Anode-Free Solid-State Dry-Room Specs And Controls

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free solid-state battery technology represents a significant evolution in energy storage systems, emerging from decades of battery development that began with lithium-ion technologies in the early 1990s. This revolutionary approach eliminates the traditional graphite or silicon anode, allowing lithium metal to plate directly onto the current collector during charging. The concept has gained substantial momentum since 2015, when researchers demonstrated its potential to dramatically increase energy density while addressing safety concerns inherent in conventional lithium-ion batteries.

The primary objective of anode-free battery technology is to achieve unprecedented energy density—potentially exceeding 500 Wh/kg at the cell level—while maintaining acceptable cycle life and safety profiles. By removing the anode material, these batteries can theoretically store more energy in the same volume, offering a pathway to lighter, more compact energy storage solutions critical for electric vehicles and portable electronics.

A crucial aspect of anode-free battery development involves the manufacturing environment, particularly dry room specifications and controls. Unlike conventional lithium-ion batteries, anode-free designs are exceptionally sensitive to moisture and contaminants, requiring ultra-low humidity environments (typically <0.1% relative humidity) during production. This represents a significant manufacturing challenge that must be overcome for commercial viability.

The technology aims to address several limitations of current battery systems, including energy density plateaus, safety concerns related to liquid electrolytes, and resource constraints associated with anode materials. By utilizing solid-state electrolytes in conjunction with the anode-free design, these batteries promise enhanced safety through elimination of flammable liquid components while potentially extending cycle life through better interface management.

Historical development of this technology has progressed from early proof-of-concept demonstrations to increasingly sophisticated prototypes with improved cycling stability. Recent breakthroughs in solid electrolyte materials and interface engineering have accelerated progress, though significant challenges remain in scaling production while maintaining the necessary environmental controls.

The convergence of anode-free design with solid-state electrolytes represents a particularly promising direction, as it addresses multiple limitations simultaneously. This synergistic approach aims to deliver batteries that not only store more energy but also charge faster, last longer, and operate more safely than current technologies—potentially enabling the next generation of electric vehicles with ranges exceeding 500 miles on a single charge.

The primary objective of anode-free battery technology is to achieve unprecedented energy density—potentially exceeding 500 Wh/kg at the cell level—while maintaining acceptable cycle life and safety profiles. By removing the anode material, these batteries can theoretically store more energy in the same volume, offering a pathway to lighter, more compact energy storage solutions critical for electric vehicles and portable electronics.

A crucial aspect of anode-free battery development involves the manufacturing environment, particularly dry room specifications and controls. Unlike conventional lithium-ion batteries, anode-free designs are exceptionally sensitive to moisture and contaminants, requiring ultra-low humidity environments (typically <0.1% relative humidity) during production. This represents a significant manufacturing challenge that must be overcome for commercial viability.

The technology aims to address several limitations of current battery systems, including energy density plateaus, safety concerns related to liquid electrolytes, and resource constraints associated with anode materials. By utilizing solid-state electrolytes in conjunction with the anode-free design, these batteries promise enhanced safety through elimination of flammable liquid components while potentially extending cycle life through better interface management.

Historical development of this technology has progressed from early proof-of-concept demonstrations to increasingly sophisticated prototypes with improved cycling stability. Recent breakthroughs in solid electrolyte materials and interface engineering have accelerated progress, though significant challenges remain in scaling production while maintaining the necessary environmental controls.

The convergence of anode-free design with solid-state electrolytes represents a particularly promising direction, as it addresses multiple limitations simultaneously. This synergistic approach aims to deliver batteries that not only store more energy but also charge faster, last longer, and operate more safely than current technologies—potentially enabling the next generation of electric vehicles with ranges exceeding 500 miles on a single charge.

Market Analysis for Solid-State Battery Production

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for electric vehicles (EVs) and consumer electronics requiring higher energy density and safety profiles. Current market projections indicate the global solid-state battery market will reach approximately $8 billion by 2030, with a compound annual growth rate exceeding 34% between 2023 and 2030. This remarkable growth trajectory is primarily fueled by automotive applications, which are expected to account for over 60% of the total market share.

The production landscape for solid-state batteries is rapidly evolving, with significant investments being directed toward manufacturing infrastructure. Major automotive manufacturers and battery producers are establishing dedicated production facilities, with announced investments totaling over $13 billion globally in the past three years. These investments highlight the industry's commitment to transitioning from traditional lithium-ion batteries to more advanced solid-state technologies.

