What Are the Applications of Metal Mesh in Food Processing

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Technology Background and Objectives

Metal mesh technology has evolved significantly over the past century, transitioning from simple wire screens to sophisticated engineered materials with precise specifications. Originally developed for basic filtration and separation in mining and agriculture, metal mesh has become an integral component in modern food processing systems. The evolution has been driven by advancements in metallurgy, manufacturing techniques, and increasing demands for food safety and production efficiency.

The food processing industry has witnessed a paradigm shift in recent decades, with growing emphasis on hygiene standards, process automation, and sustainability. Metal mesh applications have expanded accordingly, now encompassing filtration, conveying, cooking, freezing, and packaging processes. This technological progression has been particularly accelerated since the 1990s with the introduction of computer-aided design and precision manufacturing capabilities.

Current technological trends in metal mesh development focus on several key areas: enhanced corrosion resistance for prolonged contact with acidic or alkaline food products; antimicrobial properties to prevent biofilm formation; improved cleanability to meet stringent sanitation requirements; and optimized mesh geometries for specific food processing applications. The integration of smart technologies, such as embedded sensors for real-time monitoring, represents the cutting edge of this field.

The primary objective of metal mesh technology in food processing is to maximize operational efficiency while maintaining the highest standards of food safety and quality. This includes minimizing product loss, reducing energy consumption, extending equipment lifespan, and ensuring consistent product characteristics. Secondary objectives include compliance with increasingly stringent regulatory requirements and adaptation to the growing trend of flexible manufacturing systems.

From a global perspective, metal mesh technology development has been concentrated in industrialized regions with advanced manufacturing capabilities, particularly North America, Europe, and East Asia. However, emerging economies are rapidly adopting and adapting these technologies to meet their growing food production needs, creating new markets and application scenarios.

Looking forward, the trajectory of metal mesh technology in food processing is expected to align with broader industry trends toward digitalization, sustainability, and personalized production. This includes the development of specialized alloys for specific food applications, integration with Industry 4.0 systems, and designs that facilitate circular economy principles through improved recyclability and reduced resource consumption.

The food processing industry has witnessed a paradigm shift in recent decades, with growing emphasis on hygiene standards, process automation, and sustainability. Metal mesh applications have expanded accordingly, now encompassing filtration, conveying, cooking, freezing, and packaging processes. This technological progression has been particularly accelerated since the 1990s with the introduction of computer-aided design and precision manufacturing capabilities.

Current technological trends in metal mesh development focus on several key areas: enhanced corrosion resistance for prolonged contact with acidic or alkaline food products; antimicrobial properties to prevent biofilm formation; improved cleanability to meet stringent sanitation requirements; and optimized mesh geometries for specific food processing applications. The integration of smart technologies, such as embedded sensors for real-time monitoring, represents the cutting edge of this field.

The primary objective of metal mesh technology in food processing is to maximize operational efficiency while maintaining the highest standards of food safety and quality. This includes minimizing product loss, reducing energy consumption, extending equipment lifespan, and ensuring consistent product characteristics. Secondary objectives include compliance with increasingly stringent regulatory requirements and adaptation to the growing trend of flexible manufacturing systems.

From a global perspective, metal mesh technology development has been concentrated in industrialized regions with advanced manufacturing capabilities, particularly North America, Europe, and East Asia. However, emerging economies are rapidly adopting and adapting these technologies to meet their growing food production needs, creating new markets and application scenarios.

Looking forward, the trajectory of metal mesh technology in food processing is expected to align with broader industry trends toward digitalization, sustainability, and personalized production. This includes the development of specialized alloys for specific food applications, integration with Industry 4.0 systems, and designs that facilitate circular economy principles through improved recyclability and reduced resource consumption.

Market Analysis of Metal Mesh in Food Industry

The global metal mesh market in the food processing industry has experienced significant growth over the past decade, driven primarily by increasing food safety regulations and the growing demand for efficient processing equipment. Currently valued at approximately 3.2 billion USD, this specialized segment is projected to grow at a compound annual growth rate of 5.7% through 2028, outpacing many other industrial material markets.

