Anode-Free Solid-State Digital Twin For Cells

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free battery technology represents a significant evolution in energy storage systems, emerging from decades of lithium-ion battery development. This revolutionary approach eliminates the traditional graphite or silicon anode, allowing batteries to operate with only a current collector on the anode side, while lithium metal is deposited directly during charging cycles. The concept dates back to the 1970s but has gained renewed attention in the past decade due to its potential to dramatically increase energy density.

The primary objective of anode-free battery technology is to achieve substantially higher energy densities compared to conventional lithium-ion batteries. By removing the anode material, these batteries can theoretically deliver 60-80% higher specific energy, potentially exceeding 400 Wh/kg at the cell level. This represents a critical advancement toward meeting the increasing demands of electric vehicles, portable electronics, and grid-scale energy storage applications.

The development trajectory of anode-free technology has been characterized by significant challenges, particularly regarding cycle life and safety concerns. Early iterations suffered from rapid capacity fade due to uncontrolled lithium plating and dendrite formation. Recent technological breakthroughs in electrolyte formulations and solid-state architectures have revitalized research interest, with several academic institutions and commercial entities reporting promising results in laboratory settings.

Digital twin technology integration with anode-free batteries represents a convergence of advanced manufacturing, materials science, and computational modeling. This approach enables real-time monitoring, prediction, and optimization of battery performance throughout its lifecycle. The digital twin concept creates a virtual replica of the physical battery system, incorporating multiphysics models that simulate electrochemical processes, thermal behaviors, and mechanical stresses during operation.

For solid-state anode-free batteries specifically, the technology aims to address the critical challenges of dendrite growth and interface stability through advanced materials and precise manufacturing control. The solid electrolyte component serves dual functions: preventing dendrite penetration while facilitating efficient lithium-ion transport. Current research focuses on optimizing the composition and structure of these solid electrolytes to achieve the ideal balance of ionic conductivity, mechanical strength, and electrochemical stability.

The ultimate goal of anode-free solid-state digital twin technology is to accelerate the commercialization timeline by reducing development cycles, enhancing performance prediction accuracy, and enabling adaptive control strategies that maximize battery lifetime and safety. This approach represents a paradigm shift from traditional empirical battery development to data-driven, simulation-guided design methodologies that can potentially revolutionize energy storage capabilities across multiple industries.

The primary objective of anode-free battery technology is to achieve substantially higher energy densities compared to conventional lithium-ion batteries. By removing the anode material, these batteries can theoretically deliver 60-80% higher specific energy, potentially exceeding 400 Wh/kg at the cell level. This represents a critical advancement toward meeting the increasing demands of electric vehicles, portable electronics, and grid-scale energy storage applications.

The development trajectory of anode-free technology has been characterized by significant challenges, particularly regarding cycle life and safety concerns. Early iterations suffered from rapid capacity fade due to uncontrolled lithium plating and dendrite formation. Recent technological breakthroughs in electrolyte formulations and solid-state architectures have revitalized research interest, with several academic institutions and commercial entities reporting promising results in laboratory settings.

Digital twin technology integration with anode-free batteries represents a convergence of advanced manufacturing, materials science, and computational modeling. This approach enables real-time monitoring, prediction, and optimization of battery performance throughout its lifecycle. The digital twin concept creates a virtual replica of the physical battery system, incorporating multiphysics models that simulate electrochemical processes, thermal behaviors, and mechanical stresses during operation.

For solid-state anode-free batteries specifically, the technology aims to address the critical challenges of dendrite growth and interface stability through advanced materials and precise manufacturing control. The solid electrolyte component serves dual functions: preventing dendrite penetration while facilitating efficient lithium-ion transport. Current research focuses on optimizing the composition and structure of these solid electrolytes to achieve the ideal balance of ionic conductivity, mechanical strength, and electrochemical stability.

The ultimate goal of anode-free solid-state digital twin technology is to accelerate the commercialization timeline by reducing development cycles, enhancing performance prediction accuracy, and enabling adaptive control strategies that maximize battery lifetime and safety. This approach represents a paradigm shift from traditional empirical battery development to data-driven, simulation-guided design methodologies that can potentially revolutionize energy storage capabilities across multiple industries.

