Anode-Free Solid-State Formation And Conditioning Protocols

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the market since their commercial introduction in the early 1990s. However, conventional lithium-ion batteries face inherent limitations in energy density, safety, and cost-effectiveness. Anode-free battery technology represents a revolutionary approach that addresses these challenges by eliminating the traditional graphite or silicon anode, instead utilizing lithium metal that forms in situ during the initial charging process.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities approaching 500 Wh/kg at the cell level, significantly surpassing the 250-300 Wh/kg limit of current commercial lithium-ion batteries. This advancement aligns with the industry's persistent pursuit of higher energy density storage solutions.

The primary objective of anode-free solid-state battery research is to develop formation and conditioning protocols that enable stable, dendrite-free lithium deposition during battery operation. These protocols must address the critical challenges of uniform lithium plating, interface stabilization, and prevention of capacity fade during cycling. Additionally, they aim to establish reproducible manufacturing processes that can transition from laboratory-scale demonstrations to commercial production.

Current research trends indicate a convergence of anode-free technology with solid-state electrolytes, as this combination potentially offers superior safety characteristics by eliminating flammable liquid electrolytes. This integration presents unique challenges in terms of interfacial contact, ion transport kinetics, and mechanical stability during cycling, all of which must be addressed through innovative formation and conditioning strategies.

The technological trajectory suggests that anode-free batteries could serve as a bridge technology between current lithium-ion systems and future battery chemistries. Their development is particularly relevant for electric vehicles, aerospace applications, and portable electronics where weight and volume constraints are critical. Industry projections indicate that successful commercialization could reduce battery pack costs below $100/kWh, a threshold considered essential for mass-market electric vehicle adoption.

Recent academic and industrial research has demonstrated promising results with anode-free cells achieving over 200 cycles with minimal capacity degradation under controlled laboratory conditions. However, translating these results to practical applications requires addressing challenges related to pressure management, temperature control, and electrolyte stability during the formation process.

The ultimate goal of this technology development is to establish standardized formation and conditioning protocols that can be implemented in manufacturing environments, ensuring consistent performance, long cycle life, and safe operation of anode-free solid-state batteries across various applications and operating conditions.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities approaching 500 Wh/kg at the cell level, significantly surpassing the 250-300 Wh/kg limit of current commercial lithium-ion batteries. This advancement aligns with the industry's persistent pursuit of higher energy density storage solutions.

The primary objective of anode-free solid-state battery research is to develop formation and conditioning protocols that enable stable, dendrite-free lithium deposition during battery operation. These protocols must address the critical challenges of uniform lithium plating, interface stabilization, and prevention of capacity fade during cycling. Additionally, they aim to establish reproducible manufacturing processes that can transition from laboratory-scale demonstrations to commercial production.

Current research trends indicate a convergence of anode-free technology with solid-state electrolytes, as this combination potentially offers superior safety characteristics by eliminating flammable liquid electrolytes. This integration presents unique challenges in terms of interfacial contact, ion transport kinetics, and mechanical stability during cycling, all of which must be addressed through innovative formation and conditioning strategies.

The technological trajectory suggests that anode-free batteries could serve as a bridge technology between current lithium-ion systems and future battery chemistries. Their development is particularly relevant for electric vehicles, aerospace applications, and portable electronics where weight and volume constraints are critical. Industry projections indicate that successful commercialization could reduce battery pack costs below $100/kWh, a threshold considered essential for mass-market electric vehicle adoption.

Recent academic and industrial research has demonstrated promising results with anode-free cells achieving over 200 cycles with minimal capacity degradation under controlled laboratory conditions. However, translating these results to practical applications requires addressing challenges related to pressure management, temperature control, and electrolyte stability during the formation process.

The ultimate goal of this technology development is to establish standardized formation and conditioning protocols that can be implemented in manufacturing environments, ensuring consistent performance, long cycle life, and safe operation of anode-free solid-state batteries across various applications and operating conditions.

Market Analysis for Anode-Free Solid-State Batteries

The global market for anode-free solid-state batteries is experiencing significant growth potential, driven by increasing demands for higher energy density, improved safety, and longer cycle life in energy storage solutions. Current market projections indicate that the solid-state battery market could reach $8 billion by 2026, with anode-free technologies potentially capturing a substantial portion of this emerging segment.

