Anode-Free Solid-State Current Density Limits And Scaling

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the market since their commercial introduction in the early 1990s. However, conventional lithium-ion batteries face inherent limitations in energy density, safety, and longevity. Anode-free battery technology represents a revolutionary approach that addresses these limitations by eliminating the traditional graphite or silicon anode, instead utilizing lithium metal directly deposited on the current collector during charging.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities approaching 500 Wh/kg at the cell level, significantly surpassing the 250-300 Wh/kg limit of conventional lithium-ion batteries. This dramatic improvement stems from the elimination of "dead weight" in the battery structure.

Current density limitations represent a critical challenge in anode-free solid-state battery development. Traditional liquid electrolyte systems suffer from dendrite formation at high current densities, leading to short circuits and safety hazards. Solid-state electrolytes offer a promising solution by providing mechanical resistance to dendrite growth, but they introduce new challenges related to interfacial stability and ion transport kinetics.

The primary technical objectives in this field include understanding and extending current density limits in anode-free configurations, developing scaling methodologies for commercial viability, and establishing predictive models for performance under various operating conditions. Specifically, researchers aim to achieve stable cycling at current densities exceeding 3 mA/cm² while maintaining 80% capacity retention over 1000 cycles.

Recent research has focused on the fundamental mechanisms governing lithium deposition and dissolution at the current collector interface. The morphology, uniformity, and reversibility of this process directly impact battery performance and longevity. Advanced characterization techniques, including in-situ electron microscopy and synchrotron-based spectroscopy, have provided unprecedented insights into these processes at the nanoscale.

The scaling challenges for anode-free solid-state batteries involve translating laboratory-scale successes to commercially viable manufacturing processes. This includes developing cost-effective production methods for high-quality solid electrolytes, designing optimal cell architectures to maximize energy density while ensuring mechanical stability, and implementing quality control protocols for consistent performance across large-scale production.

The convergence of anode-free design with solid-state electrolyte technology represents a potentially transformative direction for next-generation energy storage, promising to overcome the fundamental limitations of current battery systems while enabling new applications in electric vehicles, grid storage, and portable electronics.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities approaching 500 Wh/kg at the cell level, significantly surpassing the 250-300 Wh/kg limit of conventional lithium-ion batteries. This dramatic improvement stems from the elimination of "dead weight" in the battery structure.

Current density limitations represent a critical challenge in anode-free solid-state battery development. Traditional liquid electrolyte systems suffer from dendrite formation at high current densities, leading to short circuits and safety hazards. Solid-state electrolytes offer a promising solution by providing mechanical resistance to dendrite growth, but they introduce new challenges related to interfacial stability and ion transport kinetics.

The primary technical objectives in this field include understanding and extending current density limits in anode-free configurations, developing scaling methodologies for commercial viability, and establishing predictive models for performance under various operating conditions. Specifically, researchers aim to achieve stable cycling at current densities exceeding 3 mA/cm² while maintaining 80% capacity retention over 1000 cycles.

Recent research has focused on the fundamental mechanisms governing lithium deposition and dissolution at the current collector interface. The morphology, uniformity, and reversibility of this process directly impact battery performance and longevity. Advanced characterization techniques, including in-situ electron microscopy and synchrotron-based spectroscopy, have provided unprecedented insights into these processes at the nanoscale.

The scaling challenges for anode-free solid-state batteries involve translating laboratory-scale successes to commercially viable manufacturing processes. This includes developing cost-effective production methods for high-quality solid electrolytes, designing optimal cell architectures to maximize energy density while ensuring mechanical stability, and implementing quality control protocols for consistent performance across large-scale production.

The convergence of anode-free design with solid-state electrolyte technology represents a potentially transformative direction for next-generation energy storage, promising to overcome the fundamental limitations of current battery systems while enabling new applications in electric vehicles, grid storage, and portable electronics.

Market Analysis for Solid-State Battery Solutions

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher-energy-density energy storage solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating expansion to reach $8-10 billion by 2030, representing a compound annual growth rate (CAGR) of over 34% during this forecast period.