North America and Europe collectively dominate the market share, accounting for nearly 60% of global consumption, largely due to their stringent food safety standards and highly mechanized food processing sectors. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market with annual growth rates exceeding 7.5%, fueled by rapid industrialization of their food production systems and increasing adoption of Western food processing technologies.

Within the food processing sector, metal mesh applications can be segmented into several key categories. Filtration and separation systems represent the largest application segment (38% of market share), followed by conveyor belts (27%), cooking and baking equipment (18%), and specialized processing equipment (17%). The bakery and confectionery segment leads industry demand, followed closely by meat and poultry processing, dairy, and beverage production.

Consumer trends significantly impact market dynamics, with the rising demand for minimally processed foods driving innovations in gentler processing technologies that preserve nutritional content while ensuring safety. Additionally, sustainability concerns have pushed manufacturers toward developing longer-lasting, more energy-efficient metal mesh solutions that reduce waste and operational costs.

Price sensitivity varies considerably across market segments. Large-scale industrial food processors typically prioritize durability and performance over initial cost, while smaller operations and emerging markets remain more price-sensitive. Premium stainless steel mesh products command price premiums of 30-45% over standard options but offer extended operational lifespans and reduced maintenance requirements that justify the investment for many processors.

Distribution channels have evolved significantly, with direct sales to equipment manufacturers representing approximately 55% of sales, while distributor networks account for 35%, and online procurement platforms have grown to capture about 10% of the market. This shift toward digital procurement has accelerated during recent years, particularly among small to medium-sized food processors seeking cost efficiencies.

The competitive landscape features both specialized metal mesh manufacturers and diversified industrial material companies. Market concentration is moderate, with the top five players controlling approximately 42% of global market share, though regional markets often feature stronger local players with specialized knowledge of regional food processing requirements.

North America and Europe collectively dominate the market share, accounting for nearly 60% of global consumption, largely due to their stringent food safety standards and highly mechanized food processing sectors. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market with annual growth rates exceeding 7.5%, fueled by rapid industrialization of their food production systems and increasing adoption of Western food processing technologies.

Within the food processing sector, metal mesh applications can be segmented into several key categories. Filtration and separation systems represent the largest application segment (38% of market share), followed by conveyor belts (27%), cooking and baking equipment (18%), and specialized processing equipment (17%). The bakery and confectionery segment leads industry demand, followed closely by meat and poultry processing, dairy, and beverage production.

Consumer trends significantly impact market dynamics, with the rising demand for minimally processed foods driving innovations in gentler processing technologies that preserve nutritional content while ensuring safety. Additionally, sustainability concerns have pushed manufacturers toward developing longer-lasting, more energy-efficient metal mesh solutions that reduce waste and operational costs.

Price sensitivity varies considerably across market segments. Large-scale industrial food processors typically prioritize durability and performance over initial cost, while smaller operations and emerging markets remain more price-sensitive. Premium stainless steel mesh products command price premiums of 30-45% over standard options but offer extended operational lifespans and reduced maintenance requirements that justify the investment for many processors.

Distribution channels have evolved significantly, with direct sales to equipment manufacturers representing approximately 55% of sales, while distributor networks account for 35%, and online procurement platforms have grown to capture about 10% of the market. This shift toward digital procurement has accelerated during recent years, particularly among small to medium-sized food processors seeking cost efficiencies.

The competitive landscape features both specialized metal mesh manufacturers and diversified industrial material companies. Market concentration is moderate, with the top five players controlling approximately 42% of global market share, though regional markets often feature stronger local players with specialized knowledge of regional food processing requirements.

Current Applications and Technical Challenges

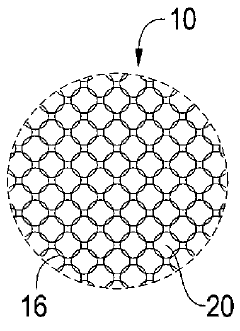

Metal mesh technology has been widely integrated into various food processing applications, revolutionizing traditional methods and enhancing efficiency across the industry. Currently, metal mesh screens and filters are extensively utilized in sorting and separating food materials based on size, shape, and quality. These applications range from simple sieving operations to complex filtration systems that remove impurities while maintaining product integrity.

