows for iterative design improvements while building safety credentials necessary for market entry and customer confidence.

International standards organizations including IEC, ISO, and UL have begun developing specific protocols for SSB safety evaluation. IEC 62660 series and UL 1642 standards are being modified to incorporate solid-state specific considerations, particularly focusing on thermal stability, mechanical integrity, and electrochemical performance under various conditions.

For anode-free SSBs specifically, certification requirements must address the distinctive failure modes associated with lithium plating/stripping processes. These include dendrite formation risks, interface stability during cycling, and potential mechanical stress at the electrolyte-electrode interfaces. The UN38.3 transportation safety requirements are particularly relevant, requiring modifications to test protocols for pressure differentials, vibration resistance, and thermal cycling.

Regulatory bodies in major markets have established different certification pathways. The European Union requires compliance with Battery Directive 2006/66/EC and upcoming Battery Regulation, with additional requirements under REACH and RoHS directives. In the United States, UL certification combined with CPSC and DOT regulations form the regulatory framework, while Japan follows JIS standards with specific METI guidelines for new battery technologies.

Automotive applications of anode-free SSBs face particularly stringent requirements under ISO 26262 for functional safety and upcoming UN GTR regulations specific to electric vehicle batteries. These standards emphasize abuse tolerance testing, including nail penetration, crush resistance, and thermal propagation control.

Emerging certification considerations specific to anode-free SSBs include protocols for evaluating long-term interface stability, lithium inventory management, and performance degradation mechanisms. Testing methodologies must account for the absence of a pre-deposited anode and the dynamics of lithium movement during battery operation.

Companies developing anode-free SSBs should implement a staged certification strategy, beginning with laboratory safety validation, progressing through third-party preliminary testing, and culminating in full certification processes. This approach allows for iterative design improvements while building safety credentials necessary for market entry and customer confidence.

Environmental Impact and Sustainability Considerations

The environmental footprint of anode-free solid-state batteries represents a significant advancement compared to conventional lithium-ion technologies. These batteries eliminate the need for graphite or silicon anodes, reducing material consumption and associated mining impacts. The simplified battery architecture decreases manufacturing complexity, potentially lowering energy requirements during production by an estimated 15-20% compared to traditional lithium-ion cells.

Life cycle assessment studies indicate that anode-free solid-state batteries may reduce greenhouse gas emissions by approximately 30-40% across their entire lifecycle when compared to conventional lithium-ion batteries. This reduction stems from both streamlined manufacturing processes and improved energy density, which translates to fewer raw materials per kWh of storage capacity.

The solid electrolytes employed in these batteries often replace conventional liquid electrolytes containing fluorinated compounds and volatile organic solvents. This substitution eliminates the release of toxic fluoride emissions during production and reduces the risk of hazardous material leakage during use or disposal. Several solid electrolyte formulations utilize more abundant elements like sulfur, phosphorus, and silicon, potentially alleviating supply chain pressures on critical materials.

End-of-life considerations for anode-free solid-state batteries present both opportunities and challenges. The absence of graphite anodes simplifies recycling processes, while the higher concentration of valuable metals per battery volume improves economic recovery rates. However, novel solid electrolyte materials may require development of specialized recycling protocols to maximize material recovery and minimize environmental impact.

Water consumption represents another important sustainability metric. Manufacturing processes for solid electrolytes typically require 40-60% less water compared to production of conventional liquid electrolytes and separator materials. This reduction becomes particularly significant in regions facing water scarcity challenges.

Safety improvements inherent to solid-state designs also yield environmental benefits by reducing the incidence of thermal runaway events and associated fires. Such incidents not only pose immediate safety hazards but also release particulate matter and toxic compounds into the atmosphere. The non-flammable nature of solid electrolytes substantially mitigates these environmental risks.

Future sustainability improvements may focus on developing solid electrolyte formulations that utilize earth-abundant materials, implementing water-based processing techniques, and designing battery architectures specifically optimized for efficient disassembly and material recovery at end-of-life.

Life cycle assessment studies indicate that anode-free solid-state batteries may reduce greenhouse gas emissions by approximately 30-40% across their entire lifecycle when compared to conventional lithium-ion batteries. This reduction stems from both streamlined manufacturing processes and improved energy density, which translates to fewer raw materials per kWh of storage capacity.

The solid electrolytes employed in these batteries often replace conventional liquid electrolytes containing fluorinated compounds and volatile organic solvents. This substitution eliminates the release of toxic fluoride emissions during production and reduces the risk of hazardous material leakage during use or disposal. Several solid electrolyte formulations utilize more abundant elements like sulfur, phosphorus, and silicon, potentially alleviating supply chain pressures on critical materials.

End-of-life considerations for anode-free solid-state batteries present both opportunities and challenges. The absence of graphite anodes simplifies recycling processes, while the higher concentration of valuable metals per battery volume improves economic recovery rates. However, novel solid electrolyte materials may require development of specialized recycling protocols to maximize material recovery and minimize environmental impact.

Water consumption represents another important sustainability metric. Manufacturing processes for solid electrolytes typically require 40-60% less water compared to production of conventional liquid electrolytes and separator materials. This reduction becomes particularly significant in regions facing water scarcity challenges.

Safety improvements inherent to solid-state designs also yield environmental benefits by reducing the incidence of thermal runaway events and associated fires. Such incidents not only pose immediate safety hazards but also release particulate matter and toxic compounds into the atmosphere. The non-flammable nature of solid electrolytes substantially mitigates these environmental risks.

Future sustainability improvements may focus on developing solid electrolyte formulations that utilize earth-abundant materials, implementing water-based processing techniques, and designing battery architectures specifically optimized for efficient disassembly and material recovery at end-of-life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!