Metal Mesh Permeability in Oil and Gas Filtration Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Filtration Technology Background and Objectives

Metal mesh filtration technology has evolved significantly over the past several decades, transforming from simple mechanical screening devices to sophisticated filtration systems with precise control over permeability characteristics. The historical development of metal mesh technology can be traced back to the early 20th century, with substantial advancements occurring post-1950s when the oil and gas industry began expanding rapidly. The evolution has been characterized by continuous improvements in mesh design, material composition, and manufacturing techniques.

The fundamental principle behind metal mesh filtration involves the use of woven or perforated metal sheets with specific pore sizes to separate solid particles from fluids. In oil and gas applications, these systems are critical for removing contaminants that could damage downstream equipment or compromise product quality. The technology has progressed from basic wire mesh screens to complex multi-layer configurations with controlled permeability gradients.

Recent technological trends indicate a shift toward precision-engineered metal meshes with nanoscale features, enabling enhanced filtration efficiency while maintaining optimal flow rates. Advanced manufacturing methods, including laser perforation, electroforming, and additive manufacturing, have revolutionized the production capabilities, allowing for unprecedented control over mesh parameters such as pore size distribution, open area percentage, and three-dimensional structures.

The primary technical objectives in metal mesh permeability development focus on several key areas. First, achieving higher filtration efficiency while minimizing pressure drop across the filter medium remains a critical goal. Second, enhancing durability and resistance to harsh operating conditions, including high temperatures, pressures, and corrosive environments typical in oil and gas operations. Third, developing self-cleaning or low-maintenance mesh designs to reduce operational downtime and replacement costs.

Another significant objective is the optimization of mesh permeability characteristics for specific applications within the oil and gas value chain, from upstream drilling operations to downstream refining processes. Each application presents unique challenges regarding particle size distribution, flow rates, and chemical compatibility requirements.

The integration of smart technologies into metal mesh filtration systems represents an emerging trend, with objectives centered on real-time monitoring of filter performance, predictive maintenance capabilities, and automated backwashing or cleaning mechanisms. These innovations aim to transform traditional passive filtration elements into active components within increasingly digitalized oil and gas operations.

As environmental regulations become more stringent globally, an additional objective has emerged: developing metal mesh technologies that enable more efficient separation of oil-water emulsions and capture of increasingly smaller particulate matter, contributing to reduced environmental footprint of oil and gas operations.

The fundamental principle behind metal mesh filtration involves the use of woven or perforated metal sheets with specific pore sizes to separate solid particles from fluids. In oil and gas applications, these systems are critical for removing contaminants that could damage downstream equipment or compromise product quality. The technology has progressed from basic wire mesh screens to complex multi-layer configurations with controlled permeability gradients.

Recent technological trends indicate a shift toward precision-engineered metal meshes with nanoscale features, enabling enhanced filtration efficiency while maintaining optimal flow rates. Advanced manufacturing methods, including laser perforation, electroforming, and additive manufacturing, have revolutionized the production capabilities, allowing for unprecedented control over mesh parameters such as pore size distribution, open area percentage, and three-dimensional structures.

The primary technical objectives in metal mesh permeability development focus on several key areas. First, achieving higher filtration efficiency while minimizing pressure drop across the filter medium remains a critical goal. Second, enhancing durability and resistance to harsh operating conditions, including high temperatures, pressures, and corrosive environments typical in oil and gas operations. Third, developing self-cleaning or low-maintenance mesh designs to reduce operational downtime and replacement costs.

Another significant objective is the optimization of mesh permeability characteristics for specific applications within the oil and gas value chain, from upstream drilling operations to downstream refining processes. Each application presents unique challenges regarding particle size distribution, flow rates, and chemical compatibility requirements.

The integration of smart technologies into metal mesh filtration systems represents an emerging trend, with objectives centered on real-time monitoring of filter performance, predictive maintenance capabilities, and automated backwashing or cleaning mechanisms. These innovations aim to transform traditional passive filtration elements into active components within increasingly digitalized oil and gas operations.