In beverage production, metal mesh filters have become indispensable for clarifying liquids such as juices, wines, and dairy products. The precision-engineered pore sizes allow for consistent filtration quality while withstanding high-pressure processing environments. Similarly, in bakery operations, metal mesh conveyor belts facilitate uniform heating and cooling of products, ensuring consistent quality across production batches.

The meat processing sector employs specialized metal mesh systems for smoking and cooking applications, where the mesh provides optimal air circulation while supporting the product. Additionally, metal mesh baskets and containers are widely used in industrial washing and blanching operations, offering superior drainage capabilities and structural integrity under thermal stress.

Despite these successful implementations, several technical challenges persist in the application of metal mesh in food processing. Foremost among these is the issue of fouling and clogging during extended operation periods. Protein-rich and high-viscosity food products tend to adhere to mesh surfaces, gradually reducing filtration efficiency and necessitating frequent cleaning cycles that impact production continuity.

Corrosion resistance remains another significant challenge, particularly when processing acidic foods or using aggressive cleaning chemicals. While stainless steel alloys offer good resistance, they may not be sufficient for all food processing environments, leading to premature degradation of the mesh structure and potential contamination concerns.

The balance between mesh aperture size and structural strength presents ongoing engineering challenges. Finer mesh sizes required for certain applications often compromise the mechanical strength needed to withstand industrial processing conditions. This limitation becomes particularly evident in high-throughput operations where mechanical stress is considerable.

Cleaning and sanitation of metal mesh components also present technical difficulties. The complex geometry of mesh structures creates numerous crevices where food particles and microorganisms can accumulate, making thorough cleaning challenging. This issue is compounded by the need for cleaning protocols that effectively remove residues without damaging the mesh or leaving chemical residues.

Emerging challenges include the need for metal mesh materials that comply with increasingly stringent food safety regulations while maintaining performance characteristics. Additionally, the industry faces growing pressure to develop mesh solutions that reduce energy consumption and environmental impact without compromising processing efficiency or product quality.

In beverage production, metal mesh filters have become indispensable for clarifying liquids such as juices, wines, and dairy products. The precision-engineered pore sizes allow for consistent filtration quality while withstanding high-pressure processing environments. Similarly, in bakery operations, metal mesh conveyor belts facilitate uniform heating and cooling of products, ensuring consistent quality across production batches.

The meat processing sector employs specialized metal mesh systems for smoking and cooking applications, where the mesh provides optimal air circulation while supporting the product. Additionally, metal mesh baskets and containers are widely used in industrial washing and blanching operations, offering superior drainage capabilities and structural integrity under thermal stress.

Despite these successful implementations, several technical challenges persist in the application of metal mesh in food processing. Foremost among these is the issue of fouling and clogging during extended operation periods. Protein-rich and high-viscosity food products tend to adhere to mesh surfaces, gradually reducing filtration efficiency and necessitating frequent cleaning cycles that impact production continuity.

Corrosion resistance remains another significant challenge, particularly when processing acidic foods or using aggressive cleaning chemicals. While stainless steel alloys offer good resistance, they may not be sufficient for all food processing environments, leading to premature degradation of the mesh structure and potential contamination concerns.

The balance between mesh aperture size and structural strength presents ongoing engineering challenges. Finer mesh sizes required for certain applications often compromise the mechanical strength needed to withstand industrial processing conditions. This limitation becomes particularly evident in high-throughput operations where mechanical stress is considerable.

Cleaning and sanitation of metal mesh components also present technical difficulties. The complex geometry of mesh structures creates numerous crevices where food particles and microorganisms can accumulate, making thorough cleaning challenging. This issue is compounded by the need for cleaning protocols that effectively remove residues without damaging the mesh or leaving chemical residues.

Emerging challenges include the need for metal mesh materials that comply with increasingly stringent food safety regulations while maintaining performance characteristics. Additionally, the industry faces growing pressure to develop mesh solutions that reduce energy consumption and environmental impact without compromising processing efficiency or product quality.

