Anode-Free Solid-State Mechanical Compliance Layers

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the energy storage landscape since their commercial introduction in the early 1990s. However, conventional lithium-ion batteries face inherent limitations in energy density, safety, and longevity, prompting researchers to explore next-generation alternatives. Among these emerging technologies, anode-free battery architecture represents a revolutionary approach that promises substantial improvements in energy density and safety profiles.

Anode-free battery technology eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that forms directly on the current collector during the charging process. This configuration theoretically enables energy densities approaching 500 Wh/kg, nearly double that of conventional lithium-ion batteries. The absence of a pre-lithiated anode also simplifies manufacturing processes and reduces overall battery weight and volume, making it particularly attractive for electric vehicles and portable electronics applications.

Despite these advantages, anode-free batteries face significant challenges, particularly regarding the formation and stability of lithium metal during cycling. Uneven lithium deposition leads to dendrite formation, which can penetrate the separator, causing short circuits and potential thermal runaway. Additionally, the high reactivity of lithium metal with liquid electrolytes results in continuous SEI (Solid Electrolyte Interphase) formation, consuming active lithium and electrolyte, ultimately leading to capacity fade and shortened battery life.

Solid-state electrolytes have emerged as a promising solution to address these challenges, offering improved safety through non-flammability and potential to suppress dendrite growth. However, the integration of solid electrolytes introduces new challenges, particularly mechanical issues at the lithium metal-electrolyte interface. During cycling, lithium undergoes significant volume changes, creating mechanical stresses that can lead to contact loss, increased impedance, and accelerated degradation.

Mechanical compliance layers represent a critical innovation in this context, designed to accommodate the volumetric changes of lithium metal while maintaining intimate contact between the electrolyte and electrode. These specialized interfacial layers must possess sufficient elasticity to buffer mechanical stresses while maintaining ionic conductivity and chemical stability against lithium metal.

The primary objective of anode-free solid-state mechanical compliance layer development is to create interfaces that can effectively manage the mechanical, chemical, and electrochemical complexities at the lithium-electrolyte boundary. This includes designing materials with optimized mechanical properties, ionic conductivity, and chemical stability to enable long-cycle life anode-free batteries with energy densities exceeding 400 Wh/kg at the cell level, while maintaining safety standards superior to conventional lithium-ion technologies.

Current research trajectories focus on polymer-ceramic composites, soft inorganic materials, and engineered interphases that can be integrated into manufacturing processes without compromising the economic viability of large-scale production. The successful development of these compliance layers represents a critical milestone toward commercializing anode-free solid-state batteries for next-generation energy storage applications.

Anode-free battery technology eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that forms directly on the current collector during the charging process. This configuration theoretically enables energy densities approaching 500 Wh/kg, nearly double that of conventional lithium-ion batteries. The absence of a pre-lithiated anode also simplifies manufacturing processes and reduces overall battery weight and volume, making it particularly attractive for electric vehicles and portable electronics applications.

Despite these advantages, anode-free batteries face significant challenges, particularly regarding the formation and stability of lithium metal during cycling. Uneven lithium deposition leads to dendrite formation, which can penetrate the separator, causing short circuits and potential thermal runaway. Additionally, the high reactivity of lithium metal with liquid electrolytes results in continuous SEI (Solid Electrolyte Interphase) formation, consuming active lithium and electrolyte, ultimately leading to capacity fade and shortened battery life.

Solid-state electrolytes have emerged as a promising solution to address these challenges, offering improved safety through non-flammability and potential to suppress dendrite growth. However, the integration of solid electrolytes introduces new challenges, particularly mechanical issues at the lithium metal-electrolyte interface. During cycling, lithium undergoes significant volume changes, creating mechanical stresses that can lead to contact loss, increased impedance, and accelerated degradation.

Mechanical compliance layers represent a critical innovation in this context, designed to accommodate the volumetric changes of lithium metal while maintaining intimate contact between the electrolyte and electrode. These specialized interfacial layers must possess sufficient elasticity to buffer mechanical stresses while maintaining ionic conductivity and chemical stability against lithium metal.

