Regulatory Compliance of Metal Mesh in Medical Devices

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Medical Device Metal Mesh Regulatory Background and Objectives

Metal mesh technology has evolved significantly in medical device applications over the past two decades. Initially developed for consumer electronics as transparent conductive materials, metal meshes have transitioned into critical components in various medical devices including implantable devices, diagnostic equipment, and wearable health monitors. The evolution of this technology has been driven by increasing demands for biocompatible materials that can maintain electrical conductivity while offering flexibility and durability in biological environments.

The regulatory landscape governing metal mesh in medical devices has undergone substantial transformation since the early 2000s. The FDA's 2016 guidance on technical considerations for additive manufactured medical devices marked a significant milestone, addressing novel materials including metal meshes. Subsequently, the European Union's Medical Device Regulation (MDR) implementation in 2021 introduced more stringent requirements for material characterization and biocompatibility assessment, particularly affecting metal mesh applications.

Current technical objectives in this field focus on achieving regulatory compliance while optimizing performance characteristics. Primary goals include developing standardized testing protocols specifically for metal mesh materials, establishing clear biocompatibility profiles across different mesh configurations, and creating validated manufacturing processes that ensure consistent quality and performance. Additionally, there is growing emphasis on developing metal mesh designs that minimize foreign body responses while maintaining functional properties.

The intersection of nanotechnology with metal mesh development presents both opportunities and regulatory challenges. As mesh structures approach nano-scale dimensions, regulatory bodies worldwide are actively developing frameworks to address potential novel risks. The FDA's Nanotechnology Task Force and similar initiatives in Europe and Asia are working to establish appropriate evaluation methods for these advanced materials.

Looking forward, the technical trajectory aims to establish harmonized global standards for metal mesh characterization in medical applications. This includes developing consensus on appropriate in vitro and in vivo testing methodologies, establishing acceptable limits for metal ion leaching, and creating standardized protocols for evaluating long-term stability in physiological environments. These efforts are essential as metal mesh technology increasingly appears in critical applications such as neural interfaces, smart implants, and advanced drug delivery systems.

The convergence of regulatory requirements across major markets represents both a challenge and an opportunity for manufacturers. Achieving compliance with the most stringent standards can facilitate global market access but requires sophisticated technical approaches to material design, characterization, and validation.

The regulatory landscape governing metal mesh in medical devices has undergone substantial transformation since the early 2000s. The FDA's 2016 guidance on technical considerations for additive manufactured medical devices marked a significant milestone, addressing novel materials including metal meshes. Subsequently, the European Union's Medical Device Regulation (MDR) implementation in 2021 introduced more stringent requirements for material characterization and biocompatibility assessment, particularly affecting metal mesh applications.

Current technical objectives in this field focus on achieving regulatory compliance while optimizing performance characteristics. Primary goals include developing standardized testing protocols specifically for metal mesh materials, establishing clear biocompatibility profiles across different mesh configurations, and creating validated manufacturing processes that ensure consistent quality and performance. Additionally, there is growing emphasis on developing metal mesh designs that minimize foreign body responses while maintaining functional properties.

The intersection of nanotechnology with metal mesh development presents both opportunities and regulatory challenges. As mesh structures approach nano-scale dimensions, regulatory bodies worldwide are actively developing frameworks to address potential novel risks. The FDA's Nanotechnology Task Force and similar initiatives in Europe and Asia are working to establish appropriate evaluation methods for these advanced materials.

Looking forward, the technical trajectory aims to establish harmonized global standards for metal mesh characterization in medical applications. This includes developing consensus on appropriate in vitro and in vivo testing methodologies, establishing acceptable limits for metal ion leaching, and creating standardized protocols for evaluating long-term stability in physiological environments. These efforts are essential as metal mesh technology increasingly appears in critical applications such as neural interfaces, smart implants, and advanced drug delivery systems.

The convergence of regulatory requirements across major markets represents both a challenge and an opportunity for manufacturers. Achieving compliance with the most stringent standards can facilitate global market access but requires sophisticated technical approaches to material design, characterization, and validation.

Market Demand Analysis for Compliant Medical Metal Mesh

The global market for compliant medical metal mesh is experiencing robust growth, driven primarily by increasing demand for minimally invasive procedures and advanced medical devices. Current market analysis indicates that the medical metal mesh sector reached approximately $2.5 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2028. This growth trajectory is particularly evident in applications such as cardiovascular stents, neurovascular devices, and orthopedic implants where regulatory-compliant metal mesh components are essential.

Healthcare providers worldwide are increasingly seeking medical devices that incorporate metal mesh technologies which meet stringent regulatory standards while delivering enhanced clinical outcomes. The demand is particularly strong in regions with aging populations, including North America, Europe, and parts of Asia, where age-related conditions necessitating implantable devices are more prevalent.

Market research reveals that patient preference for less invasive treatment options is a significant driver for compliant metal mesh technologies. These preferences align with healthcare systems' focus on reducing hospital stays and recovery times, creating a favorable market environment for devices utilizing advanced metal mesh components.

