Application of Vacuum Forming in Advanced Filtration Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Filtration: Background and Objectives

Vacuum forming has emerged as a pivotal technology in the development of advanced filtration systems, revolutionizing the way we approach air and liquid purification. This technique, which involves heating a plastic sheet and forming it over a mold using vacuum suction, has its roots in the mid-20th century. Initially used primarily in packaging and product design, vacuum forming has since found its way into more sophisticated applications, including the creation of high-performance filters.

The evolution of vacuum forming in filtration technology has been driven by the increasing demand for more efficient and cost-effective filtration solutions across various industries. From automotive air filters to water purification systems and even medical-grade air filtration, the applications of vacuum-formed filters have expanded significantly. This growth is largely attributed to the technique's ability to create complex geometries and fine structures that enhance filtration efficiency while maintaining structural integrity.

As we delve into the background of vacuum forming in filtration, it's crucial to understand the synergy between material science advancements and manufacturing process innovations. The development of new thermoplastic materials with enhanced properties has played a key role in expanding the capabilities of vacuum-formed filters. These materials offer improved heat resistance, chemical compatibility, and mechanical strength, allowing for the creation of filters that can withstand harsh environments and maintain performance over extended periods.

The primary objective of applying vacuum forming to advanced filtration systems is to overcome the limitations of traditional filter manufacturing methods. Conventional techniques often struggle to produce filters with intricate designs or those requiring precise pore sizes and distributions. Vacuum forming addresses these challenges by enabling the production of filters with highly customized shapes, controlled porosity, and optimized flow patterns. This level of customization is essential for improving filtration efficiency, reducing pressure drop, and extending filter lifespan.

Furthermore, the integration of vacuum forming into filtration technology aims to streamline production processes, reduce material waste, and lower manufacturing costs. The ability to rapidly prototype and iterate designs using vacuum forming techniques has accelerated the development cycle of new filtration solutions, allowing for quicker responses to emerging environmental and health challenges. This agility in product development is particularly crucial in addressing urgent filtration needs, such as those that arose during the global pandemic.

As we explore the application of vacuum forming in advanced filtration systems, our goal is to comprehensively assess its current capabilities, identify potential areas for improvement, and forecast future developments in this field. By understanding the technological trajectory and market demands, we can better position ourselves to leverage vacuum forming technology in creating next-generation filtration solutions that meet the evolving needs of various industries and contribute to a cleaner, healthier environment.

The evolution of vacuum forming in filtration technology has been driven by the increasing demand for more efficient and cost-effective filtration solutions across various industries. From automotive air filters to water purification systems and even medical-grade air filtration, the applications of vacuum-formed filters have expanded significantly. This growth is largely attributed to the technique's ability to create complex geometries and fine structures that enhance filtration efficiency while maintaining structural integrity.

As we delve into the background of vacuum forming in filtration, it's crucial to understand the synergy between material science advancements and manufacturing process innovations. The development of new thermoplastic materials with enhanced properties has played a key role in expanding the capabilities of vacuum-formed filters. These materials offer improved heat resistance, chemical compatibility, and mechanical strength, allowing for the creation of filters that can withstand harsh environments and maintain performance over extended periods.

The primary objective of applying vacuum forming to advanced filtration systems is to overcome the limitations of traditional filter manufacturing methods. Conventional techniques often struggle to produce filters with intricate designs or those requiring precise pore sizes and distributions. Vacuum forming addresses these challenges by enabling the production of filters with highly customized shapes, controlled porosity, and optimized flow patterns. This level of customization is essential for improving filtration efficiency, reducing pressure drop, and extending filter lifespan.

Furthermore, the integration of vacuum forming into filtration technology aims to streamline production processes, reduce material waste, and lower manufacturing costs. The ability to rapidly prototype and iterate designs using vacuum forming techniques has accelerated the development cycle of new filtration solutions, allowing for quicker responses to emerging environmental and health challenges. This agility in product development is particularly crucial in addressing urgent filtration needs, such as those that arose during the global pandemic.