Anode-free battery designs represent a revolutionary approach that eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that forms in situ during the initial charging process. This configuration offers theoretical energy density improvements of 30-50% compared to conventional lithium-ion batteries, making them particularly attractive for electric vehicle applications where range anxiety remains a primary consumer concern.

Market research indicates that automotive manufacturers are the primary drivers of demand for anode-free solid-state battery technology. Major OEMs including Toyota, Volkswagen, and BMW have made substantial investments in this technology, recognizing its potential to enable electric vehicles with 500+ mile ranges while reducing battery pack weight and volume. The premium electric vehicle segment is expected to be the first commercial application, with luxury automakers willing to absorb higher initial production costs.

Consumer electronics represents another promising market segment, with smartphone and laptop manufacturers exploring anode-free solid-state batteries to enable thinner devices with longer battery life. This segment values the enhanced safety profile of solid-state electrolytes, which eliminate the flammability concerns associated with liquid electrolytes in conventional batteries.

Significant market barriers remain, primarily centered around manufacturing scalability and formation protocol optimization. Current anode-free solid-state battery production costs exceed $500/kWh, substantially higher than conventional lithium-ion batteries at approximately $130/kWh. Industry analysts project that costs must decrease below $150/kWh to achieve mass-market adoption in automotive applications.

Regional market analysis reveals that Asia-Pacific currently dominates solid-state battery research and development, with Japan leading in patent filings related to anode-free technologies. North America and Europe are rapidly expanding their research initiatives, supported by government funding programs aimed at establishing domestic battery supply chains.

Market forecasts suggest that commercial deployment of anode-free solid-state batteries will begin with small-scale applications by 2023-2024, followed by premium electric vehicles by 2025-2026. Mass-market adoption is anticipated by 2028-2030, contingent upon successful development of scalable formation and conditioning protocols that enable consistent performance and longevity.

Anode-free battery designs represent a revolutionary approach that eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that forms in situ during the initial charging process. This configuration offers theoretical energy density improvements of 30-50% compared to conventional lithium-ion batteries, making them particularly attractive for electric vehicle applications where range anxiety remains a primary consumer concern.

Market research indicates that automotive manufacturers are the primary drivers of demand for anode-free solid-state battery technology. Major OEMs including Toyota, Volkswagen, and BMW have made substantial investments in this technology, recognizing its potential to enable electric vehicles with 500+ mile ranges while reducing battery pack weight and volume. The premium electric vehicle segment is expected to be the first commercial application, with luxury automakers willing to absorb higher initial production costs.

Consumer electronics represents another promising market segment, with smartphone and laptop manufacturers exploring anode-free solid-state batteries to enable thinner devices with longer battery life. This segment values the enhanced safety profile of solid-state electrolytes, which eliminate the flammability concerns associated with liquid electrolytes in conventional batteries.

Significant market barriers remain, primarily centered around manufacturing scalability and formation protocol optimization. Current anode-free solid-state battery production costs exceed $500/kWh, substantially higher than conventional lithium-ion batteries at approximately $130/kWh. Industry analysts project that costs must decrease below $150/kWh to achieve mass-market adoption in automotive applications.

Regional market analysis reveals that Asia-Pacific currently dominates solid-state battery research and development, with Japan leading in patent filings related to anode-free technologies. North America and Europe are rapidly expanding their research initiatives, supported by government funding programs aimed at establishing domestic battery supply chains.

Market forecasts suggest that commercial deployment of anode-free solid-state batteries will begin with small-scale applications by 2023-2024, followed by premium electric vehicles by 2025-2026. Mass-market adoption is anticipated by 2028-2030, contingent upon successful development of scalable formation and conditioning protocols that enable consistent performance and longevity.

Technical Challenges in Anode-Free Formation Protocols

Anode-free solid-state battery formation protocols face significant technical challenges that must be addressed to enable commercial viability. The primary obstacle lies in controlling the initial lithium plating process during the first charge cycle, where lithium ions migrate from the cathode to form an in-situ anode. Uneven lithium deposition frequently leads to dendrite formation, which can penetrate the solid electrolyte, causing short circuits and catastrophic battery failure.