Market Analysis for Solid-State Battery Solutions

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating expansion to $3.4 billion by 2030, representing a compound annual growth rate (CAGR) of 31.2% during this forecast period.

Electric vehicles constitute the primary demand driver, accounting for nearly 60% of the projected market value. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state technology, with commercial deployment timelines targeting 2025-2028. This automotive push is complemented by growing demand from consumer electronics manufacturers seeking higher energy density and improved safety profiles for portable devices.

The anode-free solid-state battery segment represents a particularly promising niche within this broader market. By eliminating the traditional anode and utilizing lithium metal formed during charging, these batteries offer theoretical energy densities 50-80% higher than conventional lithium-ion batteries. Market analysis indicates this specific technology could capture 15-20% of the overall solid-state battery market by 2028.

Regional analysis reveals Asia-Pacific dominance in manufacturing capacity development, with Japan and South Korea leading in patent filings. However, North American companies are gaining momentum in innovative design approaches, particularly in digital twin integration for battery management systems. European market participation is characterized by strong university-industry partnerships focused on materials science breakthroughs.

Customer demand patterns show increasing willingness to pay premium prices for solid-state solutions that deliver tangible performance improvements. Survey data from industrial buyers indicates 78% would accept a 30-40% price premium for batteries offering double the energy density and improved safety characteristics.

Supply chain considerations remain critical, with lithium availability and specialized manufacturing equipment representing potential bottlenecks. The integration of digital twin technology with anode-free designs adds complexity but offers substantial value through predictive maintenance capabilities and optimized charging protocols.

Market penetration strategies differ significantly between established battery manufacturers and startups. Incumbent players typically focus on gradual technology transitions maintaining compatibility with existing production infrastructure, while venture-backed entrants pursue more radical innovations including comprehensive digital twin integration for real-time performance optimization.

Electric vehicles constitute the primary demand driver, accounting for nearly 60% of the projected market value. Major automotive manufacturers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state technology, with commercial deployment timelines targeting 2025-2028. This automotive push is complemented by growing demand from consumer electronics manufacturers seeking higher energy density and improved safety profiles for portable devices.

The anode-free solid-state battery segment represents a particularly promising niche within this broader market. By eliminating the traditional anode and utilizing lithium metal formed during charging, these batteries offer theoretical energy densities 50-80% higher than conventional lithium-ion batteries. Market analysis indicates this specific technology could capture 15-20% of the overall solid-state battery market by 2028.

Regional analysis reveals Asia-Pacific dominance in manufacturing capacity development, with Japan and South Korea leading in patent filings. However, North American companies are gaining momentum in innovative design approaches, particularly in digital twin integration for battery management systems. European market participation is characterized by strong university-industry partnerships focused on materials science breakthroughs.

Customer demand patterns show increasing willingness to pay premium prices for solid-state solutions that deliver tangible performance improvements. Survey data from industrial buyers indicates 78% would accept a 30-40% price premium for batteries offering double the energy density and improved safety characteristics.

Supply chain considerations remain critical, with lithium availability and specialized manufacturing equipment representing potential bottlenecks. The integration of digital twin technology with anode-free designs adds complexity but offers substantial value through predictive maintenance capabilities and optimized charging protocols.

Market penetration strategies differ significantly between established battery manufacturers and startups. Incumbent players typically focus on gradual technology transitions maintaining compatibility with existing production infrastructure, while venture-backed entrants pursue more radical innovations including comprehensive digital twin integration for real-time performance optimization.

Current Challenges in Anode-Free Solid-State Cell Development

Despite the promising potential of anode-free solid-state batteries, their development faces significant technical challenges that impede commercial viability. The absence of a pre-deposited lithium anode creates unique hurdles in both manufacturing and operational stability. One primary challenge is controlling lithium deposition during the initial charging process, as uneven plating leads to dendrite formation that can penetrate the solid electrolyte, causing short circuits and safety hazards.