The regulatory landscape significantly shapes market demand patterns. Regions with well-established regulatory frameworks, such as the United States (FDA) and Europe (MDR), represent the largest market segments for compliant medical metal mesh. However, emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates as their regulatory systems mature and healthcare infrastructure expands.

Industry surveys indicate that medical device manufacturers are increasingly prioritizing suppliers who can demonstrate comprehensive regulatory compliance documentation for metal mesh components. This trend has created a premium market segment for materials that meet or exceed regulatory requirements, with price sensitivity being lower than in other medical component categories.

The COVID-19 pandemic has influenced market dynamics by highlighting supply chain vulnerabilities and accelerating the adoption of regional manufacturing capabilities for critical medical components, including specialized metal mesh products. This shift has created new market opportunities for suppliers who can ensure regulatory compliance across multiple jurisdictions while maintaining reliable supply chains.

Technological advancements in manufacturing processes, particularly in areas such as 3D printing of metal mesh structures and surface modification technologies, are expanding the potential applications and driving new market segments. These innovations are creating demand for updated regulatory frameworks that can adequately address novel manufacturing methods while ensuring patient safety.

Healthcare providers worldwide are increasingly seeking medical devices that incorporate metal mesh technologies which meet stringent regulatory standards while delivering enhanced clinical outcomes. The demand is particularly strong in regions with aging populations, including North America, Europe, and parts of Asia, where age-related conditions necessitating implantable devices are more prevalent.

Market research reveals that patient preference for less invasive treatment options is a significant driver for compliant metal mesh technologies. These preferences align with healthcare systems' focus on reducing hospital stays and recovery times, creating a favorable market environment for devices utilizing advanced metal mesh components.

The regulatory landscape significantly shapes market demand patterns. Regions with well-established regulatory frameworks, such as the United States (FDA) and Europe (MDR), represent the largest market segments for compliant medical metal mesh. However, emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates as their regulatory systems mature and healthcare infrastructure expands.

Industry surveys indicate that medical device manufacturers are increasingly prioritizing suppliers who can demonstrate comprehensive regulatory compliance documentation for metal mesh components. This trend has created a premium market segment for materials that meet or exceed regulatory requirements, with price sensitivity being lower than in other medical component categories.

The COVID-19 pandemic has influenced market dynamics by highlighting supply chain vulnerabilities and accelerating the adoption of regional manufacturing capabilities for critical medical components, including specialized metal mesh products. This shift has created new market opportunities for suppliers who can ensure regulatory compliance across multiple jurisdictions while maintaining reliable supply chains.

Technological advancements in manufacturing processes, particularly in areas such as 3D printing of metal mesh structures and surface modification technologies, are expanding the potential applications and driving new market segments. These innovations are creating demand for updated regulatory frameworks that can adequately address novel manufacturing methods while ensuring patient safety.

Current Regulatory Challenges for Metal Mesh in Medical Applications

The regulatory landscape for metal mesh in medical devices presents significant challenges for manufacturers and developers. The FDA in the United States, the European Medicines Agency (EMA) in Europe, and similar regulatory bodies in other regions have established stringent requirements for medical devices incorporating metal mesh components. These requirements focus primarily on biocompatibility, mechanical integrity, corrosion resistance, and long-term stability within the human body.

One of the most pressing challenges is the inconsistency in regulatory frameworks across different jurisdictions. While the FDA has established specific guidance for certain metal mesh applications, such as hernia repair and cardiovascular stents, there remains considerable ambiguity for novel applications. The EU's Medical Device Regulation (MDR) implementation has further complicated compliance efforts, with its enhanced requirements for clinical evidence and post-market surveillance.

Material characterization presents another significant hurdle. Regulatory bodies increasingly demand comprehensive data on metal mesh properties, including elemental composition, surface characteristics, and potential leachables. The FDA's recent emphasis on particulate matter generation from metal implants has intensified scrutiny on metal mesh devices, requiring manufacturers to develop sophisticated testing protocols that may not be standardized across the industry.

Biocompatibility testing requirements have become more complex, particularly for permanent implantable devices containing metal mesh. ISO 10993 series compliance requires extensive testing, including cytotoxicity, sensitization, irritation, and systemic toxicity assessments. For metal mesh specifically, concerns about metal ion release and potential long-term effects necessitate additional specialized testing that can extend development timelines significantly.

Risk classification variations across regions further complicate regulatory strategies. A metal mesh device classified as Class II in the United States might receive a higher-risk classification in Europe or Asia, requiring substantially different evidence packages and approval pathways. This inconsistency forces companies to develop multiple regulatory strategies, increasing costs and time-to-market.

The evolving nature of regulations presents perhaps the most persistent challenge. As scientific understanding of material-tissue interactions advances, regulatory requirements continue to evolve. Recent regulatory focus on metal allergies, particulate generation, and MRI compatibility has created moving compliance targets for manufacturers. The FDA's Safer Technologies Program and similar initiatives in other regions signal increasing regulatory attention to material safety that will likely impact metal mesh applications.

