Quality Gates And SPC In Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Anode-free solid-state batteries (ASSBs) represent a revolutionary advancement in energy storage technology, emerging from decades of research into high-energy-density power solutions. These batteries eliminate the traditional graphite or silicon anode, instead allowing lithium metal to plate directly onto the current collector during charging. This design potentially offers up to 70% higher energy density compared to conventional lithium-ion batteries while addressing safety concerns associated with liquid electrolytes.

The evolution of this technology can be traced back to the 1970s with initial solid electrolyte research, followed by significant breakthroughs in the 2010s when viable solid-state electrolytes with sufficient ionic conductivity were developed. Recent years have seen accelerated development as automotive and electronics industries seek safer, higher-capacity energy storage solutions to meet increasingly demanding consumer and regulatory requirements.

The primary technical objective for anode-free SSBs is achieving reliable, cost-effective mass production while maintaining consistent quality. Unlike traditional battery manufacturing, anode-free designs present unique challenges in process control, as the anode forms in-situ during battery operation rather than being pre-manufactured. This fundamental difference necessitates novel quality control approaches and statistical process control (SPC) methodologies specifically tailored to this technology.

Quality gates in anode-free SSB manufacturing aim to ensure uniform lithium plating, prevent dendrite formation, and maintain solid electrolyte integrity throughout the production process. These critical quality checkpoints must be established at key manufacturing stages to prevent defects that could lead to capacity fade, internal shorts, or safety issues during battery operation.

The technology targets several ambitious performance metrics: energy densities exceeding 400 Wh/kg, cycle life beyond 1,000 cycles, fast charging capabilities, and operation across wide temperature ranges. Achieving these targets requires precise manufacturing controls that can only be established through sophisticated quality management systems and advanced process monitoring.

Current technical goals focus on developing robust in-line quality assessment methods capable of detecting microscopic defects in solid electrolytes, ensuring uniform current collector surfaces, and verifying electrolyte-collector interfaces. Statistical process control for this emerging technology must evolve beyond traditional battery manufacturing approaches to address the unique dynamics of in-situ anode formation.

The ultimate objective is establishing a manufacturing ecosystem with real-time feedback loops that can maintain consistent quality while scaling production to commercially viable volumes. This requires integration of advanced sensing technologies, machine learning algorithms for defect prediction, and adaptive process controls that can respond to subtle variations in material properties and environmental conditions.

The evolution of this technology can be traced back to the 1970s with initial solid electrolyte research, followed by significant breakthroughs in the 2010s when viable solid-state electrolytes with sufficient ionic conductivity were developed. Recent years have seen accelerated development as automotive and electronics industries seek safer, higher-capacity energy storage solutions to meet increasingly demanding consumer and regulatory requirements.

The primary technical objective for anode-free SSBs is achieving reliable, cost-effective mass production while maintaining consistent quality. Unlike traditional battery manufacturing, anode-free designs present unique challenges in process control, as the anode forms in-situ during battery operation rather than being pre-manufactured. This fundamental difference necessitates novel quality control approaches and statistical process control (SPC) methodologies specifically tailored to this technology.

Quality gates in anode-free SSB manufacturing aim to ensure uniform lithium plating, prevent dendrite formation, and maintain solid electrolyte integrity throughout the production process. These critical quality checkpoints must be established at key manufacturing stages to prevent defects that could lead to capacity fade, internal shorts, or safety issues during battery operation.

The technology targets several ambitious performance metrics: energy densities exceeding 400 Wh/kg, cycle life beyond 1,000 cycles, fast charging capabilities, and operation across wide temperature ranges. Achieving these targets requires precise manufacturing controls that can only be established through sophisticated quality management systems and advanced process monitoring.

Current technical goals focus on developing robust in-line quality assessment methods capable of detecting microscopic defects in solid electrolytes, ensuring uniform current collector surfaces, and verifying electrolyte-collector interfaces. Statistical process control for this emerging technology must evolve beyond traditional battery manufacturing approaches to address the unique dynamics of in-situ anode formation.

