Stack Pressure And Mechanics In Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Solid-state batteries (SSBs) represent a significant advancement in energy storage technology, offering potential improvements in safety, energy density, and lifespan compared to conventional lithium-ion batteries. Within this domain, anode-free solid-state batteries have emerged as a particularly promising configuration that maximizes energy density by eliminating the traditional anode host material, instead utilizing lithium metal deposited directly during battery operation.

The evolution of battery technology has progressed from early primary batteries to rechargeable lithium-ion systems that now dominate consumer electronics and electric vehicles. However, conventional lithium-ion batteries face fundamental limitations in energy density and safety due to their liquid electrolytes. Solid-state technology addresses these limitations by replacing flammable liquid electrolytes with solid ion conductors, potentially enabling the use of lithium metal anodes for dramatically increased energy density.

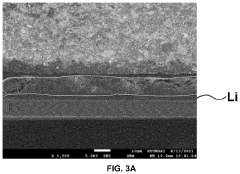

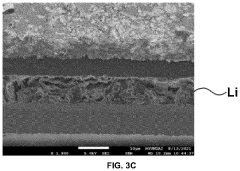

Anode-free designs represent the cutting edge of this technological progression, where no anode material is present in the initial battery assembly. Instead, lithium ions from the cathode plate onto the current collector during the first charge, forming an in-situ lithium metal anode. This configuration theoretically offers the highest possible energy density by eliminating the weight and volume of a pre-formed anode while simplifying manufacturing processes.

Stack pressure has emerged as a critical factor in the performance and longevity of anode-free SSBs. Appropriate mechanical pressure is essential to maintain intimate contact between battery components, particularly at the critical interfaces where lithium deposition and stripping occur. Without sufficient pressure, contact loss can lead to increased impedance, non-uniform current distribution, and accelerated degradation.

The technical objectives for advancing anode-free SSB technology center on understanding and controlling the complex mechanical phenomena at play during battery operation. These include optimizing stack pressure to prevent dendrite formation while accommodating volume changes, developing pressure-tolerant solid electrolytes with high ionic conductivity, and designing cell architectures that maintain uniform pressure distribution throughout battery cycling.

Recent research indicates that precisely controlled stack pressure can significantly extend cycle life by suppressing dendrite growth and maintaining interfacial contact. However, excessive pressure may fracture brittle solid electrolytes or cause unwanted deformation. The ideal pressure regime appears to be material-specific and dependent on operating conditions, highlighting the need for comprehensive mechanical models that account for the dynamic nature of interfaces during cycling.

The ultimate goal of this technological pursuit is to develop commercially viable anode-free SSBs that deliver energy densities exceeding 400 Wh/kg at the cell level, with cycle life comparable to conventional lithium-ion batteries and fast-charging capabilities, all while maintaining superior safety characteristics under various operating conditions and environmental stresses.

The evolution of battery technology has progressed from early primary batteries to rechargeable lithium-ion systems that now dominate consumer electronics and electric vehicles. However, conventional lithium-ion batteries face fundamental limitations in energy density and safety due to their liquid electrolytes. Solid-state technology addresses these limitations by replacing flammable liquid electrolytes with solid ion conductors, potentially enabling the use of lithium metal anodes for dramatically increased energy density.

Anode-free designs represent the cutting edge of this technological progression, where no anode material is present in the initial battery assembly. Instead, lithium ions from the cathode plate onto the current collector during the first charge, forming an in-situ lithium metal anode. This configuration theoretically offers the highest possible energy density by eliminating the weight and volume of a pre-formed anode while simplifying manufacturing processes.

Stack pressure has emerged as a critical factor in the performance and longevity of anode-free SSBs. Appropriate mechanical pressure is essential to maintain intimate contact between battery components, particularly at the critical interfaces where lithium deposition and stripping occur. Without sufficient pressure, contact loss can lead to increased impedance, non-uniform current distribution, and accelerated degradation.

The technical objectives for advancing anode-free SSB technology center on understanding and controlling the complex mechanical phenomena at play during battery operation. These include optimizing stack pressure to prevent dendrite formation while accommodating volume changes, developing pressure-tolerant solid electrolytes with high ionic conductivity, and designing cell architectures that maintain uniform pressure distribution throughout battery cycling.