Manufacturing process validation for metal mesh components faces heightened scrutiny, with regulators demanding robust evidence of consistent production methods that maintain critical quality attributes. This includes validation of cleaning processes, sterilization compatibility, and packaging integrity specific to the unique properties of metal mesh structures.

One of the most pressing challenges is the inconsistency in regulatory frameworks across different jurisdictions. While the FDA has established specific guidance for certain metal mesh applications, such as hernia repair and cardiovascular stents, there remains considerable ambiguity for novel applications. The EU's Medical Device Regulation (MDR) implementation has further complicated compliance efforts, with its enhanced requirements for clinical evidence and post-market surveillance.

Material characterization presents another significant hurdle. Regulatory bodies increasingly demand comprehensive data on metal mesh properties, including elemental composition, surface characteristics, and potential leachables. The FDA's recent emphasis on particulate matter generation from metal implants has intensified scrutiny on metal mesh devices, requiring manufacturers to develop sophisticated testing protocols that may not be standardized across the industry.

Biocompatibility testing requirements have become more complex, particularly for permanent implantable devices containing metal mesh. ISO 10993 series compliance requires extensive testing, including cytotoxicity, sensitization, irritation, and systemic toxicity assessments. For metal mesh specifically, concerns about metal ion release and potential long-term effects necessitate additional specialized testing that can extend development timelines significantly.

Risk classification variations across regions further complicate regulatory strategies. A metal mesh device classified as Class II in the United States might receive a higher-risk classification in Europe or Asia, requiring substantially different evidence packages and approval pathways. This inconsistency forces companies to develop multiple regulatory strategies, increasing costs and time-to-market.

The evolving nature of regulations presents perhaps the most persistent challenge. As scientific understanding of material-tissue interactions advances, regulatory requirements continue to evolve. Recent regulatory focus on metal allergies, particulate generation, and MRI compatibility has created moving compliance targets for manufacturers. The FDA's Safer Technologies Program and similar initiatives in other regions signal increasing regulatory attention to material safety that will likely impact metal mesh applications.

Manufacturing process validation for metal mesh components faces heightened scrutiny, with regulators demanding robust evidence of consistent production methods that maintain critical quality attributes. This includes validation of cleaning processes, sterilization compatibility, and packaging integrity specific to the unique properties of metal mesh structures.

Current Compliance Strategies for Metal Mesh Components

01 Metal mesh for touch screen applications

Metal mesh structures are used in touch screen technologies to create transparent conductive patterns. These meshes provide electrical conductivity while maintaining optical transparency, making them ideal for touchscreens in various electronic devices. The mesh design typically consists of fine metal lines arranged in specific patterns to optimize both conductivity and visibility. Advanced manufacturing techniques allow for creating ultra-thin metal traces that minimize visibility while maintaining touch sensitivity.- Metal mesh for touch screen applications: Metal mesh structures are used in touch screen technologies to create transparent conductive patterns. These meshes provide electrical conductivity while maintaining optical transparency, making them ideal for touchscreens in various electronic devices. The mesh design typically consists of fine metal lines arranged in specific patterns to optimize touch sensitivity and visibility.

- Manufacturing methods for metal mesh structures: Various manufacturing techniques are employed to produce metal mesh structures with precise dimensions and properties. These methods include photolithography, etching, printing, and deposition processes. Advanced manufacturing approaches allow for the creation of ultra-fine metal patterns with controlled thickness and width, which is crucial for applications requiring specific electrical and optical characteristics.

- Metal mesh for electromagnetic shielding: Metal mesh structures are utilized for electromagnetic interference (EMI) shielding in electronic devices. The mesh design allows for effective blocking of electromagnetic radiation while maintaining other functional properties such as ventilation or visibility. The spacing, thickness, and material composition of the mesh are optimized to provide effective shielding across specific frequency ranges.

- Metal mesh for filtration and separation applications: Metal mesh structures serve as filtration media in various industrial applications. The mesh design, including pore size, wire diameter, and overall structure, is tailored to specific filtration requirements. These meshes can be used for solid-liquid separation, gas filtration, and particle classification across industries such as food processing, chemical manufacturing, and water treatment.

- Metal mesh with enhanced mechanical and physical properties: Advanced metal mesh designs incorporate features to enhance mechanical strength, durability, and specific physical properties. These improvements include specialized coatings, composite structures, and innovative geometrical configurations. Enhanced metal meshes offer benefits such as increased corrosion resistance, improved thermal stability, better flexibility, and higher tensile strength, making them suitable for demanding applications in aerospace, automotive, and construction industries.

