Performance Standards for Metal Mesh in Aerospace Engineering

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Metal Mesh Technology Background and Objectives

Metal mesh technology has evolved significantly over the past decades, becoming a critical component in aerospace engineering applications. Initially developed for basic filtration and electromagnetic shielding purposes in the 1950s, metal mesh materials have undergone substantial refinement to meet the increasingly demanding requirements of modern aerospace systems. The evolution has been driven by advancements in metallurgy, manufacturing processes, and the growing complexity of aerospace applications requiring materials with exceptional performance characteristics.

The aerospace industry demands metal mesh solutions that can withstand extreme conditions including high temperatures, pressure differentials, vibration, and exposure to corrosive substances while maintaining structural integrity. Historical developments show a progression from simple woven wire structures to sophisticated engineered mesh systems with precisely controlled aperture sizes, wire diameters, and material compositions tailored for specific aerospace applications.

Current technological trends in metal mesh development focus on weight reduction without compromising strength, enhanced durability in extreme environments, and multi-functional capabilities. These trends align with the broader aerospace industry's push toward more fuel-efficient, environmentally sustainable, and cost-effective aircraft and spacecraft designs. The integration of nanotechnology and advanced composite materials with traditional metal mesh structures represents a significant frontier in this field.

The primary objective of establishing comprehensive performance standards for metal mesh in aerospace engineering is to ensure consistent quality, reliability, and safety across all applications. These standards must address mechanical properties (tensile strength, fatigue resistance), thermal characteristics, electromagnetic performance, and long-term durability under various operational conditions. Additionally, they should provide clear testing methodologies and acceptance criteria that can be universally applied throughout the industry.

Another critical goal is to harmonize international standards to facilitate global supply chain integration and certification processes. This standardization would streamline procurement, reduce development cycles, and potentially lower costs while maintaining the highest safety levels required in aerospace applications. The standards must also be forward-looking, accommodating emerging technologies and novel applications of metal mesh in next-generation aerospace systems.

Furthermore, these standards aim to establish a framework for continuous improvement in metal mesh technology, encouraging innovation while ensuring that new developments meet or exceed baseline performance requirements. This balance between standardization and innovation is essential for the continued advancement of aerospace capabilities and the long-term sustainability of the industry.

The aerospace industry demands metal mesh solutions that can withstand extreme conditions including high temperatures, pressure differentials, vibration, and exposure to corrosive substances while maintaining structural integrity. Historical developments show a progression from simple woven wire structures to sophisticated engineered mesh systems with precisely controlled aperture sizes, wire diameters, and material compositions tailored for specific aerospace applications.

Current technological trends in metal mesh development focus on weight reduction without compromising strength, enhanced durability in extreme environments, and multi-functional capabilities. These trends align with the broader aerospace industry's push toward more fuel-efficient, environmentally sustainable, and cost-effective aircraft and spacecraft designs. The integration of nanotechnology and advanced composite materials with traditional metal mesh structures represents a significant frontier in this field.

The primary objective of establishing comprehensive performance standards for metal mesh in aerospace engineering is to ensure consistent quality, reliability, and safety across all applications. These standards must address mechanical properties (tensile strength, fatigue resistance), thermal characteristics, electromagnetic performance, and long-term durability under various operational conditions. Additionally, they should provide clear testing methodologies and acceptance criteria that can be universally applied throughout the industry.

Another critical goal is to harmonize international standards to facilitate global supply chain integration and certification processes. This standardization would streamline procurement, reduce development cycles, and potentially lower costs while maintaining the highest safety levels required in aerospace applications. The standards must also be forward-looking, accommodating emerging technologies and novel applications of metal mesh in next-generation aerospace systems.

Furthermore, these standards aim to establish a framework for continuous improvement in metal mesh technology, encouraging innovation while ensuring that new developments meet or exceed baseline performance requirements. This balance between standardization and innovation is essential for the continued advancement of aerospace capabilities and the long-term sustainability of the industry.

Market Demand Analysis for Advanced Aerospace Materials

The aerospace materials market is experiencing robust growth driven by increasing aircraft production and the demand for lightweight, high-performance components. Current market valuations place the global aerospace materials sector at approximately $25.8 billion, with projections indicating growth to reach $42.4 billion by 2028, representing a compound annual growth rate of 6.5%. Metal mesh materials specifically constitute a significant segment within this market due to their versatility in applications ranging from electromagnetic interference (EMI) shielding to structural reinforcement.