Recent research indicates that precisely controlled stack pressure can significantly extend cycle life by suppressing dendrite growth and maintaining interfacial contact. However, excessive pressure may fracture brittle solid electrolytes or cause unwanted deformation. The ideal pressure regime appears to be material-specific and dependent on operating conditions, highlighting the need for comprehensive mechanical models that account for the dynamic nature of interfaces during cycling.

The ultimate goal of this technological pursuit is to develop commercially viable anode-free SSBs that deliver energy densities exceeding 400 Wh/kg at the cell level, with cycle life comparable to conventional lithium-ion batteries and fast-charging capabilities, all while maintaining superior safety characteristics under various operating conditions and environmental stresses.

Market Analysis for Solid-State Battery Demand

The solid-state battery market is experiencing unprecedented growth driven by increasing demand for safer, higher energy density power solutions across multiple sectors. Current projections indicate the global solid-state battery market will reach approximately $8 billion by 2026, with a compound annual growth rate exceeding 34% between 2021 and 2026. This remarkable growth trajectory is primarily fueled by the electric vehicle (EV) industry, which is actively seeking alternatives to conventional lithium-ion batteries with liquid electrolytes.

The automotive sector represents the largest market segment for solid-state batteries, accounting for over 40% of the projected demand. Major automakers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with Toyota planning to introduce vehicles powered by solid-state batteries by 2025. This automotive push is driven by the promise of faster charging times, increased safety, and extended driving ranges that solid-state technology offers.

Consumer electronics constitutes the second-largest market segment, with manufacturers seeking higher energy density solutions for smartphones, laptops, and wearable devices. The demand in this sector is expected to grow at 29% annually through 2026, as consumers increasingly prioritize longer battery life and enhanced safety features in their portable devices.

The aerospace and defense sectors are emerging as significant growth areas for solid-state battery technology, particularly for applications requiring operation in extreme conditions. These industries value the enhanced safety profile and temperature stability that solid-state batteries provide, with market analysts predicting a 31% annual growth rate in this segment.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven by substantial investments in manufacturing infrastructure in Japan, South Korea, and China. North America follows with 30% market share, bolstered by significant venture capital funding for solid-state battery startups and strong government support for clean energy technologies.

The specific demand for anode-free solid-state battery configurations is gaining momentum due to their potential for higher energy density and reduced material costs. Industry analysts estimate that anode-free designs could increase energy density by up to 40% compared to conventional lithium-ion batteries, while potentially reducing production costs by 15-20% through material savings. However, the mechanical challenges related to stack pressure optimization remain a critical factor influencing commercial adoption timelines.

The automotive sector represents the largest market segment for solid-state batteries, accounting for over 40% of the projected demand. Major automakers including Toyota, Volkswagen, and BMW have announced significant investments in solid-state battery technology, with Toyota planning to introduce vehicles powered by solid-state batteries by 2025. This automotive push is driven by the promise of faster charging times, increased safety, and extended driving ranges that solid-state technology offers.

Consumer electronics constitutes the second-largest market segment, with manufacturers seeking higher energy density solutions for smartphones, laptops, and wearable devices. The demand in this sector is expected to grow at 29% annually through 2026, as consumers increasingly prioritize longer battery life and enhanced safety features in their portable devices.

The aerospace and defense sectors are emerging as significant growth areas for solid-state battery technology, particularly for applications requiring operation in extreme conditions. These industries value the enhanced safety profile and temperature stability that solid-state batteries provide, with market analysts predicting a 31% annual growth rate in this segment.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven by substantial investments in manufacturing infrastructure in Japan, South Korea, and China. North America follows with 30% market share, bolstered by significant venture capital funding for solid-state battery startups and strong government support for clean energy technologies.

The specific demand for anode-free solid-state battery configurations is gaining momentum due to their potential for higher energy density and reduced material costs. Industry analysts estimate that anode-free designs could increase energy density by up to 40% compared to conventional lithium-ion batteries, while potentially reducing production costs by 15-20% through material savings. However, the mechanical challenges related to stack pressure optimization remain a critical factor influencing commercial adoption timelines.