02 Metal mesh for electromagnetic shielding

Metal meshes are utilized for electromagnetic interference (EMI) shielding in electronic devices. The mesh structure blocks or attenuates electromagnetic radiation while allowing for ventilation and heat dissipation. These meshes can be designed with specific aperture sizes and metal compositions to target particular frequency ranges. Applications include shielding for electronic enclosures, communication devices, and sensitive equipment that requires protection from external electromagnetic interference.Expand Specific Solutions03 Manufacturing processes for metal mesh structures

Various manufacturing techniques are employed to produce metal mesh structures with precise dimensions and properties. These include photolithography, etching, electroforming, and advanced printing methods. The manufacturing processes can control mesh parameters such as wire diameter, opening size, and pattern geometry. Recent innovations focus on roll-to-roll processing for high-volume production and methods to create flexible metal meshes that can be integrated into curved or bendable surfaces.Expand Specific Solutions04 Metal mesh for filtration and separation applications

Metal meshes are designed for filtration and separation processes across various industries. The mesh structures can be engineered with specific pore sizes to filter particles, separate materials, or control fluid flow. Applications include industrial sieves, filters for chemical processing, food production equipment, and environmental filtration systems. Advanced metal mesh designs incorporate multiple layers or gradient structures to enhance filtration efficiency while maintaining structural integrity under pressure or temperature variations.Expand Specific Solutions05 Metal mesh for structural reinforcement

Metal mesh structures are utilized for reinforcement in composite materials and construction applications. The mesh provides tensile strength while allowing matrix materials to flow through and bond with the structure. These reinforcement meshes can be designed with varying densities and patterns to address specific load requirements. Applications include concrete reinforcement, composite panels, architectural elements, and protective structures that require both strength and some degree of flexibility or permeability.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The regulatory compliance landscape for metal mesh in medical devices is currently in a growth phase, with an estimated market size exceeding $2 billion annually. The technology is maturing rapidly as companies advance innovative applications across cardiovascular, orthopedic, and neurological fields. Leading players like Medtronic and Boston Scientific have established strong regulatory expertise, while specialized firms such as Mirus LLC are pioneering with novel rhenium-based alloys for implantable devices. Chinese manufacturers including Microport Medical and Lifetech Scientific are gaining market share through cost-effective compliance strategies. The competitive landscape shows a clear stratification between established medical device conglomerates with comprehensive regulatory frameworks and emerging innovators focusing on material science breakthroughs to address specific compliance challenges.

Medtronic, Inc.

Technical Solution: Medtronic has developed a comprehensive regulatory compliance framework for metal mesh technologies in implantable medical devices, particularly for cardiovascular applications. Their approach integrates advanced biocompatibility testing protocols that evaluate long-term tissue interactions with metal mesh structures. Medtronic's technical solution includes specialized surface treatment processes that modify metal mesh surfaces to reduce inflammatory responses while maintaining structural integrity. Their compliance strategy incorporates extensive clinical validation studies across multiple regulatory jurisdictions, with particular focus on meeting both FDA and EU MDR requirements. Medtronic has pioneered accelerated aging methodologies specifically calibrated for metal mesh components to predict long-term performance and degradation patterns, which has become an industry benchmark for regulatory submissions.

Strengths: Extensive global regulatory expertise and established relationships with regulatory bodies; comprehensive in-house testing capabilities for metal mesh technologies; large clinical data repository supporting safety claims. Weaknesses: Higher compliance costs compared to smaller competitors; longer regulatory approval timelines due to complex product portfolio; conservative approach may slow innovation in emerging markets.

Nitinol Development Corp.

Technical Solution: Nitinol Development Corporation has pioneered specialized regulatory compliance methodologies for nitinol-based metal mesh devices, focusing on the unique properties of this shape memory alloy. Their technical approach centers on advanced material characterization techniques that document the thermomechanical properties of nitinol mesh structures across physiological temperature ranges. The company has developed proprietary testing protocols for fatigue resistance that simulate in-vivo conditions more accurately than standard regulatory tests, providing enhanced predictive value for long-term performance. Their compliance strategy incorporates specialized surface treatment validation methods that address nickel leaching concerns specific to nitinol mesh applications. Nitinol Development Corp has established reference standards for nitinol mesh performance that are increasingly recognized by regulatory bodies, positioning their compliance methodologies as industry benchmarks for this specialized material category in medical devices.

Strengths: Unparalleled expertise in nitinol-specific regulatory requirements; specialized testing capabilities tailored to shape memory alloy properties; recognized authority status with regulatory bodies for nitinol applications. Weaknesses: Narrow focus on nitinol limits broader metal mesh applications; smaller scale compared to diversified medical device manufacturers; challenges in addressing emerging regulatory requirements for novel applications.

Critical Standards and Testing Protocols for Medical Metal Mesh

Medical device metal alloy

PatentPendingUS20230248886A1

Innovation

- A medical device partially or fully formed from modified metal alloys, such as those with at least 15 wt.% rhenium, which reduces recoil and allows for smaller crimping diameters while maintaining structural integrity.

