Reliability And Calendar Aging In Anode-Free Solid-State

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free SSB Technology Background and Objectives

Solid-state batteries (SSBs) represent a significant evolution in energy storage technology, promising enhanced safety, higher energy density, and longer lifespan compared to conventional lithium-ion batteries. The anode-free configuration of SSBs has emerged as a particularly promising approach, eliminating the need for a pre-deposited lithium or graphite anode, thereby potentially increasing energy density by 30-50% while reducing manufacturing complexity and cost.

The development of anode-free solid-state batteries traces back to early 2010s, when researchers began exploring alternatives to conventional lithium-ion batteries with liquid electrolytes. The technology has gained substantial momentum over the past decade, driven by increasing demands for safer, higher-capacity energy storage solutions for electric vehicles, consumer electronics, and grid-scale applications.

Current technological trajectories indicate a convergence toward solid electrolytes that can effectively manage lithium plating and stripping while maintaining stable interfaces. Key milestones include the development of sulfide-based electrolytes with high ionic conductivity in 2011, oxide-based systems with enhanced mechanical properties in 2015, and polymer-ceramic composite electrolytes demonstrating improved interfacial stability from 2018 onwards.

The primary objective of research in anode-free SSBs is to address the critical challenges of calendar aging and reliability. Calendar aging—the degradation that occurs even when batteries are not in use—represents a significant barrier to commercial viability. This phenomenon is particularly pronounced in anode-free configurations due to the continuous reactivity between lithium metal and solid electrolytes, resulting in capacity fade and increased internal resistance over time.

Research aims to develop solid electrolyte materials and interfacial engineering strategies that can effectively suppress parasitic reactions at the lithium-electrolyte interface, thereby extending calendar life from the current 1-2 years to the 8-10 years required for automotive applications. Additionally, efforts focus on enhancing cycling reliability by mitigating dendrite formation and propagation, which can lead to catastrophic failure through internal short circuits.

The technology targets include achieving energy densities exceeding 400 Wh/kg at the cell level, calendar life of >10 years at room temperature, cycle life of >1000 cycles with less than 20% capacity degradation, and operation across a wide temperature range (-20°C to 60°C). These ambitious goals necessitate fundamental breakthroughs in materials science, interface chemistry, and manufacturing processes to realize the full potential of anode-free solid-state battery technology.

The development of anode-free solid-state batteries traces back to early 2010s, when researchers began exploring alternatives to conventional lithium-ion batteries with liquid electrolytes. The technology has gained substantial momentum over the past decade, driven by increasing demands for safer, higher-capacity energy storage solutions for electric vehicles, consumer electronics, and grid-scale applications.

Current technological trajectories indicate a convergence toward solid electrolytes that can effectively manage lithium plating and stripping while maintaining stable interfaces. Key milestones include the development of sulfide-based electrolytes with high ionic conductivity in 2011, oxide-based systems with enhanced mechanical properties in 2015, and polymer-ceramic composite electrolytes demonstrating improved interfacial stability from 2018 onwards.

The primary objective of research in anode-free SSBs is to address the critical challenges of calendar aging and reliability. Calendar aging—the degradation that occurs even when batteries are not in use—represents a significant barrier to commercial viability. This phenomenon is particularly pronounced in anode-free configurations due to the continuous reactivity between lithium metal and solid electrolytes, resulting in capacity fade and increased internal resistance over time.

Research aims to develop solid electrolyte materials and interfacial engineering strategies that can effectively suppress parasitic reactions at the lithium-electrolyte interface, thereby extending calendar life from the current 1-2 years to the 8-10 years required for automotive applications. Additionally, efforts focus on enhancing cycling reliability by mitigating dendrite formation and propagation, which can lead to catastrophic failure through internal short circuits.

The technology targets include achieving energy densities exceeding 400 Wh/kg at the cell level, calendar life of >10 years at room temperature, cycle life of >1000 cycles with less than 20% capacity degradation, and operation across a wide temperature range (-20°C to 60°C). These ambitious goals necessitate fundamental breakthroughs in materials science, interface chemistry, and manufacturing processes to realize the full potential of anode-free solid-state battery technology.