The demand for advanced metal mesh in aerospace engineering is primarily fueled by the industry's push toward fuel efficiency and reduced emissions. Aircraft manufacturers are under increasing pressure to meet stringent environmental regulations while maintaining or improving performance metrics. Metal mesh materials, particularly those incorporating advanced alloys like titanium-aluminum composites and nickel-based superalloys, offer an optimal balance of weight reduction and structural integrity that directly addresses these requirements.

Regional analysis reveals that North America currently dominates the aerospace metal mesh market with approximately 38% market share, followed by Europe at 29% and Asia-Pacific at 24%. The Asia-Pacific region, however, is demonstrating the fastest growth rate at 8.2% annually, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Application-specific demand shows that structural components represent the largest segment (42%) of metal mesh utilization in aerospace, followed by EMI shielding (27%), thermal management systems (18%), and other specialized applications (13%). The commercial aircraft sector accounts for 65% of total consumption, with military applications comprising 25% and space systems the remaining 10%.

Industry surveys indicate that aerospace engineers and procurement specialists prioritize five key performance attributes when selecting metal mesh materials: strength-to-weight ratio, corrosion resistance, temperature tolerance, fatigue resistance, and manufacturing consistency. The demand for materials meeting increasingly stringent performance standards in these areas has created premium market segments with growth rates exceeding the industry average by 2-3 percentage points.

Emerging trends in the market include growing interest in multi-functional metal mesh materials that simultaneously address multiple engineering challenges, such as meshes that provide both structural support and thermal management. Additionally, there is increasing demand for customized mesh specifications tailored to specific aircraft components, driving innovation in manufacturing processes and material science.

The demand for advanced metal mesh in aerospace engineering is primarily fueled by the industry's push toward fuel efficiency and reduced emissions. Aircraft manufacturers are under increasing pressure to meet stringent environmental regulations while maintaining or improving performance metrics. Metal mesh materials, particularly those incorporating advanced alloys like titanium-aluminum composites and nickel-based superalloys, offer an optimal balance of weight reduction and structural integrity that directly addresses these requirements.

Regional analysis reveals that North America currently dominates the aerospace metal mesh market with approximately 38% market share, followed by Europe at 29% and Asia-Pacific at 24%. The Asia-Pacific region, however, is demonstrating the fastest growth rate at 8.2% annually, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Application-specific demand shows that structural components represent the largest segment (42%) of metal mesh utilization in aerospace, followed by EMI shielding (27%), thermal management systems (18%), and other specialized applications (13%). The commercial aircraft sector accounts for 65% of total consumption, with military applications comprising 25% and space systems the remaining 10%.

Industry surveys indicate that aerospace engineers and procurement specialists prioritize five key performance attributes when selecting metal mesh materials: strength-to-weight ratio, corrosion resistance, temperature tolerance, fatigue resistance, and manufacturing consistency. The demand for materials meeting increasingly stringent performance standards in these areas has created premium market segments with growth rates exceeding the industry average by 2-3 percentage points.

Emerging trends in the market include growing interest in multi-functional metal mesh materials that simultaneously address multiple engineering challenges, such as meshes that provide both structural support and thermal management. Additionally, there is increasing demand for customized mesh specifications tailored to specific aircraft components, driving innovation in manufacturing processes and material science.

Current State and Challenges in Metal Mesh Performance

Metal mesh technology in aerospace engineering has reached a significant level of maturity, with applications spanning electromagnetic shielding, lightning strike protection, and thermal management systems. Current performance standards vary considerably across different regions and aerospace manufacturers, creating challenges for global supply chains and certification processes. In the United States, SAE AMS specifications and MIL-STD standards predominate, while European manufacturers often follow ECSS (European Cooperation for Space Standardization) guidelines, resulting in fragmented requirements that complicate international collaboration.

The primary technical challenges facing metal mesh performance center around achieving optimal balance between competing properties. Weight reduction remains paramount in aerospace applications, yet must be balanced against mechanical strength, electrical conductivity, and thermal resistance requirements. Current-generation metal meshes struggle to maintain consistent performance across extreme temperature ranges experienced in aerospace environments (-65°C to +150°C), particularly at connection points where thermal expansion differences can create structural weaknesses.