The ultimate objective is establishing a manufacturing ecosystem with real-time feedback loops that can maintain consistent quality while scaling production to commercially viable volumes. This requires integration of advanced sensing technologies, machine learning algorithms for defect prediction, and adaptive process controls that can respond to subtle variations in material properties and environmental conditions.

Market Analysis for Anode-Free Solid-State Batteries

The global market for anode-free solid-state batteries is experiencing significant growth, driven by increasing demand for high-energy-density energy storage solutions across multiple sectors. Current market projections indicate that the solid-state battery market could reach $8 billion by 2026, with anode-free technologies potentially capturing 15-20% of this segment due to their superior energy density advantages.

The automotive industry represents the primary demand driver, with electric vehicle manufacturers actively seeking battery technologies that offer greater range, faster charging capabilities, and enhanced safety profiles. Major automakers including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery research, with particular interest in anode-free configurations that promise energy densities exceeding 400 Wh/kg.

Consumer electronics constitutes the second-largest market segment, where the reduced form factor and improved safety characteristics of anode-free solid-state batteries address critical pain points for smartphone, laptop, and wearable device manufacturers. Apple, Samsung, and other major electronics companies have established strategic partnerships with battery developers focusing on this technology.

Market analysis reveals regional variations in adoption trajectories. Asia-Pacific currently leads manufacturing capacity development, with Japan and South Korea hosting the most advanced production facilities. North America demonstrates the highest growth rate in research investment, while Europe shows the strongest regulatory push toward adoption through sustainability-focused policies.

A critical market constraint remains the manufacturing scalability challenge. Current production volumes for anode-free solid-state batteries remain limited to pilot-scale operations, with costs approximately 4-5 times higher than conventional lithium-ion batteries. Industry analysts project that achieving cost parity will require significant advances in quality control systems and statistical process control (SPC) methodologies specifically tailored to the unique manufacturing challenges of these batteries.

The market demonstrates high sensitivity to quality assurance capabilities. Battery manufacturers that can demonstrate consistent performance metrics and reliability through robust quality gates command premium pricing and secure preferential supply agreements with OEMs. This creates a direct economic incentive for investment in advanced quality control technologies.

Forecasts indicate that the implementation of AI-enhanced SPC systems in anode-free solid-state battery production could reduce manufacturing costs by 30-40% by 2025, potentially accelerating market penetration. Early adopters of sophisticated quality management systems are positioned to capture disproportionate market share as production scales.

The automotive industry represents the primary demand driver, with electric vehicle manufacturers actively seeking battery technologies that offer greater range, faster charging capabilities, and enhanced safety profiles. Major automakers including Toyota, Volkswagen, and BMW have made substantial investments in solid-state battery research, with particular interest in anode-free configurations that promise energy densities exceeding 400 Wh/kg.

Consumer electronics constitutes the second-largest market segment, where the reduced form factor and improved safety characteristics of anode-free solid-state batteries address critical pain points for smartphone, laptop, and wearable device manufacturers. Apple, Samsung, and other major electronics companies have established strategic partnerships with battery developers focusing on this technology.

Market analysis reveals regional variations in adoption trajectories. Asia-Pacific currently leads manufacturing capacity development, with Japan and South Korea hosting the most advanced production facilities. North America demonstrates the highest growth rate in research investment, while Europe shows the strongest regulatory push toward adoption through sustainability-focused policies.

A critical market constraint remains the manufacturing scalability challenge. Current production volumes for anode-free solid-state batteries remain limited to pilot-scale operations, with costs approximately 4-5 times higher than conventional lithium-ion batteries. Industry analysts project that achieving cost parity will require significant advances in quality control systems and statistical process control (SPC) methodologies specifically tailored to the unique manufacturing challenges of these batteries.

The market demonstrates high sensitivity to quality assurance capabilities. Battery manufacturers that can demonstrate consistent performance metrics and reliability through robust quality gates command premium pricing and secure preferential supply agreements with OEMs. This creates a direct economic incentive for investment in advanced quality control technologies.

Forecasts indicate that the implementation of AI-enhanced SPC systems in anode-free solid-state battery production could reduce manufacturing costs by 30-40% by 2025, potentially accelerating market penetration. Early adopters of sophisticated quality management systems are positioned to capture disproportionate market share as production scales.