As environmental regulations become more stringent globally, an additional objective has emerged: developing metal mesh technologies that enable more efficient separation of oil-water emulsions and capture of increasingly smaller particulate matter, contributing to reduced environmental footprint of oil and gas operations.

Oil and Gas Industry Filtration Market Analysis

The global oil and gas filtration market has been experiencing steady growth, driven by increasing exploration and production activities worldwide. As of 2023, the market size is valued at approximately 6.8 billion USD, with projections indicating a compound annual growth rate of 4.2% through 2030. This growth trajectory is primarily fueled by the rising demand for efficient separation technologies in upstream, midstream, and downstream operations.

Metal mesh filtration systems represent a significant segment within this market, accounting for roughly 18% of the total filtration solutions deployed in the industry. The demand for these systems is particularly strong in regions with intensive extraction activities, including North America, the Middle East, and parts of Asia Pacific, where challenging operating conditions necessitate robust filtration solutions.

The market landscape is characterized by a growing emphasis on operational efficiency and environmental compliance. End-users are increasingly prioritizing filtration systems that can effectively handle higher flow rates while maintaining separation efficiency, especially in offshore operations where space constraints are a critical consideration. Metal mesh filters, with their customizable permeability characteristics, are well-positioned to address these requirements.

Recent market trends indicate a shift toward integrated filtration solutions that combine multiple separation technologies to achieve optimal performance across varying operating conditions. This has led to the development of hybrid systems incorporating metal mesh elements alongside other filtration media, creating new market opportunities for specialized providers.

The aftermarket segment for replacement filters and maintenance services represents a substantial revenue stream, estimated at 2.1 billion USD annually. This segment is expected to grow at a faster rate than new installations, reflecting the aging infrastructure in established oil and gas fields and the industry's focus on extending equipment lifespan through proper maintenance.

Regulatory factors are significantly influencing market dynamics, with increasingly stringent environmental regulations regarding produced water treatment and discharge standards driving demand for high-efficiency filtration systems. This regulatory pressure is particularly evident in North America and Europe, where compliance requirements are most advanced.

Market penetration of advanced metal mesh filtration technologies varies considerably by region, with adoption rates highest in regions with mature oil and gas industries and sophisticated supply chains. Emerging markets, while showing strong growth potential, face challenges related to technology access and cost considerations that impact adoption rates.

Metal mesh filtration systems represent a significant segment within this market, accounting for roughly 18% of the total filtration solutions deployed in the industry. The demand for these systems is particularly strong in regions with intensive extraction activities, including North America, the Middle East, and parts of Asia Pacific, where challenging operating conditions necessitate robust filtration solutions.

The market landscape is characterized by a growing emphasis on operational efficiency and environmental compliance. End-users are increasingly prioritizing filtration systems that can effectively handle higher flow rates while maintaining separation efficiency, especially in offshore operations where space constraints are a critical consideration. Metal mesh filters, with their customizable permeability characteristics, are well-positioned to address these requirements.

Recent market trends indicate a shift toward integrated filtration solutions that combine multiple separation technologies to achieve optimal performance across varying operating conditions. This has led to the development of hybrid systems incorporating metal mesh elements alongside other filtration media, creating new market opportunities for specialized providers.

The aftermarket segment for replacement filters and maintenance services represents a substantial revenue stream, estimated at 2.1 billion USD annually. This segment is expected to grow at a faster rate than new installations, reflecting the aging infrastructure in established oil and gas fields and the industry's focus on extending equipment lifespan through proper maintenance.

Regulatory factors are significantly influencing market dynamics, with increasingly stringent environmental regulations regarding produced water treatment and discharge standards driving demand for high-efficiency filtration systems. This regulatory pressure is particularly evident in North America and Europe, where compliance requirements are most advanced.

Market penetration of advanced metal mesh filtration technologies varies considerably by region, with adoption rates highest in regions with mature oil and gas industries and sophisticated supply chains. Emerging markets, while showing strong growth potential, face challenges related to technology access and cost considerations that impact adoption rates.