The solid-state electrolyte interface presents unique challenges compared to liquid electrolyte systems. The mechanical properties of the interface are critical, as insufficient contact between the newly formed lithium metal and the solid electrolyte creates voids that increase interfacial resistance. This resistance growth accelerates during cycling, severely limiting battery performance and longevity.

Temperature management during formation represents another significant hurdle. The formation protocol typically requires precise temperature control, as the process is highly temperature-dependent. Too low temperatures result in incomplete lithium migration, while excessive temperatures can trigger unwanted side reactions or damage the solid electrolyte structure. The narrow operational temperature window makes industrial-scale implementation particularly challenging.

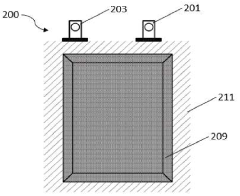

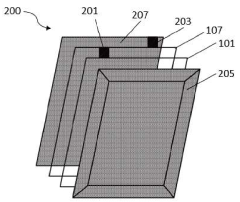

Pressure application during formation adds another layer of complexity. Insufficient pressure leads to poor interfacial contact, while excessive pressure may damage the solid electrolyte or cause mechanical deformation of cell components. Developing pressure protocols that can be uniformly applied across cells of different sizes presents significant engineering challenges.

Current density control during initial formation cycles is exceptionally difficult to optimize. High current densities accelerate the formation process but promote dendrite growth and uneven lithium deposition. Conversely, extremely low current densities, while producing more uniform lithium layers, extend formation time to commercially impractical durations, sometimes requiring days to complete.

The formation protocol must also address the challenge of electrolyte decomposition. Even with solid electrolytes, parasitic reactions occur at the newly formed lithium metal interface, consuming active lithium and creating resistive layers. These reactions are particularly problematic during the initial formation cycles when fresh lithium metal is continuously exposed to the electrolyte.

Scalability of laboratory-proven formation protocols to mass production environments represents perhaps the most significant commercialization barrier. Protocols that work effectively for small coin cells often fail when applied to larger pouch or prismatic cells due to non-uniform current distribution, thermal gradients, and pressure variations across larger cell geometries.

The solid-state electrolyte interface presents unique challenges compared to liquid electrolyte systems. The mechanical properties of the interface are critical, as insufficient contact between the newly formed lithium metal and the solid electrolyte creates voids that increase interfacial resistance. This resistance growth accelerates during cycling, severely limiting battery performance and longevity.

Temperature management during formation represents another significant hurdle. The formation protocol typically requires precise temperature control, as the process is highly temperature-dependent. Too low temperatures result in incomplete lithium migration, while excessive temperatures can trigger unwanted side reactions or damage the solid electrolyte structure. The narrow operational temperature window makes industrial-scale implementation particularly challenging.

Pressure application during formation adds another layer of complexity. Insufficient pressure leads to poor interfacial contact, while excessive pressure may damage the solid electrolyte or cause mechanical deformation of cell components. Developing pressure protocols that can be uniformly applied across cells of different sizes presents significant engineering challenges.

Current density control during initial formation cycles is exceptionally difficult to optimize. High current densities accelerate the formation process but promote dendrite growth and uneven lithium deposition. Conversely, extremely low current densities, while producing more uniform lithium layers, extend formation time to commercially impractical durations, sometimes requiring days to complete.

The formation protocol must also address the challenge of electrolyte decomposition. Even with solid electrolytes, parasitic reactions occur at the newly formed lithium metal interface, consuming active lithium and creating resistive layers. These reactions are particularly problematic during the initial formation cycles when fresh lithium metal is continuously exposed to the electrolyte.

Scalability of laboratory-proven formation protocols to mass production environments represents perhaps the most significant commercialization barrier. Protocols that work effectively for small coin cells often fail when applied to larger pouch or prismatic cells due to non-uniform current distribution, thermal gradients, and pressure variations across larger cell geometries.

