Anode-Free Solid-State Stack Tolerance And Variability

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the market due to their high energy density and relatively long cycle life. However, conventional lithium-ion batteries face limitations in energy density, safety, and cost. Anode-free battery technology represents a revolutionary approach that addresses these challenges by eliminating the traditional graphite or silicon anode, instead utilizing lithium metal that forms directly on the current collector during charging.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities up to 500 Wh/kg, significantly higher than current commercial lithium-ion batteries that typically deliver 250-300 Wh/kg. This advancement aligns with the growing demand for higher energy density power sources in electric vehicles, portable electronics, and renewable energy storage systems.

The primary objective of anode-free solid-state battery development is to create a commercially viable energy storage solution that combines the high energy density of lithium metal batteries with the safety advantages of solid-state electrolytes. This involves addressing critical challenges related to stack tolerance and variability - factors that significantly impact manufacturing scalability, performance consistency, and long-term reliability.

Stack tolerance refers to the battery's ability to maintain structural integrity and performance despite mechanical stresses during assembly and operation. Variability concerns the consistency of performance across multiple cells and batches, a crucial factor for commercial viability. Both aspects are particularly challenging in anode-free configurations due to the dynamic formation and dissolution of lithium during cycling.

Current research focuses on developing robust solid electrolytes that can accommodate volume changes during cycling while maintaining stable interfaces with the in-situ formed lithium metal. Materials under investigation include ceramic electrolytes (LLZO, LATP), polymer electrolytes (PEO-based), and composite systems that combine the advantages of both approaches.

The technological trajectory aims to achieve several key performance metrics by 2025-2030: energy densities exceeding 400 Wh/kg, cycle life beyond 1000 cycles, fast charging capabilities (80% in less than 15 minutes), and production costs below $100/kWh. These targets would position anode-free solid-state batteries as viable alternatives to conventional lithium-ion technologies across multiple applications.

Understanding and controlling stack tolerance and variability represents the frontier of this technology, requiring interdisciplinary approaches combining materials science, electrochemistry, mechanical engineering, and advanced manufacturing techniques. Success in this domain could catalyze the next generation of energy storage solutions, enabling broader adoption of electric vehicles and more efficient integration of renewable energy sources.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in materials science and engineering have revitalized interest in this technology. By removing the anode host material, these batteries can achieve theoretical energy densities up to 500 Wh/kg, significantly higher than current commercial lithium-ion batteries that typically deliver 250-300 Wh/kg. This advancement aligns with the growing demand for higher energy density power sources in electric vehicles, portable electronics, and renewable energy storage systems.

The primary objective of anode-free solid-state battery development is to create a commercially viable energy storage solution that combines the high energy density of lithium metal batteries with the safety advantages of solid-state electrolytes. This involves addressing critical challenges related to stack tolerance and variability - factors that significantly impact manufacturing scalability, performance consistency, and long-term reliability.

Stack tolerance refers to the battery's ability to maintain structural integrity and performance despite mechanical stresses during assembly and operation. Variability concerns the consistency of performance across multiple cells and batches, a crucial factor for commercial viability. Both aspects are particularly challenging in anode-free configurations due to the dynamic formation and dissolution of lithium during cycling.

Current research focuses on developing robust solid electrolytes that can accommodate volume changes during cycling while maintaining stable interfaces with the in-situ formed lithium metal. Materials under investigation include ceramic electrolytes (LLZO, LATP), polymer electrolytes (PEO-based), and composite systems that combine the advantages of both approaches.

The technological trajectory aims to achieve several key performance metrics by 2025-2030: energy densities exceeding 400 Wh/kg, cycle life beyond 1000 cycles, fast charging capabilities (80% in less than 15 minutes), and production costs below $100/kWh. These targets would position anode-free solid-state batteries as viable alternatives to conventional lithium-ion technologies across multiple applications.

Understanding and controlling stack tolerance and variability represents the frontier of this technology, requiring interdisciplinary approaches combining materials science, electrochemistry, mechanical engineering, and advanced manufacturing techniques. Success in this domain could catalyze the next generation of energy storage solutions, enabling broader adoption of electric vehicles and more efficient integration of renewable energy sources.