Electric vehicles constitute the primary demand driver, accounting for nearly 60% of the projected market value. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state technology, with commercial deployment timelines set between 2025-2028. This automotive push is complemented by growing demand from consumer electronics manufacturers seeking higher energy density and improved safety profiles for portable devices.

The anode-free solid-state battery segment represents a particularly promising niche within this broader market. By eliminating the traditional anode material and utilizing lithium metal formed during charging, these batteries offer theoretical energy densities approaching 500 Wh/kg, significantly exceeding current lithium-ion technologies limited to 250-300 Wh/kg. Market analysis indicates this specific segment could capture 15-20% of the overall solid-state market by 2028.

Current density limitations represent a critical market differentiator among competing technologies. Solutions capable of achieving higher current densities without compromising cycle life are positioned to command premium pricing and priority adoption in high-performance applications. Market research indicates customers are willing to pay 30-40% premiums for solid-state solutions that can deliver current densities above 3 mA/cm² while maintaining 1000+ cycle lifetimes.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity development, with Japan and South Korea leading in intellectual property holdings specific to anode-free designs. North America demonstrates strength in fundamental research and materials innovation, while European markets show the highest adoption readiness, particularly in the automotive sector.

Investor activity provides additional market validation, with venture capital funding for solid-state battery startups reaching $1.9 billion in 2022, a 78% increase over the previous year. Companies specifically addressing current density scaling challenges have secured disproportionately larger funding rounds, highlighting market recognition of this technical hurdle's importance.

Customer requirements analysis indicates that while energy density remains the primary purchase consideration, charging rate capabilities (directly related to current density limits) rank as the second most important factor for both automotive and consumer electronics applications, surpassing even cost considerations in premium market segments.

Electric vehicles constitute the primary demand driver, accounting for nearly 60% of the projected market value. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state technology, with commercial deployment timelines set between 2025-2028. This automotive push is complemented by growing demand from consumer electronics manufacturers seeking higher energy density and improved safety profiles for portable devices.

The anode-free solid-state battery segment represents a particularly promising niche within this broader market. By eliminating the traditional anode material and utilizing lithium metal formed during charging, these batteries offer theoretical energy densities approaching 500 Wh/kg, significantly exceeding current lithium-ion technologies limited to 250-300 Wh/kg. Market analysis indicates this specific segment could capture 15-20% of the overall solid-state market by 2028.

Current density limitations represent a critical market differentiator among competing technologies. Solutions capable of achieving higher current densities without compromising cycle life are positioned to command premium pricing and priority adoption in high-performance applications. Market research indicates customers are willing to pay 30-40% premiums for solid-state solutions that can deliver current densities above 3 mA/cm² while maintaining 1000+ cycle lifetimes.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity development, with Japan and South Korea leading in intellectual property holdings specific to anode-free designs. North America demonstrates strength in fundamental research and materials innovation, while European markets show the highest adoption readiness, particularly in the automotive sector.

Investor activity provides additional market validation, with venture capital funding for solid-state battery startups reaching $1.9 billion in 2022, a 78% increase over the previous year. Companies specifically addressing current density scaling challenges have secured disproportionately larger funding rounds, highlighting market recognition of this technical hurdle's importance.

Customer requirements analysis indicates that while energy density remains the primary purchase consideration, charging rate capabilities (directly related to current density limits) rank as the second most important factor for both automotive and consumer electronics applications, surpassing even cost considerations in premium market segments.

Current Challenges in Anode-Free Solid-State Technology

Despite significant advancements in solid-state battery technology, anode-free solid-state batteries face several critical challenges that impede their commercial viability. The most pressing issue is the current density limitation, which significantly restricts power output capabilities. Current experimental prototypes typically achieve only 1-3 mA/cm², far below the 10-20 mA/cm² required for practical applications in consumer electronics and electric vehicles.