Current Metal Mesh Solutions for Food Processing

01 Metal mesh for touch screen applications

Metal mesh structures are used in touch screen technologies to create transparent conductive patterns. These meshes provide electrical conductivity while maintaining optical transparency, making them ideal for touchscreens in various electronic devices. The metal mesh patterns can be designed with specific geometries to optimize both touch sensitivity and visual clarity, and can be manufactured using various deposition and patterning techniques.- Metal mesh for touch screen applications: Metal mesh structures are used in touch screen technologies to create transparent conductive patterns. These meshes provide electrical conductivity while maintaining optical transparency, making them ideal for touchscreens in various electronic devices. The mesh patterns can be designed with specific geometries to optimize both touch sensitivity and visual clarity. Advanced manufacturing techniques allow for ultra-fine metal lines that are nearly invisible to the naked eye.

- Metal mesh for electromagnetic shielding: Metal meshes are utilized for electromagnetic interference (EMI) shielding in electronic devices. The conductive mesh structure blocks or attenuates electromagnetic radiation, protecting sensitive components from external interference or preventing signal leakage. These meshes can be designed with specific aperture sizes and wire thicknesses to target particular frequency ranges while maintaining necessary physical properties such as flexibility or strength.

- Manufacturing processes for metal mesh structures: Various manufacturing techniques are employed to produce metal mesh structures with precise specifications. These include photolithography, etching, electroforming, and advanced printing methods. The manufacturing processes can control critical parameters such as line width, spacing, thickness, and pattern geometry. Some processes focus on cost-effective mass production while others prioritize high precision for specialized applications.

- Metal mesh for filtration and separation applications: Metal meshes serve as effective filtration media for separating particles, fluids, or gases based on size exclusion. The mesh aperture size, wire diameter, and material selection determine filtration efficiency and durability. These meshes can withstand harsh environments including high temperatures, pressure differentials, and corrosive substances. Applications range from industrial processing to laboratory research and environmental remediation.

- Metal mesh reinforcement in composite materials: Metal meshes are incorporated into composite materials to enhance mechanical properties such as strength, stiffness, and impact resistance. The mesh provides structural reinforcement while allowing the composite to maintain flexibility where needed. This technology is applied in construction materials, automotive components, and protective equipment. The integration of metal mesh can also improve thermal conductivity and electrical properties of the composite.

02 Metal mesh for electromagnetic shielding

Metal mesh structures are utilized for electromagnetic interference (EMI) shielding in electronic devices. These meshes can block or attenuate electromagnetic radiation while allowing for other desirable properties such as optical transparency or ventilation. The mesh design, including aperture size and wire thickness, can be optimized for specific frequency ranges of electromagnetic radiation, providing protection for sensitive electronic components.Expand Specific Solutions03 Manufacturing processes for metal mesh structures

Various manufacturing techniques are employed to produce metal mesh structures with precise dimensions and properties. These include photolithography, etching, electroplating, and printing methods. Advanced manufacturing processes allow for the creation of ultra-fine metal mesh patterns with controlled wire width, spacing, and thickness. These techniques can be optimized for mass production while maintaining high precision and consistency in the final product.Expand Specific Solutions04 Metal mesh for filtration and separation applications

Metal mesh structures are designed for filtration and separation processes across various industries. These meshes can be engineered with specific pore sizes and distributions to selectively filter particles, molecules, or cells. The durability of metal meshes makes them suitable for harsh environments involving high temperatures, pressures, or corrosive substances. Different metal alloys can be selected based on the specific filtration requirements and operating conditions.Expand Specific Solutions05 Metal mesh for battery and energy storage applications

Metal mesh structures serve as current collectors and electrode supports in batteries and other energy storage devices. The mesh design provides high electrical conductivity while allowing for efficient ion transport through the structure. These meshes can be coated with active materials to create electrodes with high surface area and improved electrochemical performance. The open structure of metal meshes facilitates electrolyte penetration and gas evolution during battery operation.Expand Specific Solutions

Key Manufacturers and Industry Competitors

The metal mesh market in food processing is currently in a growth phase, characterized by increasing adoption across various applications. The market size is expanding steadily, driven by demands for improved food safety, processing efficiency, and durability. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established companies like MULTIVAC Sepp Haggenmüller and Viscofan SA specializing in packaging solutions, General Mills implementing metal mesh in large-scale processing, and Silgan Containers focusing on metal food containers. Innovative developments are emerging from specialized manufacturers like Manulatex France (protective equipment) and Kuhne Anlagenbau (film technology). The competitive landscape features both traditional food processing conglomerates and specialized equipment manufacturers, with increasing research collaboration from academic institutions like Michigan State University.