Current Challenges in Metal Mesh Permeability

Metal mesh filtration systems in oil and gas applications face significant permeability challenges that impact operational efficiency and filtration effectiveness. The primary issue stems from the inherent trade-off between filtration precision and flow rate. As mesh aperture sizes decrease to capture smaller particulates, the corresponding reduction in permeability creates higher pressure differentials across the filter, increasing energy requirements and reducing throughput capacity.

Fouling represents another critical challenge, particularly in high-solids environments typical of many extraction operations. Particulate matter, asphaltenes, paraffins, and biological materials progressively accumulate on mesh surfaces, creating a phenomenon known as "filter cake" that exponentially decreases permeability over time. This necessitates frequent maintenance interventions, resulting in costly operational downtime.

Material limitations further complicate permeability management. While finer mesh constructions theoretically improve filtration precision, manufacturing constraints often create inconsistent aperture sizes and distribution patterns. These irregularities lead to unpredictable flow characteristics and "channeling" where fluid preferentially flows through paths of least resistance, compromising overall filtration efficiency.

Environmental factors introduce additional complexity to permeability management. Temperature fluctuations cause thermal expansion and contraction of metal mesh components, altering aperture dimensions during operation. Similarly, pressure variations can deform mesh structures, particularly in deep-well applications where differential pressures exceed design parameters, resulting in permanent permeability changes.

Chemical compatibility issues present ongoing challenges as well. Exposure to hydrogen sulfide, carbon dioxide, and various corrosive compounds in production fluids accelerates mesh degradation through mechanisms like stress corrosion cracking and pitting. These degradation patterns create unpredictable permeability changes and potential failure points that compromise system integrity.

Measurement and monitoring limitations further complicate permeability management. Current technologies struggle to provide real-time permeability data during operation, forcing operators to rely on indirect indicators like pressure differentials. This reactive approach often results in suboptimal maintenance scheduling and premature system failures.

The industry also faces standardization challenges, with inconsistent testing methodologies and performance metrics making direct comparisons between different mesh technologies difficult. This fragmentation impedes the development of universal design principles that could otherwise accelerate innovation in permeability optimization across the sector.

Fouling represents another critical challenge, particularly in high-solids environments typical of many extraction operations. Particulate matter, asphaltenes, paraffins, and biological materials progressively accumulate on mesh surfaces, creating a phenomenon known as "filter cake" that exponentially decreases permeability over time. This necessitates frequent maintenance interventions, resulting in costly operational downtime.

Material limitations further complicate permeability management. While finer mesh constructions theoretically improve filtration precision, manufacturing constraints often create inconsistent aperture sizes and distribution patterns. These irregularities lead to unpredictable flow characteristics and "channeling" where fluid preferentially flows through paths of least resistance, compromising overall filtration efficiency.

Environmental factors introduce additional complexity to permeability management. Temperature fluctuations cause thermal expansion and contraction of metal mesh components, altering aperture dimensions during operation. Similarly, pressure variations can deform mesh structures, particularly in deep-well applications where differential pressures exceed design parameters, resulting in permanent permeability changes.

Chemical compatibility issues present ongoing challenges as well. Exposure to hydrogen sulfide, carbon dioxide, and various corrosive compounds in production fluids accelerates mesh degradation through mechanisms like stress corrosion cracking and pitting. These degradation patterns create unpredictable permeability changes and potential failure points that compromise system integrity.

Measurement and monitoring limitations further complicate permeability management. Current technologies struggle to provide real-time permeability data during operation, forcing operators to rely on indirect indicators like pressure differentials. This reactive approach often results in suboptimal maintenance scheduling and premature system failures.

The industry also faces standardization challenges, with inconsistent testing methodologies and performance metrics making direct comparisons between different mesh technologies difficult. This fragmentation impedes the development of universal design principles that could otherwise accelerate innovation in permeability optimization across the sector.