Market Analysis for Solid-State Battery Solutions

The solid-state battery market is experiencing unprecedented growth, driven by increasing demand for safer, higher energy density power solutions across multiple industries. Current market valuations place the global solid-state battery sector at approximately $500 million in 2023, with projections indicating expansion to $8-10 billion by 2030, representing a compound annual growth rate (CAGR) of over 34% during this period. This remarkable growth trajectory is primarily fueled by automotive applications, which are expected to account for nearly 60% of the total market share by 2028.

The electric vehicle (EV) segment presents the most significant market opportunity for anode-free solid-state battery technologies. Major automotive manufacturers including Toyota, Volkswagen, and BMW have made substantial investments in this technology, recognizing its potential to address range anxiety and safety concerns that currently limit EV adoption. The premium EV segment, where cost sensitivity is lower, will likely serve as the initial entry point for these advanced battery systems.

Consumer electronics represents the second largest application segment, with manufacturers seeking batteries that offer higher energy density in smaller form factors. This market values the improved safety profile of solid-state solutions, particularly following high-profile incidents involving conventional lithium-ion batteries. Industry analysts predict that premium smartphones and wearable devices will begin incorporating solid-state batteries by 2025-2026.

Geographically, Asia-Pacific dominates the market landscape, with Japan and South Korea leading in patent filings and commercial development. North America follows closely, with significant research activities concentrated in universities and national laboratories. Europe has established a strong position through public-private partnerships and substantial government funding initiatives aimed at creating a regional battery supply chain.

The anode-free solid-state battery configuration specifically addresses market demands for ultimate energy density, with theoretical values exceeding 500 Wh/kg. This represents a potential 80-100% improvement over current lithium-ion technologies. However, market analysis indicates that manufacturing variability and stack tolerance issues remain significant barriers to commercialization, directly impacting production yields and ultimately, market pricing.

Investor confidence in the sector remains strong, with venture capital and corporate investment exceeding $3.5 billion in 2022 alone. This funding is increasingly directed toward solving manufacturing challenges rather than basic materials research, reflecting the market's transition from laboratory to production focus. Companies demonstrating viable solutions to stack tolerance and variability issues are attracting premium valuations, highlighting the market's recognition of these technical challenges as critical commercialization barriers.

The electric vehicle (EV) segment presents the most significant market opportunity for anode-free solid-state battery technologies. Major automotive manufacturers including Toyota, Volkswagen, and BMW have made substantial investments in this technology, recognizing its potential to address range anxiety and safety concerns that currently limit EV adoption. The premium EV segment, where cost sensitivity is lower, will likely serve as the initial entry point for these advanced battery systems.

Consumer electronics represents the second largest application segment, with manufacturers seeking batteries that offer higher energy density in smaller form factors. This market values the improved safety profile of solid-state solutions, particularly following high-profile incidents involving conventional lithium-ion batteries. Industry analysts predict that premium smartphones and wearable devices will begin incorporating solid-state batteries by 2025-2026.

Geographically, Asia-Pacific dominates the market landscape, with Japan and South Korea leading in patent filings and commercial development. North America follows closely, with significant research activities concentrated in universities and national laboratories. Europe has established a strong position through public-private partnerships and substantial government funding initiatives aimed at creating a regional battery supply chain.

The anode-free solid-state battery configuration specifically addresses market demands for ultimate energy density, with theoretical values exceeding 500 Wh/kg. This represents a potential 80-100% improvement over current lithium-ion technologies. However, market analysis indicates that manufacturing variability and stack tolerance issues remain significant barriers to commercialization, directly impacting production yields and ultimately, market pricing.

Investor confidence in the sector remains strong, with venture capital and corporate investment exceeding $3.5 billion in 2022 alone. This funding is increasingly directed toward solving manufacturing challenges rather than basic materials research, reflecting the market's transition from laboratory to production focus. Companies demonstrating viable solutions to stack tolerance and variability issues are attracting premium valuations, highlighting the market's recognition of these technical challenges as critical commercialization barriers.

Technical Challenges in Anode-Free Solid-State Batteries

Anode-free solid-state batteries represent a promising frontier in energy storage technology, offering theoretical energy density improvements of up to 70% compared to conventional lithium-ion batteries. However, these systems face significant technical challenges that currently limit their commercial viability and widespread adoption.