Anode-free solid-state battery production represents a particularly promising segment within this market. By eliminating the traditional anode material, manufacturers can achieve up to 50% higher energy density while reducing production costs by approximately 20%. This configuration is gaining traction among manufacturers seeking to differentiate their offerings in an increasingly competitive landscape.

Dry-room specifications and controls represent a critical aspect of solid-state battery production, with stringent requirements that exceed those of conventional lithium-ion manufacturing. The market for specialized dry-room equipment is projected to grow at 28% annually, reaching $1.2 billion by 2028. This growth is driven by the need for ultra-low humidity environments (typically below 0.5% relative humidity) essential for handling moisture-sensitive solid electrolyte materials.

Regional analysis reveals Asia-Pacific dominates the solid-state battery production market with approximately 65% share, led by Japan, South Korea, and China. North America and Europe are rapidly expanding their manufacturing capabilities, with significant government support through initiatives like the European Battery Alliance and the U.S. Infrastructure Investment and Jobs Act providing substantial funding for domestic production capacity.

Consumer demand patterns indicate strong preference for EVs with extended range capabilities, with market surveys showing 78% of potential EV buyers consider range anxiety a primary concern. Solid-state batteries, particularly anode-free configurations, address this concern directly by offering potential driving ranges exceeding 500 miles on a single charge, representing a compelling value proposition for manufacturers and consumers alike.

The market for specialized production equipment, including advanced dry-room systems with precise humidity and temperature controls, is experiencing parallel growth, with several engineering firms developing customized solutions specifically for solid-state battery manufacturing requirements.

The production landscape for solid-state batteries is rapidly evolving, with significant investments being directed toward manufacturing infrastructure. Major automotive manufacturers and battery producers are establishing dedicated production facilities, with announced investments totaling over $13 billion globally in the past three years. These investments highlight the industry's commitment to transitioning from traditional lithium-ion batteries to more advanced solid-state technologies.

Anode-free solid-state battery production represents a particularly promising segment within this market. By eliminating the traditional anode material, manufacturers can achieve up to 50% higher energy density while reducing production costs by approximately 20%. This configuration is gaining traction among manufacturers seeking to differentiate their offerings in an increasingly competitive landscape.

Dry-room specifications and controls represent a critical aspect of solid-state battery production, with stringent requirements that exceed those of conventional lithium-ion manufacturing. The market for specialized dry-room equipment is projected to grow at 28% annually, reaching $1.2 billion by 2028. This growth is driven by the need for ultra-low humidity environments (typically below 0.5% relative humidity) essential for handling moisture-sensitive solid electrolyte materials.

Regional analysis reveals Asia-Pacific dominates the solid-state battery production market with approximately 65% share, led by Japan, South Korea, and China. North America and Europe are rapidly expanding their manufacturing capabilities, with significant government support through initiatives like the European Battery Alliance and the U.S. Infrastructure Investment and Jobs Act providing substantial funding for domestic production capacity.

Consumer demand patterns indicate strong preference for EVs with extended range capabilities, with market surveys showing 78% of potential EV buyers consider range anxiety a primary concern. Solid-state batteries, particularly anode-free configurations, address this concern directly by offering potential driving ranges exceeding 500 miles on a single charge, representing a compelling value proposition for manufacturers and consumers alike.

The market for specialized production equipment, including advanced dry-room systems with precise humidity and temperature controls, is experiencing parallel growth, with several engineering firms developing customized solutions specifically for solid-state battery manufacturing requirements.

Current Dry-Room Technologies and Limitations

Current dry-room technologies for anode-free solid-state battery manufacturing primarily focus on controlling humidity and temperature to prevent lithium degradation. Most advanced facilities maintain relative humidity (RH) levels below 1%, with some ultra-low humidity environments reaching as low as 0.1% RH. These environments are created using sophisticated air handling systems incorporating desiccant wheels, molecular sieves, and multi-stage dehumidification processes.

The standard configuration includes primary and secondary desiccant systems working in tandem with precision cooling units. Temperature control typically ranges between 20-25°C, with stability requirements of ±1°C to ensure consistent manufacturing conditions. Modern dry rooms employ cascade refrigeration systems coupled with chemical desiccants to achieve these stringent specifications.