Material degradation presents another significant challenge, with galvanic corrosion occurring at interfaces between dissimilar metals, especially in humid or salt-laden environments. This corrosion accelerates under the cyclic loading conditions typical in aerospace applications, compromising both structural integrity and electrical performance over time. Advanced coating technologies have partially addressed this issue but introduce additional weight and manufacturing complexity.

Manufacturing consistency represents a persistent obstacle, with variations in mesh aperture size, wire diameter, and junction quality significantly impacting performance. Current production methods struggle to maintain tolerances below ±5μm across large surface areas, resulting in localized performance variations that can compromise overall system reliability. Quality control methodologies remain largely manual and time-consuming, limiting production scalability.

Integration challenges persist when incorporating metal mesh into composite structures, which constitute an increasing percentage of modern aircraft components. Current bonding technologies often create weak interfaces between mesh and composite matrices, leading to delamination under mechanical or thermal stress. Additionally, the electrical continuity across these interfaces frequently degrades over time, compromising electromagnetic shielding effectiveness.

Emerging requirements for multifunctional performance further complicate standardization efforts. Modern aerospace applications increasingly demand metal meshes that simultaneously provide structural support, electromagnetic shielding, thermal management, and sensor integration capabilities. Current standards inadequately address these multifunctional requirements, focusing instead on single-property specifications that fail to capture system-level performance needs.

Regulatory harmonization remains elusive, with certification processes varying significantly between civil aviation authorities. This regulatory fragmentation increases compliance costs and extends development timelines for new metal mesh technologies, ultimately slowing innovation in this critical aerospace component.

The primary technical challenges facing metal mesh performance center around achieving optimal balance between competing properties. Weight reduction remains paramount in aerospace applications, yet must be balanced against mechanical strength, electrical conductivity, and thermal resistance requirements. Current-generation metal meshes struggle to maintain consistent performance across extreme temperature ranges experienced in aerospace environments (-65°C to +150°C), particularly at connection points where thermal expansion differences can create structural weaknesses.

Material degradation presents another significant challenge, with galvanic corrosion occurring at interfaces between dissimilar metals, especially in humid or salt-laden environments. This corrosion accelerates under the cyclic loading conditions typical in aerospace applications, compromising both structural integrity and electrical performance over time. Advanced coating technologies have partially addressed this issue but introduce additional weight and manufacturing complexity.

Manufacturing consistency represents a persistent obstacle, with variations in mesh aperture size, wire diameter, and junction quality significantly impacting performance. Current production methods struggle to maintain tolerances below ±5μm across large surface areas, resulting in localized performance variations that can compromise overall system reliability. Quality control methodologies remain largely manual and time-consuming, limiting production scalability.

Integration challenges persist when incorporating metal mesh into composite structures, which constitute an increasing percentage of modern aircraft components. Current bonding technologies often create weak interfaces between mesh and composite matrices, leading to delamination under mechanical or thermal stress. Additionally, the electrical continuity across these interfaces frequently degrades over time, compromising electromagnetic shielding effectiveness.

Emerging requirements for multifunctional performance further complicate standardization efforts. Modern aerospace applications increasingly demand metal meshes that simultaneously provide structural support, electromagnetic shielding, thermal management, and sensor integration capabilities. Current standards inadequately address these multifunctional requirements, focusing instead on single-property specifications that fail to capture system-level performance needs.

Regulatory harmonization remains elusive, with certification processes varying significantly between civil aviation authorities. This regulatory fragmentation increases compliance costs and extends development timelines for new metal mesh technologies, ultimately slowing innovation in this critical aerospace component.

Current Performance Testing Methodologies and Specifications

01 Electromagnetic shielding performance standards

Metal mesh structures are designed to meet specific electromagnetic shielding performance standards. These meshes are evaluated for their ability to block or attenuate electromagnetic interference across various frequency ranges. The performance metrics include shielding effectiveness, signal attenuation, and reflection loss. Testing procedures involve measuring the mesh's ability to prevent electromagnetic waves from passing through while maintaining structural integrity under different environmental conditions.- Electromagnetic shielding performance standards: Metal mesh structures are evaluated for their electromagnetic shielding effectiveness, which measures their ability to block or attenuate electromagnetic interference. These standards specify testing methodologies, frequency ranges, and minimum shielding effectiveness values that metal meshes must achieve for various applications including electronic devices, communication equipment, and sensitive instruments. The performance is typically measured in decibels (dB) across different frequency bands.