VISCOFAN SA

Technical Solution: VISCOFAN has pioneered advanced metal mesh extrusion systems for food casing production, particularly for sausage and processed meat products. Their technology utilizes precision-engineered metal mesh conveyor belts with specialized coatings that prevent product adhesion while maintaining optimal heat transfer characteristics. The company has developed a proprietary mesh pattern that creates micro-texturing on food casings, improving smoke penetration and flavor development in processed meats[3]. Their systems incorporate tension-controlled metal mesh belts that automatically adjust during thermal expansion and contraction cycles, maintaining consistent product dimensions throughout the production process. VISCOFAN's metal mesh technology features integrated cleaning systems that use high-pressure water jets and ultrasonic vibration to remove protein residues without damaging the mesh structure. The company has also developed specialized metal mesh forms for 3D food product molding, allowing for complex shapes while maintaining uniform cooking characteristics.

Strengths: Superior heat distribution leading to more consistent product quality; excellent durability in continuous production environments; precise dimensional control of food products; reduced product loss due to non-stick properties. Weaknesses: Requires specialized maintenance expertise; higher initial investment compared to conventional systems; more complex cleaning procedures to maintain food safety standards.

Manulatex France

Technical Solution: Manulatex France has developed advanced metal mesh protective equipment for food processing environments, focusing on cut-resistant gloves and aprons that utilize stainless steel rings interwoven in specific patterns. Their technology employs a proprietary ring assembly method that creates flexible yet highly durable protective gear. The company's metal mesh solutions incorporate antimicrobial treatments to prevent bacterial growth on the mesh surface, addressing a critical food safety concern. Their designs feature ergonomic considerations with weight distribution systems that reduce operator fatigue during extended use[1]. Manulatex has also pioneered detectable metal mesh technologies that can be identified by standard food industry metal detectors if fragments accidentally enter the production line, significantly enhancing food safety protocols in meat and seafood processing facilities.

Strengths: Superior cut resistance compared to textile alternatives; excellent durability with documented extended service life; fully compliant with food industry hygiene standards; detectable by standard food safety equipment. Weaknesses: Higher initial investment cost compared to non-metal alternatives; requires specific cleaning protocols; slightly heavier than polymer-based protective equipment.

Critical Patents and Technical Innovations

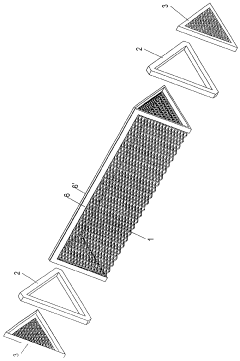

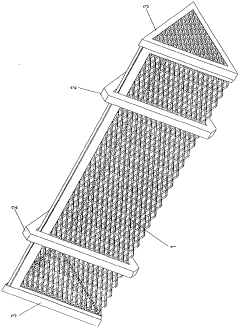

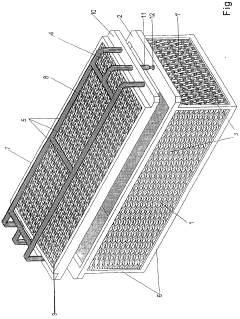

Wire netting container or wire netting support element for the shaping treatment of food or for receiving food, especially meats and sausages

PatentWO2001065946A1

Innovation

- The use of expanded metal or stamping material for the mesh lattice container or support element, which allows for easy deformation and maintenance of internal cohesion, reducing the contact surface with food and facilitating drainage, while being made from materials like stainless steel or plastics suitable for the food industry.