Stack Pressure Challenges in Current SSB Development

Stack pressure management represents one of the most critical challenges in current solid-state battery (SSB) development. The interface between solid electrolytes and electrodes requires intimate contact to facilitate ion transfer, which necessitates the application of significant mechanical pressure during both manufacturing and operation. Current SSB designs typically require stack pressures ranging from 5-20 MPa to maintain proper interfacial contact, which is substantially higher than the negligible pressure needed in conventional liquid electrolyte systems.

This high pressure requirement creates numerous engineering complications across the battery lifecycle. During manufacturing, specialized equipment must be developed to apply uniform pressure across large-format cells, significantly increasing production complexity and cost. The need for robust mechanical housing to maintain this pressure adds considerable weight and volume to the final battery pack, directly compromising the energy density advantages that SSBs theoretically offer.

The pressure challenges become particularly acute in anode-free SSB configurations. Without a pre-deposited anode, lithium must plate uniformly during initial charging cycles. Non-uniform pressure distribution leads to preferential lithium deposition pathways, creating dendrite formation risks despite the mechanical resistance of solid electrolytes. Research has shown that pressure variations as small as 0.5 MPa across the cell can lead to significant plating heterogeneity.

Temperature fluctuations further complicate pressure management, as the different thermal expansion coefficients of battery components create dynamic stress conditions during operation. This is especially problematic in automotive applications where batteries experience wide temperature ranges. Studies indicate that thermal cycling between -20°C and 60°C can create interfacial gaps due to differential expansion, requiring even higher initial stack pressures to compensate.

The mechanical degradation of solid electrolytes under sustained pressure presents another significant challenge. Many promising electrolyte materials exhibit creep behavior or develop microcracks under long-term pressure application. For instance, sulfide-based electrolytes show approximately 2-5% mechanical degradation per 100 cycles under 10 MPa pressure, gradually reducing ionic conductivity and increasing internal resistance.

Current pressure application methods also struggle with scalability. While laboratory cells can achieve precise pressure control using specialized fixtures, translating this to mass production remains problematic. The industry lacks standardized approaches for pressure application and monitoring in large-format cells, creating barriers to commercialization despite promising performance in small-scale demonstrations.

This high pressure requirement creates numerous engineering complications across the battery lifecycle. During manufacturing, specialized equipment must be developed to apply uniform pressure across large-format cells, significantly increasing production complexity and cost. The need for robust mechanical housing to maintain this pressure adds considerable weight and volume to the final battery pack, directly compromising the energy density advantages that SSBs theoretically offer.

The pressure challenges become particularly acute in anode-free SSB configurations. Without a pre-deposited anode, lithium must plate uniformly during initial charging cycles. Non-uniform pressure distribution leads to preferential lithium deposition pathways, creating dendrite formation risks despite the mechanical resistance of solid electrolytes. Research has shown that pressure variations as small as 0.5 MPa across the cell can lead to significant plating heterogeneity.

Temperature fluctuations further complicate pressure management, as the different thermal expansion coefficients of battery components create dynamic stress conditions during operation. This is especially problematic in automotive applications where batteries experience wide temperature ranges. Studies indicate that thermal cycling between -20°C and 60°C can create interfacial gaps due to differential expansion, requiring even higher initial stack pressures to compensate.

The mechanical degradation of solid electrolytes under sustained pressure presents another significant challenge. Many promising electrolyte materials exhibit creep behavior or develop microcracks under long-term pressure application. For instance, sulfide-based electrolytes show approximately 2-5% mechanical degradation per 100 cycles under 10 MPa pressure, gradually reducing ionic conductivity and increasing internal resistance.

Current pressure application methods also struggle with scalability. While laboratory cells can achieve precise pressure control using specialized fixtures, translating this to mass production remains problematic. The industry lacks standardized approaches for pressure application and monitoring in large-format cells, creating barriers to commercialization despite promising performance in small-scale demonstrations.