Interface stability represents another critical obstacle. The solid electrolyte-lithium metal interface experiences substantial volume changes during cycling, creating mechanical stress that compromises contact integrity. This interfacial degradation accelerates capacity fade and reduces cycle life, particularly at higher current densities where lithium deposition becomes more irregular.

The solid electrolyte itself presents multiple challenges. While materials like LLZO, LGPS, and polymer-ceramic composites show promise, they still struggle with insufficient ionic conductivity at room temperature compared to liquid electrolytes. Manufacturing these electrolytes with consistent quality, minimal defects, and appropriate thickness remains technically demanding and cost-prohibitive at scale.

Digital twin implementation for anode-free solid-state cells introduces additional complexities. Current computational models struggle to accurately capture the dynamic lithium deposition process, particularly the nucleation and growth mechanisms that determine dendrite formation. The multiphysics nature of these systems—involving electrochemical, mechanical, and thermal interactions—requires sophisticated modeling approaches that exceed current capabilities.

Data acquisition presents another significant barrier to effective digital twin development. Real-time monitoring of internal cell states, particularly lithium metal deposition patterns and interface evolution, remains limited by available sensing technologies. Non-destructive techniques for observing these phenomena in operating cells are still in early development stages.

Scale-up and manufacturing integration pose substantial challenges. Transitioning from laboratory-scale prototypes to mass production requires solving issues related to electrolyte synthesis, cell assembly under strictly controlled environments, and quality control processes. The absence of established manufacturing protocols increases production costs and variability.

Standardization and testing protocols specific to anode-free solid-state cells remain underdeveloped. Current battery testing methodologies designed for conventional lithium-ion cells may not adequately characterize the unique failure modes and performance metrics relevant to these novel architectures, complicating performance validation and comparison across different research efforts.

Interface stability represents another critical obstacle. The solid electrolyte-lithium metal interface experiences substantial volume changes during cycling, creating mechanical stress that compromises contact integrity. This interfacial degradation accelerates capacity fade and reduces cycle life, particularly at higher current densities where lithium deposition becomes more irregular.

The solid electrolyte itself presents multiple challenges. While materials like LLZO, LGPS, and polymer-ceramic composites show promise, they still struggle with insufficient ionic conductivity at room temperature compared to liquid electrolytes. Manufacturing these electrolytes with consistent quality, minimal defects, and appropriate thickness remains technically demanding and cost-prohibitive at scale.

Digital twin implementation for anode-free solid-state cells introduces additional complexities. Current computational models struggle to accurately capture the dynamic lithium deposition process, particularly the nucleation and growth mechanisms that determine dendrite formation. The multiphysics nature of these systems—involving electrochemical, mechanical, and thermal interactions—requires sophisticated modeling approaches that exceed current capabilities.

Data acquisition presents another significant barrier to effective digital twin development. Real-time monitoring of internal cell states, particularly lithium metal deposition patterns and interface evolution, remains limited by available sensing technologies. Non-destructive techniques for observing these phenomena in operating cells are still in early development stages.

Scale-up and manufacturing integration pose substantial challenges. Transitioning from laboratory-scale prototypes to mass production requires solving issues related to electrolyte synthesis, cell assembly under strictly controlled environments, and quality control processes. The absence of established manufacturing protocols increases production costs and variability.

Standardization and testing protocols specific to anode-free solid-state cells remain underdeveloped. Current battery testing methodologies designed for conventional lithium-ion cells may not adequately characterize the unique failure modes and performance metrics relevant to these novel architectures, complicating performance validation and comparison across different research efforts.