As we explore the application of vacuum forming in advanced filtration systems, our goal is to comprehensively assess its current capabilities, identify potential areas for improvement, and forecast future developments in this field. By understanding the technological trajectory and market demands, we can better position ourselves to leverage vacuum forming technology in creating next-generation filtration solutions that meet the evolving needs of various industries and contribute to a cleaner, healthier environment.

Market Analysis for Advanced Filtration Systems

The advanced filtration systems market is experiencing significant growth, driven by increasing demand for clean water, air purification, and industrial process optimization. The global market for advanced filtration systems is projected to reach $20.8 billion by 2025, with a compound annual growth rate (CAGR) of 7.3% from 2020 to 2025. This growth is primarily attributed to stringent environmental regulations, rising awareness of health and safety concerns, and the need for efficient industrial processes.

The water treatment sector represents the largest segment of the advanced filtration systems market, accounting for approximately 40% of the total market share. This is due to the growing global water scarcity issues and the increasing need for clean drinking water in developing countries. The industrial sector follows closely, with a market share of around 35%, driven by the demand for high-performance filtration systems in manufacturing, oil and gas, and chemical industries.

Geographically, North America and Europe dominate the advanced filtration systems market, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a CAGR of 8.5% from 2020 to 2025. This growth is fueled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The application of vacuum forming in advanced filtration systems is gaining traction due to its ability to produce complex filter shapes with high precision and cost-effectiveness. This technology is particularly valuable in the production of membrane filters, which are increasingly used in water treatment, pharmaceutical, and biotechnology applications. The market for vacuum-formed filtration components is expected to grow at a CAGR of 6.8% from 2020 to 2025.

Key market drivers for vacuum-formed advanced filtration systems include the growing demand for customized filtration solutions, the need for lightweight and durable filter components, and the increasing adoption of membrane filtration technologies. Additionally, the rising focus on sustainability and recyclability in filter manufacturing processes is expected to further boost the demand for vacuum-formed filtration systems.

However, the market also faces challenges such as high initial investment costs for vacuum forming equipment and the need for specialized expertise in filter design and manufacturing. These factors may limit market growth, particularly for small and medium-sized enterprises in the filtration industry.

The water treatment sector represents the largest segment of the advanced filtration systems market, accounting for approximately 40% of the total market share. This is due to the growing global water scarcity issues and the increasing need for clean drinking water in developing countries. The industrial sector follows closely, with a market share of around 35%, driven by the demand for high-performance filtration systems in manufacturing, oil and gas, and chemical industries.

Geographically, North America and Europe dominate the advanced filtration systems market, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, with a CAGR of 8.5% from 2020 to 2025. This growth is fueled by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

The application of vacuum forming in advanced filtration systems is gaining traction due to its ability to produce complex filter shapes with high precision and cost-effectiveness. This technology is particularly valuable in the production of membrane filters, which are increasingly used in water treatment, pharmaceutical, and biotechnology applications. The market for vacuum-formed filtration components is expected to grow at a CAGR of 6.8% from 2020 to 2025.

Key market drivers for vacuum-formed advanced filtration systems include the growing demand for customized filtration solutions, the need for lightweight and durable filter components, and the increasing adoption of membrane filtration technologies. Additionally, the rising focus on sustainability and recyclability in filter manufacturing processes is expected to further boost the demand for vacuum-formed filtration systems.

However, the market also faces challenges such as high initial investment costs for vacuum forming equipment and the need for specialized expertise in filter design and manufacturing. These factors may limit market growth, particularly for small and medium-sized enterprises in the filtration industry.

Vacuum Forming Technology: Current State and Challenges

Vacuum forming technology has made significant strides in recent years, particularly in its application to advanced filtration systems. However, the current state of this technology presents both opportunities and challenges that warrant careful consideration.