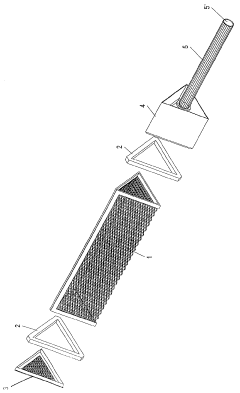

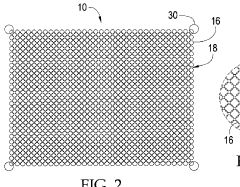

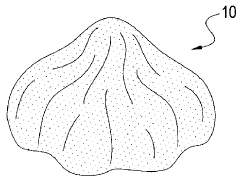

Metal mesh food wrap

PatentInactiveUS9247847B2

Innovation

- A flexible metal mesh food wrap made of interlocking metal rings with air pockets, which acts as an insulating layer to reduce heat and moisture loss, allowing natural juices to permeate and maintain food temperature.

Food Safety Compliance and Standards

The implementation of metal mesh technology in food processing necessitates strict adherence to comprehensive food safety regulations and standards across global markets. In the United States, the Food and Drug Administration (FDA) has established specific guidelines under the Food Safety Modernization Act (FSMA) that govern materials used in food contact applications, including metal mesh components. These regulations mandate that all metal mesh materials must be fabricated from food-grade metals such as stainless steel 304 or 316, which demonstrate superior corrosion resistance and minimal leaching properties.

European regulations, particularly the European Food Safety Authority (EFSA) guidelines and EC 1935/2004 framework, impose additional requirements regarding migration limits and material traceability for metal mesh applications in food processing environments. Manufacturers must provide detailed documentation certifying that their metal mesh products comply with these standards, including migration testing results and material composition declarations.

The International Organization for Standardization (ISO) has developed several standards specifically addressing hygienic design principles for food processing equipment, such as ISO 14159 and ISO 22000. These standards outline critical requirements for metal mesh components, including cleanability, prevention of microbial harborage, and resistance to cleaning chemicals. Compliance with these standards often requires specialized design features like electropolished surfaces and welded joints rather than mechanical connections.

Hazard Analysis Critical Control Point (HACCP) principles must be integrated into the implementation of metal mesh technologies within food processing operations. This involves identifying potential physical, chemical, and biological hazards associated with metal mesh applications and establishing appropriate control measures. Regular inspection protocols for metal mesh integrity are essential to prevent metal fragment contamination, which represents a significant physical hazard in food production.

Third-party certification programs, including NSF International and 3-A Sanitary Standards, provide additional validation frameworks for metal mesh components in food processing equipment. These certifications verify that products meet specific design and performance criteria for sanitary applications, offering food manufacturers greater assurance regarding regulatory compliance and food safety protection.

Emerging regulations concerning nanomaterials and novel metal alloys are increasingly relevant as metal mesh technology advances. Regulatory bodies worldwide are developing new frameworks to address potential safety concerns associated with these innovations, requiring manufacturers to conduct additional safety assessments and validation studies before implementation in food processing environments.

European regulations, particularly the European Food Safety Authority (EFSA) guidelines and EC 1935/2004 framework, impose additional requirements regarding migration limits and material traceability for metal mesh applications in food processing environments. Manufacturers must provide detailed documentation certifying that their metal mesh products comply with these standards, including migration testing results and material composition declarations.

The International Organization for Standardization (ISO) has developed several standards specifically addressing hygienic design principles for food processing equipment, such as ISO 14159 and ISO 22000. These standards outline critical requirements for metal mesh components, including cleanability, prevention of microbial harborage, and resistance to cleaning chemicals. Compliance with these standards often requires specialized design features like electropolished surfaces and welded joints rather than mechanical connections.

Hazard Analysis Critical Control Point (HACCP) principles must be integrated into the implementation of metal mesh technologies within food processing operations. This involves identifying potential physical, chemical, and biological hazards associated with metal mesh applications and establishing appropriate control measures. Regular inspection protocols for metal mesh integrity are essential to prevent metal fragment contamination, which represents a significant physical hazard in food production.

Third-party certification programs, including NSF International and 3-A Sanitary Standards, provide additional validation frameworks for metal mesh components in food processing equipment. These certifications verify that products meet specific design and performance criteria for sanitary applications, offering food manufacturers greater assurance regarding regulatory compliance and food safety protection.