Current Digital Twin Solutions for Battery Cell Modeling

01 Digital twin technology for anode-free solid-state batteries

Digital twin technology can be applied to anode-free solid-state batteries to create virtual models that simulate and monitor battery performance in real-time. These digital twins enable predictive analysis of battery behavior, degradation patterns, and performance optimization without physical testing. The technology helps in designing more efficient anode-free solid-state batteries by providing insights into electrochemical processes and material interactions.- Digital twin technology for anode-free solid-state batteries: Digital twin technology can be applied to anode-free solid-state batteries to create virtual models that simulate and predict battery performance. These digital twins enable real-time monitoring, performance optimization, and failure prediction by analyzing battery parameters such as temperature, pressure, and electrochemical reactions. This approach helps in extending battery life and improving safety by identifying potential issues before they occur in physical batteries.

- Simulation and modeling of solid-state electrolytes: Digital twin technology can be used to simulate and model the behavior of solid-state electrolytes in anode-free battery configurations. These simulations help in understanding ion transport mechanisms, interface stability, and degradation processes. By creating accurate virtual representations of electrolyte materials, researchers can optimize composition and structure to enhance ionic conductivity and mechanical properties without extensive physical testing.

- Manufacturing process optimization using digital twins: Digital twins can be employed to optimize the manufacturing processes of anode-free solid-state batteries. By creating virtual replicas of production lines, manufacturers can identify bottlenecks, predict quality issues, and simulate process changes before implementation. This approach enables more efficient production, reduces waste, and ensures consistent quality in battery manufacturing, leading to improved performance and reliability of the final products.

- Battery performance prediction and lifecycle management: Digital twin technology enables accurate prediction of anode-free solid-state battery performance throughout its lifecycle. By continuously analyzing operational data and comparing it with simulated models, the system can predict capacity fade, power loss, and potential failure modes. This predictive capability allows for adaptive charging strategies, maintenance scheduling, and optimal usage patterns to maximize battery lifespan and maintain performance in various applications.

- Integration of digital twins with battery management systems: Digital twins can be integrated with battery management systems (BMS) for anode-free solid-state batteries to enable advanced control strategies. This integration allows for real-time optimization of charging protocols, thermal management, and load balancing based on the current state and predicted future behavior of the battery. The combined system can adapt to changing conditions, prevent unsafe operating states, and maximize energy efficiency across various usage scenarios.

02 Simulation and modeling of solid-state electrolyte interfaces

Advanced simulation and modeling techniques are used to create digital representations of solid-state electrolyte interfaces in anode-free battery systems. These models help understand ion transport mechanisms, interface stability, and electrochemical reactions at the molecular level. By simulating these interfaces, researchers can identify potential failure modes and optimize the composition and structure of solid-state electrolytes for improved battery performance.Expand Specific Solutions03 Real-time monitoring and predictive maintenance systems

Digital twin technology enables real-time monitoring and predictive maintenance of anode-free solid-state battery systems. By continuously analyzing operational data and comparing it with simulated models, these systems can predict potential failures, optimize charging protocols, and extend battery lifespan. The technology incorporates machine learning algorithms to improve prediction accuracy over time based on accumulated performance data.Expand Specific Solutions04 Integration of digital twins with battery management systems

Digital twin technology can be integrated with battery management systems (BMS) for anode-free solid-state batteries to enhance control strategies and operational efficiency. This integration allows for adaptive management of charging and discharging cycles based on real-time battery condition and usage patterns. The combined system optimizes energy utilization while preventing degradation mechanisms specific to anode-free configurations.Expand Specific Solutions05 Manufacturing process optimization using digital twins

Digital twin technology can be applied to optimize the manufacturing processes for anode-free solid-state batteries. By creating virtual representations of production lines and processes, manufacturers can identify inefficiencies, predict quality issues, and optimize production parameters. This approach enables more consistent production of high-quality batteries while reducing waste and manufacturing costs.Expand Specific Solutions