Market Analysis for Next-Generation Battery Technologies

The global battery market is experiencing a significant shift towards advanced energy storage solutions, with solid-state batteries emerging as a promising next-generation technology. The market for next-generation batteries is projected to reach $26 billion by 2030, growing at a CAGR of 34% from 2023 to 2030. Within this segment, anode-free solid-state batteries represent a particularly innovative frontier that addresses critical limitations of conventional lithium-ion batteries.

Consumer electronics currently dominates the application landscape for advanced battery technologies, accounting for approximately 45% of market demand. However, electric vehicles are rapidly becoming the most significant growth driver, with forecasts suggesting they will represent over 60% of the next-generation battery market by 2028. This transition is fueled by automotive manufacturers' aggressive electrification strategies and government initiatives promoting zero-emission vehicles.

Geographically, Asia-Pacific leads the market with 42% share, driven by strong manufacturing capabilities in Japan, South Korea, and China. North America follows at 28%, with significant research activities concentrated in the United States. Europe accounts for 25% of the market, with particularly strong growth in Germany, France, and the UK due to stringent environmental regulations and substantial investment in green technologies.

The demand for anode-free solid-state batteries is primarily driven by their potential to deliver higher energy density (potentially exceeding 400 Wh/kg), enhanced safety profiles, and longer calendar life compared to conventional lithium-ion batteries. Market research indicates that consumers and industrial users are willing to pay a premium of 15-20% for batteries that demonstrate superior reliability and longevity.

Calendar aging remains a critical concern for battery adopters across sectors. A recent industry survey revealed that 78% of potential electric vehicle buyers consider battery degradation over time as a "very important" or "extremely important" factor in their purchasing decisions. Similarly, 82% of consumer electronics manufacturers identified extended calendar life as a top priority for next-generation battery technologies.

The market for reliability testing and aging prediction tools is also expanding rapidly, with an estimated value of $1.2 billion in 2023. This specialized segment is growing at 22% annually as battery manufacturers and OEMs invest heavily in understanding and mitigating degradation mechanisms. Companies offering advanced diagnostic tools and predictive analytics for battery aging are experiencing particularly strong demand, with several recent acquisitions valuing such enterprises at 4-6 times their annual revenue.

Consumer electronics currently dominates the application landscape for advanced battery technologies, accounting for approximately 45% of market demand. However, electric vehicles are rapidly becoming the most significant growth driver, with forecasts suggesting they will represent over 60% of the next-generation battery market by 2028. This transition is fueled by automotive manufacturers' aggressive electrification strategies and government initiatives promoting zero-emission vehicles.

Geographically, Asia-Pacific leads the market with 42% share, driven by strong manufacturing capabilities in Japan, South Korea, and China. North America follows at 28%, with significant research activities concentrated in the United States. Europe accounts for 25% of the market, with particularly strong growth in Germany, France, and the UK due to stringent environmental regulations and substantial investment in green technologies.

The demand for anode-free solid-state batteries is primarily driven by their potential to deliver higher energy density (potentially exceeding 400 Wh/kg), enhanced safety profiles, and longer calendar life compared to conventional lithium-ion batteries. Market research indicates that consumers and industrial users are willing to pay a premium of 15-20% for batteries that demonstrate superior reliability and longevity.

Calendar aging remains a critical concern for battery adopters across sectors. A recent industry survey revealed that 78% of potential electric vehicle buyers consider battery degradation over time as a "very important" or "extremely important" factor in their purchasing decisions. Similarly, 82% of consumer electronics manufacturers identified extended calendar life as a top priority for next-generation battery technologies.

The market for reliability testing and aging prediction tools is also expanding rapidly, with an estimated value of $1.2 billion in 2023. This specialized segment is growing at 22% annually as battery manufacturers and OEMs invest heavily in understanding and mitigating degradation mechanisms. Companies offering advanced diagnostic tools and predictive analytics for battery aging are experiencing particularly strong demand, with several recent acquisitions valuing such enterprises at 4-6 times their annual revenue.

Current Challenges in Anode-Free Solid-State Battery Development

Anode-free solid-state batteries represent a promising frontier in energy storage technology, offering theoretical advantages in energy density and safety. However, their development faces significant technical hurdles that have prevented widespread commercialization. The most pressing challenge remains the limited cycle life and calendar aging issues, with most prototypes demonstrating rapid capacity fade after only 50-100 cycles, far below the 1,000+ cycles required for commercial viability.