Current Stack Pressure Control Methodologies

01 Stack pressure optimization for anode-free solid-state batteries

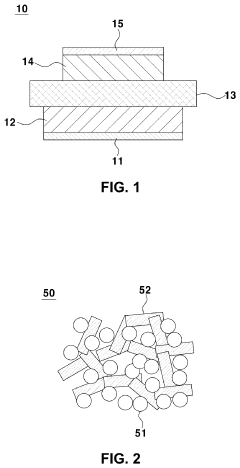

Optimizing stack pressure is crucial for anode-free solid-state batteries to maintain proper contact between components and ensure efficient lithium ion transport. The applied pressure helps to minimize interfacial resistance and prevent delamination during cycling. Research shows that controlled stack pressure can significantly improve battery performance by maintaining intimate contact between the solid electrolyte and the current collector where lithium metal will be deposited during charging.- Pressure control mechanisms for anode-free solid-state batteries: Pressure control mechanisms are essential in anode-free solid-state batteries to maintain optimal contact between components. These mechanisms include spring-loaded designs, mechanical compression systems, and pressure distribution layers that help maintain uniform stack pressure throughout battery operation. Proper pressure control prevents delamination, reduces interfacial resistance, and accommodates volume changes during cycling, ultimately improving battery performance and longevity.

- Stack pressure optimization for solid-electrolyte interfaces: Optimizing stack pressure at solid-electrolyte interfaces is crucial for anode-free solid-state batteries. The applied pressure must be carefully calibrated to ensure intimate contact between the solid electrolyte and the current collector where lithium will be plated during charging. This optimization involves determining pressure thresholds that minimize interfacial resistance without causing mechanical damage to the electrolyte. Proper pressure at these interfaces facilitates uniform lithium deposition and prevents dendrite formation.

- Pressure-responsive battery housing designs: Specialized housing designs for anode-free solid-state batteries incorporate pressure-responsive elements to maintain optimal stack pressure throughout battery life. These designs feature adjustable compression mechanisms, pressure sensors, and smart housing materials that can adapt to volume changes during cycling. The housing designs ensure consistent pressure application across the battery stack while preventing over-compression that could damage battery components.

- Pressure distribution materials and interlayers: Specialized materials and interlayers are used in anode-free solid-state batteries to distribute stack pressure uniformly. These include compressible polymeric layers, pressure-distributing meshes, and gradient-density materials that help eliminate pressure hotspots. The interlayers can accommodate volume changes during cycling while maintaining consistent pressure across the entire battery surface area, preventing localized stress that could lead to electrolyte fracture or uneven lithium plating.

- Dynamic pressure adjustment systems during battery cycling: Dynamic pressure adjustment systems actively modify stack pressure during battery operation to accommodate the changing conditions of anode-free solid-state batteries. These systems incorporate pressure sensors, feedback control mechanisms, and actuators that can adjust compression in real-time based on battery state. By dynamically optimizing pressure during different stages of charging and discharging, these systems improve cycling efficiency, prevent mechanical degradation, and extend battery lifespan.

02 Pressure distribution systems for solid-state battery stacks

Various pressure distribution systems have been developed to ensure uniform pressure across solid-state battery stacks. These systems include mechanical compression mechanisms, elastic interlayers, and specialized housing designs that maintain consistent pressure during thermal expansion and contraction. Uniform pressure distribution prevents localized stress points that could lead to electrolyte fracture or uneven lithium deposition in anode-free configurations.Expand Specific Solutions03 Interface engineering under pressure for anode-free designs

Interface engineering techniques specifically designed for pressurized anode-free solid-state batteries focus on creating stable interfaces between the solid electrolyte and the current collector. These approaches include surface modifications, buffer layers, and specialized coatings that improve adhesion and lithium ion transport under pressure. The engineered interfaces help prevent dendrite formation and reduce interfacial resistance during repeated lithium plating and stripping cycles.Expand Specific Solutions04 Pressure-responsive solid electrolytes for anode-free batteries