Despite technological advances, current dry-room technologies face significant limitations. Energy consumption represents a major challenge, with large-scale facilities requiring 2-5 kWh per cubic meter of processed air, resulting in substantial operational costs. The desiccant regeneration process alone can account for up to 40% of the total energy consumption in advanced dry rooms.

Material compatibility issues also present obstacles, as certain solid electrolyte materials exhibit sensitivity not only to moisture but also to oxygen and carbon dioxide. Conventional dry rooms primarily address humidity without adequately controlling these secondary contaminants, necessitating additional purification systems that increase complexity and cost.

Personnel comfort and productivity limitations cannot be overlooked. Extended exposure to ultra-low humidity environments causes physical discomfort including dry skin, respiratory irritation, and eye strain. Most facilities limit continuous worker exposure to 4-6 hours, requiring rotation schedules that complicate manufacturing workflows and reduce operational efficiency.

Scalability presents another significant challenge. As production volumes increase from laboratory to industrial scale, maintaining uniform environmental conditions becomes exponentially more difficult. Current technologies struggle to provide homogeneous conditions across large manufacturing spaces exceeding 1,000 square meters, resulting in quality inconsistencies in battery production.

Monitoring and control systems also face limitations in response time and accuracy. Most humidity sensors exhibit drift in ultra-dry environments, requiring frequent recalibration. The typical response time of 30-60 seconds for environmental adjustments proves inadequate for rapid production processes, potentially exposing sensitive materials to damaging conditions during transitional states.

The standard configuration includes primary and secondary desiccant systems working in tandem with precision cooling units. Temperature control typically ranges between 20-25°C, with stability requirements of ±1°C to ensure consistent manufacturing conditions. Modern dry rooms employ cascade refrigeration systems coupled with chemical desiccants to achieve these stringent specifications.

Despite technological advances, current dry-room technologies face significant limitations. Energy consumption represents a major challenge, with large-scale facilities requiring 2-5 kWh per cubic meter of processed air, resulting in substantial operational costs. The desiccant regeneration process alone can account for up to 40% of the total energy consumption in advanced dry rooms.

Material compatibility issues also present obstacles, as certain solid electrolyte materials exhibit sensitivity not only to moisture but also to oxygen and carbon dioxide. Conventional dry rooms primarily address humidity without adequately controlling these secondary contaminants, necessitating additional purification systems that increase complexity and cost.

Personnel comfort and productivity limitations cannot be overlooked. Extended exposure to ultra-low humidity environments causes physical discomfort including dry skin, respiratory irritation, and eye strain. Most facilities limit continuous worker exposure to 4-6 hours, requiring rotation schedules that complicate manufacturing workflows and reduce operational efficiency.

Scalability presents another significant challenge. As production volumes increase from laboratory to industrial scale, maintaining uniform environmental conditions becomes exponentially more difficult. Current technologies struggle to provide homogeneous conditions across large manufacturing spaces exceeding 1,000 square meters, resulting in quality inconsistencies in battery production.

Monitoring and control systems also face limitations in response time and accuracy. Most humidity sensors exhibit drift in ultra-dry environments, requiring frequent recalibration. The typical response time of 30-60 seconds for environmental adjustments proves inadequate for rapid production processes, potentially exposing sensitive materials to damaging conditions during transitional states.

Current Dry-Room Control Solutions for Anode-Free Batteries

01 Humidity control specifications for dry rooms in anode-free battery manufacturing

Maintaining precise humidity levels in dry rooms is critical for anode-free solid-state battery manufacturing. These specifications typically require dew points below -40°C and relative humidity below 1% to prevent moisture contamination of moisture-sensitive materials like lithium metal and solid electrolytes. Advanced dehumidification systems with molecular sieves and desiccant wheels are employed to maintain these ultra-dry conditions, which are essential for preventing degradation of battery components during assembly.- Dry-room humidity and temperature control for solid-state battery manufacturing: Controlling humidity and temperature in dry rooms is critical for anode-free solid-state battery manufacturing. These environments typically maintain relative humidity below 1% and precise temperature control to prevent moisture contamination of moisture-sensitive materials like lithium metal and solid electrolytes. Advanced HVAC systems with desiccant wheels and molecular sieves are employed to achieve these ultra-dry conditions, which are essential for maintaining battery performance and safety during production.