The solid electrolyte-lithium metal interface presents a fundamental challenge, as the high interfacial resistance creates a bottleneck for lithium ion transport. This resistance increases with cycling, leading to capacity fade and shortened battery life. Unlike liquid electrolyte systems where interfacial contact is maintained through wetting, solid-state systems struggle with maintaining consistent physical contact during volume changes.

Dendrite formation remains problematic even in solid-state configurations. Contrary to earlier hypotheses that solid electrolytes would mechanically suppress dendrite growth, recent studies have demonstrated that lithium can still penetrate through grain boundaries and defects in the solid electrolyte at current densities as low as 0.5-1 mA/cm². This penetration creates short circuits and safety hazards.

Scaling production presents another significant hurdle. Laboratory-scale fabrication methods such as pulsed laser deposition or atomic layer deposition produce high-quality interfaces but are impractical for mass production. Alternative techniques like tape casting and roll-to-roll processing introduce more defects and inconsistencies, further limiting achievable current densities in scaled-up cells.

The mechanical stability of the anode-free architecture during cycling poses additional challenges. Without a host material to accommodate lithium deposition, the repeated plating and stripping processes create substantial mechanical stress at the interface. This stress leads to delamination and increased interfacial resistance, creating a negative feedback loop that further reduces current density capabilities.

Temperature sensitivity compounds these issues, as the ionic conductivity of most solid electrolytes drops significantly at room temperature and below. While operating at elevated temperatures (60-80°C) improves conductivity, it introduces thermal management complexities and reduces the practical advantage over conventional lithium-ion batteries.

Material compatibility issues further complicate development efforts. Many promising solid electrolytes are unstable against lithium metal, forming resistive interphases that grow with cycling. Protective interlayers have shown promise in laboratory settings but add complexity to manufacturing and often degrade under the high current densities needed for practical applications.

The solid electrolyte-lithium metal interface presents a fundamental challenge, as the high interfacial resistance creates a bottleneck for lithium ion transport. This resistance increases with cycling, leading to capacity fade and shortened battery life. Unlike liquid electrolyte systems where interfacial contact is maintained through wetting, solid-state systems struggle with maintaining consistent physical contact during volume changes.

Dendrite formation remains problematic even in solid-state configurations. Contrary to earlier hypotheses that solid electrolytes would mechanically suppress dendrite growth, recent studies have demonstrated that lithium can still penetrate through grain boundaries and defects in the solid electrolyte at current densities as low as 0.5-1 mA/cm². This penetration creates short circuits and safety hazards.

Scaling production presents another significant hurdle. Laboratory-scale fabrication methods such as pulsed laser deposition or atomic layer deposition produce high-quality interfaces but are impractical for mass production. Alternative techniques like tape casting and roll-to-roll processing introduce more defects and inconsistencies, further limiting achievable current densities in scaled-up cells.

The mechanical stability of the anode-free architecture during cycling poses additional challenges. Without a host material to accommodate lithium deposition, the repeated plating and stripping processes create substantial mechanical stress at the interface. This stress leads to delamination and increased interfacial resistance, creating a negative feedback loop that further reduces current density capabilities.

Temperature sensitivity compounds these issues, as the ionic conductivity of most solid electrolytes drops significantly at room temperature and below. While operating at elevated temperatures (60-80°C) improves conductivity, it introduces thermal management complexities and reduces the practical advantage over conventional lithium-ion batteries.

Material compatibility issues further complicate development efforts. Many promising solid electrolytes are unstable against lithium metal, forming resistive interphases that grow with cycling. Protective interlayers have shown promise in laboratory settings but add complexity to manufacturing and often degrade under the high current densities needed for practical applications.

Current Approaches to Current Density Enhancement

01 Electrolyte composition for high current density

Specialized electrolyte compositions can significantly improve current density limits in anode-free solid-state batteries. These include composite electrolytes combining inorganic and polymer materials, doped ceramic electrolytes with enhanced ionic conductivity, and electrolytes with additives that stabilize the lithium metal interface. These formulations reduce interfacial resistance and enable faster lithium-ion transport, allowing the battery to operate at higher current densities without performance degradation.- Electrolyte composition for high current density: Specialized electrolyte compositions in anode-free solid-state batteries can significantly increase current density limits. These compositions typically include solid polymer electrolytes, ceramic electrolytes, or composite electrolytes that facilitate faster ion transport while maintaining stability at the lithium metal interface. The electrolyte formulations often incorporate additives that enhance ionic conductivity and reduce interfacial resistance, allowing for higher current densities without dendrite formation or capacity loss.