The primary advantage of vacuum forming in filtration systems lies in its ability to create complex, three-dimensional filter shapes with high precision and consistency. This capability has revolutionized the design of air and liquid filters, allowing for increased surface area and improved flow dynamics. Current vacuum forming processes can produce filters with intricate pleats, curves, and channels that were previously difficult or impossible to manufacture using traditional methods.

Despite these advancements, several challenges persist in the field of vacuum forming for filtration applications. One of the most significant issues is material selection. While vacuum forming works well with thermoplastics, not all filter materials are suitable for this process. High-efficiency particulate air (HEPA) filters, for instance, often require specialized materials that may not respond well to vacuum forming techniques. This limitation has led to ongoing research into developing new thermoplastic composites that can meet both the formability requirements of vacuum forming and the filtration efficiency standards of advanced systems.

Another challenge lies in the scalability of vacuum forming for large-scale filter production. While the technology is well-suited for small to medium-sized filters, producing large-format filters with consistent quality across the entire surface area remains problematic. Uneven heating and cooling during the forming process can lead to variations in thickness and structural integrity, potentially compromising filter performance.

The integration of vacuum-formed components with other filter elements also presents technical hurdles. Ensuring proper sealing and bonding between vacuum-formed parts and other filter materials is crucial for maintaining filtration efficiency. Current solutions often involve additional manufacturing steps, such as ultrasonic welding or adhesive bonding, which can increase production complexity and costs.

Furthermore, the environmental impact of vacuum forming in filter production is a growing concern. Many thermoplastics used in this process are derived from non-renewable resources and can be difficult to recycle. The industry is actively seeking more sustainable materials and processes to address these environmental challenges while maintaining the benefits of vacuum forming technology.

In conclusion, while vacuum forming has significantly advanced the field of filtration system manufacturing, it still faces several technical and environmental challenges. Overcoming these obstacles will require continued innovation in materials science, process engineering, and sustainable manufacturing practices. The future development of this technology will likely focus on addressing these key areas to fully realize its potential in advanced filtration applications.

The primary advantage of vacuum forming in filtration systems lies in its ability to create complex, three-dimensional filter shapes with high precision and consistency. This capability has revolutionized the design of air and liquid filters, allowing for increased surface area and improved flow dynamics. Current vacuum forming processes can produce filters with intricate pleats, curves, and channels that were previously difficult or impossible to manufacture using traditional methods.

Despite these advancements, several challenges persist in the field of vacuum forming for filtration applications. One of the most significant issues is material selection. While vacuum forming works well with thermoplastics, not all filter materials are suitable for this process. High-efficiency particulate air (HEPA) filters, for instance, often require specialized materials that may not respond well to vacuum forming techniques. This limitation has led to ongoing research into developing new thermoplastic composites that can meet both the formability requirements of vacuum forming and the filtration efficiency standards of advanced systems.

Another challenge lies in the scalability of vacuum forming for large-scale filter production. While the technology is well-suited for small to medium-sized filters, producing large-format filters with consistent quality across the entire surface area remains problematic. Uneven heating and cooling during the forming process can lead to variations in thickness and structural integrity, potentially compromising filter performance.

The integration of vacuum-formed components with other filter elements also presents technical hurdles. Ensuring proper sealing and bonding between vacuum-formed parts and other filter materials is crucial for maintaining filtration efficiency. Current solutions often involve additional manufacturing steps, such as ultrasonic welding or adhesive bonding, which can increase production complexity and costs.

Furthermore, the environmental impact of vacuum forming in filter production is a growing concern. Many thermoplastics used in this process are derived from non-renewable resources and can be difficult to recycle. The industry is actively seeking more sustainable materials and processes to address these environmental challenges while maintaining the benefits of vacuum forming technology.

In conclusion, while vacuum forming has significantly advanced the field of filtration system manufacturing, it still faces several technical and environmental challenges. Overcoming these obstacles will require continued innovation in materials science, process engineering, and sustainable manufacturing practices. The future development of this technology will likely focus on addressing these key areas to fully realize its potential in advanced filtration applications.