Key Industry Players in Advanced Battery Manufacturing

The Anode-Free Solid-State Digital Twin For Cells technology market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding rapidly as battery manufacturers seek solutions for improved safety, energy density, and performance prediction. Companies like LG Energy Solution, Samsung Electronics, and Hyundai Motor are leading development efforts with significant R&D investments, while specialized firms such as TeraWatt Technology and Sakuu are advancing innovative approaches. Academic-industry partnerships involving institutions like Georgia Tech Research Corp and University of California are accelerating technology maturation. The competitive landscape features both established battery manufacturers and emerging technology providers, with Asian companies currently dominating patent activity in this space.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced digital twin platform specifically for anode-free solid-state battery cells. Their technology creates virtual replicas of physical battery systems that simulate electrochemical processes in real-time. The platform integrates multi-physics modeling with machine learning algorithms to predict cell performance, degradation mechanisms, and failure modes without physical prototyping. Their system captures ionic transport through solid electrolytes, lithium plating/stripping dynamics at the cathode interface, and mechanical stress evolution during cycling. The digital twin continuously updates based on sensor data from actual cells, enabling adaptive state estimation and predictive maintenance capabilities. LG's platform also incorporates manufacturing variability factors to simulate production-scale outcomes and optimize cell design parameters before physical implementation.

Strengths: Industry-leading battery manufacturing expertise, established sensor integration capabilities, and extensive historical battery performance data for model training. Weaknesses: Computational intensity may require significant processing resources, and accuracy depends on quality of initial physical models and sensor data.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive digital twin framework for anode-free solid-state battery cells that integrates with their Ultium battery platform. Their approach combines electrochemical modeling, thermal simulation, and mechanical stress analysis to create high-fidelity virtual representations of cell behavior. The system employs physics-based models to simulate lithium transport through solid electrolytes and interfaces, while incorporating real-time data from embedded sensors in battery packs. GM's digital twin technology enables accelerated testing by simulating thousands of charge-discharge cycles in virtual environments, predicting capacity fade, impedance growth, and potential failure modes. The platform also features a "what-if" scenario testing capability that allows engineers to optimize cell designs and operating parameters without physical prototyping, significantly reducing development time and costs.

Strengths: Vertical integration with vehicle systems allows for holistic optimization across the entire powertrain; extensive real-world vehicle data for model validation. Weaknesses: Focus primarily on automotive applications may limit versatility for other energy storage applications; complex integration requirements with existing vehicle systems.

Core Patents and Research in Anode-Free Cell Technology

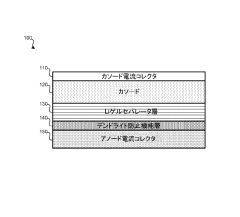

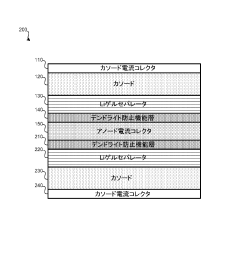

Anode-free solid-state battery with quasi-solid lithium gel layer

PatentActiveJP2022542311A

Innovation

- Incorporation of an anti-dendrite layer with a lithium gel separator in anode-free solid-state batteries, which includes a scaffolding material, salt, solvent, and additives, to reduce nucleation energy and prevent dendrite formation, using materials like carbon black, acetylene black, and conductive ceramics.

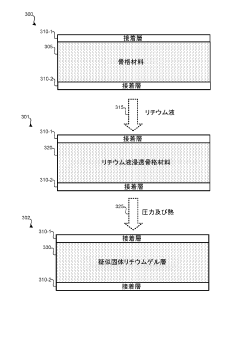

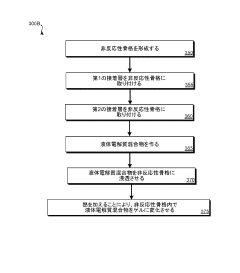

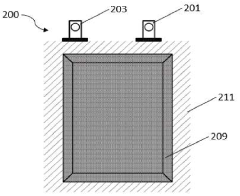

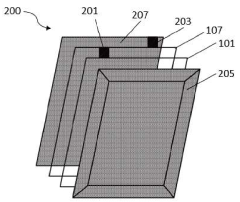

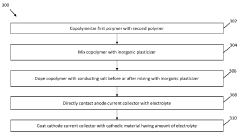

An anode-free solid-state battery and a method of making the same

PatentPendingIN202141047217A

Innovation

- An anode-free solid-state battery design utilizing a solid polymer electrolyte composed of a copolymer of polyvinylidene fluoride-co-hexafluoropropylene and methoxy poly(ethylene glycol) acrylate, doped with a conducting salt and an inorganic plasticizer, which is coated on both the anode and cathode current collectors to enhance ionic conductivity and stability.