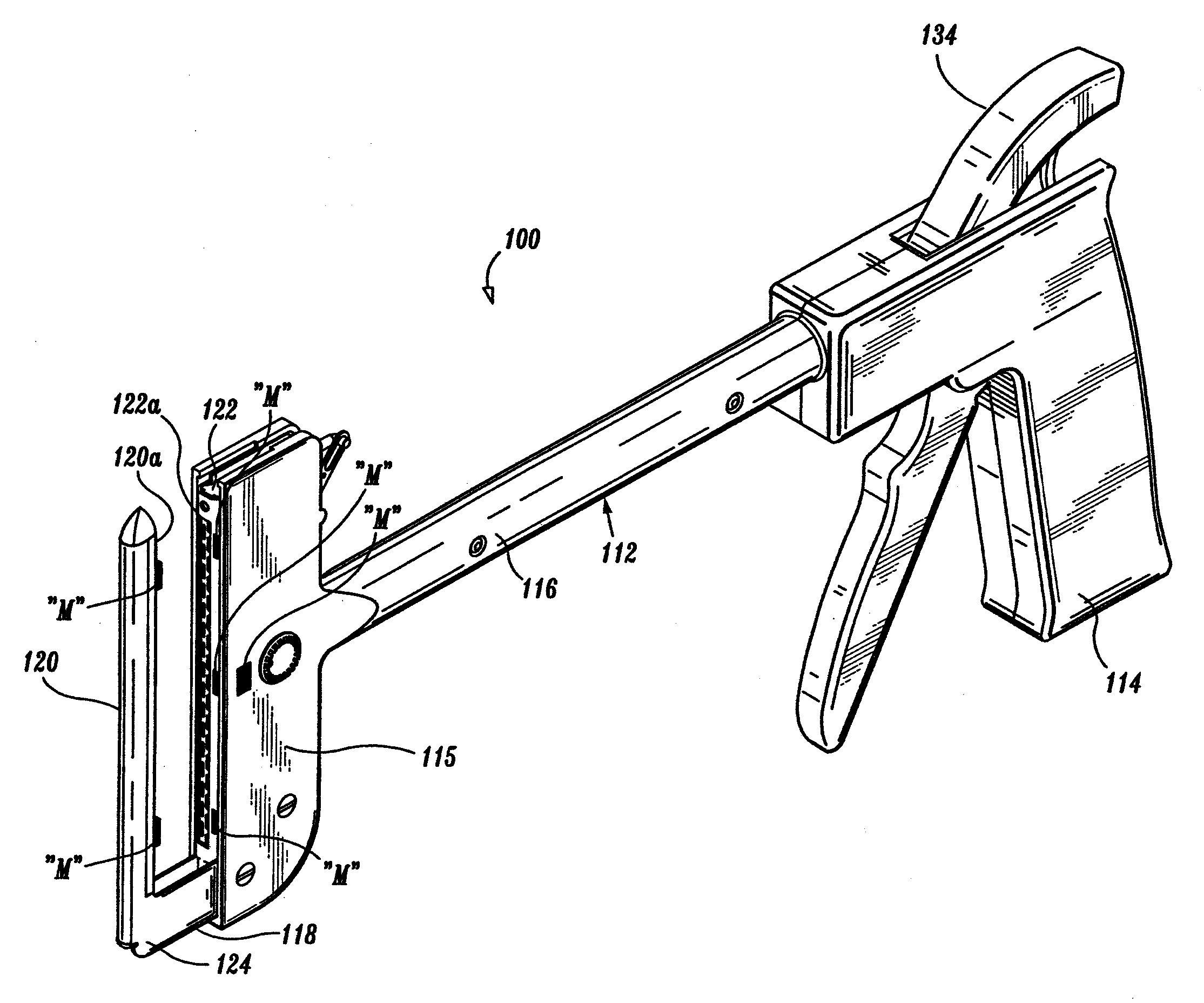

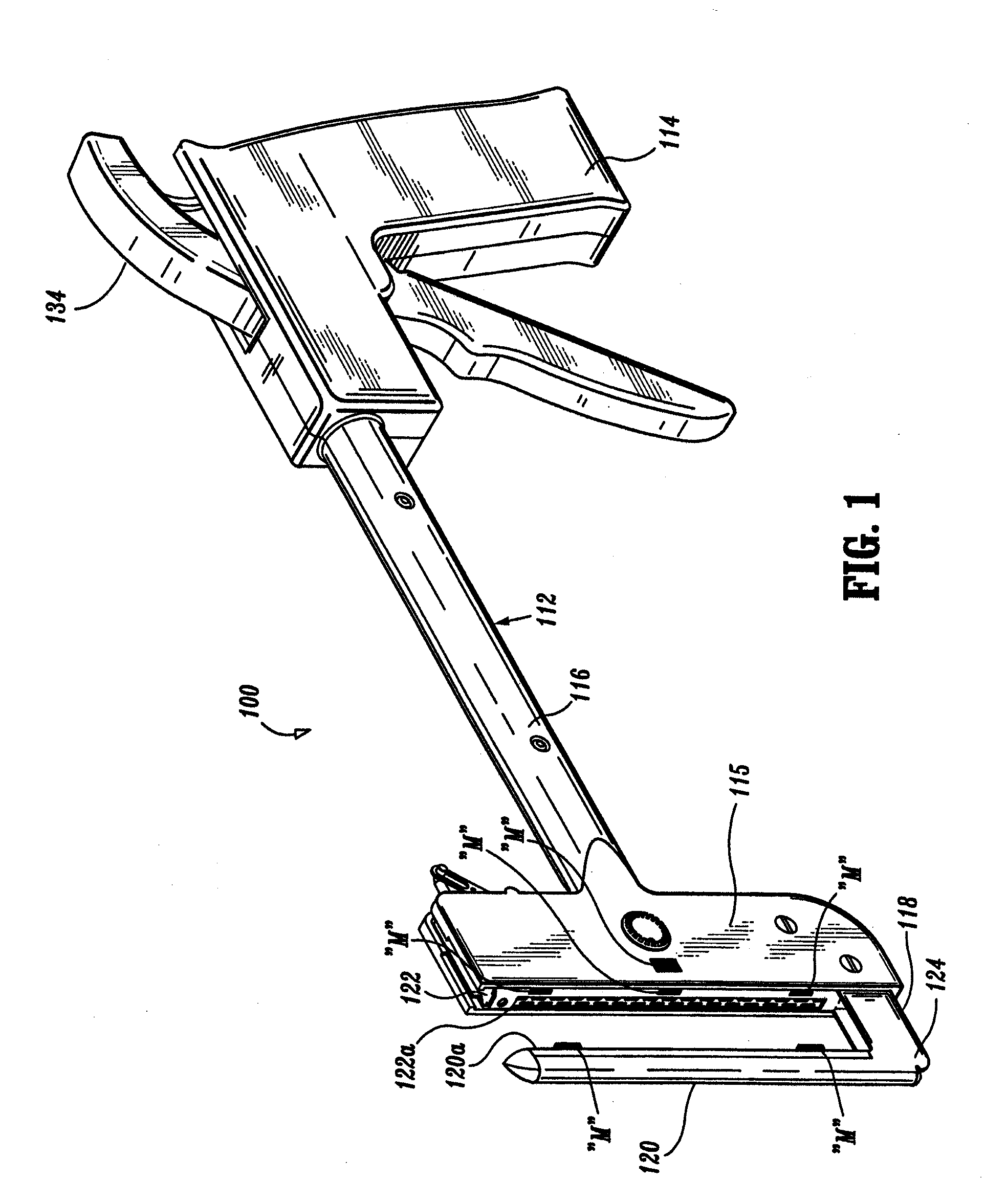

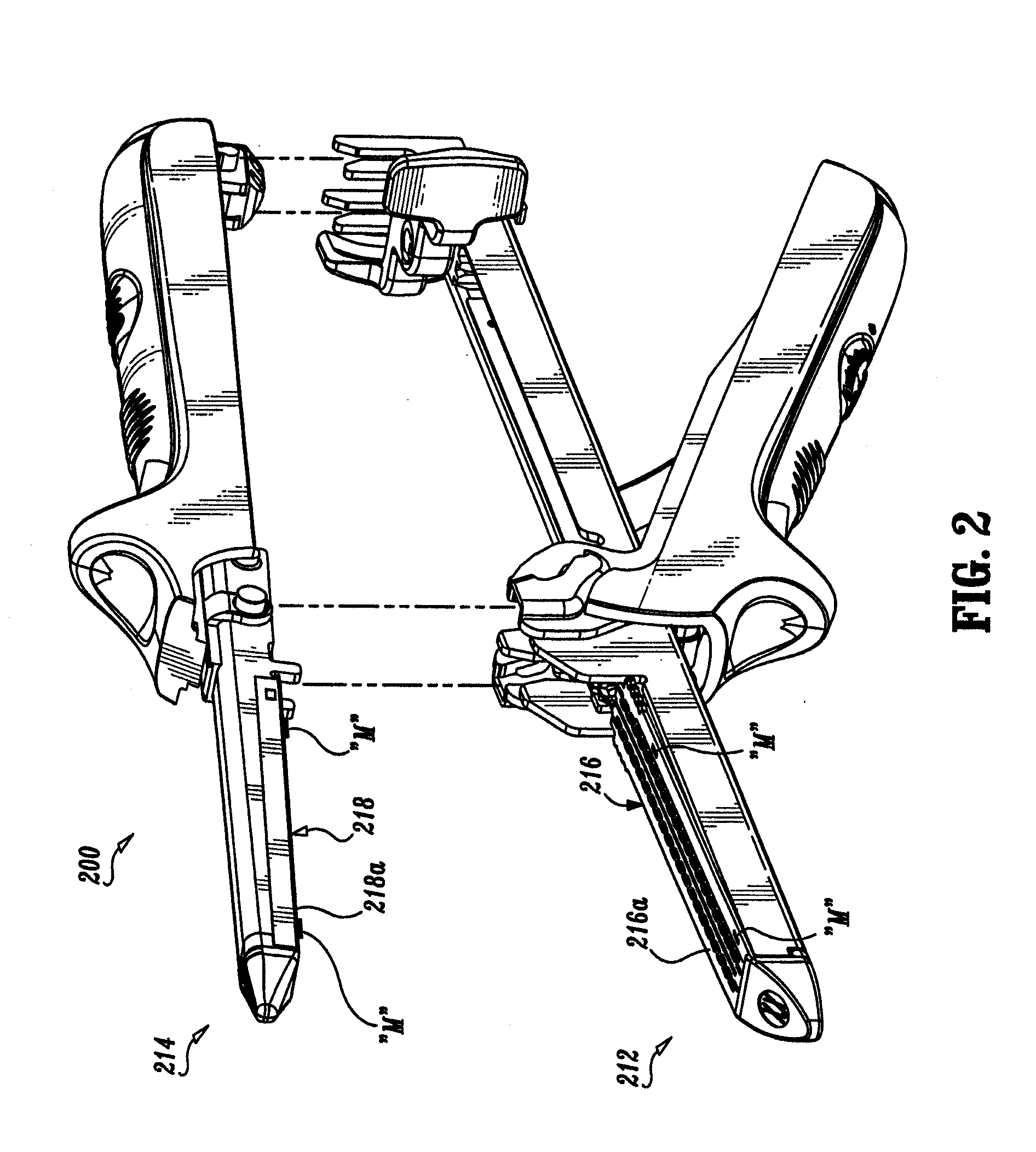

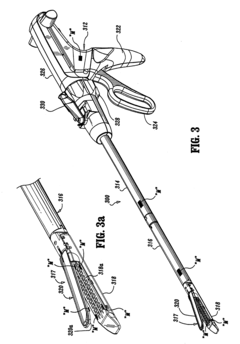

Surgical Instrument Including MEMS Devices

PatentInactiveUS20120016362A1

Innovation

- Integration of micro-electromechanical systems (MEMS) devices into surgical instruments, including pressure sensors, displacement sensors, and other types of sensors, to measure and control conditions such as tissue thickness and pressure, providing real-time feedback for precise operation.

Risk Management Approaches for Metal Mesh Implementation

Implementing metal mesh in medical devices requires comprehensive risk management strategies to ensure patient safety while maximizing technological benefits. A multi-layered approach begins with systematic risk identification through techniques such as Failure Mode and Effects Analysis (FMEA) and Hazard Analysis and Critical Control Points (HACCP), specifically adapted for metal mesh applications in medical contexts.

Risk categorization follows identification, classifying potential hazards based on severity, occurrence probability, and detectability. For metal mesh implementations, particular attention must be paid to biocompatibility risks, electrical conductivity concerns, and mechanical integrity issues that could compromise device functionality or patient safety.

Quantitative risk assessment methodologies provide objective evaluation frameworks, incorporating statistical models and historical performance data of metal mesh in similar applications. These assessments should consider both acute risks (immediate patient harm) and chronic risks (long-term exposure effects), with special consideration for patient populations with metal sensitivities or implanted electronic devices.