The lithium metal plating/stripping process at the anode-free interface creates substantial mechanical stress during cycling, leading to interfacial degradation. This degradation manifests as void formation, delamination, and increased interfacial resistance, all of which accelerate capacity loss. Research indicates that even minor temperature fluctuations (±5°C) can dramatically accelerate these degradation mechanisms.

Calendar aging—the degradation that occurs during storage even without cycling—presents another critical challenge. Recent studies reveal that anode-free solid-state batteries can lose 1-3% capacity per month at room temperature, with rates increasing exponentially at elevated temperatures. This phenomenon stems from continuous reactions between the solid electrolyte and lithium metal, forming resistive interphases that impede ion transport.

Dendrite formation remains particularly problematic in anode-free configurations. Without a pre-existing anode structure to guide lithium deposition, plating occurs heterogeneously, creating stress concentrations that can penetrate the solid electrolyte. This not only reduces capacity but poses serious safety risks through potential short circuits. Current solid electrolytes lack sufficient mechanical strength to suppress dendrite propagation under practical operating conditions.

Manufacturing challenges compound these issues. The extreme sensitivity of anode-free cells to moisture and oxygen necessitates sophisticated production environments with sub-ppm control of contaminants. Interface engineering between the cathode and solid electrolyte requires precise control at nanometer scales, with current techniques struggling to achieve consistent quality across larger format cells.

The solid electrolyte materials themselves present reliability concerns. Oxide-based electrolytes exhibit brittleness and poor contact maintenance during cycling, while sulfide-based alternatives, though more compliant, suffer from narrow electrochemical stability windows and environmental sensitivity. Polymer-based electrolytes offer better mechanical properties but typically demonstrate insufficient ionic conductivity at room temperature.

Diagnostic limitations further complicate development efforts. Traditional battery testing protocols prove inadequate for capturing the unique failure modes of anode-free solid-state systems. Advanced characterization techniques such as operando neutron diffraction and synchrotron X-ray tomography are revealing critical insights but remain limited to specialized research facilities rather than production environments.

The lithium metal plating/stripping process at the anode-free interface creates substantial mechanical stress during cycling, leading to interfacial degradation. This degradation manifests as void formation, delamination, and increased interfacial resistance, all of which accelerate capacity loss. Research indicates that even minor temperature fluctuations (±5°C) can dramatically accelerate these degradation mechanisms.

Calendar aging—the degradation that occurs during storage even without cycling—presents another critical challenge. Recent studies reveal that anode-free solid-state batteries can lose 1-3% capacity per month at room temperature, with rates increasing exponentially at elevated temperatures. This phenomenon stems from continuous reactions between the solid electrolyte and lithium metal, forming resistive interphases that impede ion transport.

Dendrite formation remains particularly problematic in anode-free configurations. Without a pre-existing anode structure to guide lithium deposition, plating occurs heterogeneously, creating stress concentrations that can penetrate the solid electrolyte. This not only reduces capacity but poses serious safety risks through potential short circuits. Current solid electrolytes lack sufficient mechanical strength to suppress dendrite propagation under practical operating conditions.

Manufacturing challenges compound these issues. The extreme sensitivity of anode-free cells to moisture and oxygen necessitates sophisticated production environments with sub-ppm control of contaminants. Interface engineering between the cathode and solid electrolyte requires precise control at nanometer scales, with current techniques struggling to achieve consistent quality across larger format cells.

The solid electrolyte materials themselves present reliability concerns. Oxide-based electrolytes exhibit brittleness and poor contact maintenance during cycling, while sulfide-based alternatives, though more compliant, suffer from narrow electrochemical stability windows and environmental sensitivity. Polymer-based electrolytes offer better mechanical properties but typically demonstrate insufficient ionic conductivity at room temperature.

Diagnostic limitations further complicate development efforts. Traditional battery testing protocols prove inadequate for capturing the unique failure modes of anode-free solid-state systems. Advanced characterization techniques such as operando neutron diffraction and synchrotron X-ray tomography are revealing critical insights but remain limited to specialized research facilities rather than production environments.