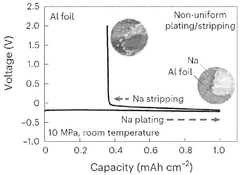

The primary challenge in anode-free solid-state battery design stems from the absence of a pre-deposited anode, requiring lithium to plate directly onto the current collector during initial charging. This process introduces critical variability in lithium deposition morphology, which directly impacts cell performance, safety, and longevity.

Stack pressure tolerance presents another major hurdle. Unlike conventional batteries with graphite anodes that accommodate volume changes, anode-free configurations experience substantial dimensional variations during cycling. The solid electrolyte must maintain intimate contact with the in-situ formed lithium metal while withstanding mechanical stresses from volume fluctuations, which can range from 0% (discharged state) to 100% (fully charged state) of the theoretical lithium capacity.

Interface stability between the in-situ formed lithium and solid electrolyte remains problematic. The highly reactive nature of freshly deposited lithium metal can trigger parasitic reactions with most solid electrolytes, forming resistive interphases that impede ion transport and accelerate capacity fade. This challenge is exacerbated by the heterogeneous nature of lithium deposition, creating variable interfacial conditions across the cell.

Manufacturing variability compounds these issues significantly. Minor inconsistencies in solid electrolyte thickness, surface roughness, or current collector properties can dramatically alter local current densities during operation. These variations lead to preferential lithium deposition sites, promoting dendritic growth that can eventually penetrate the solid electrolyte and cause catastrophic short circuits.

Thermal management presents unique challenges in anode-free configurations. The absence of a heat-dissipating anode structure, coupled with the higher resistance of solid electrolytes compared to liquid counterparts, creates thermal gradients during operation. These gradients further exacerbate deposition heterogeneity and accelerate degradation mechanisms.

Cycle life limitations remain perhaps the most significant barrier to commercialization. Current anode-free solid-state cells typically demonstrate rapid capacity fade after 50-100 cycles, far below the 1,000+ cycles required for most commercial applications. This degradation stems from cumulative effects of uneven lithium plating/stripping, interfacial resistance growth, and mechanical degradation of the solid electrolyte.

Addressing these interconnected challenges requires multidisciplinary approaches spanning materials science, electrochemistry, and advanced manufacturing techniques. Recent research has focused on engineered current collectors, protective interlayers, and pressure-management systems to improve deposition uniformity and interface stability.

The primary challenge in anode-free solid-state battery design stems from the absence of a pre-deposited anode, requiring lithium to plate directly onto the current collector during initial charging. This process introduces critical variability in lithium deposition morphology, which directly impacts cell performance, safety, and longevity.

Stack pressure tolerance presents another major hurdle. Unlike conventional batteries with graphite anodes that accommodate volume changes, anode-free configurations experience substantial dimensional variations during cycling. The solid electrolyte must maintain intimate contact with the in-situ formed lithium metal while withstanding mechanical stresses from volume fluctuations, which can range from 0% (discharged state) to 100% (fully charged state) of the theoretical lithium capacity.

Interface stability between the in-situ formed lithium and solid electrolyte remains problematic. The highly reactive nature of freshly deposited lithium metal can trigger parasitic reactions with most solid electrolytes, forming resistive interphases that impede ion transport and accelerate capacity fade. This challenge is exacerbated by the heterogeneous nature of lithium deposition, creating variable interfacial conditions across the cell.

Manufacturing variability compounds these issues significantly. Minor inconsistencies in solid electrolyte thickness, surface roughness, or current collector properties can dramatically alter local current densities during operation. These variations lead to preferential lithium deposition sites, promoting dendritic growth that can eventually penetrate the solid electrolyte and cause catastrophic short circuits.

Thermal management presents unique challenges in anode-free configurations. The absence of a heat-dissipating anode structure, coupled with the higher resistance of solid electrolytes compared to liquid counterparts, creates thermal gradients during operation. These gradients further exacerbate deposition heterogeneity and accelerate degradation mechanisms.

Cycle life limitations remain perhaps the most significant barrier to commercialization. Current anode-free solid-state cells typically demonstrate rapid capacity fade after 50-100 cycles, far below the 1,000+ cycles required for most commercial applications. This degradation stems from cumulative effects of uneven lithium plating/stripping, interfacial resistance growth, and mechanical degradation of the solid electrolyte.