The primary objective of anode-free solid-state mechanical compliance layer development is to create interfaces that can effectively manage the mechanical, chemical, and electrochemical complexities at the lithium-electrolyte boundary. This includes designing materials with optimized mechanical properties, ionic conductivity, and chemical stability to enable long-cycle life anode-free batteries with energy densities exceeding 400 Wh/kg at the cell level, while maintaining safety standards superior to conventional lithium-ion technologies.

Current research trajectories focus on polymer-ceramic composites, soft inorganic materials, and engineered interphases that can be integrated into manufacturing processes without compromising the economic viability of large-scale production. The successful development of these compliance layers represents a critical milestone toward commercializing anode-free solid-state batteries for next-generation energy storage applications.

Market Analysis for Solid-State Battery Solutions

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 34.2% through 2030, potentially reaching a market value of $3.4 billion. This remarkable growth trajectory is primarily fueled by automotive applications, which account for nearly 40% of the current market share.

Consumer electronics represents the second-largest application segment at 28%, followed by industrial applications at 18%, and emerging sectors including aerospace, medical devices, and grid storage collectively comprising the remaining 14%. The demand for anode-free solid-state battery technologies specifically is anticipated to grow at an even higher rate of 38.7% CAGR, as these designs offer theoretical energy density improvements of up to 70% compared to conventional lithium-ion batteries.

Regional analysis reveals Asia-Pacific dominates the market with 45% share, led by Japan, South Korea, and China's aggressive investments in manufacturing infrastructure. North America follows at 30%, with significant venture capital flowing into startups developing novel mechanical compliance layer technologies. Europe accounts for 22% of the market, with particularly strong growth in automotive applications driven by stringent emissions regulations.

Key market drivers include the electric vehicle revolution, with major automakers committing billions to electrification strategies that increasingly favor solid-state technology for its superior safety profile and potential for faster charging capabilities. Consumer demand for longer-lasting portable electronics represents another significant market pull, with smartphone and laptop manufacturers actively seeking battery solutions offering 30-50% longer runtime in the same form factor.

Market barriers include high production costs, with current anode-free solid-state cells costing 4-8 times more per kWh than conventional lithium-ion batteries. Manufacturing scalability remains challenging, particularly regarding the consistent production of mechanical compliance layers at industrial scales. Additionally, the fragmented intellectual property landscape creates market entry barriers for new participants.

Customer requirements analysis indicates automotive OEMs prioritize cycle life (>1,000 cycles), safety (no thermal runaway), and fast charging capabilities (80% charge in under 15 minutes). Consumer electronics manufacturers emphasize energy density (>400 Wh/kg) and form factor flexibility. Both sectors demand mechanical compliance layers that can accommodate volume changes during cycling while maintaining consistent electrical contact.

Consumer electronics represents the second-largest application segment at 28%, followed by industrial applications at 18%, and emerging sectors including aerospace, medical devices, and grid storage collectively comprising the remaining 14%. The demand for anode-free solid-state battery technologies specifically is anticipated to grow at an even higher rate of 38.7% CAGR, as these designs offer theoretical energy density improvements of up to 70% compared to conventional lithium-ion batteries.

Regional analysis reveals Asia-Pacific dominates the market with 45% share, led by Japan, South Korea, and China's aggressive investments in manufacturing infrastructure. North America follows at 30%, with significant venture capital flowing into startups developing novel mechanical compliance layer technologies. Europe accounts for 22% of the market, with particularly strong growth in automotive applications driven by stringent emissions regulations.

Key market drivers include the electric vehicle revolution, with major automakers committing billions to electrification strategies that increasingly favor solid-state technology for its superior safety profile and potential for faster charging capabilities. Consumer demand for longer-lasting portable electronics represents another significant market pull, with smartphone and laptop manufacturers actively seeking battery solutions offering 30-50% longer runtime in the same form factor.

Market barriers include high production costs, with current anode-free solid-state cells costing 4-8 times more per kWh than conventional lithium-ion batteries. Manufacturing scalability remains challenging, particularly regarding the consistent production of mechanical compliance layers at industrial scales. Additionally, the fragmented intellectual property landscape creates market entry barriers for new participants.