Current Challenges in SSB Manufacturing Quality Control

The manufacturing of anode-free solid-state batteries (SSBs) presents unique quality control challenges that significantly differ from conventional lithium-ion battery production. Current quality control systems struggle to adapt to the novel materials, interfaces, and manufacturing processes inherent to SSB technology. Traditional statistical process control (SPC) methods often fail to capture the complex interdependencies between solid electrolyte properties, lithium metal behavior, and interface formation.

A primary challenge lies in the real-time monitoring of solid electrolyte uniformity during manufacturing. Unlike liquid electrolytes, solid electrolytes require precise thickness control, density measurements, and detection of micro-cracks or voids that can lead to catastrophic battery failure. Conventional optical inspection systems lack the resolution and analytical capabilities to detect these defects reliably, especially at production speeds.

Interface quality between the cathode and solid electrolyte represents another critical control point. Current metrology tools cannot adequately characterize the interfacial resistance in-line, forcing manufacturers to rely on destructive testing of sample batteries. This approach significantly increases production costs and cycle times while providing limited statistical confidence in overall batch quality.

The absence of an anode in these systems creates additional complexity for quality gates. The in-situ formation of the lithium metal anode during the first charge cycle must be carefully monitored and controlled. However, existing quality control frameworks lack appropriate parameters and thresholds for this unique process. Manufacturers currently struggle to establish correlations between manufacturing variables and the eventual performance of the lithium metal interface.

Temperature uniformity during processing represents another significant challenge. Solid-state battery components often require precise thermal treatments to ensure proper material integration and interface formation. Current thermal imaging systems lack the resolution and analytical frameworks to detect subtle temperature variations that can significantly impact battery performance and safety.

Data integration across multiple process steps presents a systemic challenge. Quality parameters measured at different stages of production must be correlated with final battery performance, yet existing manufacturing execution systems (MES) lack the sophisticated data models needed for SSB production. This gap prevents the implementation of comprehensive SPC systems that could identify process drift before it impacts product quality.

The development of non-destructive testing methods remains particularly challenging. X-ray techniques show promise but currently lack the throughput needed for high-volume manufacturing environments. Ultrasonic methods offer potential for detecting internal defects but require significant development to achieve the sensitivity and specificity needed for SSB quality control.

A primary challenge lies in the real-time monitoring of solid electrolyte uniformity during manufacturing. Unlike liquid electrolytes, solid electrolytes require precise thickness control, density measurements, and detection of micro-cracks or voids that can lead to catastrophic battery failure. Conventional optical inspection systems lack the resolution and analytical capabilities to detect these defects reliably, especially at production speeds.

Interface quality between the cathode and solid electrolyte represents another critical control point. Current metrology tools cannot adequately characterize the interfacial resistance in-line, forcing manufacturers to rely on destructive testing of sample batteries. This approach significantly increases production costs and cycle times while providing limited statistical confidence in overall batch quality.

The absence of an anode in these systems creates additional complexity for quality gates. The in-situ formation of the lithium metal anode during the first charge cycle must be carefully monitored and controlled. However, existing quality control frameworks lack appropriate parameters and thresholds for this unique process. Manufacturers currently struggle to establish correlations between manufacturing variables and the eventual performance of the lithium metal interface.

Temperature uniformity during processing represents another significant challenge. Solid-state battery components often require precise thermal treatments to ensure proper material integration and interface formation. Current thermal imaging systems lack the resolution and analytical frameworks to detect subtle temperature variations that can significantly impact battery performance and safety.

Data integration across multiple process steps presents a systemic challenge. Quality parameters measured at different stages of production must be correlated with final battery performance, yet existing manufacturing execution systems (MES) lack the sophisticated data models needed for SSB production. This gap prevents the implementation of comprehensive SPC systems that could identify process drift before it impacts product quality.

The development of non-destructive testing methods remains particularly challenging. X-ray techniques show promise but currently lack the throughput needed for high-volume manufacturing environments. Ultrasonic methods offer potential for detecting internal defects but require significant development to achieve the sensitivity and specificity needed for SSB quality control.