Current Formation and Conditioning Methodologies

01 Initial formation protocols for anode-free solid-state batteries

Initial formation protocols for anode-free solid-state batteries involve specific procedures to establish the first lithium metal layer at the anode current collector interface. These protocols typically include controlled initial charging rates, temperature conditions, and pressure applications to ensure uniform lithium deposition. The formation process is critical as it establishes the foundation for subsequent battery performance, influencing the solid electrolyte interphase (SEI) formation and initial lithium morphology.- Lithium metal deposition protocols for anode-free batteries: Specific protocols for controlled lithium metal deposition in anode-free solid-state batteries involve precise current density control, temperature management, and step-wise formation cycles. These protocols enable uniform lithium plating on current collectors, reducing dendrite formation and improving cycling stability. The formation process typically includes initial low-current conditioning steps followed by gradually increasing current densities to establish stable solid electrolyte interphase (SEI) layers.

- Solid electrolyte interface engineering for anode-free batteries: Engineering stable solid electrolyte interfaces (SEI) is critical for anode-free solid-state batteries. Formation protocols incorporate additives, protective coatings, or specialized electrolyte formulations to create robust interfaces between the deposited lithium and solid electrolyte. Conditioning cycles with specific voltage limits and rest periods allow for SEI maturation, reducing impedance growth and preventing electrolyte decomposition during subsequent cycling.

- Temperature-controlled formation techniques: Temperature management during formation and conditioning is essential for anode-free solid-state batteries. Elevated temperature protocols (typically 40-60°C) during initial cycles facilitate ion transport through solid electrolytes and promote uniform lithium deposition. Controlled temperature gradients and thermal cycling can be employed to optimize interface formation, reduce internal resistance, and enhance overall battery performance and longevity.

- Pressure-assisted conditioning methods: Applying controlled pressure during formation and conditioning improves solid-state battery performance by enhancing interfacial contact between components. Pressure-assisted protocols maintain intimate contact between the cathode, solid electrolyte, and in-situ formed lithium anode, reducing interfacial resistance. These methods often involve specialized cell fixtures that apply uniform pressure during initial cycles, with pressure profiles optimized based on electrolyte composition and cell design.

- Multi-stage cycling protocols for performance optimization: Multi-stage cycling protocols optimize anode-free solid-state battery performance through carefully sequenced formation steps. These protocols typically begin with low-rate partial capacity cycles followed by progressively deeper discharge/charge cycles at increasing rates. Rest periods between stages allow for system equilibration and stress relaxation. Advanced protocols may incorporate pulse charging/discharging techniques to improve lithium distribution and minimize concentration gradients across the solid electrolyte.

02 Cycling and conditioning methods for performance optimization

Specific cycling and conditioning methods are employed to optimize the performance of anode-free solid-state batteries. These methods include graduated cycling protocols with progressively increasing current densities, rest periods between cycles, and controlled temperature environments. Such conditioning helps to stabilize the lithium-electrolyte interface, improve coulombic efficiency, and extend cycle life by promoting more uniform lithium deposition and stripping during subsequent cycles.Expand Specific Solutions03 Pressure application techniques during battery operation

Pressure application techniques play a crucial role in anode-free solid-state battery operation. Controlled stack pressure during formation and cycling helps maintain intimate contact between the lithium metal and solid electrolyte, reducing interfacial resistance and preventing void formation. Various pressure application methods, including mechanical compression systems and elastic interlayers, are used to optimize the pressure distribution and accommodate volume changes during cycling.Expand Specific Solutions04 Temperature management strategies for formation and cycling

Temperature management strategies are essential for proper formation and cycling of anode-free solid-state batteries. Elevated temperatures during initial formation can enhance ionic conductivity and promote uniform lithium deposition, while controlled temperature gradients during cycling can prevent dendrite formation. Thermal management systems are designed to maintain optimal operating temperatures and prevent localized heating that could lead to electrolyte degradation or thermal runaway.Expand Specific Solutions05 Electrolyte interface stabilization techniques

Electrolyte interface stabilization techniques are critical for anode-free solid-state batteries to ensure long-term performance. These include the use of interface engineering approaches such as protective coatings on current collectors, electrolyte additives that promote favorable SEI formation, and gradient electrolyte structures. Pre-conditioning treatments may also be applied to the solid electrolyte to improve its compatibility with in-situ formed lithium metal and reduce interfacial resistance during battery operation.Expand Specific Solutions