- Interface engineering for improved current flow: Engineering the interfaces between the cathode, solid electrolyte, and in-situ formed anode is crucial for achieving higher current density limits in anode-free solid-state batteries. This approach involves creating stable interfaces that minimize resistance to lithium ion transport while preventing unwanted side reactions. Techniques include surface coatings, buffer layers, and gradient interfaces that accommodate volume changes during cycling while maintaining excellent electronic and ionic conductivity pathways.

- Cathode structure optimization for anode-free designs: The cathode structure in anode-free solid-state batteries significantly impacts achievable current density limits. Advanced cathode designs incorporate hierarchical porosity, optimized active material loading, and conductive networks that facilitate both electron and ion transport. These structures are engineered to accommodate the stress generated during lithium plating/stripping cycles while maintaining intimate contact with the solid electrolyte, enabling higher operational current densities without performance degradation.

- Pressure regulation systems for maintaining contact: Implementing pressure regulation systems in anode-free solid-state batteries helps maintain intimate contact between battery components during cycling, which is essential for achieving high current density operation. These systems apply controlled pressure to compensate for volume changes during lithium plating and stripping, preventing void formation and ensuring continuous ionic pathways. Advanced designs incorporate dynamic pressure adjustment mechanisms that respond to the battery's state of charge, optimizing performance across various operating conditions.

- Temperature management for enhanced ion mobility: Effective temperature management systems enable anode-free solid-state batteries to achieve higher current density limits by enhancing lithium ion mobility while preventing thermal runaway. These systems maintain optimal operating temperatures that reduce electrolyte resistance without triggering degradation mechanisms. Advanced thermal management approaches include phase-change materials, active cooling systems, and thermally conductive components that distribute heat evenly throughout the cell, allowing for sustained high-current operation without compromising safety or cycle life.

02 Interface engineering for improved current flow

Interface engineering between the cathode and solid electrolyte is crucial for achieving higher current density limits in anode-free solid-state batteries. This involves creating specialized interlayers, surface coatings, or gradient interfaces that facilitate smooth ion transfer while minimizing resistance. Advanced interface designs can prevent dendrite formation, reduce mechanical stress, and maintain stable electrochemical performance even at elevated current densities.Expand Specific Solutions03 Cathode architecture optimization

Optimizing cathode architecture is essential for enhancing current density limits in anode-free solid-state batteries. This includes developing hierarchical porous structures, controlling particle size and distribution, and incorporating conductive additives. Advanced cathode designs with optimized active material loading and thickness can accommodate volume changes during cycling and facilitate rapid ion diffusion, enabling operation at higher current densities without capacity loss.Expand Specific Solutions04 Pressure and temperature management systems

Implementing effective pressure and temperature management systems can significantly increase the current density limits of anode-free solid-state batteries. Controlled stack pressure maintains intimate contact between components, while temperature regulation optimizes ion mobility within the solid electrolyte. Advanced thermal management designs prevent hotspots and ensure uniform current distribution, allowing the battery to safely operate at higher current densities.Expand Specific Solutions05 Novel manufacturing techniques

Innovative manufacturing techniques can overcome current density limitations in anode-free solid-state batteries. These include advanced deposition methods for ultra-thin electrolytes, co-sintering processes for improved component integration, and precision assembly techniques that minimize interfacial defects. These manufacturing approaches create batteries with more uniform structures and fewer imperfections, enabling higher current densities without compromising cycle life or safety.Expand Specific Solutions