- Mechanical strength and durability standards: Standards for metal mesh mechanical properties include tensile strength, tear resistance, impact resistance, and fatigue performance. These standards ensure that metal meshes can withstand physical stresses during installation and use. Testing protocols measure the mesh's ability to maintain structural integrity under various environmental conditions and mechanical loads, with specific requirements varying by application from construction to filtration systems.

- Optical and transparency performance metrics: For applications requiring both conductivity and visibility, metal mesh standards address optical properties such as light transmission, haze, clarity, and color neutrality. These metrics are particularly important for touch screens, displays, and architectural glass applications. Testing methodologies measure the balance between electrical conductivity and optical transparency, with standards specifying minimum visible light transmission percentages while maintaining required conductivity levels.

- Electrical conductivity and resistance specifications: Metal mesh performance standards define acceptable ranges for electrical properties including sheet resistance, conductivity uniformity, and contact resistance. These specifications are critical for applications in electronics, sensors, and heating elements. Testing protocols measure resistance across the mesh surface and at connection points, with standards typically specifying maximum resistance values in ohms per square and minimum conductivity requirements for different applications.

- Environmental resistance and corrosion standards: Standards for metal mesh environmental performance address corrosion resistance, temperature stability, humidity tolerance, and chemical compatibility. These specifications ensure long-term functionality in challenging environments. Testing methodologies include salt spray tests, temperature cycling, and exposure to various chemicals, with standards defining minimum performance requirements for specific environmental conditions and service life expectations.

02 Mechanical and structural integrity standards

Metal mesh performance is evaluated based on mechanical properties such as tensile strength, flexibility, durability, and resistance to deformation. Standards specify requirements for mesh aperture size, wire diameter, weave pattern, and overall structural integrity. Testing protocols assess the mesh's ability to withstand physical stress, environmental exposure, and repeated use without compromising functionality. These standards ensure that metal meshes maintain their intended performance characteristics throughout their operational lifetime.Expand Specific Solutions03 Thermal and optical performance criteria

Metal mesh performance standards include specifications for thermal conductivity, heat resistance, and optical properties. These standards evaluate how effectively the mesh transfers or blocks heat while maintaining visibility requirements. Testing methods measure parameters such as light transmission, infrared reflection, and thermal stability under various temperature conditions. The standards ensure that metal meshes used in applications requiring specific thermal or optical characteristics meet the necessary performance requirements.Expand Specific Solutions04 Filtration and separation efficiency standards

Metal mesh performance is evaluated based on filtration efficiency, particle retention capability, and flow resistance. Standards specify testing methods to measure the mesh's ability to separate particles of different sizes while maintaining adequate flow rates. Performance criteria include pore size distribution, filtration efficiency at various particle sizes, pressure drop across the mesh, and clogging resistance. These standards ensure that metal meshes used in filtration applications meet specific separation requirements while maintaining operational efficiency.Expand Specific Solutions05 Quality control and manufacturing standards

Metal mesh performance standards include specifications for manufacturing consistency, quality control procedures, and defect tolerance. These standards define acceptable variations in mesh properties such as wire spacing, thickness uniformity, and surface finish. Testing protocols involve dimensional inspection, material composition analysis, and performance validation. The standards ensure that metal meshes are produced with consistent quality and meet the required specifications for their intended applications.Expand Specific Solutions

Key Industry Players in Aerospace Metal Mesh Development

The aerospace metal mesh performance standards market is currently in a growth phase, with increasing demand driven by advancements in lightweight materials for aircraft structures. The global market is estimated at approximately $2.5 billion, expanding at 6-8% annually as aerospace manufacturers seek materials with superior strength-to-weight ratios. Technologically, the field is moderately mature but rapidly evolving, with companies like QuesTek Innovations and Arconic Technologies leading materials innovation through computational design approaches. Research institutions including Beijing Institute of Aeronautical Materials and Harbin Institute of Technology are advancing fundamental research, while established manufacturers such as Kaiser Aluminum, ArcelorMittal, and Sumitomo Electric are optimizing production processes for aerospace-grade metal mesh that meets increasingly stringent performance requirements for thermal stability, fatigue resistance, and electromagnetic shielding.