Leading Companies in Anode-Free Battery Development

The anode-free solid-state battery formation and conditioning protocols market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global solid-state battery market is projected to reach $8-10 billion by 2030, with anode-free technologies representing a promising segment due to their potential for higher energy density. Technical maturity varies across key players: automotive companies like GM Global Technology and Hyundai are advancing practical applications, while specialized battery developers such as Sion Power and LionVolt are pioneering innovative approaches. Research institutions including Georgia Tech and Chinese Academy of Science are contributing fundamental breakthroughs, while established materials companies like Applied Materials and BASF are developing manufacturing solutions to bridge laboratory success with commercial viability.

Chinese Academy of Science Institute of Chemistry

Technical Solution: The Chinese Academy of Science Institute of Chemistry has developed advanced anode-free solid-state battery systems utilizing gradient-structured solid electrolytes. Their approach focuses on creating engineered interfaces that facilitate controlled lithium deposition during initial formation. Their research has demonstrated that tailored solid electrolyte compositions with gradually changing mechanical and electrochemical properties can guide lithium ion transport and deposition patterns. Their conditioning protocols incorporate multi-stage formation processes with precisely controlled temperature gradients and current densities to establish stable interfaces. The Institute has pioneered the use of artificial intelligence algorithms to optimize formation protocols based on electrochemical impedance spectroscopy feedback during initial cycles, allowing for adaptive conditioning that responds to individual cell characteristics and variations in manufacturing.

Strengths: Gradient-structured electrolytes provide superior control over lithium deposition; AI-optimized formation protocols improve consistency; fundamental research approach addresses underlying mechanisms. Weaknesses: Complex electrolyte synthesis may limit scalability; requires sophisticated control systems for formation; longer formation times compared to conventional approaches.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed proprietary anode-free solid-state battery technology leveraging their expertise in ceramic materials and electronic components. Their approach utilizes specialized ceramic-polymer composite electrolytes with engineered grain boundaries that facilitate controlled lithium transport during formation. Murata's conditioning protocols focus on establishing stable interfaces through carefully controlled initial cycles with gradually increasing depth of discharge. Their technology incorporates specialized current collectors with nanoscale surface texturing that creates preferred nucleation sites for initial lithium deposition, promoting more uniform anode formation. Murata has also developed advanced sensing and monitoring systems integrated directly into their battery cells that provide real-time feedback during formation, allowing for precise control of the process. Their formation protocols include temperature-controlled stages that optimize electrolyte-lithium interactions during critical initial cycles.

Strengths: Leverages Murata's expertise in ceramic materials; integrated sensing enables precise formation control; engineered current collectors promote uniform lithium deposition. Weaknesses: Higher manufacturing complexity due to specialized components; requires precise temperature control during formation; may face challenges with scaling to larger format cells.

Key Patents in Anode-Free Solid-State Battery Formation

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

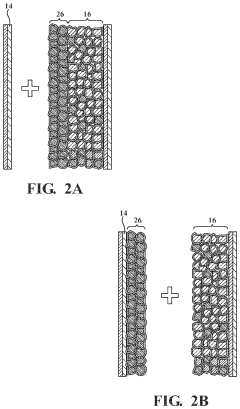

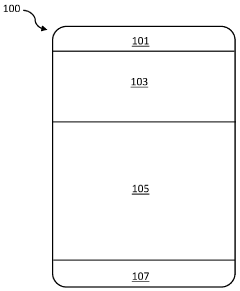

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

An anode-free solid-state battery and a method of making the same

PatentPendingIN202141047217A

Innovation

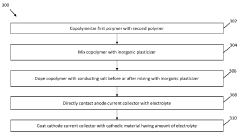

- An anode-free solid-state battery design utilizing a solid polymer electrolyte composed of a copolymer of polyvinylidene fluoride-co-hexafluoropropylene and methoxy poly(ethylene glycol) acrylate, doped with a conducting salt and an inorganic plasticizer, which is coated on both the anode and cathode current collectors to enhance ionic conductivity and stability.