Current Vacuum Forming Solutions for Filtration Systems

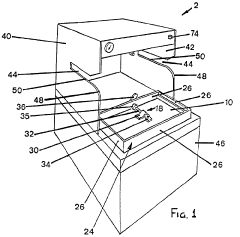

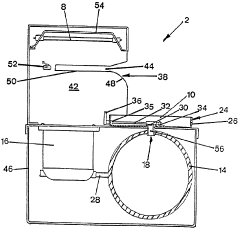

01 Vacuum forming process and apparatus

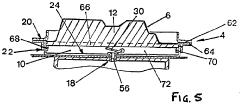

Vacuum forming is a thermoforming process where a plastic sheet is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. This process is widely used in manufacturing various plastic products. The apparatus typically includes a heating element, a mold, and a vacuum system.- Vacuum forming process improvements: Advancements in vacuum forming techniques to enhance efficiency and product quality. This includes optimizing the heating process, improving mold design, and refining the vacuum application method to achieve better formed products with reduced material waste and cycle times.

- Material selection for vacuum forming: Exploration of various materials suitable for vacuum forming, including thermoplastics and composite materials. The selection of appropriate materials can significantly impact the final product's properties, such as strength, flexibility, and surface finish.

- Automation and control systems in vacuum forming: Integration of advanced automation and control systems in vacuum forming processes. This includes the use of sensors, programmable logic controllers, and computer-aided manufacturing to improve precision, repeatability, and overall production efficiency.

- Specialized vacuum forming applications: Development of vacuum forming techniques for specific industries or applications, such as packaging, automotive components, or medical devices. These specialized applications often require unique considerations in terms of material properties, forming parameters, and quality control.

- Energy efficiency in vacuum forming: Innovations aimed at reducing energy consumption in vacuum forming processes. This includes optimizing heating systems, improving insulation, and developing more efficient vacuum pumps to minimize overall energy usage while maintaining or improving product quality.

02 Improvements in mold design for vacuum forming

Advancements in mold design for vacuum forming focus on enhancing the quality of formed products and improving process efficiency. These improvements may include optimized mold geometries, innovative venting systems, and the use of advanced materials for mold construction. Such enhancements can lead to better product detail, faster cycle times, and reduced material waste.Expand Specific Solutions03 Control systems for vacuum forming machines

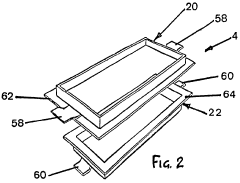

Modern vacuum forming machines incorporate sophisticated control systems to optimize the forming process. These systems may include sensors for temperature monitoring, pressure control, and cycle timing. Advanced control algorithms can adjust process parameters in real-time, ensuring consistent product quality and maximizing production efficiency.Expand Specific Solutions04 Material innovations for vacuum forming

Research in vacuum forming extends to the development of new materials with enhanced properties for thermoforming. These materials may offer improved formability, better heat resistance, or enhanced surface finish. Innovations in this area can expand the range of applications for vacuum-formed products and improve their overall quality and performance.Expand Specific Solutions05 Specialized vacuum forming techniques

Various specialized vacuum forming techniques have been developed for specific applications or to achieve particular product characteristics. These may include multi-stage forming processes, combination with other manufacturing methods, or the use of auxiliary equipment to enhance forming capabilities. Such techniques can enable the production of complex shapes or improve the properties of vacuum-formed products.Expand Specific Solutions

Key Players in Vacuum Forming and Filtration Industries

The application of vacuum forming in advanced filtration systems is in a growth phase, with increasing market size driven by demand for high-performance filtration across industries. The technology is moderately mature, with ongoing innovations to enhance efficiency and applicability. Key players like Donaldson Co., Inc., Edwards Ltd., and ULVAC, Inc. are leading development efforts, leveraging their expertise in vacuum technology and filtration systems. Companies such as Agilent Technologies and 3M Innovative Properties Co. are also contributing to advancements in this field, indicating a competitive landscape with diverse technological approaches. The market shows potential for further expansion as industries seek more sophisticated filtration solutions.

