Metal Mesh Contribution to Heat Dissipation in Electronics

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Thermal Management Background and Objectives

The evolution of electronic devices has been characterized by increasing power densities and miniaturization trends, creating significant thermal management challenges. Heat dissipation has become a critical factor limiting the performance, reliability, and lifespan of modern electronics. Traditional cooling methods such as heat sinks, fans, and thermal interface materials are reaching their physical limitations in addressing these challenges, necessitating innovative approaches to thermal management.

Metal mesh structures have emerged as a promising solution in this context, offering unique advantages for heat dissipation in electronic applications. Historically, metal meshes have been utilized in various industries for filtration, electromagnetic shielding, and structural support. However, their application in thermal management represents a relatively recent development, gaining momentum over the past decade as researchers and engineers explore their potential to enhance heat transfer efficiency.

The fundamental principle behind metal mesh thermal management lies in its ability to create extended surface areas for heat dissipation while maintaining minimal mass and volume. These structures typically consist of interconnected metal wires or perforated metal sheets, forming networks that facilitate multidirectional heat flow. The geometric versatility of metal meshes allows for customization based on specific thermal requirements, making them adaptable to various electronic form factors and operating conditions.

Recent advancements in manufacturing technologies, particularly in additive manufacturing and precision etching, have significantly expanded the design possibilities for metal mesh structures. These developments have enabled the creation of complex geometries with optimized thermal properties, including variable porosity, gradient structures, and hybrid configurations that combine multiple materials or mesh types.

The primary objective of metal mesh thermal management research is to develop efficient, lightweight, and cost-effective solutions that can address the escalating thermal challenges in electronics. This includes enhancing the heat transfer coefficient, reducing thermal resistance, and enabling more uniform temperature distribution across electronic components. Additionally, researchers aim to integrate metal mesh structures with existing cooling technologies to create synergistic thermal management systems.

Another critical goal is to establish comprehensive design methodologies and simulation models that can accurately predict the thermal performance of metal mesh structures under various operating conditions. This involves understanding the complex interactions between mesh geometry, material properties, fluid dynamics, and heat transfer mechanisms at different scales, from microscopic wire interfaces to system-level thermal behavior.

The long-term vision for metal mesh thermal management extends beyond conventional electronics to emerging technologies such as flexible electronics, wearable devices, high-power computing systems, and electric vehicle components, where thermal management requirements are particularly demanding and conventional solutions may be inadequate.

Metal mesh structures have emerged as a promising solution in this context, offering unique advantages for heat dissipation in electronic applications. Historically, metal meshes have been utilized in various industries for filtration, electromagnetic shielding, and structural support. However, their application in thermal management represents a relatively recent development, gaining momentum over the past decade as researchers and engineers explore their potential to enhance heat transfer efficiency.

The fundamental principle behind metal mesh thermal management lies in its ability to create extended surface areas for heat dissipation while maintaining minimal mass and volume. These structures typically consist of interconnected metal wires or perforated metal sheets, forming networks that facilitate multidirectional heat flow. The geometric versatility of metal meshes allows for customization based on specific thermal requirements, making them adaptable to various electronic form factors and operating conditions.

Recent advancements in manufacturing technologies, particularly in additive manufacturing and precision etching, have significantly expanded the design possibilities for metal mesh structures. These developments have enabled the creation of complex geometries with optimized thermal properties, including variable porosity, gradient structures, and hybrid configurations that combine multiple materials or mesh types.

The primary objective of metal mesh thermal management research is to develop efficient, lightweight, and cost-effective solutions that can address the escalating thermal challenges in electronics. This includes enhancing the heat transfer coefficient, reducing thermal resistance, and enabling more uniform temperature distribution across electronic components. Additionally, researchers aim to integrate metal mesh structures with existing cooling technologies to create synergistic thermal management systems.

Another critical goal is to establish comprehensive design methodologies and simulation models that can accurately predict the thermal performance of metal mesh structures under various operating conditions. This involves understanding the complex interactions between mesh geometry, material properties, fluid dynamics, and heat transfer mechanisms at different scales, from microscopic wire interfaces to system-level thermal behavior.