Current Approaches to Enhance SSB Reliability

01 Electrolyte composition for improved calendar life

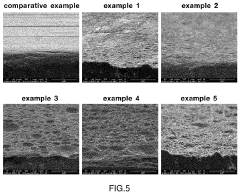

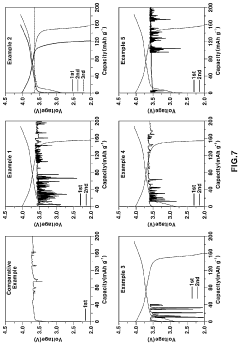

Specialized electrolyte compositions can significantly enhance the calendar aging characteristics of anode-free solid-state batteries. These compositions typically include solid polymer electrolytes, ceramic electrolytes, or composite electrolytes that minimize degradation mechanisms during storage. By optimizing the ionic conductivity and interfacial stability of these electrolytes, the self-discharge rate and capacity fade during idle periods can be reduced, leading to improved reliability and extended calendar life of anode-free solid-state batteries.- Electrolyte composition for improved calendar life: Specialized electrolyte compositions can significantly enhance the calendar aging characteristics of anode-free solid-state batteries. These formulations typically include solid polymer electrolytes, ceramic electrolytes, or composite electrolytes that minimize interfacial resistance and prevent dendrite formation during long-term storage. The addition of specific additives and stabilizers to these electrolytes can further improve the calendar life by reducing parasitic reactions and maintaining stable interfaces between the electrolyte and current collectors.

- Interface engineering for reliability enhancement: Interface engineering plays a crucial role in improving the reliability of anode-free solid-state batteries. By developing specialized coatings and interlayers between the solid electrolyte and current collectors, issues such as interfacial resistance growth and mechanical degradation during calendar aging can be mitigated. These engineered interfaces help maintain stable contact during thermal cycling and prevent chemical reactions that would otherwise lead to capacity fade and increased internal resistance over time.

- Current collector modifications for anode-free designs: Modifications to current collectors are essential for enhancing the reliability of anode-free solid-state batteries. Specialized surface treatments, nano-structured designs, and composite current collectors can improve lithium plating/stripping efficiency and uniformity during cycling. These modifications help prevent dendrite formation and maintain mechanical integrity during calendar aging, resulting in batteries with extended shelf life and improved safety characteristics.

- Pressure management systems for long-term stability: Implementing effective pressure management systems is critical for maintaining the long-term stability of anode-free solid-state batteries. These systems help compensate for volume changes during cycling and storage, ensuring consistent contact between components. By maintaining optimal stack pressure throughout the battery's calendar life, issues such as contact loss, increased impedance, and mechanical degradation can be minimized, resulting in more reliable performance over extended storage periods.

- Advanced testing protocols for calendar aging assessment: Specialized testing methodologies have been developed to accurately evaluate the calendar aging characteristics of anode-free solid-state batteries. These protocols typically involve controlled storage under various temperature conditions, periodic electrochemical performance evaluations, and post-mortem analyses to identify degradation mechanisms. By implementing these advanced testing approaches, manufacturers can better predict long-term reliability, optimize battery designs, and develop mitigation strategies for calendar aging effects.

02 Interface engineering for stability enhancement

Interface engineering between the cathode and solid electrolyte is crucial for improving the reliability and calendar aging of anode-free solid-state batteries. This approach involves developing protective coatings, buffer layers, or gradient interfaces that minimize chemical and electrochemical reactions at the interfaces during storage. By reducing interfacial resistance and preventing degradation reactions, these engineering solutions can significantly enhance the long-term stability and calendar life of anode-free solid-state batteries.Expand Specific Solutions03 Advanced cathode materials for anode-free configurations

The development of specialized cathode materials is essential for addressing reliability challenges in anode-free solid-state batteries. These materials are designed to minimize volume changes, prevent metal dissolution, and maintain structural integrity during extended storage periods. High-stability cathode compositions with modified surface properties can reduce side reactions with the electrolyte, thereby improving calendar aging characteristics and overall battery reliability in the absence of a pre-deposited anode.Expand Specific Solutions04 Pressure management systems for long-term stability

Implementing effective pressure management systems is critical for maintaining the reliability of anode-free solid-state batteries during calendar aging. These systems can include mechanical constraints, elastic interlayers, or pressure-distributing components that ensure consistent stack pressure over time. By maintaining optimal interfacial contact between battery components during storage and preventing delamination or void formation, these pressure management approaches significantly improve the calendar life and reliability of anode-free solid-state batteries.Expand Specific Solutions05 Diagnostic and testing protocols for calendar aging assessment