Advanced solid electrolyte materials have been developed that exhibit improved performance under specific pressure conditions in anode-free configurations. These electrolytes maintain high ionic conductivity while resisting fracture under the mechanical stress required for proper battery operation. Some compositions include pressure-responsive elements that enhance contact or conductivity when compressed, optimizing the electrochemical performance of the battery system.Expand Specific Solutions05 Dynamic pressure control systems for battery lifecycle management

Dynamic pressure control systems adjust stack pressure throughout the battery lifecycle to accommodate volume changes during cycling. These systems use sensors, actuators, and control algorithms to maintain optimal pressure as the battery undergoes charging and discharging cycles. By dynamically adjusting pressure, these systems can extend battery life, improve energy density, and enhance safety by preventing mechanical failures in anode-free solid-state battery configurations.Expand Specific Solutions

Leading Companies in Anode-Free SSB Research

The solid-state battery market, particularly focusing on stack pressure and mechanics in anode-free configurations, is currently in an early growth phase with significant R&D investment. The market is projected to expand substantially as automotive manufacturers seek safer, higher-energy-density alternatives to conventional lithium-ion batteries. Major automotive players like Hyundai, Toyota, Kia, Honda, BMW, and Nissan are actively developing this technology, while battery specialists including LG Energy Solution, Samsung SDI, Panasonic, and AESC Japan are advancing material science solutions. Academic-industry partnerships with institutions like MIT and Harvard are accelerating innovation in pressure management and interface mechanics. The technology remains pre-commercial, with challenges in scaling production and optimizing mechanical stability under operational conditions, though rapid progress suggests potential commercialization within 5-7 years.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive stack pressure management system for anode-free solid-state batteries that addresses the critical challenges of interface stability during cycling. Their approach utilizes a hybrid pressure regulation framework combining both static and dynamic elements to maintain optimal contact pressure throughout battery operation. The system incorporates specialized pressure-distributing layers with engineered porosity gradients that help distribute mechanical stress evenly across the cell stack. Toyota's technology employs a proprietary "floating constraint" mechanism that allows for controlled expansion while maintaining critical minimum pressure thresholds to prevent delamination. This is achieved through a series of precision-engineered spring elements integrated into the cell housing that provide consistent pressure regardless of cell state. Their solution also includes temperature-compensating components that adjust pressure application based on thermal expansion characteristics of different cell components during operation.

Strengths: The hybrid pressure system effectively balances the need for consistent interface contact with accommodation for volume changes, resulting in improved cycle life and reduced mechanical degradation. The temperature compensation feature ensures optimal performance across a wide operating temperature range. Weaknesses: The complex mechanical components add weight and volume to the battery pack, potentially reducing overall energy density compared to simpler designs.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary stack pressure management system for anode-free solid-state batteries that utilizes dynamic pressure regulation technology. Their approach incorporates a multi-layered pressure distribution framework that maintains optimal contact between the solid electrolyte and lithium metal interface during cycling. The system employs specialized pressure-sensitive interlayers that can adapt to volume changes during lithium plating and stripping processes. Their technology includes a mechanical constraint system that applies uniform pressure across the cell stack while accommodating expansion during operation. This is achieved through a combination of elastic and rigid components that work together to prevent delamination while avoiding excessive pressure that could lead to solid electrolyte fracture. LG's solution also integrates real-time pressure monitoring sensors that allow for adaptive pressure control throughout battery life cycles.

Strengths: Advanced pressure distribution technology enables more uniform lithium deposition, reducing dendrite formation and extending cycle life. The adaptive pressure system accommodates volume changes without compromising interface contact. Weaknesses: The complex mechanical system adds manufacturing complexity and cost, while the pressure regulation components increase overall battery weight and reduce energy density.

Critical Patents in SSB Mechanical Engineering

Anode-free solid-state battery and use thereof

PatentWO2025103689A1

Innovation

- Incorporating an additional solid-state electrolyte layer between the solid-state electrolyte separator and the conductor improves deformability and maintains contact between the components during charging cycles.