Safety and Performance Validation Standards

The development of safety and performance validation standards for anode-free solid-state batteries represents a critical frontier in battery technology advancement. Current validation protocols designed for conventional lithium-ion batteries prove inadequate for anode-free solid-state configurations due to their unique formation mechanisms and failure modes. Establishing comprehensive standards requires addressing both safety concerns and performance metrics specific to this emerging technology.

Safety validation for anode-free solid-state batteries must account for their distinctive thermal behavior during lithium plating processes. Standard tests need modification to evaluate thermal runaway risks under conditions that specifically challenge solid electrolyte interfaces during formation cycles. Mechanical integrity testing becomes particularly important as lithium deposition can create pressure gradients that conventional battery safety standards fail to address.

Electrochemical safety parameters require redefinition, with particular attention to voltage limits during initial formation cycles when lithium is first deposited onto the current collector. Industry stakeholders, including UL, IEC, and ISO, are currently developing specialized testing protocols that incorporate extended voltage hold periods and modified cycling parameters to ensure safe lithium deposition patterns.

Performance validation standards must establish benchmarks for initial capacity achievement during formation protocols. Unlike conventional batteries, anode-free systems require metrics that account for the efficiency of in-situ anode formation, with standards defining acceptable ranges for first-cycle coulombic efficiency and capacity retention after formation. These metrics directly correlate with the quality of the formed lithium layer.

Cycle life validation presents unique challenges, necessitating standardized protocols that distinguish between degradation from normal cycling versus inadequate initial formation. Accelerated testing methodologies must be recalibrated to account for the distinctive aging mechanisms in solid-state systems, particularly those related to lithium/electrolyte interface evolution over time.

Regulatory bodies and industry consortia are working to establish minimum performance thresholds specific to anode-free technologies. These include standards for formation cycle duration, temperature profiles during conditioning, and acceptable impedance growth rates. The Battery Standards Consortium has proposed draft guidelines requiring anode-free cells to maintain at least 80% capacity retention after standardized formation protocols before qualifying for further validation testing.

Harmonization of these emerging standards across international markets remains challenging, with European, Asian, and North American regulatory frameworks taking different approaches to validation requirements. This fragmentation creates compliance challenges for manufacturers developing anode-free technologies for global markets, highlighting the need for coordinated international standardization efforts.

Safety validation for anode-free solid-state batteries must account for their distinctive thermal behavior during lithium plating processes. Standard tests need modification to evaluate thermal runaway risks under conditions that specifically challenge solid electrolyte interfaces during formation cycles. Mechanical integrity testing becomes particularly important as lithium deposition can create pressure gradients that conventional battery safety standards fail to address.

Electrochemical safety parameters require redefinition, with particular attention to voltage limits during initial formation cycles when lithium is first deposited onto the current collector. Industry stakeholders, including UL, IEC, and ISO, are currently developing specialized testing protocols that incorporate extended voltage hold periods and modified cycling parameters to ensure safe lithium deposition patterns.

Performance validation standards must establish benchmarks for initial capacity achievement during formation protocols. Unlike conventional batteries, anode-free systems require metrics that account for the efficiency of in-situ anode formation, with standards defining acceptable ranges for first-cycle coulombic efficiency and capacity retention after formation. These metrics directly correlate with the quality of the formed lithium layer.

Cycle life validation presents unique challenges, necessitating standardized protocols that distinguish between degradation from normal cycling versus inadequate initial formation. Accelerated testing methodologies must be recalibrated to account for the distinctive aging mechanisms in solid-state systems, particularly those related to lithium/electrolyte interface evolution over time.

Regulatory bodies and industry consortia are working to establish minimum performance thresholds specific to anode-free technologies. These include standards for formation cycle duration, temperature profiles during conditioning, and acceptable impedance growth rates. The Battery Standards Consortium has proposed draft guidelines requiring anode-free cells to maintain at least 80% capacity retention after standardized formation protocols before qualifying for further validation testing.

Harmonization of these emerging standards across international markets remains challenging, with European, Asian, and North American regulatory frameworks taking different approaches to validation requirements. This fragmentation creates compliance challenges for manufacturers developing anode-free technologies for global markets, highlighting the need for coordinated international standardization efforts.