QuesTek Innovations LLC

Technical Solution: QuesTek has revolutionized metal mesh technology for aerospace applications through their Integrated Computational Materials Engineering (ICME) approach. Their proprietary Ferrium® alloy-based metal meshes deliver exceptional strength-to-weight ratios while maintaining flexibility and formability required for complex aerospace geometries. QuesTek's metal mesh performance standards include fatigue resistance exceeding 10^7 cycles at high stress amplitudes and operating temperature ranges from -60°C to +450°C without significant property degradation. Their manufacturing process ensures consistent mesh aperture control within ±5μm tolerance, critical for applications requiring precise fluid or air filtration properties. QuesTek's aerospace metal meshes incorporate specialized surface treatments that enhance corrosion resistance in marine environments while maintaining electrical conductivity for EMI shielding and lightning strike protection applications.

Strengths: Computational materials design expertise, superior fatigue resistance, and excellent high/low temperature performance. Weaknesses: Limited production scale compared to larger manufacturers and higher initial costs due to specialized alloy compositions.

Beijing Institute of Aeronautical Materials

Technical Solution: Beijing Institute of Aeronautical Materials (BIAM) has pioneered advanced metal mesh technologies specifically for China's aerospace industry, developing high-performance nickel-chromium alloy meshes with exceptional heat resistance up to 1200°C. Their proprietary manufacturing process creates uniform mesh structures with controlled porosity (typically 40-60%) that maintain structural integrity under extreme thermal cycling conditions. BIAM's metal mesh standards include specialized surface treatments that enhance oxidation resistance while maintaining electromagnetic shielding effectiveness of >80dB across 1-18GHz frequency range. Their research has established performance benchmarks for metal mesh in hypersonic applications, where materials must withstand both extreme temperatures and aerodynamic loads while maintaining dimensional stability within 0.5% tolerance.

Strengths: Exceptional high-temperature performance, advanced manufacturing capabilities for specialized aerospace applications, and comprehensive testing facilities. Weaknesses: Limited international availability and higher costs compared to conventional materials.

Critical Patents and Research in Metal Mesh Engineering

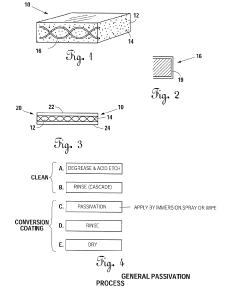

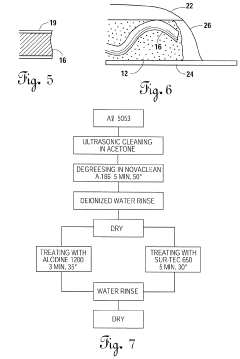

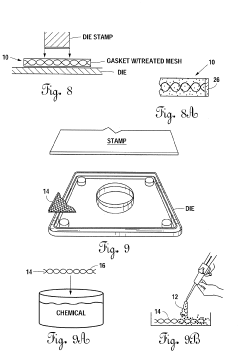

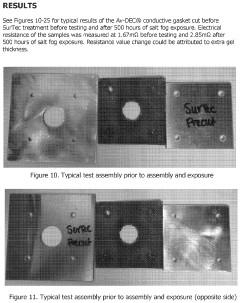

Metal mesh with a low electrical resistance conversion coating for use with aircraft structures

PatentInactiveUS20210041023A1

Innovation

- A gel-bodied gasket with a metallic skeleton coated using a thin, conductive or semi-conductive chromium-based conversion coating, which is encapsulated in a polyurethane gel, offering corrosion resistance and electrical conductivity, thereby preventing galvanic corrosion and maintaining EMI shielding.