Customer requirements analysis indicates automotive OEMs prioritize cycle life (>1,000 cycles), safety (no thermal runaway), and fast charging capabilities (80% charge in under 15 minutes). Consumer electronics manufacturers emphasize energy density (>400 Wh/kg) and form factor flexibility. Both sectors demand mechanical compliance layers that can accommodate volume changes during cycling while maintaining consistent electrical contact.

Technical Challenges in Mechanical Compliance Layers

The development of anode-free solid-state batteries represents a significant advancement in energy storage technology, yet the mechanical compliance layers within these systems face substantial technical challenges. The primary obstacle stems from the inherent volume changes that occur during lithium plating and stripping cycles, creating mechanical stresses that can lead to interface delamination and eventual battery failure.

Material selection presents a formidable challenge, as compliance layers must simultaneously exhibit excellent ionic conductivity while maintaining mechanical flexibility. Current materials often represent a compromise between these properties, with few candidates successfully balancing both requirements. Polymeric materials offer superior flexibility but typically suffer from lower ionic conductivity, while ceramic-based options provide better conductivity at the expense of mechanical compliance.

Interface engineering between the compliance layer and adjacent battery components introduces another layer of complexity. The formation of stable interfaces that can withstand repeated cycling without degradation remains elusive. Chemical compatibility issues frequently arise, particularly at the electrolyte-compliance layer boundary, where unwanted side reactions can form resistive layers that impede ion transport and accelerate capacity fade.

Manufacturing scalability constitutes a significant hurdle for widespread implementation. Current laboratory-scale fabrication methods for high-performance compliance layers often involve complex processes that are difficult to translate to mass production. Techniques such as atomic layer deposition provide excellent control over layer properties but face limitations in throughput and cost-effectiveness at industrial scales.

Thickness control represents another critical challenge, as compliance layers must be thin enough to minimize resistance to ion transport while remaining thick enough to provide effective mechanical buffering. This delicate balance is difficult to achieve consistently across large-area batteries, leading to performance variations and reliability concerns.

Long-term stability under various operating conditions remains inadequately addressed. Compliance layers must maintain their functional properties across wide temperature ranges and throughout thousands of cycles—a requirement that few current materials can satisfy. Degradation mechanisms such as mechanical fatigue, chemical decomposition, and interfacial resistance growth often accelerate over time, limiting battery lifespan.

Analytical characterization of these thin, often amorphous layers presents methodological challenges. In-situ monitoring of mechanical behavior and ion transport during cycling requires sophisticated techniques that are not widely available. This limitation hinders the fundamental understanding necessary for rational design improvements and slows the optimization process for next-generation compliance layer materials.

Material selection presents a formidable challenge, as compliance layers must simultaneously exhibit excellent ionic conductivity while maintaining mechanical flexibility. Current materials often represent a compromise between these properties, with few candidates successfully balancing both requirements. Polymeric materials offer superior flexibility but typically suffer from lower ionic conductivity, while ceramic-based options provide better conductivity at the expense of mechanical compliance.

Interface engineering between the compliance layer and adjacent battery components introduces another layer of complexity. The formation of stable interfaces that can withstand repeated cycling without degradation remains elusive. Chemical compatibility issues frequently arise, particularly at the electrolyte-compliance layer boundary, where unwanted side reactions can form resistive layers that impede ion transport and accelerate capacity fade.

Manufacturing scalability constitutes a significant hurdle for widespread implementation. Current laboratory-scale fabrication methods for high-performance compliance layers often involve complex processes that are difficult to translate to mass production. Techniques such as atomic layer deposition provide excellent control over layer properties but face limitations in throughput and cost-effectiveness at industrial scales.

Thickness control represents another critical challenge, as compliance layers must be thin enough to minimize resistance to ion transport while remaining thick enough to provide effective mechanical buffering. This delicate balance is difficult to achieve consistently across large-area batteries, leading to performance variations and reliability concerns.