Existing Quality Gates and SPC Methodologies for SSB

01 Quality control systems for anode-free solid-state batteries

Quality control systems specifically designed for anode-free solid-state batteries involve specialized monitoring techniques to ensure consistent performance and safety. These systems typically include automated inspection tools that can detect defects in the solid electrolyte layer and cathode materials. The quality gates established in these systems focus on critical parameters such as electrolyte uniformity, interface stability, and absence of dendrite formation sites, which are particularly important in anode-free configurations.- Quality control systems for anode-free solid-state batteries: Quality control systems specifically designed for anode-free solid-state batteries involve specialized testing protocols and measurement techniques to ensure consistent performance and safety. These systems monitor critical parameters such as electrolyte uniformity, cathode-electrolyte interface quality, and overall cell integrity. Advanced quality gates are implemented at various manufacturing stages to detect defects early in the production process, reducing failure rates and improving battery reliability.

- Statistical Process Control (SPC) methodologies for battery manufacturing: Statistical Process Control methodologies applied to battery manufacturing utilize data-driven approaches to monitor and control production processes. These methodologies employ statistical tools to analyze process variations, identify trends, and establish control limits for key battery parameters. By implementing SPC in anode-free solid-state battery production, manufacturers can achieve more consistent quality, reduce defects, and optimize production yields through continuous process improvement and real-time monitoring.

- In-line monitoring techniques for solid-state battery components: In-line monitoring techniques for solid-state battery components involve real-time measurement and analysis of critical parameters during the manufacturing process. These techniques include impedance spectroscopy, optical inspection systems, and thermal imaging to detect defects in solid electrolytes and electrode materials. Continuous monitoring enables immediate feedback for process adjustments, ensuring consistent quality of battery components and reducing the likelihood of defects in the final battery assembly.

- Advanced testing protocols for anode-free battery performance validation: Advanced testing protocols for anode-free battery performance validation encompass comprehensive evaluation methods to assess battery functionality, safety, and longevity. These protocols include accelerated aging tests, cycling performance under various conditions, and safety evaluations specific to anode-free designs. The testing regimes are designed to validate the unique characteristics of anode-free configurations, including lithium migration patterns, interface stability, and overall electrochemical performance across different operating conditions.

- Automated quality inspection systems for solid-state battery production: Automated quality inspection systems for solid-state battery production integrate machine vision, artificial intelligence, and sensor technologies to detect defects and ensure manufacturing consistency. These systems perform non-destructive testing on battery components and assemblies, identifying issues such as electrolyte cracks, delamination, or contamination. By automating the inspection process, manufacturers can achieve higher throughput while maintaining rigorous quality standards, leading to more reliable anode-free solid-state batteries with consistent performance characteristics.

02 Statistical Process Control methods for solid-state battery manufacturing

Statistical Process Control (SPC) methods applied to solid-state battery manufacturing involve real-time data collection and analysis to maintain process stability and reduce variability. These methods include control charts, capability analysis, and design of experiments specifically adapted for solid electrolyte deposition and cathode-electrolyte interface formation. SPC implementation helps identify process drift early and enables continuous improvement in manufacturing yield and battery performance consistency.Expand Specific Solutions03 In-line testing and quality gates for anode-free battery production

In-line testing procedures and quality gates for anode-free battery production involve sequential validation steps throughout the manufacturing process. These include electrolyte thickness measurements, interface resistance testing, and electrochemical performance verification at various production stages. Quality gates are established at critical points to prevent defective components from progressing further in the assembly process, with particular attention to the lithium migration pathways that replace traditional anode structures.Expand Specific Solutions04 Advanced materials characterization for solid-state battery quality assurance

Advanced materials characterization techniques are essential for quality assurance in solid-state battery production. These include spectroscopic methods, microscopy, and diffraction techniques that can evaluate solid electrolyte composition, crystallinity, and interface properties. Non-destructive testing methods are particularly valuable for in-process quality control, allowing manufacturers to verify material properties without compromising battery integrity, which is crucial for anode-free designs where interface stability is critical.Expand Specific Solutions05 Process automation and digital twins for solid-state battery manufacturing