- Moisture monitoring and control systems for anode-free battery production: Sophisticated moisture monitoring and control systems are essential in dry rooms for anode-free solid-state battery manufacturing. These systems employ advanced sensors that continuously measure dew point and moisture levels, with real-time feedback loops that adjust dehumidification equipment accordingly. Automated alert systems notify operators when moisture levels exceed predetermined thresholds, while airlocks and personnel dehumidification chambers prevent moisture ingress. These controls ensure consistent environmental conditions critical for the quality and performance of moisture-sensitive battery components.

- Material handling protocols in dry-room environments: Specialized material handling protocols are implemented in dry-room environments for anode-free solid-state battery production. These include the use of sealed transfer containers, glove boxes, and automated material handling systems to minimize exposure to ambient conditions. Materials are often pre-dried before entering the dry room, and storage containers with desiccants are used for moisture-sensitive components. Personnel training on proper handling procedures and the use of specialized clothing and equipment help maintain the integrity of battery materials throughout the manufacturing process.

- Dry-room design and construction specifications: Dry-room design and construction for anode-free solid-state battery manufacturing requires specialized architectural and engineering considerations. These facilities feature vapor barriers, specialized wall and floor coatings, and airlock systems to maintain ultra-low humidity levels. The construction materials must be non-outgassing and moisture-resistant, while the room layout optimizes workflow while minimizing moisture introduction. Redundant dehumidification systems ensure continuous operation, and the facility design incorporates energy recovery systems to manage the high energy consumption associated with maintaining ultra-dry conditions.

- Quality control and validation procedures for dry-room operations: Comprehensive quality control and validation procedures are essential for dry-room operations in anode-free solid-state battery manufacturing. These include regular calibration of humidity and temperature sensors, periodic validation of environmental conditions against established standards, and documentation of all environmental parameters during production. In-process testing of battery components for moisture contamination, along with finished product testing to verify performance metrics, ensures product quality. Validation protocols also include challenge testing of the dry-room systems to verify their response to potential failure scenarios.

02 Temperature control and stability requirements for solid-state battery dry rooms

Temperature control in dry rooms for anode-free solid-state battery production requires maintaining stable temperatures typically between 20-25°C with minimal fluctuations (±1°C). This stability is crucial for consistent battery performance and manufacturing processes. HVAC systems with precise temperature regulation capabilities are implemented alongside thermal insulation to prevent condensation and maintain the integrity of temperature-sensitive battery components during assembly and testing phases.Expand Specific Solutions03 Airflow management and filtration systems for contamination control

Airflow management in dry rooms for anode-free solid-state batteries involves laminar flow systems that minimize particulate contamination. These systems typically maintain ISO Class 5-7 cleanliness levels with HEPA or ULPA filtration to remove particles down to 0.1-0.3 microns. Positive pressure differentials between manufacturing zones prevent external contaminant infiltration, while airlocks and material transfer protocols maintain the integrity of the controlled environment during personnel and material movement.Expand Specific Solutions04 Monitoring and control systems for dry room environmental parameters

Advanced monitoring systems for anode-free solid-state battery dry rooms employ networks of sensors that continuously track humidity, temperature, pressure, and particulate levels. These systems feature real-time data logging, automated alerts for parameter deviations, and integration with facility management systems. Redundant monitoring equipment ensures reliability, while calibration protocols maintain measurement accuracy. The control systems often utilize PID controllers with feedback loops to make immediate adjustments to maintain optimal environmental conditions.Expand Specific Solutions05 Material handling and personnel protocols for dry room operations

Specialized protocols for material handling in anode-free solid-state battery dry rooms include moisture-proof packaging, vacuum-sealed transfer containers, and dedicated airlocks for material entry. Personnel must undergo dehumidification in transition chambers before entering, and wear appropriate cleanroom garments that minimize particle and moisture introduction. Training programs ensure compliance with strict entry/exit procedures, while automated material transfer systems reduce human intervention and associated contamination risks. These protocols are essential for maintaining the integrity of moisture-sensitive battery components throughout the manufacturing process.Expand Specific Solutions