Long-term stability under various operating conditions remains inadequately addressed. Compliance layers must maintain their functional properties across wide temperature ranges and throughout thousands of cycles—a requirement that few current materials can satisfy. Degradation mechanisms such as mechanical fatigue, chemical decomposition, and interfacial resistance growth often accelerate over time, limiting battery lifespan.

Analytical characterization of these thin, often amorphous layers presents methodological challenges. In-situ monitoring of mechanical behavior and ion transport during cycling requires sophisticated techniques that are not widely available. This limitation hinders the fundamental understanding necessary for rational design improvements and slows the optimization process for next-generation compliance layer materials.

Current Mechanical Compliance Layer Solutions

01 Anode-free solid-state battery designs with mechanical compliance layers

Anode-free solid-state batteries incorporate specialized mechanical compliance layers to accommodate volume changes during cycling. These designs eliminate the traditional anode structure, instead forming the anode in-situ during the first charge cycle from lithium ions that plate onto a current collector. The mechanical compliance layers help maintain interfacial contact between components, reducing mechanical stress and preventing delamination while improving cycle life and safety.- Anode-free battery designs with mechanical compliance layers: Anode-free battery designs incorporate mechanical compliance layers to accommodate volume changes during cycling. These specialized layers help maintain contact between components while allowing for expansion and contraction, which is particularly important in solid-state batteries where no traditional anode is present at assembly. The compliance layers can be made of various materials that provide elasticity while maintaining ionic conductivity, improving cycle life and performance.

- Solid-state electrolyte interfaces with mechanical compliance: Solid-state electrolytes require specialized interfaces with mechanical compliance properties to ensure proper contact with electrodes. These interfaces must accommodate mechanical stress while maintaining ionic conductivity. The design includes layers that can flex and adapt to dimensional changes during battery operation, preventing delamination and crack formation. Materials with both elastic properties and ion transport capabilities are used to create these critical interface regions.

- Mechanical stress management in solid-state battery systems: Managing mechanical stress in solid-state battery systems involves specialized layers that can absorb and distribute pressure. These systems employ various materials and structural designs to prevent component failure due to expansion and contraction during cycling. The compliance layers act as buffers between rigid components, allowing for dimensional changes while maintaining electrical contact and structural integrity throughout the battery's operational life.

- Materials selection for compliance layers in energy storage devices: The selection of appropriate materials for compliance layers in energy storage devices is critical for performance. These materials must balance mechanical properties with electrochemical stability and ionic conductivity. Polymers, composites, and specialized ceramics are commonly used, each offering different advantages in terms of elasticity, durability, and compatibility with other battery components. The material composition can be tailored to specific battery chemistries and operating conditions.

- Manufacturing techniques for integrating compliance layers: Specialized manufacturing techniques are required for effectively integrating compliance layers into solid-state battery structures. These processes must ensure uniform application, proper adhesion, and maintenance of material properties. Methods include controlled deposition, lamination, and in-situ formation of compliance layers. Advanced manufacturing approaches allow for precise control of layer thickness and composition, which directly impacts the mechanical and electrochemical performance of the final battery system.

02 Materials for mechanical compliance layers in solid-state batteries

Various materials are employed as mechanical compliance layers in solid-state battery systems to enhance performance and durability. These materials include polymer-based composites, elastomeric substrates, and specialized ceramic-polymer hybrids that provide both ionic conductivity and mechanical flexibility. The selection of appropriate materials helps manage interfacial stress, accommodate volume expansion, and maintain electrical contact between battery components during cycling.Expand Specific Solutions03 Manufacturing methods for compliance layers in solid-state energy storage

Advanced manufacturing techniques are employed to create effective mechanical compliance layers in solid-state energy storage systems. These methods include solution processing, vapor deposition, lamination techniques, and additive manufacturing approaches that enable precise control over layer thickness and composition. The manufacturing processes focus on creating uniform interfaces with optimized mechanical properties to enhance battery performance and longevity.Expand Specific Solutions04 Interface engineering for solid-state battery mechanical stability