Donaldson Co., Inc.

Technical Solution: Donaldson has developed advanced vacuum forming techniques for their filtration systems, particularly in air and liquid filtration. Their PowerCore technology utilizes a unique pleating process that incorporates vacuum forming to create high-efficiency filter media with increased surface area[1]. This process allows for the creation of compact yet highly effective filters that can remove particles as small as 0.3 microns with up to 99.97% efficiency[2]. The company has also applied vacuum forming in their Synteq XP media technology, which combines multiple layers of filter media to enhance filtration performance in hydraulic and fuel systems[3].

Strengths: High filtration efficiency, compact design, versatility across various applications. Weaknesses: Potentially higher production costs, limited to certain types of filter media.

EMD Millipore Corp.

Technical Solution: EMD Millipore has integrated vacuum forming into their advanced filtration systems, particularly for biopharmaceutical applications. Their Millipak series of filters utilizes a proprietary vacuum forming process to create asymmetric membranes with precise pore structures[4]. This technology enables the production of sterilizing-grade filters with high flow rates and low protein binding characteristics. The company's Viresolve Pro series also incorporates vacuum-formed membranes for virus filtration, achieving log reduction values (LRV) of up to 6 for small viruses while maintaining high protein recovery rates of over 98%[5].

Strengths: High performance in biopharmaceutical applications, excellent virus retention, and protein recovery. Weaknesses: Specialized application may limit broader market appeal, potentially higher costs for high-end filtration solutions.

Innovations in Vacuum Forming for Advanced Filtration

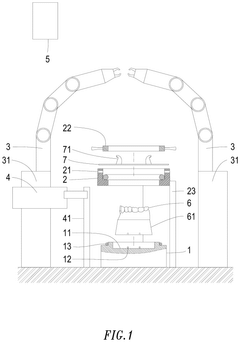

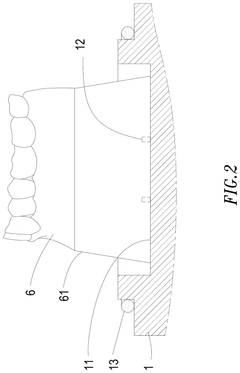

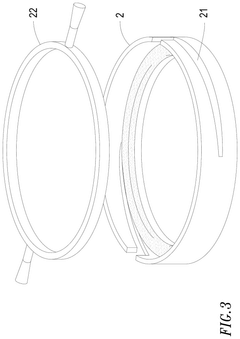

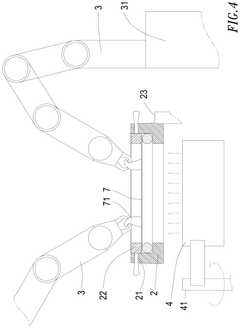

Vacuum forming method for membrane-like objects having protruding structures and forming apparatus thereof

PatentPendingUS20250042076A1

Innovation

- A computer simulation is used to pre-construct and position special structures on a membrane-like object, which is then transferred to a predetermined forming position using a controllable transfer device during the vacuum forming process, ensuring precise attachment to a mold.

A vacuum forming machine in which vacuum is automatically initiated upon delivery of the sheet to the machine

PatentInactiveGB2248579A

Innovation

- A simplified vacuum forming machine design featuring a holder that moves from a heating position to a forming position automatically operates the valve, creating a vacuum to shape the plastic sheet, with a spring-biased valve plate and guide means for easy operation and reduced manual intervention.

Environmental Impact of Vacuum-Formed Filtration Systems

The environmental impact of vacuum-formed filtration systems is a critical consideration in their application and development. These systems, while offering significant advantages in terms of efficiency and performance, also present unique environmental challenges and opportunities.