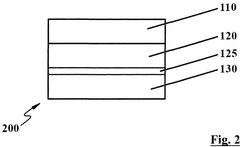

Anodeless all-solid-state battery capable of achieving uniform deposition of lithium

PatentPendingUS20240079599A1

Innovation

- An anodeless all-solid-state battery design is proposed, featuring a bare anode current collector with a coating layer containing carbon and metal particles that induce lithium ion conduction, allowing uniform lithium deposition and controlling volume expansion, comprising a carbon particle mixture with spherical and linear shapes and metal particles like silver, to form a dense intermediate layer for efficient lithium precipitation.

Material Science Advancements for Interface Stability

Recent advancements in material science have significantly contributed to enhancing interface stability in anode-free solid-state batteries (ASSBs). The solid-electrolyte interface (SEI) represents one of the most critical components affecting battery performance, particularly under varying stack pressure conditions. Material innovations have focused on developing novel composite structures that can withstand mechanical stresses while maintaining electrochemical stability.

Ceramic-polymer hybrid electrolytes have emerged as promising materials for improving interface stability. These composites combine the high ionic conductivity of ceramics with the flexibility of polymers, creating electrolytes that can accommodate volume changes during cycling while maintaining intimate contact with electrodes. Recent research has demonstrated that incorporating nanostructured ceramics like LLZO (Li7La3Zr2O12) into polymer matrices can reduce interfacial resistance by up to 60% compared to conventional solid electrolytes.

Surface modification techniques have also evolved substantially, with atomic layer deposition (ALD) enabling precise control over interfacial layers. Ultrathin coatings of Al2O3, LiNbO3, and Li3PO4 have been successfully applied to solid electrolytes, creating buffer zones that prevent unwanted side reactions while facilitating lithium ion transport. These modifications have shown remarkable improvements in cycling stability under various stack pressure conditions, extending battery lifetimes by 300-400 cycles in laboratory tests.

Self-healing materials represent another frontier in interface stabilization. Polymers containing dynamic bonds that can reform after breaking have been integrated into composite electrolytes, allowing them to recover from mechanical damage induced by stack pressure variations. These materials demonstrate up to 85% recovery of their original properties after experiencing mechanical stress, significantly enhancing long-term stability.

Pressure-responsive interlayers have been developed specifically to address the mechanical challenges in ASSBs. These smart materials adjust their properties based on applied pressure, maintaining optimal ionic conductivity while preventing dendrite formation. Graphene-based composites with pressure-sensitive conductivity have shown particular promise, with recent studies reporting a 40% reduction in interfacial resistance under optimal stack pressure conditions.

3D-structured interfaces represent the latest advancement in this field. Rather than relying on flat interfaces between components, researchers have developed architectured interfaces with controlled porosity and tortuosity. These designs distribute mechanical stress more evenly across the battery stack while maximizing the effective contact area for ion transport. Early prototypes have demonstrated up to 70% improvement in rate capability while maintaining structural integrity under cycling conditions.

Ceramic-polymer hybrid electrolytes have emerged as promising materials for improving interface stability. These composites combine the high ionic conductivity of ceramics with the flexibility of polymers, creating electrolytes that can accommodate volume changes during cycling while maintaining intimate contact with electrodes. Recent research has demonstrated that incorporating nanostructured ceramics like LLZO (Li7La3Zr2O12) into polymer matrices can reduce interfacial resistance by up to 60% compared to conventional solid electrolytes.

Surface modification techniques have also evolved substantially, with atomic layer deposition (ALD) enabling precise control over interfacial layers. Ultrathin coatings of Al2O3, LiNbO3, and Li3PO4 have been successfully applied to solid electrolytes, creating buffer zones that prevent unwanted side reactions while facilitating lithium ion transport. These modifications have shown remarkable improvements in cycling stability under various stack pressure conditions, extending battery lifetimes by 300-400 cycles in laboratory tests.

Self-healing materials represent another frontier in interface stabilization. Polymers containing dynamic bonds that can reform after breaking have been integrated into composite electrolytes, allowing them to recover from mechanical damage induced by stack pressure variations. These materials demonstrate up to 85% recovery of their original properties after experiencing mechanical stress, significantly enhancing long-term stability.