Interface engineering plays a crucial role in enhancing the mechanical stability of solid-state batteries. This involves designing specialized interlayers that improve adhesion between solid electrolytes and electrodes, reducing interfacial resistance and preventing delamination. Various surface modification techniques and gradient structures are employed to create mechanically robust interfaces that can withstand volume changes during battery operation.Expand Specific Solutions05 Testing and characterization methods for mechanical compliance in solid-state batteries

Specialized testing and characterization methods are essential for evaluating the performance of mechanical compliance layers in solid-state batteries. These include in-situ stress measurement techniques, nanoindentation, acoustic emission monitoring, and advanced imaging methods to observe interfacial changes during cycling. Computational modeling approaches are also employed to predict mechanical behavior and optimize compliance layer designs for improved battery performance.Expand Specific Solutions

Leading Companies in Anode-Free Battery Development

The anode-free solid-state battery market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The market is projected to expand rapidly as automotive manufacturers like Hyundai, Kia, Toyota, Nissan, and Mercedes-Benz pursue zero-emission vehicle strategies. Technology maturity varies considerably among key players, with companies like Samsung SDI, LG Energy Solution, and Murata Manufacturing leading in mechanical compliance layer innovations. Traditional automotive suppliers (Bosch) and semiconductor manufacturers (TSMC, Applied Materials) are also making strategic investments. Research institutions like Georgia Tech and Northwestern University are contributing fundamental breakthroughs, while startups like LionVolt are developing novel 3D architectures to address mechanical interface challenges in solid-state systems.

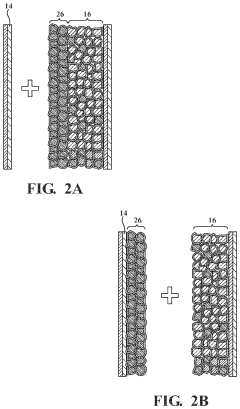

Lionvolt BV

Technical Solution: Lionvolt has developed a revolutionary 3D solid-state battery architecture incorporating specialized mechanical compliance layers for anode-free designs. Their approach utilizes a core-shell structure where the mechanical compliance layer is conformally deposited on 3D-structured solid electrolytes. This unique geometry provides significantly increased surface area for lithium plating/stripping while maintaining short ion transport distances. The compliance layer consists of a gradient polymer-ceramic composite with tailored mechanical properties that vary from soft (0.05 GPa) at the lithium interface to rigid (10 GPa) at the electrolyte interface. Lionvolt's proprietary deposition technique enables ultra-thin (1-3 μm) and defect-free compliance layers even on complex 3D structures. Their technology incorporates self-regulating features that promote uniform lithium deposition across the entire surface area, effectively preventing dendrite formation and hot spots. The 3D architecture combined with the specialized compliance layer enables exceptional volumetric energy density (>1000 Wh/L) while maintaining excellent mechanical stability during cycling.

Strengths: Revolutionary 3D architecture maximizes energy density while solving mechanical interface issues; excellent thermal management due to distributed lithium plating; potential for ultra-fast charging capabilities. Weaknesses: Complex manufacturing process with high precision requirements; challenges in quality control for 3D structures; higher initial investment costs for production equipment.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an innovative approach to anode-free solid-state batteries utilizing advanced mechanical compliance layers. Their technology employs a multi-functional interlayer system that addresses the critical challenges of volume expansion and interfacial stability. The compliance layer consists of a nanocomposite structure combining high-modulus ceramic nanoparticles embedded in a low-modulus polymer matrix, creating a mechanically robust yet flexible interface. This design incorporates gradient structures with varying concentrations of ceramic particles (5-40% by volume) to optimize both ionic conductivity and mechanical properties. Samsung's approach utilizes specialized surface modification techniques to create strong chemical bonds between the compliance layer and the solid electrolyte, ensuring intimate contact throughout battery cycling. Their latest generation incorporates self-healing polymers containing dynamic covalent bonds that can repair microcracks formed during cycling, significantly extending battery lifespan. The compliance layer also features engineered porosity that accommodates volume expansion while maintaining critical ion transport pathways.

Strengths: Excellent cycling stability with >1000 cycles demonstrated; superior energy density (>400 Wh/kg); compatible with existing manufacturing infrastructure. Weaknesses: Complex materials system requires precise quality control; higher material costs compared to conventional batteries; performance degradation at extreme temperatures.