Current Metal Mesh Permeability Solutions

01 Metal mesh design factors affecting permeability

The permeability of metal meshes is influenced by various design factors including mesh size, wire diameter, weave pattern, and material selection. By optimizing these parameters, manufacturers can achieve specific permeability characteristics for different applications. The mesh opening size and percentage of open area directly impact flow rates and filtration efficiency, while the wire diameter affects structural integrity and resistance to flow.- Metal mesh design factors affecting permeability: The permeability of metal meshes is influenced by various design factors including mesh size, wire diameter, weave pattern, and open area percentage. By adjusting these parameters, manufacturers can create meshes with specific permeability characteristics suitable for different applications. The relationship between these design factors and permeability follows established fluid dynamics principles, where smaller mesh openings and thicker wires reduce permeability while larger openings and thinner wires increase it.

- Testing and measurement methods for metal mesh permeability: Various methods and apparatus are used to test and measure the permeability of metal meshes. These include standardized testing procedures that measure flow rates through mesh samples under controlled conditions, pressure differential measurements across the mesh, and specialized equipment designed to quantify permeability characteristics. Advanced imaging techniques may also be employed to analyze mesh structures and predict permeability based on geometric properties. These measurements are crucial for quality control and ensuring that metal meshes meet specific application requirements.

- Applications of metal mesh permeability in filtration and separation: Metal meshes with controlled permeability are widely used in filtration and separation processes across various industries. The specific permeability characteristics allow for selective passage of fluids while trapping particles of certain sizes. Applications include industrial filtration systems, water treatment facilities, food processing equipment, and chemical processing. The durability of metal meshes makes them suitable for harsh environments where polymer-based filters might fail. The permeability can be tailored to achieve specific separation efficiency and flow rate requirements.

- Metal mesh permeability in electromagnetic applications: Metal meshes with specific permeability characteristics are used in electromagnetic applications such as EMI/RFI shielding, antennas, and signal filtering. The mesh structure allows for controlled passage of electromagnetic waves while providing electrical conductivity. The permeability to electromagnetic radiation depends on the mesh opening size relative to the wavelength of the radiation. These meshes can be designed to block certain frequencies while allowing others to pass through, making them valuable in electronic devices, communication equipment, and scientific instruments.

- Advanced manufacturing techniques for controlling metal mesh permeability: Innovative manufacturing techniques have been developed to precisely control the permeability of metal meshes. These include advanced weaving methods, micro-perforation technologies, additive manufacturing, and precision etching processes. These techniques allow for the creation of metal meshes with complex patterns, graduated permeability, and specialized surface treatments that can enhance performance characteristics. Some methods enable the production of multi-layered mesh structures with different permeability zones to optimize flow dynamics for specific applications.

02 Electromagnetic shielding applications of metal mesh

Metal meshes are widely used for electromagnetic shielding while maintaining permeability to air, light, or other media. These meshes can block specific electromagnetic frequencies while allowing desired transmission of other elements. The balance between shielding effectiveness and permeability can be controlled through mesh density, material composition, and surface treatments. Applications include electronic devices, communication equipment, and sensitive instrumentation protection.Expand Specific Solutions03 Testing and measurement methods for metal mesh permeability

Various testing methodologies have been developed to accurately measure and characterize metal mesh permeability. These include standardized flow tests, pressure differential measurements, and advanced imaging techniques to analyze pore structure. Testing procedures may involve fluid dynamics analysis, computational modeling, and empirical validation to ensure consistent performance across production batches. These methods help in quality control and performance verification for critical applications.Expand Specific Solutions04 Surface treatments and coatings to modify mesh permeability

Surface treatments and specialized coatings can be applied to metal meshes to modify their permeability characteristics. These treatments may include hydrophobic or hydrophilic coatings, anti-fouling layers, or catalytic materials that enhance specific functions while maintaining desired flow properties. Such modifications can extend the functional lifespan of meshes by preventing clogging, reducing corrosion, or enhancing selectivity for particular substances.Expand Specific Solutions05 Advanced manufacturing techniques for precision metal meshes