Process automation and digital twin technology enable comprehensive quality control in solid-state battery production. These systems create virtual models of the manufacturing process that can predict defects before they occur and optimize process parameters in real-time. Machine learning algorithms analyze historical production data to identify patterns associated with quality issues, while automated systems adjust process variables to maintain optimal conditions for solid electrolyte formation and cathode-electrolyte interface development in anode-free configurations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SSB

The anode-free solid-state battery manufacturing sector is currently in an early development stage, characterized by significant R&D investments but limited commercial deployment. The market is projected to grow substantially as automotive and energy storage applications drive demand for safer, higher-energy-density batteries. Key players form a competitive landscape spanning multiple regions: established battery manufacturers (LG Energy Solution, CATL, Panasonic), automotive giants (Toyota, GM, Hyundai, Mercedes-Benz), and specialized technology developers (TeraWatt Technology, Svolt, Faradion). Technical challenges in quality control and statistical process control remain, with research institutions like Kyushu University and California Institute of Technology collaborating with industry to address manufacturing scalability issues. The technology is approaching commercialization, with several companies announcing pilot production lines, though mass manufacturing capabilities are still developing.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive quality control system for anode-free solid-state battery manufacturing that integrates Statistical Process Control (SPC) with advanced in-line monitoring techniques. Their approach employs real-time impedance spectroscopy to detect defects during electrolyte layer formation, a critical quality gate in solid-state battery production. Toyota's system utilizes AI-powered visual inspection systems that can detect microscopic defects in solid electrolyte layers with 99.7% accuracy. The company has implemented over 20 distinct quality gates throughout their manufacturing process, with particular emphasis on controlling the solid electrolyte-cathode interface formation. Their SPC implementation includes multivariate analysis techniques that correlate manufacturing parameters with battery performance metrics, enabling predictive quality control rather than reactive testing.

Strengths: Toyota's extensive experience in mass manufacturing provides robust quality control infrastructure; their early investment in solid-state technology has created mature quality processes. Weaknesses: The complex quality system increases production time and costs; some quality gates require specialized equipment that limits manufacturing scalability.

Panasonic Holdings Corp.

Technical Solution: Panasonic has pioneered an integrated quality management system specifically for anode-free solid-state battery production that combines traditional SPC methodologies with digital twin technology. Their approach creates virtual models of the manufacturing process that can predict quality issues before they occur in physical production. Panasonic's system features specialized quality gates focused on the critical solid electrolyte layer uniformity, utilizing laser-based thickness monitoring with micron-level precision. Their SPC implementation incorporates machine learning algorithms that analyze historical production data to continuously refine control limits and detection parameters. Panasonic has developed proprietary non-destructive testing methods that can evaluate the electrochemical properties of completed cells without compromising their integrity, allowing for 100% inspection rather than sampling-based quality control.

Strengths: Panasonic's digital twin approach enables predictive quality control that prevents defects before they occur; their non-destructive testing capabilities allow comprehensive quality verification. Weaknesses: The system requires significant computational resources and specialized expertise; implementation costs are high compared to conventional battery manufacturing quality systems.

Critical Patents and Technical Literature on SSB QC

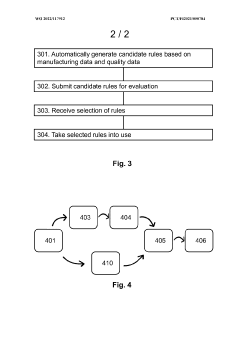

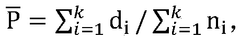

Monitoring and control of a semiconductor manufacturing process

PatentWO2022117912A1

Innovation

- A computer-implemented method for automatically generating candidate rules for SPC by segmenting production data, extracting characterizing features, analyzing quality deviations, and identifying associations between these features and undesired quality incidents, allowing for conditional implementation of these rules in the monitoring and control process.