Emerging regulations concerning nanomaterials and novel metal alloys are increasingly relevant as metal mesh technology advances. Regulatory bodies worldwide are developing new frameworks to address potential safety concerns associated with these innovations, requiring manufacturers to conduct additional safety assessments and validation studies before implementation in food processing environments.

Environmental Impact and Sustainability Considerations

The food processing industry's use of metal mesh technologies has significant environmental implications that warrant careful consideration. The production of metal mesh components involves resource extraction, energy-intensive manufacturing processes, and potential chemical treatments that generate considerable carbon emissions. Traditional stainless steel mesh manufacturing can contribute to environmental degradation through mining activities and high-temperature metal processing, which typically consumes substantial fossil fuel energy.

Water usage represents another critical environmental concern, as metal mesh cleaning and maintenance in food processing facilities often requires large volumes of water and chemical cleaning agents. These processes generate wastewater containing detergents, sanitizers, and food residues that require proper treatment before discharge to prevent ecosystem contamination.

Recent sustainability innovations have emerged to address these challenges. Advanced manufacturing techniques now enable the production of thinner yet equally durable metal mesh components, reducing raw material requirements by up to 30%. Additionally, new alloy formulations have improved corrosion resistance, extending product lifespan and decreasing replacement frequency, thereby minimizing waste generation and resource consumption over time.

The recyclability of metal mesh presents a significant sustainability advantage. Unlike many plastic alternatives, stainless steel and other metal mesh materials can be fully recycled multiple times without degradation in quality, supporting circular economy principles. Leading food processing equipment manufacturers have implemented take-back programs, collecting end-of-life metal mesh components for recycling, which can reduce the environmental footprint by approximately 60% compared to virgin material production.

Energy efficiency improvements in metal mesh applications also contribute to sustainability goals. Modern mesh designs optimize airflow and heat transfer in drying and cooking processes, potentially reducing energy consumption by 15-25%. Furthermore, precision-engineered mesh filtration systems minimize product loss during processing, improving resource efficiency throughout the production chain.

Regulatory frameworks increasingly emphasize environmental performance, with standards like ISO 14001 and industry-specific certifications driving adoption of more sustainable metal mesh technologies. Forward-thinking manufacturers are conducting comprehensive life cycle assessments to quantify environmental impacts from raw material extraction through disposal, enabling data-driven sustainability improvements and transparent environmental reporting to stakeholders.

Water usage represents another critical environmental concern, as metal mesh cleaning and maintenance in food processing facilities often requires large volumes of water and chemical cleaning agents. These processes generate wastewater containing detergents, sanitizers, and food residues that require proper treatment before discharge to prevent ecosystem contamination.

Recent sustainability innovations have emerged to address these challenges. Advanced manufacturing techniques now enable the production of thinner yet equally durable metal mesh components, reducing raw material requirements by up to 30%. Additionally, new alloy formulations have improved corrosion resistance, extending product lifespan and decreasing replacement frequency, thereby minimizing waste generation and resource consumption over time.

The recyclability of metal mesh presents a significant sustainability advantage. Unlike many plastic alternatives, stainless steel and other metal mesh materials can be fully recycled multiple times without degradation in quality, supporting circular economy principles. Leading food processing equipment manufacturers have implemented take-back programs, collecting end-of-life metal mesh components for recycling, which can reduce the environmental footprint by approximately 60% compared to virgin material production.

Energy efficiency improvements in metal mesh applications also contribute to sustainability goals. Modern mesh designs optimize airflow and heat transfer in drying and cooking processes, potentially reducing energy consumption by 15-25%. Furthermore, precision-engineered mesh filtration systems minimize product loss during processing, improving resource efficiency throughout the production chain.

Regulatory frameworks increasingly emphasize environmental performance, with standards like ISO 14001 and industry-specific certifications driving adoption of more sustainable metal mesh technologies. Forward-thinking manufacturers are conducting comprehensive life cycle assessments to quantify environmental impacts from raw material extraction through disposal, enabling data-driven sustainability improvements and transparent environmental reporting to stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!