Leading Companies in Dry-Room and Battery Production Equipment

The anode-free solid-state battery market is currently in an early growth phase, characterized by intensive R&D activities and limited commercial deployment. The global market size is projected to expand significantly, driven by increasing demand for higher energy density and safer battery technologies. Technical maturity varies across key players, with companies like LG Energy Solution, Samsung SDI, and Tesla leading commercial development efforts while maintaining substantial patent portfolios. Research institutions including KIST, University of California, and Karlsruhe Institute of Technology are advancing fundamental science in this domain. Emerging players such as TeraWatt Technology and Nextech Batteries are introducing innovative approaches to overcome manufacturing challenges, particularly in dry-room specifications and controls that are critical for successful commercialization of this promising technology.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed comprehensive dry-room specifications for anode-free solid-state battery production with humidity control below 100ppm (-40°C dew point) to prevent lithium metal degradation. Their approach includes multi-stage dehumidification systems with molecular sieve desiccant wheels and redundant HVAC controls. The company implements real-time monitoring with distributed sensor networks throughout production areas, maintaining humidity gradients between material handling zones. Their specifications include airlock systems with automated pressure differentials and personnel entry protocols requiring specialized garments and acclimation periods. LG's dry rooms feature electrostatic discharge (ESD) protection integrated with humidity control systems to prevent damage to sensitive battery components during manufacturing.

Strengths: Advanced multi-stage dehumidification technology allows for precise humidity control at extremely low levels. Integrated ESD protection systems address both moisture and static electricity concerns simultaneously. Weaknesses: High energy consumption for maintaining ultra-low humidity environments increases production costs. Complex system requires specialized maintenance personnel and extensive training programs.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered specialized dry-room environments for anode-free solid-state battery production featuring multi-tiered humidity control systems maintaining less than 50ppm moisture content (-45°C dew point). Their approach incorporates cascade refrigeration dehumidification with chemical desiccant backup systems for redundancy. The company's specifications include zoned production areas with graduated humidity levels based on material sensitivity, with the most critical lithium handling zones maintaining the strictest conditions. Samsung's control architecture employs AI-driven predictive maintenance algorithms that anticipate dehumidification system failures before they impact production conditions. Their dry rooms feature specialized polymer flooring and wall materials that minimize moisture retention and outgassing, while automated material transfer systems reduce door cycling and human traffic that could compromise environmental integrity.

Strengths: Extremely low moisture levels (below 50ppm) provide optimal conditions for handling highly reactive lithium materials. AI-driven predictive maintenance reduces unexpected downtime and humidity excursions. Weaknesses: Significant capital investment required for cascade refrigeration systems and specialized construction materials. High operational costs due to energy-intensive dehumidification processes.

Critical Patents in Humidity Control for Solid-State Battery Production

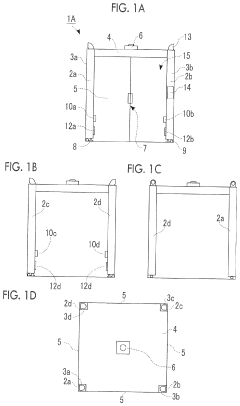

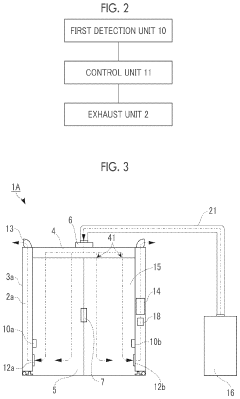

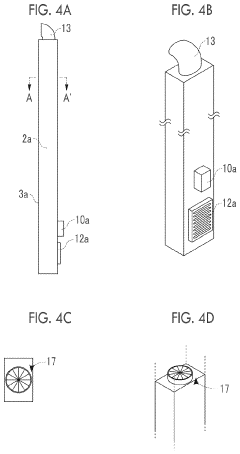

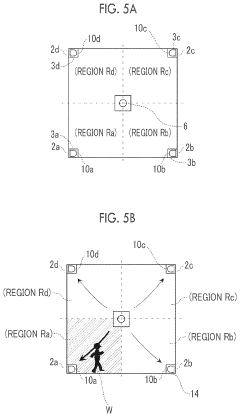

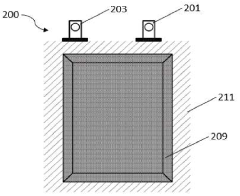

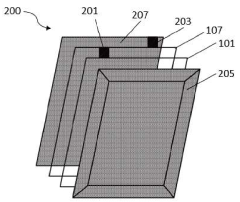

Dry room and method for controlling same

PatentActiveUS12013145B2

Innovation

- The implementation of a dry room system with multiple exhaust units in different regions, each individually adjusting air exhaust amounts based on detected changes in dew point temperature, utilizing detection units to preempt and manage humidity rises, ensuring precise control of dew point temperature.