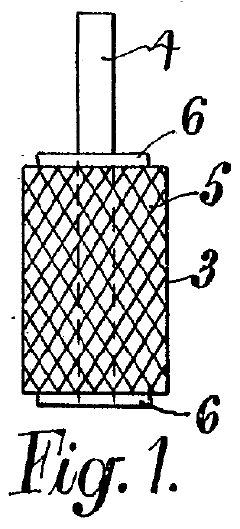

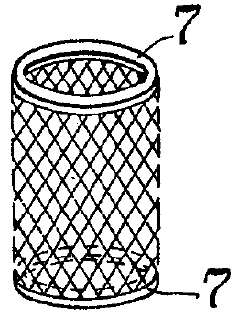

Improvements in and in the manufacture of metal mesh screens

PatentInactiveGB471810A

Innovation

- A process of electrically depositing metal on a core with a mesh pattern, followed by removing the core to create a seamless tubular metal mesh screen, using a low-melting-point core that can be broken down by heating or chemical processes, and employing grinding or lapping to expose the mesh, ensuring no seams or joints.

Regulatory Framework and Certification Requirements

The aerospace industry operates under one of the most stringent regulatory frameworks globally, necessitating comprehensive certification requirements for all components, including metal mesh materials. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish the primary regulatory standards that govern metal mesh performance in aerospace applications. These agencies mandate compliance with specific airworthiness directives (ADs) and technical standard orders (TSOs) that directly impact metal mesh specifications.

Metal mesh used in aerospace engineering must adhere to SAE Aerospace Material Specifications (AMS), particularly AMS 4884 for titanium alloy mesh and AMS 5506 for stainless steel mesh variants. These specifications outline critical parameters including tensile strength, corrosion resistance, fatigue performance, and dimensional stability under extreme temperature conditions. Additionally, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) certification is increasingly becoming mandatory for manufacturers producing metal mesh components.

Environmental compliance represents another significant regulatory consideration. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar environmental protection frameworks worldwide impose restrictions on certain metal alloys and surface treatments commonly used in mesh manufacturing. Manufacturers must demonstrate that their products contain no prohibited substances while maintaining required performance characteristics.

The certification process for metal mesh involves rigorous testing protocols established by ASTM International, particularly ASTM E2016 for particle filtration efficiency and ASTM F1608 for bacterial filtration efficiency when used in environmental control systems. Military specifications such as MIL-DTL-83420 for aircraft control cables and MIL-DTL-87161 for flexible metal hose assemblies provide additional requirements for specialized applications.

Quality management systems certification, typically ISO 9001 and the aerospace-specific AS9100, is mandatory for suppliers of metal mesh components. These certifications ensure consistent manufacturing processes and traceability throughout the supply chain. Furthermore, non-destructive testing (NDT) certifications according to NAS 410 standards are required for personnel inspecting metal mesh components during production and maintenance operations.

Recent regulatory trends indicate increasing emphasis on lifecycle assessment and sustainability metrics. Emerging standards are beginning to incorporate requirements for recyclability, reduced environmental impact during manufacturing, and documentation of the carbon footprint associated with metal mesh production. These evolving requirements will significantly influence future material selection and manufacturing processes in the aerospace metal mesh sector.

Metal mesh used in aerospace engineering must adhere to SAE Aerospace Material Specifications (AMS), particularly AMS 4884 for titanium alloy mesh and AMS 5506 for stainless steel mesh variants. These specifications outline critical parameters including tensile strength, corrosion resistance, fatigue performance, and dimensional stability under extreme temperature conditions. Additionally, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) certification is increasingly becoming mandatory for manufacturers producing metal mesh components.

Environmental compliance represents another significant regulatory consideration. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations in Europe and similar environmental protection frameworks worldwide impose restrictions on certain metal alloys and surface treatments commonly used in mesh manufacturing. Manufacturers must demonstrate that their products contain no prohibited substances while maintaining required performance characteristics.

The certification process for metal mesh involves rigorous testing protocols established by ASTM International, particularly ASTM E2016 for particle filtration efficiency and ASTM F1608 for bacterial filtration efficiency when used in environmental control systems. Military specifications such as MIL-DTL-83420 for aircraft control cables and MIL-DTL-87161 for flexible metal hose assemblies provide additional requirements for specialized applications.

Quality management systems certification, typically ISO 9001 and the aerospace-specific AS9100, is mandatory for suppliers of metal mesh components. These certifications ensure consistent manufacturing processes and traceability throughout the supply chain. Furthermore, non-destructive testing (NDT) certifications according to NAS 410 standards are required for personnel inspecting metal mesh components during production and maintenance operations.