The long-term vision for metal mesh thermal management extends beyond conventional electronics to emerging technologies such as flexible electronics, wearable devices, high-power computing systems, and electric vehicle components, where thermal management requirements are particularly demanding and conventional solutions may be inadequate.

Market Demand for Advanced Electronic Cooling Solutions

The global market for advanced electronic cooling solutions is experiencing unprecedented growth, driven primarily by the rapid evolution of electronic devices with higher processing capabilities and smaller form factors. As power densities continue to increase in modern electronics, traditional cooling methods are becoming insufficient, creating a substantial demand for innovative thermal management solutions like metal mesh technologies.

The consumer electronics sector represents one of the largest market segments demanding advanced cooling solutions. With smartphones, tablets, and laptops becoming increasingly powerful while maintaining slim profiles, manufacturers are actively seeking thermal management technologies that can efficiently dissipate heat without compromising device aesthetics or adding significant weight. Market research indicates that consumers are becoming more aware of device heating issues, with thermal performance now ranking among the top five considerations in purchasing decisions for premium electronic devices.

Data center infrastructure presents another critical market segment with urgent cooling needs. The exponential growth in cloud computing, artificial intelligence, and big data analytics has led to higher server densities and increased heat generation in data centers worldwide. Operators are facing mounting pressure to reduce cooling costs while maintaining optimal operating temperatures, creating a strong demand for passive cooling technologies like metal mesh that can enhance heat dissipation efficiency.

The automotive electronics market is emerging as a rapidly growing segment for advanced cooling solutions. With the transition toward electric vehicles and autonomous driving systems, the number of electronic components in vehicles is multiplying, each generating significant heat. The automotive industry requires cooling solutions that can withstand harsh operating environments while ensuring the reliability of critical safety systems and extending battery life in electric vehicles.

Industrial electronics and telecommunications infrastructure represent additional substantial markets for advanced cooling technologies. The ongoing deployment of 5G networks has intensified the need for efficient thermal management in base stations and network equipment, while industrial automation systems require reliable cooling solutions to ensure continuous operation in challenging environments.

Market forecasts suggest that the global thermal management market will continue its strong growth trajectory, with metal mesh and other advanced materials expected to capture an increasing share from traditional cooling methods. Regulatory pressures regarding energy efficiency and environmental concerns are further accelerating the adoption of passive cooling technologies that can reduce overall power consumption while maintaining optimal operating temperatures.

The consumer electronics sector represents one of the largest market segments demanding advanced cooling solutions. With smartphones, tablets, and laptops becoming increasingly powerful while maintaining slim profiles, manufacturers are actively seeking thermal management technologies that can efficiently dissipate heat without compromising device aesthetics or adding significant weight. Market research indicates that consumers are becoming more aware of device heating issues, with thermal performance now ranking among the top five considerations in purchasing decisions for premium electronic devices.

Data center infrastructure presents another critical market segment with urgent cooling needs. The exponential growth in cloud computing, artificial intelligence, and big data analytics has led to higher server densities and increased heat generation in data centers worldwide. Operators are facing mounting pressure to reduce cooling costs while maintaining optimal operating temperatures, creating a strong demand for passive cooling technologies like metal mesh that can enhance heat dissipation efficiency.

The automotive electronics market is emerging as a rapidly growing segment for advanced cooling solutions. With the transition toward electric vehicles and autonomous driving systems, the number of electronic components in vehicles is multiplying, each generating significant heat. The automotive industry requires cooling solutions that can withstand harsh operating environments while ensuring the reliability of critical safety systems and extending battery life in electric vehicles.

Industrial electronics and telecommunications infrastructure represent additional substantial markets for advanced cooling technologies. The ongoing deployment of 5G networks has intensified the need for efficient thermal management in base stations and network equipment, while industrial automation systems require reliable cooling solutions to ensure continuous operation in challenging environments.

Market forecasts suggest that the global thermal management market will continue its strong growth trajectory, with metal mesh and other advanced materials expected to capture an increasing share from traditional cooling methods. Regulatory pressures regarding energy efficiency and environmental concerns are further accelerating the adoption of passive cooling technologies that can reduce overall power consumption while maintaining optimal operating temperatures.