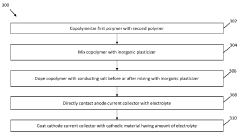

An anode-free solid-state battery and a method of making the same

PatentPendingIN202141047217A

Innovation

- An anode-free solid-state battery design utilizing a solid polymer electrolyte composed of a copolymer of polyvinylidene fluoride-co-hexafluoropropylene and methoxy poly(ethylene glycol) acrylate, doped with a conducting salt and an inorganic plasticizer, which is coated on both the anode and cathode current collectors to enhance ionic conductivity and stability.

Energy Efficiency and Sustainability in Dry-Room Operations

The dry-room environment essential for anode-free solid-state battery manufacturing presents significant energy consumption challenges due to the strict humidity control requirements. Traditional dry-room operations typically consume between 30-50% of a battery manufacturing facility's total energy budget, primarily through dehumidification systems that operate continuously to maintain ultra-low dew points below -40°C.

Recent advancements in energy-efficient dry-room technologies have demonstrated potential for reducing this consumption by 15-25% through implementation of advanced heat recovery systems. These systems capture and repurpose waste heat from dehumidification processes, significantly improving overall thermal efficiency. The integration of variable frequency drives (VFDs) in air handling units further optimizes energy usage by adjusting operation based on real-time humidity conditions rather than running at constant capacity.

Smart control systems utilizing machine learning algorithms have emerged as a promising approach to dry-room energy management. These systems can predict humidity fluctuations based on production schedules, personnel movements, and external weather conditions, enabling proactive rather than reactive humidity control. Field tests at pilot facilities have shown energy savings of up to 30% compared to conventional control methods while maintaining the required environmental specifications.

Sustainable dry-room design increasingly incorporates alternative refrigerants with lower global warming potential (GWP) in cooling systems. Traditional refrigerants used in industrial dehumidification often have GWP values exceeding 1,000, while newer alternatives can reduce this impact by 60-90%. This transition aligns with global environmental regulations and corporate sustainability commitments across the battery manufacturing sector.

Modular dry-room construction represents another sustainability advancement, allowing for targeted humidity control in specific manufacturing zones rather than maintaining entire facilities at the strictest specifications. This zoned approach can reduce energy consumption by up to 40% in facilities where only certain processes require ultra-low humidity conditions, such as electrode assembly areas in anode-free battery production.

Life cycle assessment (LCA) studies indicate that investments in energy-efficient dry-room technologies typically achieve return on investment within 3-5 years through reduced operational costs, while simultaneously reducing the carbon footprint associated with battery manufacturing. As the industry scales to meet growing demand for solid-state batteries, these efficiency improvements become increasingly critical to economic and environmental sustainability.

Recent advancements in energy-efficient dry-room technologies have demonstrated potential for reducing this consumption by 15-25% through implementation of advanced heat recovery systems. These systems capture and repurpose waste heat from dehumidification processes, significantly improving overall thermal efficiency. The integration of variable frequency drives (VFDs) in air handling units further optimizes energy usage by adjusting operation based on real-time humidity conditions rather than running at constant capacity.

Smart control systems utilizing machine learning algorithms have emerged as a promising approach to dry-room energy management. These systems can predict humidity fluctuations based on production schedules, personnel movements, and external weather conditions, enabling proactive rather than reactive humidity control. Field tests at pilot facilities have shown energy savings of up to 30% compared to conventional control methods while maintaining the required environmental specifications.

Sustainable dry-room design increasingly incorporates alternative refrigerants with lower global warming potential (GWP) in cooling systems. Traditional refrigerants used in industrial dehumidification often have GWP values exceeding 1,000, while newer alternatives can reduce this impact by 60-90%. This transition aligns with global environmental regulations and corporate sustainability commitments across the battery manufacturing sector.

Modular dry-room construction represents another sustainability advancement, allowing for targeted humidity control in specific manufacturing zones rather than maintaining entire facilities at the strictest specifications. This zoned approach can reduce energy consumption by up to 40% in facilities where only certain processes require ultra-low humidity conditions, such as electrode assembly areas in anode-free battery production.

Life cycle assessment (LCA) studies indicate that investments in energy-efficient dry-room technologies typically achieve return on investment within 3-5 years through reduced operational costs, while simultaneously reducing the carbon footprint associated with battery manufacturing. As the industry scales to meet growing demand for solid-state batteries, these efficiency improvements become increasingly critical to economic and environmental sustainability.