Key Patents in Solid-State Interface Engineering

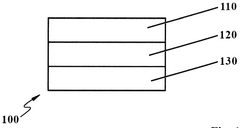

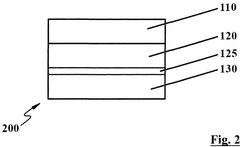

Anode-free solid-state battery and use thereof

PatentWO2025103689A1

Innovation

- Incorporating an additional solid-state electrolyte layer between the solid-state electrolyte separator and the conductor improves deformability and maintains contact between the components during charging cycles.

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

Safety Standards for Next-Generation Batteries

The evolution of battery technology has necessitated the development of comprehensive safety standards specifically tailored for next-generation battery systems. With anode-free solid-state batteries incorporating mechanical compliance layers emerging as promising candidates for future energy storage solutions, existing safety protocols require significant adaptation to address their unique characteristics and potential failure modes.

Current safety standards for lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, primarily focus on conventional liquid electrolyte systems and do not adequately address the specific safety considerations of anode-free solid-state configurations. The mechanical compliance layers in these novel batteries introduce distinct safety challenges related to interface stability, pressure distribution, and mechanical integrity during cycling that must be systematically evaluated.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have initiated working groups to develop specialized testing protocols for solid-state batteries. These emerging standards emphasize mechanical abuse tolerance, thermal runaway resistance, and interface stability under various operating conditions. Particular attention is being directed toward the evaluation of mechanical compliance layers' performance during thermal and mechanical stress events.

Safety certification for anode-free solid-state batteries with mechanical compliance layers requires new testing methodologies that assess the resilience of these interfaces under extreme conditions. Proposed testing protocols include cyclic mechanical loading tests, thermal gradient stability assessments, and accelerated aging under variable pressure conditions to evaluate long-term safety performance of the compliance layers.

The automotive industry has been particularly proactive in developing enhanced safety requirements for next-generation batteries. SAE International and ISO are collaborating on standards that specifically address solid-state battery safety in electric vehicles, with dedicated sections on mechanical interface stability and compliance layer degradation monitoring.

Material safety data requirements are also evolving to encompass the unique compositions used in mechanical compliance layers. These requirements now mandate detailed characterization of interfacial stability under various environmental conditions and comprehensive analysis of potential degradation products that might form during battery operation or failure events.

Harmonization of global safety standards remains a significant challenge, with different regions adopting varying approaches to certifying next-generation battery technologies. A coordinated international effort is essential to establish consistent safety benchmarks that can facilitate the commercial deployment of anode-free solid-state batteries with mechanical compliance layers across global markets.

Current safety standards for lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, primarily focus on conventional liquid electrolyte systems and do not adequately address the specific safety considerations of anode-free solid-state configurations. The mechanical compliance layers in these novel batteries introduce distinct safety challenges related to interface stability, pressure distribution, and mechanical integrity during cycling that must be systematically evaluated.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have initiated working groups to develop specialized testing protocols for solid-state batteries. These emerging standards emphasize mechanical abuse tolerance, thermal runaway resistance, and interface stability under various operating conditions. Particular attention is being directed toward the evaluation of mechanical compliance layers' performance during thermal and mechanical stress events.

Safety certification for anode-free solid-state batteries with mechanical compliance layers requires new testing methodologies that assess the resilience of these interfaces under extreme conditions. Proposed testing protocols include cyclic mechanical loading tests, thermal gradient stability assessments, and accelerated aging under variable pressure conditions to evaluate long-term safety performance of the compliance layers.

The automotive industry has been particularly proactive in developing enhanced safety requirements for next-generation batteries. SAE International and ISO are collaborating on standards that specifically address solid-state battery safety in electric vehicles, with dedicated sections on mechanical interface stability and compliance layer degradation monitoring.

Material safety data requirements are also evolving to encompass the unique compositions used in mechanical compliance layers. These requirements now mandate detailed characterization of interfacial stability under various environmental conditions and comprehensive analysis of potential degradation products that might form during battery operation or failure events.