Recent regulatory trends indicate increasing emphasis on lifecycle assessment and sustainability metrics. Emerging standards are beginning to incorporate requirements for recyclability, reduced environmental impact during manufacturing, and documentation of the carbon footprint associated with metal mesh production. These evolving requirements will significantly influence future material selection and manufacturing processes in the aerospace metal mesh sector.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing focus on environmental sustainability has significantly influenced metal mesh performance standards. Traditional manufacturing processes for metal meshes often involve energy-intensive methods and hazardous chemicals that generate substantial carbon emissions and toxic waste. Recent lifecycle assessments indicate that the production of high-performance metal meshes for aerospace applications can generate between 5-8 tons of CO2 equivalent per ton of finished product, highlighting the urgent need for greener alternatives.

Sustainable material sourcing has emerged as a critical consideration in metal mesh standards. The industry is increasingly adopting recycled titanium, aluminum, and nickel alloys, which can reduce energy consumption by up to 95% compared to virgin material extraction. Leading aerospace manufacturers now require suppliers to provide environmental impact documentation, including material origin certificates and carbon footprint calculations for their metal mesh components.

Manufacturing process optimization represents another significant sustainability frontier. Advanced techniques such as additive manufacturing and precision laser cutting have demonstrated potential to reduce material waste by 30-40% compared to traditional stamping and etching processes. These technologies also enable more precise control over mesh geometry, potentially extending service life and reducing replacement frequency.

End-of-life considerations have been incorporated into recent performance standards, with requirements for metal meshes to be designed for disassembly and material recovery. This circular economy approach ensures valuable aerospace-grade materials can be reclaimed and reprocessed, rather than becoming landfill waste. Some standards now specify minimum recyclability percentages, typically requiring at least 85% of the mesh material to be recoverable through existing recycling technologies.

Chemical composition standards are evolving to eliminate substances of high environmental concern. Hexavalent chromium, cadmium, and certain perfluorinated compounds previously used in metal mesh treatments are being phased out in favor of environmentally benign alternatives. Performance standards now frequently include restricted substance lists aligned with global regulations such as REACH and RoHS, even when these regulations don't directly apply to aerospace applications.

Weight optimization remains a sustainability priority, as lighter metal meshes directly contribute to fuel efficiency and emissions reduction during aircraft operation. Advanced computational modeling has enabled the development of performance standards that balance mechanical requirements with minimum material usage, potentially saving thousands of tons of fuel and associated emissions over an aircraft's operational lifetime.

Sustainable material sourcing has emerged as a critical consideration in metal mesh standards. The industry is increasingly adopting recycled titanium, aluminum, and nickel alloys, which can reduce energy consumption by up to 95% compared to virgin material extraction. Leading aerospace manufacturers now require suppliers to provide environmental impact documentation, including material origin certificates and carbon footprint calculations for their metal mesh components.

Manufacturing process optimization represents another significant sustainability frontier. Advanced techniques such as additive manufacturing and precision laser cutting have demonstrated potential to reduce material waste by 30-40% compared to traditional stamping and etching processes. These technologies also enable more precise control over mesh geometry, potentially extending service life and reducing replacement frequency.

End-of-life considerations have been incorporated into recent performance standards, with requirements for metal meshes to be designed for disassembly and material recovery. This circular economy approach ensures valuable aerospace-grade materials can be reclaimed and reprocessed, rather than becoming landfill waste. Some standards now specify minimum recyclability percentages, typically requiring at least 85% of the mesh material to be recoverable through existing recycling technologies.

Chemical composition standards are evolving to eliminate substances of high environmental concern. Hexavalent chromium, cadmium, and certain perfluorinated compounds previously used in metal mesh treatments are being phased out in favor of environmentally benign alternatives. Performance standards now frequently include restricted substance lists aligned with global regulations such as REACH and RoHS, even when these regulations don't directly apply to aerospace applications.

Weight optimization remains a sustainability priority, as lighter metal meshes directly contribute to fuel efficiency and emissions reduction during aircraft operation. Advanced computational modeling has enabled the development of performance standards that balance mechanical requirements with minimum material usage, potentially saving thousands of tons of fuel and associated emissions over an aircraft's operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!