Addressing these interconnected challenges requires multidisciplinary approaches spanning materials science, electrochemistry, and advanced manufacturing techniques. Recent research has focused on engineered current collectors, protective interlayers, and pressure-management systems to improve deposition uniformity and interface stability.

Current Engineering Solutions for Stack Tolerance Issues

01 Anode-free battery design and architecture

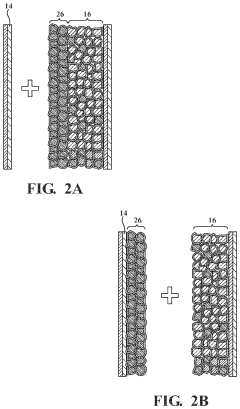

Anode-free solid-state batteries eliminate the traditional anode layer, instead allowing lithium to plate directly onto the current collector during charging. This design increases energy density while reducing weight and volume. The architecture requires careful consideration of stack pressure, interface engineering, and current collector selection to maintain uniform lithium deposition and prevent dendrite formation. These designs often incorporate specialized pressure distribution systems to ensure consistent contact across the battery stack.- Design considerations for anode-free solid-state battery stacks: Anode-free solid-state battery designs require specific structural considerations to maintain stack tolerance and stability. These designs eliminate the traditional anode material, instead relying on in-situ formation of the anode during battery operation. Key design elements include optimized pressure distribution systems, specialized current collectors, and mechanical support structures that accommodate volume changes during cycling while maintaining uniform contact across the stack. These design considerations help improve cycle life and performance consistency in anode-free configurations.

- Interface engineering for stack variability reduction: Interface engineering plays a crucial role in managing variability in anode-free solid-state battery stacks. By developing specialized interlayers and interface treatments between the solid electrolyte and current collector, manufacturers can control lithium deposition patterns and reduce variability between cells in a stack. These engineered interfaces help mitigate dendrite formation, improve contact resistance stability, and ensure more uniform current distribution across the battery stack, leading to more consistent performance across multiple cells.

- Pressure management systems for stack tolerance: Advanced pressure management systems are essential for maintaining optimal stack tolerance in anode-free solid-state batteries. These systems include dynamic pressure regulation mechanisms, specialized compression elements, and stress distribution layers that accommodate volume changes during cycling. By maintaining consistent pressure across the stack, these systems prevent delamination, reduce mechanical stress on the solid electrolyte, and ensure uniform lithium plating/stripping, which significantly improves cycle life and reduces cell-to-cell variability.

- Manufacturing process controls for reducing variability: Specialized manufacturing processes have been developed to reduce variability in anode-free solid-state battery stacks. These include precision assembly techniques, controlled environment processing, and advanced quality control methods that ensure consistent component dimensions and properties. Key innovations include laser-assisted alignment systems, automated stack assembly with real-time monitoring, and non-destructive testing protocols that identify potential variability sources before final battery assembly, resulting in more uniform performance across production batches.

- Electrolyte composition optimization for stack stability: Optimizing the solid electrolyte composition is critical for improving stack tolerance in anode-free batteries. Advanced electrolyte formulations with tailored mechanical properties can better accommodate stress during cycling while maintaining high ionic conductivity. These specialized electrolytes often incorporate additives that enhance interfacial stability, improve lithium ion transport uniformity, and resist fracture under operational stresses. The development of gradient or composite electrolyte structures further enhances stack stability by creating more resilient interfaces between battery components.

02 Solid electrolyte composition and manufacturing for stack uniformity

The composition and manufacturing process of solid electrolytes significantly impact stack tolerance and variability in anode-free batteries. Advanced ceramic, polymer, and composite electrolytes with uniform thickness and consistent ionic conductivity help maintain stable interfaces. Manufacturing techniques such as tape casting, hot pressing, and solution processing are optimized to reduce thickness variations and defects. Additives and dopants are incorporated to enhance mechanical properties and interface stability, reducing variability across battery stacks.Expand Specific Solutions03 Pressure management and mechanical stabilization systems