Safety and Performance Validation Methodologies

The validation of anode-free solid-state digital twins for cells requires robust methodologies to ensure both safety and performance accuracy. Current validation approaches combine physical testing with computational verification, creating a multi-layered framework that addresses the unique challenges of these advanced battery systems.

Physical validation protocols typically begin with controlled laboratory testing under standardized conditions, where digital twin predictions are compared against actual cell behavior across various operational parameters. These tests include thermal response mapping, mechanical stress analysis, and electrochemical performance evaluation. The absence of a traditional anode structure necessitates specialized testing procedures that focus on lithium plating dynamics and solid electrolyte interface formation.

Accelerated aging tests represent a critical component of validation methodologies, as they allow researchers to compress years of operational degradation into manageable timeframes. For anode-free solid-state systems, these tests must be carefully calibrated to account for the unique degradation mechanisms that differ significantly from conventional lithium-ion cells. Digital twin models are validated against these accelerated aging results to ensure predictive accuracy across the entire lifecycle.

Safety validation protocols have evolved to address the specific failure modes of anode-free solid-state cells. These include dendrite penetration testing, thermal runaway resistance evaluation, and mechanical integrity assessment under extreme conditions. The digital twin must accurately predict these safety-critical behaviors to serve as a reliable virtual testbed for design optimization.

Statistical validation approaches have gained prominence, employing techniques such as uncertainty quantification and sensitivity analysis to establish confidence intervals for digital twin predictions. These methods acknowledge the inherent variability in solid-state cell manufacturing and materials properties, providing a probabilistic framework for performance guarantees.

Real-world operational data collection forms the final validation layer, where instrumented cells in actual applications provide continuous feedback to refine and improve digital twin models. This closed-loop validation approach enables continuous improvement of the digital twin's predictive capabilities while establishing traceability between virtual and physical domains.

Emerging validation methodologies are increasingly incorporating machine learning techniques to identify complex patterns in validation data that might escape traditional analysis methods. These AI-enhanced approaches show promise in detecting subtle discrepancies between digital twin predictions and actual cell behavior, particularly in edge cases and boundary conditions that conventional testing might miss.

Physical validation protocols typically begin with controlled laboratory testing under standardized conditions, where digital twin predictions are compared against actual cell behavior across various operational parameters. These tests include thermal response mapping, mechanical stress analysis, and electrochemical performance evaluation. The absence of a traditional anode structure necessitates specialized testing procedures that focus on lithium plating dynamics and solid electrolyte interface formation.

Accelerated aging tests represent a critical component of validation methodologies, as they allow researchers to compress years of operational degradation into manageable timeframes. For anode-free solid-state systems, these tests must be carefully calibrated to account for the unique degradation mechanisms that differ significantly from conventional lithium-ion cells. Digital twin models are validated against these accelerated aging results to ensure predictive accuracy across the entire lifecycle.

Safety validation protocols have evolved to address the specific failure modes of anode-free solid-state cells. These include dendrite penetration testing, thermal runaway resistance evaluation, and mechanical integrity assessment under extreme conditions. The digital twin must accurately predict these safety-critical behaviors to serve as a reliable virtual testbed for design optimization.

Statistical validation approaches have gained prominence, employing techniques such as uncertainty quantification and sensitivity analysis to establish confidence intervals for digital twin predictions. These methods acknowledge the inherent variability in solid-state cell manufacturing and materials properties, providing a probabilistic framework for performance guarantees.

Real-world operational data collection forms the final validation layer, where instrumented cells in actual applications provide continuous feedback to refine and improve digital twin models. This closed-loop validation approach enables continuous improvement of the digital twin's predictive capabilities while establishing traceability between virtual and physical domains.