Leading Companies and Research Institutions in Solid-State Batteries

The solid-state battery market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The anode-free solid-state battery technology represents a frontier innovation with potential to dramatically increase energy density and safety. Market size is projected to expand rapidly, with automotive companies like Hyundai, Kia, and Tesla driving demand alongside electronics manufacturers. Technical maturity varies significantly among key players: established companies like Panasonic Energy and LG Energy Solution possess manufacturing expertise but newer entrants like Sila Nanotechnologies and TeraWatt Technology are making breakthroughs in materials science. Research institutions including KIST and University of California collaborate with industry to address current density limitations and scaling challenges, with commercial viability expected within 5-7 years as manufacturing processes mature.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has developed a hybrid solid-state electrolyte system for anode-free batteries that addresses current density limitations through a novel interface management approach. Their technology utilizes a composite electrolyte with a sulfide-based primary layer combined with a thin polymer buffer layer at the lithium metal interface. This architecture has demonstrated stable cycling at current densities of 2-3 mA/cm² without dendrite penetration. Panasonic's innovation includes a proprietary surface treatment process that creates nanoscale features on the electrolyte surface, increasing the effective surface area for lithium deposition and reducing local current density hotspots. Their research shows this approach reduces the critical current density for dendrite formation by approximately 40% compared to untreated surfaces. For manufacturing scalability, Panasonic has adapted their established battery production lines to accommodate solid electrolyte handling, with specialized dry-room processing that maintains moisture levels below 10 ppm to prevent degradation of moisture-sensitive solid electrolytes.

Strengths: Panasonic's approach leverages their extensive manufacturing experience and existing production infrastructure, potentially enabling faster commercialization. Their interface engineering effectively addresses the critical dendrite formation issue. Weaknesses: The hybrid electrolyte system may introduce additional interfaces that could become failure points during long-term cycling, and the specialized processing requirements increase production costs compared to conventional lithium-ion batteries.

TeraWatt Technology, Inc.

Technical Solution: TeraWatt Technology has developed a specialized solid-state battery architecture focused on maximizing current density in anode-free configurations. Their approach utilizes a multi-layer solid electrolyte system with gradient properties that optimize both ionic conductivity and mechanical stability. The company's proprietary "ion-funneling" technology creates preferential pathways for lithium ion transport while mechanically inhibiting dendrite growth, enabling sustained operation at current densities exceeding 3.5 mA/cm². TeraWatt's solid electrolyte incorporates self-healing components that can repair microcracks formed during cycling, addressing a key degradation mechanism in solid-state systems. Their research demonstrates that this self-healing capability extends cycle life by approximately 60% at high current densities compared to conventional solid electrolytes. For manufacturing scalability, TeraWatt has developed a modular production approach that allows for incremental capacity expansion with lower capital intensity than traditional gigafactory models, enabling more flexible scaling as the technology matures.

Strengths: TeraWatt's self-healing electrolyte technology addresses a fundamental challenge in solid-state batteries by mitigating mechanical degradation during cycling. Their modular manufacturing approach reduces scaling risks. Weaknesses: The complex multi-layer electrolyte system increases production complexity and may present challenges for quality control in mass production. The technology is less mature than competitors with established manufacturing capabilities.

Critical Patents and Research on Anode-Free Architectures

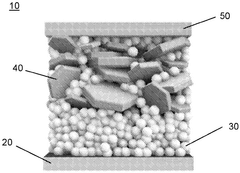

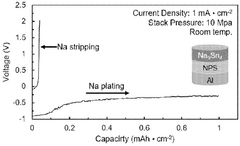

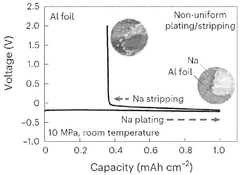

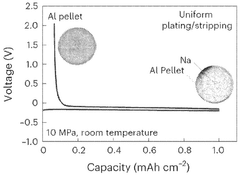

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Material Science Innovations for Solid-State Electrolytes

Recent advancements in solid-state electrolyte materials have revolutionized the landscape of energy storage technologies. These innovations address critical challenges in traditional lithium-ion batteries, particularly concerning safety, energy density, and longevity. Solid-state electrolytes (SSEs) represent a paradigm shift from conventional liquid electrolytes, offering superior thermal stability and reduced risk of flammability.