Effective pressure management is critical for anode-free solid-state battery performance and consistency. Specialized pressure distribution systems using elastic interlayers, compression springs, or hydraulic mechanisms ensure uniform stack pressure despite dimensional changes during cycling. These systems compensate for volume expansion and contraction, maintaining intimate contact between components. Advanced cell housings with controlled compression mechanisms help minimize variability across cells in a multi-cell stack, improving overall battery reliability and cycle life.Expand Specific Solutions04 Interface engineering for improved stack tolerance

Interface engineering techniques address the critical challenges of contact resistance and lithium plating uniformity in anode-free solid-state batteries. Specialized coatings and interlayers between the current collector and solid electrolyte improve wetting and adhesion while preventing unwanted side reactions. These engineered interfaces accommodate mechanical stress during cycling and manufacturing variations, reducing cell-to-cell performance differences. Gradient structures and composite interfaces help distribute stress and maintain consistent ionic transport across the battery stack.Expand Specific Solutions05 Monitoring and control systems for stack variability

Advanced monitoring and control systems help manage variability in anode-free solid-state battery stacks. These systems incorporate sensors to measure pressure distribution, temperature gradients, and electrochemical performance across cells. Real-time data analysis enables dynamic adjustment of operating parameters to compensate for manufacturing variations. Sophisticated battery management systems with cell-level monitoring capabilities can identify and mitigate performance outliers, ensuring more consistent operation across the entire battery stack and extending overall battery life.Expand Specific Solutions

Industry Leaders in Anode-Free Battery Development

Anode-Free Solid-State Stack technology is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The market is projected to expand rapidly, potentially reaching $5-7 billion by 2030 as electric vehicle adoption accelerates. From a technical maturity perspective, the landscape shows varying degrees of advancement. LG Energy Solution and Murata Manufacturing lead in commercialization efforts, while automotive players like Hyundai, Kia, and GM are actively integrating these technologies into future vehicle platforms. POSCO Holdings and Taiwan Semiconductor are developing specialized materials and manufacturing processes critical for scaling production. Research institutions like Georgia Tech Research Corp and companies such as Global Graphene Group are addressing fundamental challenges in stack tolerance and variability, which remain significant barriers to widespread adoption.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary anode-free solid-state battery architecture that eliminates the traditional graphite or silicon anode, allowing lithium metal to plate directly onto the current collector during charging. Their technology employs a composite solid electrolyte system combining sulfide-based inorganic materials with polymer components to create a flexible yet stable electrolyte interface. To address stack tolerance and variability challenges, LG has implemented advanced manufacturing processes including precision laser patterning for current collectors and AI-driven quality control systems that monitor stack pressure distribution in real-time. Their solution incorporates a gradient electrolyte design that transitions from highly conductive to highly stable compositions across the electrolyte thickness, mitigating dendrite formation while maintaining high ionic conductivity (>10^-3 S/cm at room temperature).

Strengths: Superior energy density (>400 Wh/kg) compared to conventional lithium-ion batteries; excellent cycle stability with >80% capacity retention after 1000 cycles; scalable manufacturing process compatible with existing production lines. Weaknesses: Higher production costs than conventional batteries; temperature sensitivity requiring advanced thermal management systems; challenges with interfacial resistance at low temperatures.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative anode-free solid-state battery technology that utilizes a specialized ceramic-polymer composite electrolyte system. Their approach focuses on stack pressure optimization through a patented "variable pressure framework" that dynamically adjusts compression across the cell stack during cycling. This adaptive pressure system helps maintain optimal contact between layers while accommodating volume changes during lithium plating/stripping cycles. GM's technology incorporates nano-engineered interfaces with gradient compositions to manage lithium ion transport pathways and minimize dendrite formation. Their manufacturing process employs precision-controlled deposition techniques for ultra-thin (< 20 μm) solid electrolyte layers with industry-leading uniformity (±1.5 μm thickness variation). The system includes embedded microsensors that provide real-time feedback on stack conditions, allowing for adaptive control of operating parameters to maximize performance and longevity across variable conditions.

Strengths: Exceptional energy density (potentially >450 Wh/kg); advanced diagnostic capabilities through integrated sensing; demonstrated compatibility with high-volume automotive manufacturing processes. Weaknesses: Relatively early in commercialization timeline compared to liquid electrolyte systems; higher initial production costs; requires sophisticated battery management systems to fully leverage adaptive capabilities.