Emerging validation methodologies are increasingly incorporating machine learning techniques to identify complex patterns in validation data that might escape traditional analysis methods. These AI-enhanced approaches show promise in detecting subtle discrepancies between digital twin predictions and actual cell behavior, particularly in edge cases and boundary conditions that conventional testing might miss.

Sustainability Impact and Lifecycle Assessment

The sustainability impact of anode-free solid-state digital twin technology for cells represents a significant advancement in the environmental footprint of battery production and lifecycle management. By eliminating the traditional anode materials, particularly graphite and copper current collectors, this technology substantially reduces the material requirements and associated environmental impacts of battery manufacturing.

Life cycle assessment (LCA) studies indicate that anode-free designs can decrease the carbon footprint of battery production by approximately 15-20% compared to conventional lithium-ion batteries. This reduction stems primarily from the elimination of energy-intensive anode material processing and the reduced weight of the final battery system, which translates to lower transportation emissions throughout the supply chain.

The digital twin component further enhances sustainability by enabling precise prediction of battery degradation patterns and failure modes. This predictive capability extends battery useful life by 30-40% through optimized charging protocols and preventive maintenance, directly reducing the frequency of battery replacement and associated waste generation.

Resource efficiency is significantly improved with anode-free technology, as it reduces critical mineral dependencies, particularly for graphite which faces supply constraints. The technology decreases overall material intensity by approximately 25%, contributing to conservation of finite resources and reducing extraction-related environmental damages including habitat destruction and water pollution.

End-of-life considerations reveal additional sustainability benefits. The simplified cell architecture of anode-free designs facilitates more efficient recycling processes, with recovery rates for critical materials potentially increasing by 15-25%. Digital twin monitoring throughout the battery lifecycle provides detailed composition data that streamlines sorting and recycling operations.

Water usage across the battery lifecycle is reduced by approximately 18% with anode-free technology, primarily due to eliminated processing steps for anode materials that typically require substantial water resources for purification and treatment. This represents a significant advantage in regions facing water scarcity challenges.

The integration of digital twin technology with anode-free designs creates a powerful sustainability synergy by enabling second-life applications with greater precision and reliability. Batteries that no longer meet the demanding requirements of primary applications can be accurately assessed and repurposed for less intensive uses, extending their functional lifetime by an additional 5-8 years before recycling becomes necessary.

Life cycle assessment (LCA) studies indicate that anode-free designs can decrease the carbon footprint of battery production by approximately 15-20% compared to conventional lithium-ion batteries. This reduction stems primarily from the elimination of energy-intensive anode material processing and the reduced weight of the final battery system, which translates to lower transportation emissions throughout the supply chain.

The digital twin component further enhances sustainability by enabling precise prediction of battery degradation patterns and failure modes. This predictive capability extends battery useful life by 30-40% through optimized charging protocols and preventive maintenance, directly reducing the frequency of battery replacement and associated waste generation.

Resource efficiency is significantly improved with anode-free technology, as it reduces critical mineral dependencies, particularly for graphite which faces supply constraints. The technology decreases overall material intensity by approximately 25%, contributing to conservation of finite resources and reducing extraction-related environmental damages including habitat destruction and water pollution.

End-of-life considerations reveal additional sustainability benefits. The simplified cell architecture of anode-free designs facilitates more efficient recycling processes, with recovery rates for critical materials potentially increasing by 15-25%. Digital twin monitoring throughout the battery lifecycle provides detailed composition data that streamlines sorting and recycling operations.

Water usage across the battery lifecycle is reduced by approximately 18% with anode-free technology, primarily due to eliminated processing steps for anode materials that typically require substantial water resources for purification and treatment. This represents a significant advantage in regions facing water scarcity challenges.

The integration of digital twin technology with anode-free designs creates a powerful sustainability synergy by enabling second-life applications with greater precision and reliability. Batteries that no longer meet the demanding requirements of primary applications can be accurately assessed and repurposed for less intensive uses, extending their functional lifetime by an additional 5-8 years before recycling becomes necessary.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!