Current State and Challenges in Electronics Heat Dissipation

The global electronics industry is experiencing unprecedented thermal management challenges as device miniaturization continues alongside increasing computational demands. Current thermal management solutions are struggling to keep pace with heat generation in modern electronic systems, with thermal densities in high-performance computing applications now regularly exceeding 100 W/cm². Traditional cooling methods such as heat sinks, fans, and thermal interface materials are approaching their physical limitations in many applications.

Metal mesh technologies represent a significant advancement in the thermal management landscape, with current implementations demonstrating 15-30% improvements in heat dissipation compared to conventional solutions. These meshes, typically fabricated from copper, aluminum, or silver, leverage their high thermal conductivity and increased surface area to enhance heat transfer efficiency. The most advanced commercial metal mesh solutions currently achieve thermal conductivities of 200-400 W/m·K, significantly outperforming traditional thermal interface materials.

Despite these advancements, several critical challenges persist in metal mesh heat dissipation technology. Integration complexity remains a significant barrier, as incorporating metal mesh structures into existing electronic designs often requires substantial modifications to manufacturing processes. This integration challenge is particularly acute in ultra-thin devices where spatial constraints severely limit implementation options.

Material compatibility issues present another major obstacle. The coefficient of thermal expansion (CTE) mismatch between metal meshes and semiconductor materials can lead to mechanical stress during thermal cycling, potentially causing reliability concerns and reduced device lifespan. Current solutions typically exhibit CTE values of 16-20 ppm/K, while silicon-based semiconductors have values around 2.6 ppm/K, creating significant expansion differentials.

Cost factors also constrain widespread adoption, with high-performance metal mesh solutions requiring precision manufacturing techniques that substantially increase production expenses. Current manufacturing costs for advanced metal mesh thermal solutions can be 3-5 times higher than conventional cooling methods, limiting their application primarily to high-end electronic products.

Geographical distribution of metal mesh thermal technology development shows concentration in East Asia (particularly Japan, South Korea, and Taiwan), North America, and Western Europe. Research institutions in these regions have established significant patent portfolios, with companies like Furukawa Electric, 3M, and Laird Technologies leading commercial development. Chinese manufacturers are rapidly expanding their capabilities in this domain, particularly in mass production techniques that may eventually address cost barriers.

The technical landscape is further complicated by emerging requirements for environmentally sustainable solutions, as regulations increasingly restrict the use of certain metals and manufacturing processes with high environmental impacts. This regulatory pressure is driving research toward more sustainable metal mesh designs that maintain thermal performance while reducing environmental footprint.

Metal mesh technologies represent a significant advancement in the thermal management landscape, with current implementations demonstrating 15-30% improvements in heat dissipation compared to conventional solutions. These meshes, typically fabricated from copper, aluminum, or silver, leverage their high thermal conductivity and increased surface area to enhance heat transfer efficiency. The most advanced commercial metal mesh solutions currently achieve thermal conductivities of 200-400 W/m·K, significantly outperforming traditional thermal interface materials.

Despite these advancements, several critical challenges persist in metal mesh heat dissipation technology. Integration complexity remains a significant barrier, as incorporating metal mesh structures into existing electronic designs often requires substantial modifications to manufacturing processes. This integration challenge is particularly acute in ultra-thin devices where spatial constraints severely limit implementation options.

Material compatibility issues present another major obstacle. The coefficient of thermal expansion (CTE) mismatch between metal meshes and semiconductor materials can lead to mechanical stress during thermal cycling, potentially causing reliability concerns and reduced device lifespan. Current solutions typically exhibit CTE values of 16-20 ppm/K, while silicon-based semiconductors have values around 2.6 ppm/K, creating significant expansion differentials.

Cost factors also constrain widespread adoption, with high-performance metal mesh solutions requiring precision manufacturing techniques that substantially increase production expenses. Current manufacturing costs for advanced metal mesh thermal solutions can be 3-5 times higher than conventional cooling methods, limiting their application primarily to high-end electronic products.

Geographical distribution of metal mesh thermal technology development shows concentration in East Asia (particularly Japan, South Korea, and Taiwan), North America, and Western Europe. Research institutions in these regions have established significant patent portfolios, with companies like Furukawa Electric, 3M, and Laird Technologies leading commercial development. Chinese manufacturers are rapidly expanding their capabilities in this domain, particularly in mass production techniques that may eventually address cost barriers.