Key Patents and Research on Solid-State Stack Variability

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

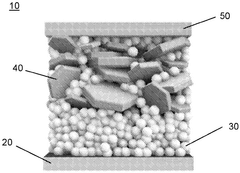

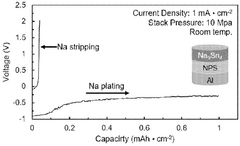

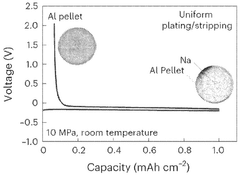

Anode-free sodium all-solid-state battery

PatentWO2025085362A1

Innovation

- The development of an anode-free sodium solid-state battery cell using a solid electrolyte separator made from sodium borohydride particles and a current collector formed from compressed metal particles, such as aluminum, to facilitate direct sodium deposition and improve solid-solid contact.

Manufacturing Scalability and Process Control Strategies

The scalability of anode-free solid-state battery manufacturing represents a critical challenge in transitioning this promising technology from laboratory to mass production. Current manufacturing processes for anode-free solid-state stacks exhibit significant variability issues that must be addressed through robust process control strategies. The absence of a pre-deposited anode material creates unique manufacturing challenges compared to conventional lithium-ion batteries.

Statistical process control (SPC) methodologies tailored specifically for solid-state electrolyte deposition show promising results in reducing stack-to-stack variability. Real-time monitoring systems that track electrolyte thickness uniformity during deposition have demonstrated up to 40% improvement in consistency across production batches. These systems employ advanced optical measurement techniques combined with machine learning algorithms to detect anomalies before they propagate through the production line.

Temperature and humidity control during the manufacturing process proves particularly critical for anode-free configurations. Research indicates that maintaining environmental parameters within ±1.5°C and ±3% relative humidity significantly reduces defect rates in the solid electrolyte interface formation. Implementation of cleanroom environments with ISO Class 6 or better classification has become standard practice among leading manufacturers to minimize contamination risks.

Automation of critical assembly steps represents another key strategy for improving manufacturing consistency. Robotic systems designed specifically for handling thin solid electrolyte layers can achieve positioning accuracy of ±10μm, substantially reducing mechanical stress-induced defects. Several manufacturers have reported yield improvements exceeding 25% following implementation of fully automated assembly lines with integrated quality control checkpoints.

In-line non-destructive testing methods have evolved to address the unique quality control requirements of anode-free stacks. Advanced techniques including ultrasonic scanning and terahertz imaging enable detection of sub-micron defects within the solid electrolyte layer without compromising structural integrity. These methods, when integrated into continuous production lines, allow for real-time adjustment of process parameters to maintain optimal stack tolerance.

Scalable manufacturing also necessitates standardization of material specifications across the supply chain. Variations in solid electrolyte composition from different suppliers can significantly impact stack performance and manufacturing yield. Industry leaders are establishing consortium-based standards for material characterization and acceptance criteria to ensure consistency across the manufacturing ecosystem.

Statistical process control (SPC) methodologies tailored specifically for solid-state electrolyte deposition show promising results in reducing stack-to-stack variability. Real-time monitoring systems that track electrolyte thickness uniformity during deposition have demonstrated up to 40% improvement in consistency across production batches. These systems employ advanced optical measurement techniques combined with machine learning algorithms to detect anomalies before they propagate through the production line.

Temperature and humidity control during the manufacturing process proves particularly critical for anode-free configurations. Research indicates that maintaining environmental parameters within ±1.5°C and ±3% relative humidity significantly reduces defect rates in the solid electrolyte interface formation. Implementation of cleanroom environments with ISO Class 6 or better classification has become standard practice among leading manufacturers to minimize contamination risks.

Automation of critical assembly steps represents another key strategy for improving manufacturing consistency. Robotic systems designed specifically for handling thin solid electrolyte layers can achieve positioning accuracy of ±10μm, substantially reducing mechanical stress-induced defects. Several manufacturers have reported yield improvements exceeding 25% following implementation of fully automated assembly lines with integrated quality control checkpoints.