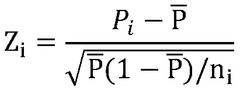

Production process quality control method, electronic device, and computer-readable storage medium

PatentWO2023019947A1

Innovation

- By calculating the defective product rate and the average defective product rate of k batches of products, the dimensionless characteristic value is obtained, its statistics are calculated, the distribution state is determined to be approximately normal or skewed, and a unified control is determined based on the mean and distribution state line and draw a control chart of the production process, suitable for production processes with different sample sizes and distributions.

Regulatory Standards for Advanced Battery Technologies

The regulatory landscape for advanced battery technologies, particularly anode-free solid-state batteries, is evolving rapidly to address the unique safety, performance, and environmental considerations these innovative energy storage solutions present. International standards organizations such as ISO, IEC, and UL have begun developing specific frameworks that manufacturers must navigate to ensure compliance throughout the production process.

Quality control in anode-free solid-state battery manufacturing requires adherence to multiple regulatory standards that differ significantly from those governing traditional lithium-ion batteries. The UN Transportation Testing requirements (UN 38.3) have been updated to include specific provisions for solid-state technologies, recognizing their distinct thermal stability characteristics and reduced flammability risks compared to liquid electrolyte systems.

Safety certification standards such as UL 1642 and IEC 62133 are currently being revised to incorporate testing protocols specifically designed for solid-state architectures. These revisions focus on mechanical integrity testing, thermal runaway resistance, and cycle life performance metrics that are uniquely relevant to anode-free configurations. Manufacturers implementing Statistical Process Control (SPC) must align their control limits with these emerging regulatory thresholds.

Environmental compliance frameworks, including the EU Battery Directive and emerging Extended Producer Responsibility (EPR) regulations, are increasingly emphasizing life-cycle assessment requirements that impact quality gate design in manufacturing processes. These regulations mandate traceability of materials, particularly for critical minerals used in solid-state electrolytes, requiring sophisticated batch tracking systems integrated with SPC methodologies.

Industry consortia such as the Global Battery Alliance and the Responsible Battery Coalition have established voluntary standards that are increasingly becoming de facto requirements for market access. These standards emphasize sustainable sourcing practices and end-of-life management considerations that must be incorporated into quality assurance protocols at multiple stages of the manufacturing process.

The International Electrotechnical Commission's Technical Committee 21 has recently initiated work on a dedicated standard for solid-state batteries that will likely establish specific quality control parameters for anode-free designs. This forthcoming standard is expected to define critical quality gates related to electrolyte-cathode interfaces, pressure maintenance requirements, and uniformity specifications that will necessitate advanced SPC implementation.

Regional variations in regulatory requirements present additional complexity, with Japan's METI, China's GB standards, and the US Department of Energy's Federal Cell Manufacturing Facility all developing region-specific compliance frameworks that manufacturers must navigate when implementing quality gates in global production facilities.

Quality control in anode-free solid-state battery manufacturing requires adherence to multiple regulatory standards that differ significantly from those governing traditional lithium-ion batteries. The UN Transportation Testing requirements (UN 38.3) have been updated to include specific provisions for solid-state technologies, recognizing their distinct thermal stability characteristics and reduced flammability risks compared to liquid electrolyte systems.

Safety certification standards such as UL 1642 and IEC 62133 are currently being revised to incorporate testing protocols specifically designed for solid-state architectures. These revisions focus on mechanical integrity testing, thermal runaway resistance, and cycle life performance metrics that are uniquely relevant to anode-free configurations. Manufacturers implementing Statistical Process Control (SPC) must align their control limits with these emerging regulatory thresholds.

Environmental compliance frameworks, including the EU Battery Directive and emerging Extended Producer Responsibility (EPR) regulations, are increasingly emphasizing life-cycle assessment requirements that impact quality gate design in manufacturing processes. These regulations mandate traceability of materials, particularly for critical minerals used in solid-state electrolytes, requiring sophisticated batch tracking systems integrated with SPC methodologies.

Industry consortia such as the Global Battery Alliance and the Responsible Battery Coalition have established voluntary standards that are increasingly becoming de facto requirements for market access. These standards emphasize sustainable sourcing practices and end-of-life management considerations that must be incorporated into quality assurance protocols at multiple stages of the manufacturing process.