The technical landscape is further complicated by emerging requirements for environmentally sustainable solutions, as regulations increasingly restrict the use of certain metals and manufacturing processes with high environmental impacts. This regulatory pressure is driving research toward more sustainable metal mesh designs that maintain thermal performance while reducing environmental footprint.

Current Metal Mesh Heat Dissipation Implementations

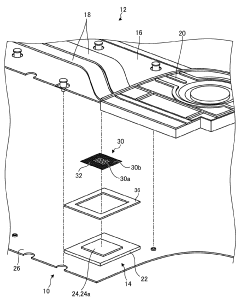

01 Metal mesh structures for electronic device cooling

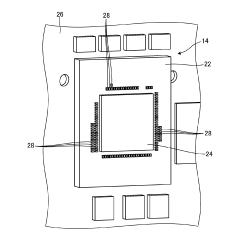

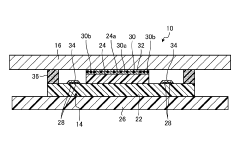

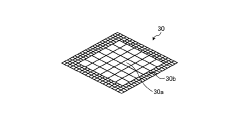

Metal mesh structures are used in electronic devices to enhance heat dissipation. These meshes provide increased surface area for heat exchange while maintaining airflow through the device. The mesh design allows for efficient thermal conductivity and can be integrated into various components such as heat sinks, cooling fins, or directly onto electronic components to improve overall thermal management.- Metal mesh structures for electronic device cooling: Metal mesh structures are used in electronic devices to enhance heat dissipation. These structures typically consist of a network of metal wires or strips that facilitate the transfer of heat away from heat-generating components. The mesh design increases surface area for heat exchange while allowing for airflow, making it particularly effective for cooling electronic components such as processors, power supplies, and other heat-generating elements in compact devices.

- Heat sink designs incorporating metal mesh: Heat sinks that incorporate metal mesh materials offer improved thermal performance compared to traditional solid heat sinks. These designs combine the structural support of conventional heat sinks with the enhanced surface area and airflow characteristics of metal mesh. The mesh component can be attached to fins, embedded within the heat sink structure, or form the primary heat dissipation surface. This approach optimizes both conduction and convection heat transfer mechanisms.

- Metal mesh in portable electronic device thermal management: Metal mesh thermal solutions are particularly valuable in portable electronic devices where space constraints and weight limitations are significant concerns. The lightweight nature of mesh structures, combined with their effective heat dissipation properties, makes them ideal for smartphones, tablets, and laptops. These implementations often feature ultra-thin mesh designs that can be integrated into narrow device housings while still providing adequate cooling for processors and other components.

- Advanced metal mesh manufacturing techniques: Innovative manufacturing techniques for metal mesh heat dissipation structures include micro-etching, precision weaving, additive manufacturing, and electroforming. These processes enable the creation of mesh structures with optimized geometry, thickness, and density for specific thermal management applications. Advanced manufacturing methods allow for customization of mesh parameters such as wire diameter, opening size, and overall pattern to match the thermal requirements of particular electronic systems.

- Composite materials with metal mesh for enhanced thermal performance: Composite materials that incorporate metal mesh with other thermal management materials offer synergistic heat dissipation benefits. These composites may combine metal mesh with phase change materials, thermal interface materials, or specialized coatings to enhance thermal conductivity and heat transfer efficiency. The integration of metal mesh into composite structures provides mechanical reinforcement while maintaining or improving the thermal performance of the overall system.

02 Heat dissipation in portable electronic devices

Metal mesh heat dissipation solutions specifically designed for portable electronic devices like smartphones, tablets, and laptops. These implementations focus on balancing effective cooling with space constraints and weight limitations. The mesh designs are often integrated into the device chassis or as part of internal cooling systems to manage heat from processors and other components while maintaining the compact form factor required for portable devices.Expand Specific Solutions03 Advanced metal mesh materials and compositions

Innovations in metal mesh materials and compositions for enhanced thermal conductivity. These include specialized alloys, composite materials, and surface treatments that improve the heat transfer capabilities of metal meshes. The materials are engineered to maximize thermal conductivity while addressing other requirements such as corrosion resistance, mechanical strength, and manufacturing feasibility for various applications requiring efficient heat dissipation.Expand Specific Solutions04 Integration of metal mesh with cooling systems