Material science breakthroughs have yielded several promising SSE categories, including oxide-based ceramics, sulfide-based materials, polymer electrolytes, and composite structures. Oxide-based ceramics such as LLZO (Li7La3Zr2O12) demonstrate excellent chemical stability against lithium metal anodes but face challenges in mechanical properties and interfacial resistance. Sulfide-based materials like Li10GeP2S12 (LGPS) exhibit remarkable ionic conductivity approaching 10^-2 S/cm at room temperature, rivaling liquid electrolytes.

Polymer-based electrolytes offer manufacturing advantages through flexibility and processability, though they typically suffer from lower ionic conductivity. Recent innovations in cross-linking strategies and nanocomposite approaches have significantly enhanced their performance metrics. The integration of ceramic fillers into polymer matrices creates hybrid electrolytes that combine the mechanical strength of ceramics with the flexibility of polymers.

Interface engineering represents another frontier in SSE development. Novel coating technologies and interlayer designs mitigate the formation of high-resistance interfaces between electrolytes and electrodes. Atomic layer deposition (ALD) and solution-based methods have enabled precise control over interfacial chemistry, substantially reducing impedance and enhancing cycling stability.

Computational materials science has accelerated discovery in this field through high-throughput screening and machine learning algorithms. These approaches have identified promising new material compositions with optimized properties for specific applications. Molecular dynamics simulations provide insights into ion transport mechanisms at atomic scales, guiding rational design principles.

Manufacturing scalability remains a significant challenge for many advanced SSE materials. Innovations in processing techniques, including cold sintering, solution-based methods, and advanced ceramic processing, are addressing these limitations. Recent developments in co-sintering approaches have demonstrated potential for mass production of ceramic-based SSEs with controlled microstructures and minimized defects.

The quest for SSEs compatible with anode-free configurations represents a particularly promising direction, as it could enable unprecedented energy densities while maintaining safety advantages. Materials that can withstand high current densities without dendrite formation are essential for realizing the full potential of next-generation solid-state batteries.

Material science breakthroughs have yielded several promising SSE categories, including oxide-based ceramics, sulfide-based materials, polymer electrolytes, and composite structures. Oxide-based ceramics such as LLZO (Li7La3Zr2O12) demonstrate excellent chemical stability against lithium metal anodes but face challenges in mechanical properties and interfacial resistance. Sulfide-based materials like Li10GeP2S12 (LGPS) exhibit remarkable ionic conductivity approaching 10^-2 S/cm at room temperature, rivaling liquid electrolytes.

Polymer-based electrolytes offer manufacturing advantages through flexibility and processability, though they typically suffer from lower ionic conductivity. Recent innovations in cross-linking strategies and nanocomposite approaches have significantly enhanced their performance metrics. The integration of ceramic fillers into polymer matrices creates hybrid electrolytes that combine the mechanical strength of ceramics with the flexibility of polymers.

Interface engineering represents another frontier in SSE development. Novel coating technologies and interlayer designs mitigate the formation of high-resistance interfaces between electrolytes and electrodes. Atomic layer deposition (ALD) and solution-based methods have enabled precise control over interfacial chemistry, substantially reducing impedance and enhancing cycling stability.

Computational materials science has accelerated discovery in this field through high-throughput screening and machine learning algorithms. These approaches have identified promising new material compositions with optimized properties for specific applications. Molecular dynamics simulations provide insights into ion transport mechanisms at atomic scales, guiding rational design principles.

Manufacturing scalability remains a significant challenge for many advanced SSE materials. Innovations in processing techniques, including cold sintering, solution-based methods, and advanced ceramic processing, are addressing these limitations. Recent developments in co-sintering approaches have demonstrated potential for mass production of ceramic-based SSEs with controlled microstructures and minimized defects.

The quest for SSEs compatible with anode-free configurations represents a particularly promising direction, as it could enable unprecedented energy densities while maintaining safety advantages. Materials that can withstand high current densities without dendrite formation are essential for realizing the full potential of next-generation solid-state batteries.