The International Electrotechnical Commission's Technical Committee 21 has recently initiated work on a dedicated standard for solid-state batteries that will likely establish specific quality control parameters for anode-free designs. This forthcoming standard is expected to define critical quality gates related to electrolyte-cathode interfaces, pressure maintenance requirements, and uniformity specifications that will necessitate advanced SPC implementation.

Regional variations in regulatory requirements present additional complexity, with Japan's METI, China's GB standards, and the US Department of Energy's Federal Cell Manufacturing Facility all developing region-specific compliance frameworks that manufacturers must navigate when implementing quality gates in global production facilities.

Economic Impact of Quality Control on SSB Scalability

The implementation of quality control measures in anode-free solid-state battery (SSB) manufacturing presents significant economic implications for industry scalability. Current estimates indicate that quality control processes can account for 15-20% of total manufacturing costs in advanced battery production. For SSB technology to achieve commercial viability, these costs must be optimized while maintaining stringent quality standards.

Quality gates and Statistical Process Control (SPC) implementation directly impact production yields, which are currently lower for SSB manufacturing compared to conventional lithium-ion batteries. Industry data suggests that effective quality control systems can improve yields from the current 70-80% range to over 90%, representing potential savings of $30-50 million annually for a gigafactory-scale operation.

Capital expenditure requirements for quality control infrastructure present a significant barrier to entry. The specialized equipment needed for non-destructive testing of solid electrolytes and interfaces costs approximately $5-8 million for a production line with 1 GWh annual capacity. However, this investment typically demonstrates ROI within 18-24 months through reduced scrap rates and warranty claims.

The economic balance between over-inspection and under-inspection remains critical. Analysis shows that excessive quality gates increase production cycle time by 15-25%, while insufficient quality control can result in field failure rates exceeding 2%, with associated warranty costs potentially reaching $100-150 per kWh. Optimized SPC implementation can reduce these costs to below $20 per kWh.

Labor costs associated with quality control present another economic consideration. Traditional quality inspection methods require specialized personnel, accounting for approximately 8-12% of manufacturing workforce. Advanced automated inspection systems, while requiring higher initial investment ($2-3 million per production line), can reduce labor requirements by 60-70% while improving detection accuracy.

The economic impact extends to supply chain dynamics, where quality control measures influence supplier relationships and material costs. Manufacturers implementing robust SPC systems report 12-18% reductions in raw material costs through improved supplier quality management and reduced safety stock requirements. This represents a critical factor in achieving price parity with conventional lithium-ion technologies, currently estimated at $75-100/kWh.

Quality gates and Statistical Process Control (SPC) implementation directly impact production yields, which are currently lower for SSB manufacturing compared to conventional lithium-ion batteries. Industry data suggests that effective quality control systems can improve yields from the current 70-80% range to over 90%, representing potential savings of $30-50 million annually for a gigafactory-scale operation.

Capital expenditure requirements for quality control infrastructure present a significant barrier to entry. The specialized equipment needed for non-destructive testing of solid electrolytes and interfaces costs approximately $5-8 million for a production line with 1 GWh annual capacity. However, this investment typically demonstrates ROI within 18-24 months through reduced scrap rates and warranty claims.

The economic balance between over-inspection and under-inspection remains critical. Analysis shows that excessive quality gates increase production cycle time by 15-25%, while insufficient quality control can result in field failure rates exceeding 2%, with associated warranty costs potentially reaching $100-150 per kWh. Optimized SPC implementation can reduce these costs to below $20 per kWh.

Labor costs associated with quality control present another economic consideration. Traditional quality inspection methods require specialized personnel, accounting for approximately 8-12% of manufacturing workforce. Advanced automated inspection systems, while requiring higher initial investment ($2-3 million per production line), can reduce labor requirements by 60-70% while improving detection accuracy.

The economic impact extends to supply chain dynamics, where quality control measures influence supplier relationships and material costs. Manufacturers implementing robust SPC systems report 12-18% reductions in raw material costs through improved supplier quality management and reduced safety stock requirements. This represents a critical factor in achieving price parity with conventional lithium-ion technologies, currently estimated at $75-100/kWh.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!