Mitigation strategies should be developed using the hierarchy of controls principle, prioritizing elimination of risks where possible, followed by engineering controls, administrative measures, and finally procedural safeguards. For metal mesh specifically, this might include specialized coating technologies to prevent corrosion, enhanced manufacturing protocols to ensure consistent mesh integrity, and comprehensive testing regimes under simulated biological conditions.

Continuous monitoring systems represent a critical component of ongoing risk management. These should include post-market surveillance protocols specifically designed to detect metal mesh-related adverse events, with established thresholds for triggering investigative actions. Real-time monitoring technologies, where applicable, can provide early warning of mesh degradation or unexpected interactions with biological systems.

Documentation frameworks must be established that capture the entire risk management lifecycle, from initial assessment through implementation of controls to ongoing monitoring results. These records serve both regulatory compliance purposes and provide valuable data for iterative improvement of metal mesh applications in future medical device generations.

Cross-functional collaboration between materials scientists, biomedical engineers, regulatory specialists, and clinical practitioners ensures comprehensive risk evaluation from multiple perspectives. This collaborative approach helps identify potential failure modes that might be overlooked within siloed expertise domains.

AI-powered predictive analytics are increasingly valuable for anticipating potential metal mesh failure scenarios before they manifest clinically, allowing for preemptive design modifications or enhanced monitoring protocols in high-risk applications.

Risk categorization follows identification, classifying potential hazards based on severity, occurrence probability, and detectability. For metal mesh implementations, particular attention must be paid to biocompatibility risks, electrical conductivity concerns, and mechanical integrity issues that could compromise device functionality or patient safety.

Quantitative risk assessment methodologies provide objective evaluation frameworks, incorporating statistical models and historical performance data of metal mesh in similar applications. These assessments should consider both acute risks (immediate patient harm) and chronic risks (long-term exposure effects), with special consideration for patient populations with metal sensitivities or implanted electronic devices.

Mitigation strategies should be developed using the hierarchy of controls principle, prioritizing elimination of risks where possible, followed by engineering controls, administrative measures, and finally procedural safeguards. For metal mesh specifically, this might include specialized coating technologies to prevent corrosion, enhanced manufacturing protocols to ensure consistent mesh integrity, and comprehensive testing regimes under simulated biological conditions.

Continuous monitoring systems represent a critical component of ongoing risk management. These should include post-market surveillance protocols specifically designed to detect metal mesh-related adverse events, with established thresholds for triggering investigative actions. Real-time monitoring technologies, where applicable, can provide early warning of mesh degradation or unexpected interactions with biological systems.