Pressure-responsive interlayers have been developed specifically to address the mechanical challenges in ASSBs. These smart materials adjust their properties based on applied pressure, maintaining optimal ionic conductivity while preventing dendrite formation. Graphene-based composites with pressure-sensitive conductivity have shown particular promise, with recent studies reporting a 40% reduction in interfacial resistance under optimal stack pressure conditions.

3D-structured interfaces represent the latest advancement in this field. Rather than relying on flat interfaces between components, researchers have developed architectured interfaces with controlled porosity and tortuosity. These designs distribute mechanical stress more evenly across the battery stack while maximizing the effective contact area for ion transport. Early prototypes have demonstrated up to 70% improvement in rate capability while maintaining structural integrity under cycling conditions.

Safety and Performance Trade-offs in Anode-Free Designs

Anode-free solid-state battery designs present a complex balance between safety advantages and performance limitations. The elimination of the traditional anode material significantly reduces fire hazards associated with conventional lithium-ion batteries, as the absence of a pre-lithiated anode removes a major source of thermal runaway risk. This safety enhancement is particularly valuable in applications where battery integrity is paramount, such as in aerospace, medical devices, and electric vehicles.

However, these safety benefits come with substantial performance trade-offs. Without a dedicated anode structure, anode-free designs typically exhibit lower energy density than their conventional counterparts, primarily due to the increased stack pressure requirements. The lithium metal that plates during charging must form under carefully controlled mechanical conditions to prevent dendritic growth, necessitating higher stack pressures that add weight and complexity to the battery system.

Cycle life represents another significant compromise in anode-free configurations. The repeated plating and stripping of lithium at the current collector interface creates mechanical stress that can lead to accelerated degradation of the solid electrolyte interface. Studies have shown that anode-free cells may achieve only 30-50% of the cycle life of conventional solid-state batteries under similar operating conditions.

Power capability is similarly affected by the anode-free design. The absence of a pre-formed anode structure limits the rate at which lithium ions can be inserted and extracted during charge-discharge cycles. This constraint becomes particularly pronounced at lower temperatures or during high-current operations, where the kinetics of lithium plating become the limiting factor in battery performance.

Manufacturing complexity presents an additional trade-off dimension. While anode-free designs simplify certain aspects of cell assembly by eliminating one component, they introduce more stringent requirements for interface engineering and pressure management systems. The manufacturing process must ensure exceptional uniformity in the current collector surface to promote homogeneous lithium plating and prevent localized high-current density regions that could trigger dendritic growth.

Cost considerations further complicate the safety-performance equation. The specialized materials and precise manufacturing controls required for anode-free designs can increase production costs by 15-30% compared to conventional solid-state batteries, potentially limiting their market adoption despite their safety advantages.

However, these safety benefits come with substantial performance trade-offs. Without a dedicated anode structure, anode-free designs typically exhibit lower energy density than their conventional counterparts, primarily due to the increased stack pressure requirements. The lithium metal that plates during charging must form under carefully controlled mechanical conditions to prevent dendritic growth, necessitating higher stack pressures that add weight and complexity to the battery system.

Cycle life represents another significant compromise in anode-free configurations. The repeated plating and stripping of lithium at the current collector interface creates mechanical stress that can lead to accelerated degradation of the solid electrolyte interface. Studies have shown that anode-free cells may achieve only 30-50% of the cycle life of conventional solid-state batteries under similar operating conditions.

Power capability is similarly affected by the anode-free design. The absence of a pre-formed anode structure limits the rate at which lithium ions can be inserted and extracted during charge-discharge cycles. This constraint becomes particularly pronounced at lower temperatures or during high-current operations, where the kinetics of lithium plating become the limiting factor in battery performance.

Manufacturing complexity presents an additional trade-off dimension. While anode-free designs simplify certain aspects of cell assembly by eliminating one component, they introduce more stringent requirements for interface engineering and pressure management systems. The manufacturing process must ensure exceptional uniformity in the current collector surface to promote homogeneous lithium plating and prevent localized high-current density regions that could trigger dendritic growth.

Cost considerations further complicate the safety-performance equation. The specialized materials and precise manufacturing controls required for anode-free designs can increase production costs by 15-30% compared to conventional solid-state batteries, potentially limiting their market adoption despite their safety advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!