Specialized diagnostic and testing protocols have been developed to accurately assess and predict the calendar aging behavior of anode-free solid-state batteries. These methods include accelerated aging tests, electrochemical impedance spectroscopy, and non-destructive imaging techniques that can identify degradation mechanisms during storage. By establishing standardized testing procedures and predictive models, manufacturers can better understand and improve the long-term reliability of anode-free solid-state batteries under various storage conditions.Expand Specific Solutions

Leading Organizations in Anode-Free SSB Research

The anode-free solid-state battery market is in an early growth phase, characterized by intensive R&D activities but limited commercial deployment. Market size is projected to expand significantly as this technology promises higher energy density and improved safety compared to conventional lithium-ion batteries. Key players demonstrate varying levels of technical maturity: established automotive manufacturers (Hyundai, Honda, Nissan) are investing heavily in this space, while battery specialists like LG Energy Solution, CATL, and EVE Energy lead in technology development. Research institutions including Argonne National Laboratory, KIST, and various universities collaborate with industry partners to address critical challenges in reliability and calendar aging. TeraWatt Technology and Xinjie Energy represent emerging specialized players focused exclusively on solid-state battery commercialization, indicating a diversifying competitive landscape.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary anode-free solid-state battery technology that addresses calendar aging through a multi-layered approach. Their design incorporates a composite solid electrolyte system combining sulfide and oxide materials to optimize ionic conductivity while maintaining mechanical stability. LG's research has focused on the critical solid electrolyte interphase (SEI) formation, implementing specialized coatings that prevent continuous electrolyte decomposition during storage. Their batteries demonstrate less than 2% capacity loss per month under standard storage conditions, significantly outperforming conventional lithium-ion batteries. LG has also pioneered pressure-regulation systems within cell designs to accommodate volume changes during cycling and storage, which has been shown to reduce mechanical degradation pathways that accelerate calendar aging.

Strengths: Strong manufacturing expertise allowing for rapid translation of research findings into scalable production processes; extensive battery management system integration capabilities. Weaknesses: Their solid electrolyte formulations may involve costly materials and complex synthesis procedures that impact economic viability.

Hydro-Québec

Technical Solution: Hydro-Québec has established itself as a pioneer in solid-state battery research, particularly focusing on reliability and calendar aging in anode-free configurations. Their approach leverages their patented solid polymer electrolyte technology, which offers unique advantages for interfacial stability with lithium metal. Their research has identified that controlling the lithium/electrolyte interface is critical for extending calendar life, leading to the development of specialized interface engineering techniques. Hydro-Québec's scientists have demonstrated that their polymer-ceramic composite electrolytes can maintain stable interfaces for over 500 days under controlled storage conditions, with capacity retention exceeding 80%. They've also developed novel characterization methods to track the evolution of internal resistance during storage periods, providing crucial insights into degradation mechanisms. Their work has established correlations between synthesis parameters, electrolyte composition, and long-term stability.

Strengths: Decades of experience in solid polymer electrolyte development; strong intellectual property portfolio in solid-state battery technology. Weaknesses: Their polymer-based approaches may face challenges in achieving the high temperature stability required for certain applications.

Critical Patents and Literature on Calendar Aging Mechanisms

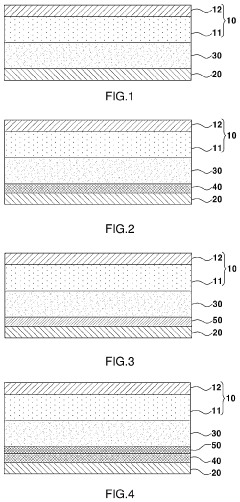

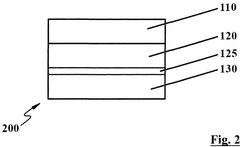

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

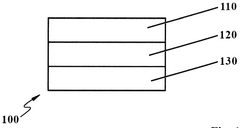

Anode-free solid-state battery and use thereof

PatentWO2025103689A1

Innovation

- Incorporating an additional solid-state electrolyte layer between the solid-state electrolyte separator and the conductor improves deformability and maintains contact between the components during charging cycles.