Innovative manufacturing techniques enable the production of metal meshes with precisely controlled permeability characteristics. These include advanced weaving methods, micro-perforation technologies, additive manufacturing, and precision etching processes. Such techniques allow for the creation of complex mesh geometries with gradient permeability, customized flow patterns, or integrated functional elements that were previously impossible to achieve with conventional manufacturing methods.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The metal mesh permeability market in oil and gas filtration systems is currently in a growth phase, with increasing demand driven by stringent filtration requirements in upstream and downstream operations. The market is characterized by a mix of established industrial players and specialized filtration companies. Leading competitors include Halliburton Energy Services focusing on oilfield applications, HYDAC Filtertechnik and MANN+HUMMEL providing advanced filtration technologies, and 3M Innovative Properties contributing material science expertise. The technology is reaching maturity in conventional applications but continues to evolve for high-pressure, high-temperature environments. Innovation centers on improving permeability-to-strength ratios, with research institutions like MIT and Harbin Institute of Technology collaborating with industry to develop next-generation mesh materials with enhanced corrosion resistance and fouling prevention capabilities.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered advanced metal mesh filtration technology for oil and gas applications through their Micro-Porous Metal Mesh (MPMM) system. This technology utilizes precision-engineered metal mesh with controlled pore sizes ranging from sub-micron to 100 microns, created through proprietary sintering and diffusion bonding processes. The mesh structure incorporates multiple layers with graduated pore sizes to maximize dirt-holding capacity while maintaining flow efficiency. 3M's metal mesh filters feature unique three-dimensional geometries that increase surface area by up to 300% compared to conventional flat mesh designs, significantly extending service life in challenging oil and gas environments. Their systems employ specialized nickel-chromium and stainless steel alloys with enhanced resistance to hydrogen sulfide, carbon dioxide, and chloride corrosion. Additionally, 3M has developed hydrophobic and oleophobic surface treatments for their metal mesh that reduce fouling and improve separation efficiency of oil-water emulsions, a critical factor in production fluid filtration.

Strengths: Exceptional filtration precision with consistent pore size distribution and high particle capture efficiency (>99.9% for specified particle sizes). Advanced surface treatments provide superior resistance to fouling and emulsion separation capabilities. Weaknesses: Premium pricing compared to conventional filtration solutions. Limited flexibility for retrofitting into existing systems due to specialized design requirements.

HYDAC Filtertechnik GmbH

Technical Solution: HYDAC has developed sophisticated metal mesh filtration solutions specifically engineered for the oil and gas sector's demanding requirements. Their MetalMesh™ technology employs multi-layered sintered metal mesh constructions with precisely calibrated pore sizes ranging from 1-150 microns. The company utilizes a proprietary weaving and sintering process that creates a three-dimensional pore structure optimized for both particle retention and flow characteristics. HYDAC's metal mesh filters incorporate differential pressure-resistant designs capable of withstanding pressure spikes up to 420 bar without deformation or performance degradation. Their technology features specialized pleating geometries that increase effective filtration area by up to 250% compared to standard cylindrical designs, significantly extending service intervals in high-contamination environments. HYDAC has also pioneered hybrid metal mesh systems that combine stainless steel mesh with advanced polymer supports to reduce weight while maintaining structural integrity. For offshore applications, their SuperMesh series incorporates specialized copper-nickel alloys with enhanced resistance to seawater corrosion and biofouling.

Strengths: Exceptional mechanical stability under high differential pressures and flow rate variations. Superior backwashing capabilities that restore nearly 100% of original permeability, extending operational life significantly. Weaknesses: Higher initial investment compared to conventional filter media. Requires specialized handling during installation and maintenance to prevent damage to the precision mesh structure.

Key Patents and Technical Innovations in Filtration Media

Aerosol filter

PatentWO1998017372A1

Innovation

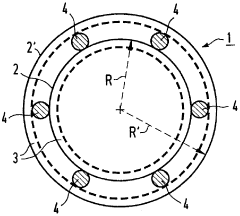

- The use of a metal mesh as filter surfaces, which has lower micro-roughness and reduced adherence for oils and aerosols, allowing for easy cleaning and regeneration by blowing back, and a multi-layered structure with defined pore sizes to enhance separation efficiency.