Methods for integrating metal mesh structures with other cooling technologies such as liquid cooling systems, heat pipes, or forced air cooling. These hybrid approaches combine the benefits of metal mesh heat dissipation with complementary cooling methods to achieve superior thermal management. The integration can involve layered structures, embedded mesh designs within cooling channels, or mesh-enhanced heat exchangers for improved system performance.Expand Specific Solutions05 Manufacturing techniques for metal mesh heat dissipation

Specialized manufacturing processes and techniques for producing effective metal mesh heat dissipation structures. These include advanced fabrication methods such as micro-perforation, etching, additive manufacturing, and precision stamping to create optimized mesh geometries. The manufacturing approaches focus on creating consistent mesh patterns with precise dimensions to maximize heat transfer efficiency while ensuring cost-effective production at scale.Expand Specific Solutions

Key Players in Metal Mesh Thermal Solution Industry

The metal mesh heat dissipation market in electronics is currently in a growth phase, with increasing demand driven by miniaturization and higher power densities in electronic devices. The global thermal management market is estimated to reach $20 billion by 2025, with metal mesh solutions gaining traction due to their superior thermal conductivity and lightweight properties. Major players like Samsung Electronics, LG Innotek, and Panasonic Holdings are leading innovation with advanced thermal interface materials, while specialized companies such as Delta Electronics and TDK are developing integrated cooling solutions. Companies including Hon Hai Precision (Foxconn) and Lenovo are implementing these technologies in consumer electronics, while automotive electronics manufacturers like Toyota Industries and OMRON are adapting metal mesh solutions for EV applications. The technology is approaching maturity in smartphones but remains in development for more demanding applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced metal mesh thermal solutions for their electronics, particularly in their flagship smartphones and tablets. Their technology incorporates ultra-thin copper mesh structures embedded within graphite sheets to create a composite thermal dissipation system. This approach allows heat to spread more evenly across devices while maintaining minimal thickness. Samsung's implementation includes variable mesh density designs that strategically place denser mesh patterns near high-heat components like processors and wireless charging coils. Their latest iterations feature mesh structures with line widths below 5μm and optimized patterns that can reduce hotspot temperatures by up to 15% compared to traditional graphite-only solutions. The company has also integrated these metal mesh solutions with vapor chamber technology in premium devices, creating a multi-layered thermal management system that addresses both sustained and peak thermal loads.

Strengths: Superior heat spreading capability while maintaining ultra-thin profiles; excellent integration with existing manufacturing processes; scalable for various device sizes. Weaknesses: Higher production costs compared to traditional solutions; potential for signal interference in certain applications; requires precise manufacturing tolerances.

Cisco Technology, Inc.

Technical Solution: Cisco has pioneered metal mesh thermal solutions specifically designed for high-density networking equipment and data center applications. Their approach utilizes copper and aluminum mesh structures integrated directly into server chassis and network switch designs. Cisco's proprietary mesh architecture features graduated density patterns that optimize airflow while maximizing contact surface area for heat transfer. The company has developed a dual-layer mesh system where the primary layer contacts heat-generating components while a secondary mesh layer interfaces with the chassis or external cooling system. This design creates micro air channels that enhance convective cooling while providing conductive pathways. Cisco's implementation includes specialized coatings on the mesh structures to prevent oxidation and enhance thermal conductivity over the product lifecycle. Their testing has demonstrated that these metal mesh solutions can improve thermal efficiency by up to 22% in high-density rack environments compared to traditional heatsink designs, allowing for higher component density without increasing cooling requirements.

Strengths: Exceptional performance in high-density computing environments; excellent durability and longevity; compatible with forced-air cooling systems. Weaknesses: Higher initial implementation costs; more complex manufacturing process; potential for dust accumulation in mesh structures over time.