Safety and Reliability Considerations for High-Density Batteries

The safety and reliability of high-density batteries represent critical concerns in the development of anode-free solid-state battery technologies. As current density limits continue to be pushed in pursuit of higher energy storage capabilities, several safety challenges emerge that require systematic evaluation and mitigation strategies.

Thermal runaway presents one of the most significant safety risks in high-density battery systems. When anode-free solid-state batteries operate at elevated current densities, localized heating can occur at interfaces between the solid electrolyte and current collectors. This heating may initiate cascading thermal events that compromise cell integrity, particularly when dendrite formation creates internal short circuits that generate excessive heat.

Mechanical stability concerns also arise as solid-state batteries cycle at high current densities. The absence of a traditional anode creates unique stress patterns during lithium plating and stripping processes. Volumetric changes during cycling can lead to interfacial delamination, creating voids that increase internal resistance and potentially compromise safety through mechanical failure points.

Dendrite propagation mechanisms require special attention in anode-free configurations. Without the physical buffer of a conventional anode, lithium dendrites can more readily penetrate solid electrolytes when operating beyond critical current density thresholds. Research indicates that dendrite growth accelerates non-linearly with increasing current density, creating a narrow operational safety window for high-performance applications.

Long-term reliability testing protocols must be established specifically for anode-free systems. Conventional battery testing methodologies often fail to capture the unique degradation mechanisms of these advanced architectures. Accelerated aging tests that accurately predict performance under various current density regimes are essential for establishing safety margins and operational limits.

Pressure management systems represent another crucial safety consideration. The interfacial pressure between solid electrolyte and current collector significantly impacts lithium deposition morphology. Maintaining optimal pressure distribution becomes increasingly challenging as cell dimensions scale up, requiring innovative engineering solutions to prevent pressure-induced failure modes.

Fault detection and management systems must evolve to address the unique failure modes of anode-free solid-state batteries. Early warning indicators of dendrite formation or interfacial degradation could enable preventive measures before catastrophic failure occurs. Advanced sensing technologies that can monitor internal cell conditions without compromising the solid-state architecture represent a promising research direction.

Thermal runaway presents one of the most significant safety risks in high-density battery systems. When anode-free solid-state batteries operate at elevated current densities, localized heating can occur at interfaces between the solid electrolyte and current collectors. This heating may initiate cascading thermal events that compromise cell integrity, particularly when dendrite formation creates internal short circuits that generate excessive heat.

Mechanical stability concerns also arise as solid-state batteries cycle at high current densities. The absence of a traditional anode creates unique stress patterns during lithium plating and stripping processes. Volumetric changes during cycling can lead to interfacial delamination, creating voids that increase internal resistance and potentially compromise safety through mechanical failure points.

Dendrite propagation mechanisms require special attention in anode-free configurations. Without the physical buffer of a conventional anode, lithium dendrites can more readily penetrate solid electrolytes when operating beyond critical current density thresholds. Research indicates that dendrite growth accelerates non-linearly with increasing current density, creating a narrow operational safety window for high-performance applications.

Long-term reliability testing protocols must be established specifically for anode-free systems. Conventional battery testing methodologies often fail to capture the unique degradation mechanisms of these advanced architectures. Accelerated aging tests that accurately predict performance under various current density regimes are essential for establishing safety margins and operational limits.

Pressure management systems represent another crucial safety consideration. The interfacial pressure between solid electrolyte and current collector significantly impacts lithium deposition morphology. Maintaining optimal pressure distribution becomes increasingly challenging as cell dimensions scale up, requiring innovative engineering solutions to prevent pressure-induced failure modes.

Fault detection and management systems must evolve to address the unique failure modes of anode-free solid-state batteries. Early warning indicators of dendrite formation or interfacial degradation could enable preventive measures before catastrophic failure occurs. Advanced sensing technologies that can monitor internal cell conditions without compromising the solid-state architecture represent a promising research direction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!