Filter material, in particular for hydraulic filters

PatentInactiveEP2945723A1

Innovation

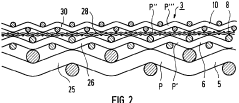

- A filter material design featuring warp and weft threads arranged to form channel guides within the filter layer, allowing undisturbed flow without the need for large mesh widths, maintaining mechanical strength while optimizing flow conditions through specific thread orientations and configurations.

Environmental Impact and Sustainability Considerations

The environmental impact of metal mesh filtration systems in oil and gas operations extends beyond their primary function of separating contaminants. These systems significantly reduce the discharge of harmful particulates and hydrocarbons into surrounding ecosystems, protecting water bodies, soil quality, and local biodiversity. When properly designed with optimal permeability characteristics, metal mesh filters can minimize the environmental footprint of extraction and processing activities.

Sustainability considerations for metal mesh filtration technology have become increasingly important as regulatory frameworks evolve globally. The durability of metal mesh materials contributes to extended operational lifespans, reducing the frequency of replacement and associated waste generation. Advanced alloys and surface treatments have further enhanced corrosion resistance, enabling these filtration systems to maintain performance integrity in harsh operating conditions while minimizing maintenance-related environmental disruptions.

Energy efficiency represents another critical environmental dimension of metal mesh permeability design. Optimized mesh configurations that balance filtration effectiveness with minimal pressure drop can substantially reduce pumping energy requirements. This energy conservation translates directly to lower greenhouse gas emissions across the operational lifecycle of filtration systems, aligning with industry decarbonization initiatives and climate commitments.

The recyclability of metal mesh components offers significant end-of-life sustainability advantages compared to alternative filtration media. High-grade stainless steel and specialized alloys retain considerable value in recycling streams, creating closed-loop material pathways that reduce primary resource extraction demands. This circular economy approach is increasingly factored into lifecycle assessments of filtration technologies within environmental management systems.

Water conservation benefits emerge as another environmental advantage of advanced metal mesh filtration. By enabling more efficient separation processes, these systems can facilitate increased water recycling within operations, reducing freshwater withdrawal requirements in water-stressed regions. This aspect has particular relevance in unconventional oil and gas operations where water management presents significant environmental challenges.

Emerging research focuses on integrating biofouling-resistant properties into metal mesh designs, potentially eliminating the need for environmentally problematic chemical treatments. Surface modifications that incorporate antimicrobial properties or self-cleaning mechanisms represent promising developments that could further enhance the environmental profile of these filtration systems while maintaining optimal permeability characteristics throughout their operational lifespan.

Sustainability considerations for metal mesh filtration technology have become increasingly important as regulatory frameworks evolve globally. The durability of metal mesh materials contributes to extended operational lifespans, reducing the frequency of replacement and associated waste generation. Advanced alloys and surface treatments have further enhanced corrosion resistance, enabling these filtration systems to maintain performance integrity in harsh operating conditions while minimizing maintenance-related environmental disruptions.

Energy efficiency represents another critical environmental dimension of metal mesh permeability design. Optimized mesh configurations that balance filtration effectiveness with minimal pressure drop can substantially reduce pumping energy requirements. This energy conservation translates directly to lower greenhouse gas emissions across the operational lifecycle of filtration systems, aligning with industry decarbonization initiatives and climate commitments.

The recyclability of metal mesh components offers significant end-of-life sustainability advantages compared to alternative filtration media. High-grade stainless steel and specialized alloys retain considerable value in recycling streams, creating closed-loop material pathways that reduce primary resource extraction demands. This circular economy approach is increasingly factored into lifecycle assessments of filtration technologies within environmental management systems.

Water conservation benefits emerge as another environmental advantage of advanced metal mesh filtration. By enabling more efficient separation processes, these systems can facilitate increased water recycling within operations, reducing freshwater withdrawal requirements in water-stressed regions. This aspect has particular relevance in unconventional oil and gas operations where water management presents significant environmental challenges.

Emerging research focuses on integrating biofouling-resistant properties into metal mesh designs, potentially eliminating the need for environmentally problematic chemical treatments. Surface modifications that incorporate antimicrobial properties or self-cleaning mechanisms represent promising developments that could further enhance the environmental profile of these filtration systems while maintaining optimal permeability characteristics throughout their operational lifespan.