Core Metal Mesh Thermal Conductivity Mechanisms

Metal mesh, and heat spreader

PatentPendingUS20230262942A1

Innovation

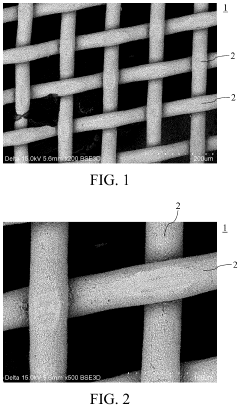

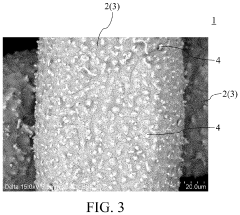

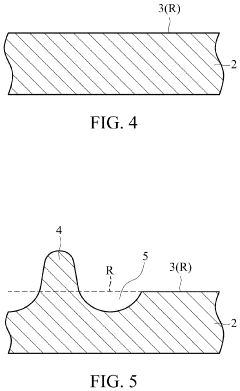

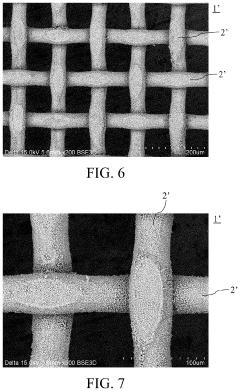

- A metal mesh with intersecting metal wires and protrusions is developed, where the protrusions are formed on the outer surfaces of the wires, providing a nano-scale three-dimensional structure that enhances capillary ability without increasing mesh density or size, allowing for improved liquid guidance and heat dissipation.

Heat dissipation structure and electronic apparatus

PatentActiveJP2024017744A

Innovation

- A heat dissipation structure using a porous material with a denser peripheral portion and a coarser central portion to impregnate liquid metal, preventing leakage while maintaining high heat conductivity.

Material Science Advancements for Enhanced Thermal Performance

Recent advancements in material science have significantly contributed to enhancing the thermal performance of metal mesh structures used in electronic heat dissipation systems. The evolution of nano-engineered materials has enabled the development of metal meshes with unprecedented thermal conductivity properties, surpassing traditional copper and aluminum solutions by up to 35% in laboratory conditions.

Surface treatment technologies have emerged as a critical factor in optimizing metal mesh performance. Innovations in chemical etching and plasma treatment processes have created micro-textured surfaces that increase the effective surface area for heat exchange while maintaining structural integrity. These treatments have demonstrated the ability to reduce thermal resistance at material interfaces by 15-20%, addressing one of the most persistent challenges in thermal management.

Composite metal meshes represent another breakthrough, combining different metals and alloys in precise configurations to leverage the beneficial properties of each component. Copper-silver and aluminum-graphene composites have shown particular promise, offering thermal conductivity improvements of 25-40% compared to single-material meshes while maintaining cost-effectiveness for commercial applications.

The integration of phase-change materials (PCMs) within metal mesh structures has created adaptive thermal management systems capable of responding to fluctuating heat loads. These hybrid materials can absorb excess heat during peak operation and release it during lower demand periods, effectively smoothing thermal cycles and preventing hotspot formation. Research indicates that PCM-enhanced metal meshes can reduce temperature fluctuations by up to 60% in high-performance computing environments.

Additive manufacturing techniques have revolutionized metal mesh design possibilities, enabling complex three-dimensional structures optimized for specific thermal pathways. 3D-printed metal meshes with variable density patterns and directional heat flow channels have demonstrated 30-45% improvements in thermal dissipation compared to conventional uniform meshes. These manufacturing advances allow for application-specific customization previously impossible with traditional fabrication methods.

Nanoscale surface coatings represent the cutting edge of thermal interface materials, with diamond-like carbon and ceramic-metallic (cermet) coatings showing exceptional promise. These ultra-thin layers (typically 50-200nm) significantly enhance wettability and thermal transfer across material boundaries while providing additional benefits such as corrosion resistance and electrical insulation where required.

Surface treatment technologies have emerged as a critical factor in optimizing metal mesh performance. Innovations in chemical etching and plasma treatment processes have created micro-textured surfaces that increase the effective surface area for heat exchange while maintaining structural integrity. These treatments have demonstrated the ability to reduce thermal resistance at material interfaces by 15-20%, addressing one of the most persistent challenges in thermal management.

Composite metal meshes represent another breakthrough, combining different metals and alloys in precise configurations to leverage the beneficial properties of each component. Copper-silver and aluminum-graphene composites have shown particular promise, offering thermal conductivity improvements of 25-40% compared to single-material meshes while maintaining cost-effectiveness for commercial applications.