One of the primary environmental benefits of vacuum-formed filtration systems is their potential for reducing energy consumption. The precise shaping and customization capabilities of vacuum forming allow for the creation of highly efficient filter designs that can operate at lower pressures. This translates to reduced energy requirements for fluid or air movement through the filtration system, contributing to overall energy savings and decreased carbon emissions in industrial processes.

However, the production of vacuum-formed filters often involves the use of plastics, which raises concerns about resource depletion and end-of-life disposal. Many of these filters are made from thermoplastics, which, while potentially recyclable, often end up in landfills due to contamination from filtered materials. This issue highlights the need for developing more sustainable materials for vacuum-formed filters, such as biodegradable plastics or materials derived from renewable resources.

The manufacturing process of vacuum-formed filters itself has environmental implications. While vacuum forming is generally considered a low-waste production method, it still requires energy for heating and shaping materials. Efforts to optimize this process, such as using more efficient heating systems or recycling waste heat, can significantly reduce the environmental footprint of filter production.

Another important aspect is the longevity and durability of vacuum-formed filters. Their customized designs often result in filters that are more resistant to wear and tear, potentially lasting longer than traditional filters. This increased lifespan can lead to reduced waste generation and less frequent filter replacements, which is beneficial from both an environmental and economic perspective.

The application of vacuum-formed filters in advanced filtration systems also has indirect environmental impacts. In industrial settings, these filters can improve the efficiency of pollution control systems, leading to cleaner air and water emissions. In water treatment applications, vacuum-formed filters can enhance the removal of contaminants, contributing to improved water quality and conservation efforts.

Looking towards the future, the environmental impact of vacuum-formed filtration systems could be further improved through innovations in material science and manufacturing processes. Research into fully recyclable or biodegradable filter materials, coupled with advancements in energy-efficient vacuum forming techniques, could significantly enhance the sustainability profile of these filtration systems.

One of the primary environmental benefits of vacuum-formed filtration systems is their potential for reducing energy consumption. The precise shaping and customization capabilities of vacuum forming allow for the creation of highly efficient filter designs that can operate at lower pressures. This translates to reduced energy requirements for fluid or air movement through the filtration system, contributing to overall energy savings and decreased carbon emissions in industrial processes.

However, the production of vacuum-formed filters often involves the use of plastics, which raises concerns about resource depletion and end-of-life disposal. Many of these filters are made from thermoplastics, which, while potentially recyclable, often end up in landfills due to contamination from filtered materials. This issue highlights the need for developing more sustainable materials for vacuum-formed filters, such as biodegradable plastics or materials derived from renewable resources.

The manufacturing process of vacuum-formed filters itself has environmental implications. While vacuum forming is generally considered a low-waste production method, it still requires energy for heating and shaping materials. Efforts to optimize this process, such as using more efficient heating systems or recycling waste heat, can significantly reduce the environmental footprint of filter production.

Another important aspect is the longevity and durability of vacuum-formed filters. Their customized designs often result in filters that are more resistant to wear and tear, potentially lasting longer than traditional filters. This increased lifespan can lead to reduced waste generation and less frequent filter replacements, which is beneficial from both an environmental and economic perspective.

The application of vacuum-formed filters in advanced filtration systems also has indirect environmental impacts. In industrial settings, these filters can improve the efficiency of pollution control systems, leading to cleaner air and water emissions. In water treatment applications, vacuum-formed filters can enhance the removal of contaminants, contributing to improved water quality and conservation efforts.

Looking towards the future, the environmental impact of vacuum-formed filtration systems could be further improved through innovations in material science and manufacturing processes. Research into fully recyclable or biodegradable filter materials, coupled with advancements in energy-efficient vacuum forming techniques, could significantly enhance the sustainability profile of these filtration systems.

Cost-Benefit Analysis of Vacuum Forming in Filtration

The cost-benefit analysis of vacuum forming in filtration systems reveals a complex interplay of economic factors and technological advantages. Initial investment in vacuum forming equipment and tooling can be substantial, potentially deterring smaller manufacturers. However, the long-term benefits often outweigh these upfront costs, particularly for large-scale production.