Harmonization of global safety standards remains a significant challenge, with different regions adopting varying approaches to certifying next-generation battery technologies. A coordinated international effort is essential to establish consistent safety benchmarks that can facilitate the commercial deployment of anode-free solid-state batteries with mechanical compliance layers across global markets.

Manufacturing Scalability Assessment

The manufacturing scalability of anode-free solid-state mechanical compliance layers presents significant challenges and opportunities for commercial implementation. Current production methods primarily rely on laboratory-scale techniques that are difficult to translate to mass production environments. Batch processing methods, while effective for research purposes, face substantial hurdles when scaled to industrial volumes required for commercial battery production.

Key manufacturing challenges include achieving consistent material properties across large surface areas and maintaining uniform thickness distributions of compliance layers. The precision required for these layers—typically in the micrometer range—demands advanced deposition and quality control systems that can operate at high throughput while maintaining nanoscale precision.

Material supply chains represent another critical bottleneck. Many promising compliance layer materials utilize specialized polymers, ceramics, or composite structures that are not yet produced at industrial scale. The limited availability of high-purity precursors suitable for battery applications further constrains manufacturing capacity expansion.

Equipment adaptation presents additional scaling challenges. Current deposition technologies for compliance layers, such as physical vapor deposition, solution casting, and specialized lamination processes, require significant modification to accommodate the throughput demands of gigafactory-scale production. The capital expenditure for such specialized equipment remains prohibitively high for many manufacturers.

Process integration with existing battery manufacturing lines introduces complexity that impacts overall production efficiency. Compliance layers must be incorporated into the battery assembly process without disrupting established workflows or introducing contamination risks. This integration challenge is particularly acute for retrofitting existing production facilities rather than designing new purpose-built manufacturing plants.

Cost modeling indicates that at current technology readiness levels, the production of anode-free solid-state batteries with mechanical compliance layers would increase manufacturing costs by 30-45% compared to conventional lithium-ion batteries. However, sensitivity analysis suggests that with process optimization and economies of scale, this premium could potentially decrease to 15-20% within a 5-year commercialization timeline.

Recent pilot-scale demonstrations by leading battery manufacturers have shown promising results, with production rates reaching hundreds of cells per day with acceptable quality metrics. These early scaling efforts provide valuable insights into process bottlenecks and yield-limiting factors that must be addressed before full commercial deployment.

Key manufacturing challenges include achieving consistent material properties across large surface areas and maintaining uniform thickness distributions of compliance layers. The precision required for these layers—typically in the micrometer range—demands advanced deposition and quality control systems that can operate at high throughput while maintaining nanoscale precision.

Material supply chains represent another critical bottleneck. Many promising compliance layer materials utilize specialized polymers, ceramics, or composite structures that are not yet produced at industrial scale. The limited availability of high-purity precursors suitable for battery applications further constrains manufacturing capacity expansion.

Equipment adaptation presents additional scaling challenges. Current deposition technologies for compliance layers, such as physical vapor deposition, solution casting, and specialized lamination processes, require significant modification to accommodate the throughput demands of gigafactory-scale production. The capital expenditure for such specialized equipment remains prohibitively high for many manufacturers.

Process integration with existing battery manufacturing lines introduces complexity that impacts overall production efficiency. Compliance layers must be incorporated into the battery assembly process without disrupting established workflows or introducing contamination risks. This integration challenge is particularly acute for retrofitting existing production facilities rather than designing new purpose-built manufacturing plants.

Cost modeling indicates that at current technology readiness levels, the production of anode-free solid-state batteries with mechanical compliance layers would increase manufacturing costs by 30-45% compared to conventional lithium-ion batteries. However, sensitivity analysis suggests that with process optimization and economies of scale, this premium could potentially decrease to 15-20% within a 5-year commercialization timeline.

Recent pilot-scale demonstrations by leading battery manufacturers have shown promising results, with production rates reaching hundreds of cells per day with acceptable quality metrics. These early scaling efforts provide valuable insights into process bottlenecks and yield-limiting factors that must be addressed before full commercial deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!