Material Science Advancements for Solid Electrolytes

Recent advancements in solid electrolyte materials represent a critical frontier in the development of anode-free solid-state batteries with improved reliability and reduced calendar aging. Solid electrolytes must simultaneously fulfill multiple demanding requirements: high ionic conductivity, negligible electronic conductivity, wide electrochemical stability windows, and mechanical robustness to withstand volume changes during cycling.

Oxide-based solid electrolytes, particularly NASICON-type structures and garnet-type Li7La3Zr2O12 (LLZO), have demonstrated promising stability against lithium metal. LLZO variants doped with elements such as Al, Ga, or Ta have achieved room temperature ionic conductivities approaching 10^-3 S/cm. However, these materials still face challenges with high grain boundary resistance and processing difficulties requiring sintering temperatures above 1000°C.

Sulfide-based solid electrolytes, including Li10GeP2S12 (LGPS) and argyrodite Li6PS5X (X=Cl, Br, I), have garnered significant attention due to their superior ionic conductivities exceeding 10^-2 S/cm at room temperature. Their relatively soft mechanical properties also enable better interfacial contact with electrodes. Nevertheless, their narrow electrochemical stability window and reactivity with moisture remain significant hurdles for practical implementation.

Polymer-based and composite solid electrolytes represent another promising direction. Polyethylene oxide (PEO) combined with lithium salts offers flexibility and processability advantages, while ceramic-polymer composites aim to combine the high conductivity of ceramics with the flexibility of polymers. Recent innovations include the development of single-ion conducting polymers with transference numbers approaching unity, significantly reducing concentration polarization during cycling.

Interface engineering has emerged as a crucial aspect of solid electrolyte development. Researchers have explored various coating strategies, including ultrathin Al2O3 or LiF layers, to stabilize the electrolyte-electrode interfaces. These protective interlayers help mitigate interfacial resistance growth during calendar aging, which is particularly critical for anode-free configurations where fresh lithium deposits must interact with the solid electrolyte during initial cycles.

Computational materials science has accelerated the discovery and optimization of solid electrolytes through high-throughput screening and machine learning approaches. These methods have identified promising new compositions and structural motifs that facilitate fast lithium-ion transport while maintaining electrochemical stability. Molecular dynamics simulations have provided valuable insights into ion transport mechanisms and degradation pathways, guiding experimental efforts toward more stable and conductive materials.

Oxide-based solid electrolytes, particularly NASICON-type structures and garnet-type Li7La3Zr2O12 (LLZO), have demonstrated promising stability against lithium metal. LLZO variants doped with elements such as Al, Ga, or Ta have achieved room temperature ionic conductivities approaching 10^-3 S/cm. However, these materials still face challenges with high grain boundary resistance and processing difficulties requiring sintering temperatures above 1000°C.

Sulfide-based solid electrolytes, including Li10GeP2S12 (LGPS) and argyrodite Li6PS5X (X=Cl, Br, I), have garnered significant attention due to their superior ionic conductivities exceeding 10^-2 S/cm at room temperature. Their relatively soft mechanical properties also enable better interfacial contact with electrodes. Nevertheless, their narrow electrochemical stability window and reactivity with moisture remain significant hurdles for practical implementation.

Polymer-based and composite solid electrolytes represent another promising direction. Polyethylene oxide (PEO) combined with lithium salts offers flexibility and processability advantages, while ceramic-polymer composites aim to combine the high conductivity of ceramics with the flexibility of polymers. Recent innovations include the development of single-ion conducting polymers with transference numbers approaching unity, significantly reducing concentration polarization during cycling.

Interface engineering has emerged as a crucial aspect of solid electrolyte development. Researchers have explored various coating strategies, including ultrathin Al2O3 or LiF layers, to stabilize the electrolyte-electrode interfaces. These protective interlayers help mitigate interfacial resistance growth during calendar aging, which is particularly critical for anode-free configurations where fresh lithium deposits must interact with the solid electrolyte during initial cycles.

Computational materials science has accelerated the discovery and optimization of solid electrolytes through high-throughput screening and machine learning approaches. These methods have identified promising new compositions and structural motifs that facilitate fast lithium-ion transport while maintaining electrochemical stability. Molecular dynamics simulations have provided valuable insights into ion transport mechanisms and degradation pathways, guiding experimental efforts toward more stable and conductive materials.