Scalability and Manufacturing Considerations

The scalability of anode-free solid-state battery manufacturing represents a critical challenge for commercialization. Current laboratory-scale formation and conditioning protocols typically involve time-intensive processes that may extend from several hours to multiple days, creating significant bottlenecks for mass production. These protocols must be substantially accelerated and optimized to achieve economically viable manufacturing throughput while maintaining electrochemical performance and safety standards.

Manufacturing considerations for anode-free solid-state batteries differ fundamentally from conventional lithium-ion batteries due to the absence of a pre-deposited anode. The in-situ formation of the lithium metal anode during initial charging requires precise control of environmental conditions, particularly moisture and oxygen levels below 1 ppm. This necessitates specialized dry room facilities or inert atmosphere processing lines, significantly increasing capital expenditure requirements compared to conventional battery production.

Equipment compatibility presents another significant challenge. The formation and conditioning protocols for anode-free solid-state batteries often require specialized cycling equipment capable of precise current control, temperature regulation, and pressure application. Existing battery manufacturing infrastructure may require substantial modification or replacement to accommodate these requirements, creating additional barriers to rapid scaling.

Process integration complexity further complicates manufacturing scalability. The sequential steps of solid electrolyte preparation, cathode composite formation, cell assembly, and conditioning must be seamlessly integrated into a continuous production flow. Current discontinuities between these processes create inefficiencies that must be addressed through innovative manufacturing approaches, potentially including roll-to-roll processing for solid electrolyte components and automated assembly systems specifically designed for solid-state architectures.

Quality control methodologies for anode-free systems require development of new in-line monitoring techniques. Non-destructive evaluation methods such as ultrasonic inspection, impedance spectroscopy, and optical analysis must be adapted to verify proper lithium deposition patterns during formation. The absence of visual indicators that exist in conventional battery manufacturing necessitates development of novel quality assurance protocols specific to anode-free technologies.

Cost modeling indicates that while material costs may eventually decrease through economies of scale, the specialized equipment and processing requirements for formation and conditioning will remain significant contributors to overall manufacturing expenses. Economic viability will depend on developing formation protocols that balance performance optimization with manufacturing efficiency, potentially accepting minor performance trade-offs to achieve substantial reductions in processing time and complexity.

Manufacturing considerations for anode-free solid-state batteries differ fundamentally from conventional lithium-ion batteries due to the absence of a pre-deposited anode. The in-situ formation of the lithium metal anode during initial charging requires precise control of environmental conditions, particularly moisture and oxygen levels below 1 ppm. This necessitates specialized dry room facilities or inert atmosphere processing lines, significantly increasing capital expenditure requirements compared to conventional battery production.

Equipment compatibility presents another significant challenge. The formation and conditioning protocols for anode-free solid-state batteries often require specialized cycling equipment capable of precise current control, temperature regulation, and pressure application. Existing battery manufacturing infrastructure may require substantial modification or replacement to accommodate these requirements, creating additional barriers to rapid scaling.

Process integration complexity further complicates manufacturing scalability. The sequential steps of solid electrolyte preparation, cathode composite formation, cell assembly, and conditioning must be seamlessly integrated into a continuous production flow. Current discontinuities between these processes create inefficiencies that must be addressed through innovative manufacturing approaches, potentially including roll-to-roll processing for solid electrolyte components and automated assembly systems specifically designed for solid-state architectures.

Quality control methodologies for anode-free systems require development of new in-line monitoring techniques. Non-destructive evaluation methods such as ultrasonic inspection, impedance spectroscopy, and optical analysis must be adapted to verify proper lithium deposition patterns during formation. The absence of visual indicators that exist in conventional battery manufacturing necessitates development of novel quality assurance protocols specific to anode-free technologies.

Cost modeling indicates that while material costs may eventually decrease through economies of scale, the specialized equipment and processing requirements for formation and conditioning will remain significant contributors to overall manufacturing expenses. Economic viability will depend on developing formation protocols that balance performance optimization with manufacturing efficiency, potentially accepting minor performance trade-offs to achieve substantial reductions in processing time and complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!