Regulatory Standards for Oil and Gas Filtration Systems

Regulatory standards for oil and gas filtration systems have evolved significantly over the past decades, reflecting growing concerns about environmental protection, operational safety, and resource conservation. The American Petroleum Institute (API) has established comprehensive guidelines specifically addressing metal mesh permeability requirements in filtration applications, with standards such as API 13C for drilling fluid screening and API 4F for filtration equipment design.

The International Organization for Standardization (ISO) provides complementary global standards, including ISO 16889 for multi-pass testing of hydraulic filters and ISO 4406 for fluid cleanliness codes. These standards establish precise methodologies for measuring and reporting metal mesh permeability characteristics in filtration contexts, ensuring consistent performance evaluation across the industry.

Environmental regulations have become increasingly stringent, with the U.S. Environmental Protection Agency (EPA) implementing the National Pollutant Discharge Elimination System (NPDES) that directly impacts filtration requirements for produced water and drilling waste. These regulations specify minimum filtration efficiencies and maximum allowable discharge concentrations, driving innovations in metal mesh design to achieve higher permeability while maintaining filtration integrity.

Regional variations in regulatory frameworks present significant challenges for equipment manufacturers and operators. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose additional requirements on materials used in filtration systems, including metal mesh components, particularly regarding potential leaching of heavy metals or other contaminants during operation.

Offshore operations face particularly rigorous standards under frameworks like OSPAR (Oslo-Paris Convention) for the North-East Atlantic and MARPOL (International Convention for the Prevention of Pollution from Ships) globally. These regulations mandate specific filtration performance levels for discharged water, necessitating precise control of metal mesh permeability characteristics to achieve compliance.

Industry self-regulation through organizations like the International Association of Drilling Contractors (IADC) has also established best practices for filtration system design and maintenance. These guidelines often exceed minimum regulatory requirements, addressing practical operational concerns related to metal mesh performance in challenging environments.

Emerging regulations increasingly focus on lifecycle assessment of filtration equipment, including considerations for recyclability and disposal of spent metal mesh components. This trend is driving research into more durable mesh designs with consistent permeability characteristics throughout their operational lifespan, reducing waste generation and environmental impact while maintaining filtration efficiency.

The International Organization for Standardization (ISO) provides complementary global standards, including ISO 16889 for multi-pass testing of hydraulic filters and ISO 4406 for fluid cleanliness codes. These standards establish precise methodologies for measuring and reporting metal mesh permeability characteristics in filtration contexts, ensuring consistent performance evaluation across the industry.

Environmental regulations have become increasingly stringent, with the U.S. Environmental Protection Agency (EPA) implementing the National Pollutant Discharge Elimination System (NPDES) that directly impacts filtration requirements for produced water and drilling waste. These regulations specify minimum filtration efficiencies and maximum allowable discharge concentrations, driving innovations in metal mesh design to achieve higher permeability while maintaining filtration integrity.

Regional variations in regulatory frameworks present significant challenges for equipment manufacturers and operators. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose additional requirements on materials used in filtration systems, including metal mesh components, particularly regarding potential leaching of heavy metals or other contaminants during operation.

Offshore operations face particularly rigorous standards under frameworks like OSPAR (Oslo-Paris Convention) for the North-East Atlantic and MARPOL (International Convention for the Prevention of Pollution from Ships) globally. These regulations mandate specific filtration performance levels for discharged water, necessitating precise control of metal mesh permeability characteristics to achieve compliance.

Industry self-regulation through organizations like the International Association of Drilling Contractors (IADC) has also established best practices for filtration system design and maintenance. These guidelines often exceed minimum regulatory requirements, addressing practical operational concerns related to metal mesh performance in challenging environments.

Emerging regulations increasingly focus on lifecycle assessment of filtration equipment, including considerations for recyclability and disposal of spent metal mesh components. This trend is driving research into more durable mesh designs with consistent permeability characteristics throughout their operational lifespan, reducing waste generation and environmental impact while maintaining filtration efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!