Documentation frameworks must be established that capture the entire risk management lifecycle, from initial assessment through implementation of controls to ongoing monitoring results. These records serve both regulatory compliance purposes and provide valuable data for iterative improvement of metal mesh applications in future medical device generations.

Cross-functional collaboration between materials scientists, biomedical engineers, regulatory specialists, and clinical practitioners ensures comprehensive risk evaluation from multiple perspectives. This collaborative approach helps identify potential failure modes that might be overlooked within siloed expertise domains.

AI-powered predictive analytics are increasingly valuable for anticipating potential metal mesh failure scenarios before they manifest clinically, allowing for preemptive design modifications or enhanced monitoring protocols in high-risk applications.

Biocompatibility and Safety Considerations

Biocompatibility assessment of metal mesh materials in medical devices requires rigorous evaluation according to ISO 10993 standards. These materials must undergo cytotoxicity, sensitization, and irritation testing to ensure they do not cause adverse cellular responses or allergic reactions when in contact with human tissues. For implantable devices containing metal mesh, additional genotoxicity, carcinogenicity, and systemic toxicity evaluations become mandatory to assess long-term safety profiles.

Metal ion leaching presents a significant safety concern, particularly with meshes containing nickel, chromium, or cobalt. Environmental factors such as pH variations, mechanical stress, and electrochemical interactions can accelerate corrosion processes, potentially leading to localized tissue reactions or systemic toxicity. Manufacturers must conduct comprehensive leachable and extractable studies under simulated physiological conditions to quantify potential ion release over the device's intended lifespan.

Surface modifications of metal meshes significantly impact biocompatibility outcomes. Techniques such as passivation, electropolishing, and application of biocompatible coatings can enhance safety profiles by creating stable oxide layers that minimize ion release. Plasma-treated surfaces and hydroxyapatite coatings have demonstrated improved tissue integration while maintaining mechanical integrity. These modifications must be validated through accelerated aging studies to ensure long-term stability.

Immunological responses to metal mesh implants vary considerably among patient populations. Metal hypersensitivity, particularly to nickel, affects approximately 10-15% of patients and can manifest as delayed-type hypersensitivity reactions. Pre-screening protocols for metal allergies are increasingly recommended for high-risk patients before implantation of metal mesh devices. Manufacturers must consider these immunological factors during material selection and device design phases.

Sterilization methods significantly impact the safety profile of metal mesh devices. Common techniques include ethylene oxide, gamma irradiation, and steam sterilization, each carrying specific implications for material integrity. Sterilization validation must demonstrate both efficacy against microbial contamination and preservation of material properties. Residual sterilization agents must be quantified to ensure levels remain below established safety thresholds.

Risk management frameworks for metal mesh devices should incorporate material-specific hazard identification, including potential degradation mechanisms, particulate generation, and galvanic corrosion when multiple metals are present. Benefit-risk assessments must consider the intended anatomical location, expected duration of contact, and patient population characteristics. Post-market surveillance strategies should specifically monitor for delayed hypersensitivity reactions and long-term material degradation effects.

Metal ion leaching presents a significant safety concern, particularly with meshes containing nickel, chromium, or cobalt. Environmental factors such as pH variations, mechanical stress, and electrochemical interactions can accelerate corrosion processes, potentially leading to localized tissue reactions or systemic toxicity. Manufacturers must conduct comprehensive leachable and extractable studies under simulated physiological conditions to quantify potential ion release over the device's intended lifespan.

Surface modifications of metal meshes significantly impact biocompatibility outcomes. Techniques such as passivation, electropolishing, and application of biocompatible coatings can enhance safety profiles by creating stable oxide layers that minimize ion release. Plasma-treated surfaces and hydroxyapatite coatings have demonstrated improved tissue integration while maintaining mechanical integrity. These modifications must be validated through accelerated aging studies to ensure long-term stability.

Immunological responses to metal mesh implants vary considerably among patient populations. Metal hypersensitivity, particularly to nickel, affects approximately 10-15% of patients and can manifest as delayed-type hypersensitivity reactions. Pre-screening protocols for metal allergies are increasingly recommended for high-risk patients before implantation of metal mesh devices. Manufacturers must consider these immunological factors during material selection and device design phases.

Sterilization methods significantly impact the safety profile of metal mesh devices. Common techniques include ethylene oxide, gamma irradiation, and steam sterilization, each carrying specific implications for material integrity. Sterilization validation must demonstrate both efficacy against microbial contamination and preservation of material properties. Residual sterilization agents must be quantified to ensure levels remain below established safety thresholds.

Risk management frameworks for metal mesh devices should incorporate material-specific hazard identification, including potential degradation mechanisms, particulate generation, and galvanic corrosion when multiple metals are present. Benefit-risk assessments must consider the intended anatomical location, expected duration of contact, and patient population characteristics. Post-market surveillance strategies should specifically monitor for delayed hypersensitivity reactions and long-term material degradation effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!