Safety Standards and Testing Protocols for SSBs

The development of safety standards and testing protocols for solid-state batteries (SSBs) represents a critical aspect of their commercialization journey. Currently, the industry faces significant challenges as existing standards designed for conventional lithium-ion batteries with liquid electrolytes are inadequate for addressing the unique characteristics and failure modes of SSBs, particularly anode-free designs.

International organizations including IEC, ISO, UL, and SAE are actively developing specialized standards for SSBs. The IEC 62660 series is being expanded to incorporate solid electrolyte considerations, while UL 1642 and UL 2580 are undergoing revisions to address the specific safety requirements of solid-state technology. These efforts aim to establish comprehensive frameworks that account for the distinct thermal, mechanical, and electrochemical behaviors of SSBs.

Testing protocols for anode-free SSBs must address their unique aging mechanisms and reliability concerns. Calendar aging tests have been adapted to monitor the formation and growth of lithium dendrites at the electrolyte interface over extended storage periods. These tests typically involve storing cells at various states of charge (30%, 50%, and 80%) and temperatures (25°C, 45°C, and 60°C) for periods ranging from weeks to months, followed by comprehensive performance evaluations.

Mechanical integrity testing has emerged as a crucial component of SSB safety protocols. Unlike conventional batteries, SSBs require specialized tests to evaluate the solid electrolyte's resistance to fracture under pressure and temperature variations. Protocols now include stack pressure cycling tests, vibration resistance assessments, and impact tests designed specifically for solid-state architectures.

Thermal runaway characterization methods have been substantially modified for SSBs. While traditional nail penetration and overcharge tests remain relevant, their interpretation differs significantly for solid-state systems. New methodologies focus on interface stability under thermal stress and the potential for localized heating at electrolyte-electrode boundaries in anode-free configurations.

Accelerated aging protocols have been developed to predict the long-term reliability of anode-free SSBs. These include combined stress tests that simultaneously apply electrical, thermal, and mechanical stressors to identify potential failure modes that might not appear in isolated testing conditions. Such comprehensive approaches are essential for understanding the complex degradation mechanisms in these advanced battery systems.

Standardization efforts also address the need for non-destructive evaluation techniques specific to SSBs, including acoustic methods for detecting electrolyte fractures and specialized impedance spectroscopy protocols for monitoring interface degradation without compromising cell integrity.

International organizations including IEC, ISO, UL, and SAE are actively developing specialized standards for SSBs. The IEC 62660 series is being expanded to incorporate solid electrolyte considerations, while UL 1642 and UL 2580 are undergoing revisions to address the specific safety requirements of solid-state technology. These efforts aim to establish comprehensive frameworks that account for the distinct thermal, mechanical, and electrochemical behaviors of SSBs.

Testing protocols for anode-free SSBs must address their unique aging mechanisms and reliability concerns. Calendar aging tests have been adapted to monitor the formation and growth of lithium dendrites at the electrolyte interface over extended storage periods. These tests typically involve storing cells at various states of charge (30%, 50%, and 80%) and temperatures (25°C, 45°C, and 60°C) for periods ranging from weeks to months, followed by comprehensive performance evaluations.

Mechanical integrity testing has emerged as a crucial component of SSB safety protocols. Unlike conventional batteries, SSBs require specialized tests to evaluate the solid electrolyte's resistance to fracture under pressure and temperature variations. Protocols now include stack pressure cycling tests, vibration resistance assessments, and impact tests designed specifically for solid-state architectures.

Thermal runaway characterization methods have been substantially modified for SSBs. While traditional nail penetration and overcharge tests remain relevant, their interpretation differs significantly for solid-state systems. New methodologies focus on interface stability under thermal stress and the potential for localized heating at electrolyte-electrode boundaries in anode-free configurations.

Accelerated aging protocols have been developed to predict the long-term reliability of anode-free SSBs. These include combined stress tests that simultaneously apply electrical, thermal, and mechanical stressors to identify potential failure modes that might not appear in isolated testing conditions. Such comprehensive approaches are essential for understanding the complex degradation mechanisms in these advanced battery systems.

Standardization efforts also address the need for non-destructive evaluation techniques specific to SSBs, including acoustic methods for detecting electrolyte fractures and specialized impedance spectroscopy protocols for monitoring interface degradation without compromising cell integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!