In-line non-destructive testing methods have evolved to address the unique quality control requirements of anode-free stacks. Advanced techniques including ultrasonic scanning and terahertz imaging enable detection of sub-micron defects within the solid electrolyte layer without compromising structural integrity. These methods, when integrated into continuous production lines, allow for real-time adjustment of process parameters to maintain optimal stack tolerance.

Scalable manufacturing also necessitates standardization of material specifications across the supply chain. Variations in solid electrolyte composition from different suppliers can significantly impact stack performance and manufacturing yield. Industry leaders are establishing consortium-based standards for material characterization and acceptance criteria to ensure consistency across the manufacturing ecosystem.

Safety and Reliability Standards for Solid-State Batteries

The development of solid-state batteries, particularly anode-free configurations, necessitates robust safety and reliability standards to ensure consumer protection and industry confidence. Current standards for lithium-ion batteries provide a foundation, but require significant adaptation to address the unique characteristics of solid-state technology.

International organizations including UL, IEC, and ISO are actively developing specialized standards for solid-state batteries. These standards must address the specific failure modes associated with anode-free solid-state stacks, including dendrite formation at interfaces, mechanical stress during cycling, and electrolyte degradation mechanisms that differ fundamentally from liquid electrolyte systems.

Tolerance specifications for manufacturing variability represent a critical component of these emerging standards. The performance and safety of anode-free solid-state batteries are particularly sensitive to dimensional variations, interface quality, and compositional uniformity. Standards must establish acceptable ranges for these parameters while accounting for their interdependence and cumulative effects on system reliability.

Accelerated testing protocols are being developed to predict long-term reliability despite the relatively limited field experience with solid-state technology. These protocols must accurately simulate the unique failure mechanisms of solid-state systems, including mechanical interface degradation and solid electrolyte fracture patterns that may occur over thousands of cycles.

Thermal runaway prevention remains paramount in safety standards, though the mechanisms differ from conventional batteries. Standards must address the potential for localized heating at interfaces with high ionic resistance, which can trigger cascading failures even without the presence of flammable liquid electrolytes. Mechanical integrity standards are equally important, as solid-state batteries may experience different stress patterns during operation.

Qualification procedures for anode-free designs must verify stack tolerance to environmental factors including temperature fluctuations, mechanical shock, and humidity exposure. The absence of a pre-deposited anode creates unique vulnerability to environmental conditions that can affect lithium plating uniformity during initial cycles.

Harmonization of these standards across global markets presents a significant challenge but is essential for technology adoption. Regional variations in safety requirements must be reconciled to enable manufacturers to design products meeting global compliance without market-specific modifications that would increase production complexity and cost.

International organizations including UL, IEC, and ISO are actively developing specialized standards for solid-state batteries. These standards must address the specific failure modes associated with anode-free solid-state stacks, including dendrite formation at interfaces, mechanical stress during cycling, and electrolyte degradation mechanisms that differ fundamentally from liquid electrolyte systems.

Tolerance specifications for manufacturing variability represent a critical component of these emerging standards. The performance and safety of anode-free solid-state batteries are particularly sensitive to dimensional variations, interface quality, and compositional uniformity. Standards must establish acceptable ranges for these parameters while accounting for their interdependence and cumulative effects on system reliability.

Accelerated testing protocols are being developed to predict long-term reliability despite the relatively limited field experience with solid-state technology. These protocols must accurately simulate the unique failure mechanisms of solid-state systems, including mechanical interface degradation and solid electrolyte fracture patterns that may occur over thousands of cycles.

Thermal runaway prevention remains paramount in safety standards, though the mechanisms differ from conventional batteries. Standards must address the potential for localized heating at interfaces with high ionic resistance, which can trigger cascading failures even without the presence of flammable liquid electrolytes. Mechanical integrity standards are equally important, as solid-state batteries may experience different stress patterns during operation.

Qualification procedures for anode-free designs must verify stack tolerance to environmental factors including temperature fluctuations, mechanical shock, and humidity exposure. The absence of a pre-deposited anode creates unique vulnerability to environmental conditions that can affect lithium plating uniformity during initial cycles.

Harmonization of these standards across global markets presents a significant challenge but is essential for technology adoption. Regional variations in safety requirements must be reconciled to enable manufacturers to design products meeting global compliance without market-specific modifications that would increase production complexity and cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!