Safety Standards and Compliance for Battery Manufacturing Facilities

The manufacturing of anode-free solid-state batteries requires strict adherence to comprehensive safety standards and compliance frameworks due to the sensitive nature of materials involved and potential hazards in the production environment. International standards such as ISO 45001 for occupational health and safety management systems provide the foundational framework for establishing safe manufacturing practices in battery production facilities.

Specific to battery manufacturing, standards like IEC 62133 (safety requirements for portable sealed secondary cells) and UN 38.3 (transportation testing requirements for lithium batteries) must be integrated into facility design and operational protocols. For dry room environments where anode-free solid-state batteries are manufactured, NFPA 70E standards for electrical safety are particularly relevant due to the heightened risk of static discharge in low-humidity environments.

Regulatory compliance extends beyond general safety to include environmental considerations. The EPA's Clean Air Act regulations govern emissions and air quality standards that must be maintained, especially considering the specialized ventilation systems required in dry rooms. Additionally, facilities must comply with OSHA's Process Safety Management (PSM) standards when handling hazardous materials common in battery production.

Fire safety represents a critical compliance area for battery manufacturing facilities. NFPA 855, which specifically addresses the installation of stationary energy storage systems, provides guidelines for fire prevention and suppression systems that must be implemented. The dry room environment presents unique fire safety challenges due to the combination of low humidity and potentially reactive materials.

Material handling compliance is governed by standards such as ASTM E2021 for cleanroom operations and ISO 14644 for cleanroom classification, both essential for maintaining the controlled environment necessary for anode-free solid-state battery production. These standards dictate protocols for material transfer, personnel movement, and contamination control within the dry room.

Emergency response planning constitutes another vital compliance area. Facilities must develop comprehensive emergency action plans in accordance with OSHA 1910.38 requirements, including specific protocols for chemical spills, fires, and other incidents unique to battery manufacturing environments. These plans must account for the specialized nature of dry room evacuations and emergency response in controlled environments.

Regular compliance auditing and certification processes are necessary to maintain operational approval. This includes periodic third-party assessments against standards like UL 9540A for battery safety testing and IEC 61508 for functional safety of electrical/electronic safety-related systems. Documentation of these compliance efforts must be meticulously maintained and regularly updated to reflect evolving regulatory requirements and technological advancements in anode-free solid-state battery manufacturing.

Specific to battery manufacturing, standards like IEC 62133 (safety requirements for portable sealed secondary cells) and UN 38.3 (transportation testing requirements for lithium batteries) must be integrated into facility design and operational protocols. For dry room environments where anode-free solid-state batteries are manufactured, NFPA 70E standards for electrical safety are particularly relevant due to the heightened risk of static discharge in low-humidity environments.

Regulatory compliance extends beyond general safety to include environmental considerations. The EPA's Clean Air Act regulations govern emissions and air quality standards that must be maintained, especially considering the specialized ventilation systems required in dry rooms. Additionally, facilities must comply with OSHA's Process Safety Management (PSM) standards when handling hazardous materials common in battery production.

Fire safety represents a critical compliance area for battery manufacturing facilities. NFPA 855, which specifically addresses the installation of stationary energy storage systems, provides guidelines for fire prevention and suppression systems that must be implemented. The dry room environment presents unique fire safety challenges due to the combination of low humidity and potentially reactive materials.

Material handling compliance is governed by standards such as ASTM E2021 for cleanroom operations and ISO 14644 for cleanroom classification, both essential for maintaining the controlled environment necessary for anode-free solid-state battery production. These standards dictate protocols for material transfer, personnel movement, and contamination control within the dry room.

Emergency response planning constitutes another vital compliance area. Facilities must develop comprehensive emergency action plans in accordance with OSHA 1910.38 requirements, including specific protocols for chemical spills, fires, and other incidents unique to battery manufacturing environments. These plans must account for the specialized nature of dry room evacuations and emergency response in controlled environments.

Regular compliance auditing and certification processes are necessary to maintain operational approval. This includes periodic third-party assessments against standards like UL 9540A for battery safety testing and IEC 61508 for functional safety of electrical/electronic safety-related systems. Documentation of these compliance efforts must be meticulously maintained and regularly updated to reflect evolving regulatory requirements and technological advancements in anode-free solid-state battery manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!