Operational costs for vacuum forming are generally lower compared to traditional filtration manufacturing methods. The process requires less energy and raw materials, leading to reduced per-unit costs. Labor expenses are also minimized due to the high degree of automation in vacuum forming processes. These factors contribute to improved profit margins over time.

The efficiency of vacuum forming in producing complex filter shapes and designs is a significant benefit. This capability allows for the creation of filters with optimized surface areas and flow patterns, enhancing filtration performance. The resulting products often command higher market prices due to their superior functionality, offsetting the initial investment costs.

Vacuum forming enables rapid prototyping and production scaling, reducing time-to-market for new filtration products. This agility in manufacturing can provide a competitive edge, allowing companies to respond quickly to market demands and technological advancements. The faster production cycles also contribute to improved cash flow and inventory management.

The durability and consistency of vacuum-formed filters often result in longer product lifespans and reduced warranty claims. This enhanced product quality can lead to increased customer satisfaction and brand loyalty, indirectly benefiting the company's market position and long-term profitability.

Environmental considerations also factor into the cost-benefit analysis. Vacuum forming typically produces less waste compared to traditional manufacturing methods, aligning with sustainability goals and potentially reducing disposal costs. This eco-friendly aspect can be leveraged in marketing strategies, appealing to environmentally conscious consumers and potentially commanding premium prices.

However, the benefits of vacuum forming in filtration must be weighed against potential limitations. The process may not be suitable for all filter materials or designs, and there could be constraints on the size and complexity of filters that can be produced. These limitations may necessitate hybrid manufacturing approaches, potentially increasing overall production complexity and costs.

In conclusion, while the initial investment in vacuum forming technology for filtration systems can be significant, the long-term benefits in terms of operational efficiency, product quality, and market responsiveness often justify the costs. Companies must carefully evaluate their specific production needs, market positioning, and financial capabilities to determine if the adoption of vacuum forming aligns with their strategic goals in the filtration industry.

Operational costs for vacuum forming are generally lower compared to traditional filtration manufacturing methods. The process requires less energy and raw materials, leading to reduced per-unit costs. Labor expenses are also minimized due to the high degree of automation in vacuum forming processes. These factors contribute to improved profit margins over time.

The efficiency of vacuum forming in producing complex filter shapes and designs is a significant benefit. This capability allows for the creation of filters with optimized surface areas and flow patterns, enhancing filtration performance. The resulting products often command higher market prices due to their superior functionality, offsetting the initial investment costs.

Vacuum forming enables rapid prototyping and production scaling, reducing time-to-market for new filtration products. This agility in manufacturing can provide a competitive edge, allowing companies to respond quickly to market demands and technological advancements. The faster production cycles also contribute to improved cash flow and inventory management.

The durability and consistency of vacuum-formed filters often result in longer product lifespans and reduced warranty claims. This enhanced product quality can lead to increased customer satisfaction and brand loyalty, indirectly benefiting the company's market position and long-term profitability.

Environmental considerations also factor into the cost-benefit analysis. Vacuum forming typically produces less waste compared to traditional manufacturing methods, aligning with sustainability goals and potentially reducing disposal costs. This eco-friendly aspect can be leveraged in marketing strategies, appealing to environmentally conscious consumers and potentially commanding premium prices.

However, the benefits of vacuum forming in filtration must be weighed against potential limitations. The process may not be suitable for all filter materials or designs, and there could be constraints on the size and complexity of filters that can be produced. These limitations may necessitate hybrid manufacturing approaches, potentially increasing overall production complexity and costs.

In conclusion, while the initial investment in vacuum forming technology for filtration systems can be significant, the long-term benefits in terms of operational efficiency, product quality, and market responsiveness often justify the costs. Companies must carefully evaluate their specific production needs, market positioning, and financial capabilities to determine if the adoption of vacuum forming aligns with their strategic goals in the filtration industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!