The integration of phase-change materials (PCMs) within metal mesh structures has created adaptive thermal management systems capable of responding to fluctuating heat loads. These hybrid materials can absorb excess heat during peak operation and release it during lower demand periods, effectively smoothing thermal cycles and preventing hotspot formation. Research indicates that PCM-enhanced metal meshes can reduce temperature fluctuations by up to 60% in high-performance computing environments.

Additive manufacturing techniques have revolutionized metal mesh design possibilities, enabling complex three-dimensional structures optimized for specific thermal pathways. 3D-printed metal meshes with variable density patterns and directional heat flow channels have demonstrated 30-45% improvements in thermal dissipation compared to conventional uniform meshes. These manufacturing advances allow for application-specific customization previously impossible with traditional fabrication methods.

Nanoscale surface coatings represent the cutting edge of thermal interface materials, with diamond-like carbon and ceramic-metallic (cermet) coatings showing exceptional promise. These ultra-thin layers (typically 50-200nm) significantly enhance wettability and thermal transfer across material boundaries while providing additional benefits such as corrosion resistance and electrical insulation where required.

Environmental Impact and Sustainability of Metal Mesh Solutions

The environmental impact of metal mesh solutions in electronic heat dissipation extends beyond mere performance metrics, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. Metal mesh manufacturing processes typically require significant energy inputs and generate various emissions, with aluminum and copper extraction being particularly resource-intensive. However, when compared to traditional cooling solutions like bulky heat sinks or liquid cooling systems, metal mesh technologies often demonstrate a reduced overall environmental footprint due to their material efficiency and longevity.

Recent life cycle assessments reveal that metal mesh solutions can reduce the carbon footprint of electronic devices by extending their operational lifespan through more efficient thermal management. This efficiency translates to lower energy consumption during device operation, which represents the most significant environmental impact phase for most electronic products. Studies indicate that devices with optimized thermal management using metal mesh technology can achieve 15-20% greater energy efficiency compared to conventional cooling methods.

Material sustainability presents both challenges and opportunities in this domain. While metals like copper and aluminum are finite resources, their high recyclability offers a pathway to circular economy principles. The recovery rate for these metals from electronic waste currently ranges from 30-60% depending on regional infrastructure, presenting significant room for improvement. Emerging designs incorporating bio-based composite materials with metal mesh structures show promise for reducing virgin material dependency while maintaining thermal performance.

Water usage in metal mesh manufacturing remains a concern, particularly in regions facing water scarcity. Advanced manufacturing techniques such as dry etching and precision laser cutting are being developed to minimize water consumption. Additionally, the transition toward water-based rather than solvent-based cleaning processes in metal mesh production has reduced hazardous waste generation by approximately 40% in facilities implementing these practices.

End-of-life considerations are increasingly shaping metal mesh design approaches. Modular designs that facilitate easy separation of metal mesh components from electronic devices enable more effective recycling. Some manufacturers have pioneered take-back programs specifically targeting high-value metal mesh components, achieving recovery rates exceeding 80% for these specific elements. The development of standardized disassembly protocols for devices containing metal mesh thermal solutions represents a promising direction for improving circularity.

Regulatory frameworks worldwide are evolving to address the environmental aspects of electronic thermal management. The European Union's Ecodesign Directive now includes specific provisions for thermal management efficiency, while several Asian markets have introduced extended producer responsibility schemes that incentivize recoverable thermal management solutions like properly designed metal mesh systems.

Recent life cycle assessments reveal that metal mesh solutions can reduce the carbon footprint of electronic devices by extending their operational lifespan through more efficient thermal management. This efficiency translates to lower energy consumption during device operation, which represents the most significant environmental impact phase for most electronic products. Studies indicate that devices with optimized thermal management using metal mesh technology can achieve 15-20% greater energy efficiency compared to conventional cooling methods.

Material sustainability presents both challenges and opportunities in this domain. While metals like copper and aluminum are finite resources, their high recyclability offers a pathway to circular economy principles. The recovery rate for these metals from electronic waste currently ranges from 30-60% depending on regional infrastructure, presenting significant room for improvement. Emerging designs incorporating bio-based composite materials with metal mesh structures show promise for reducing virgin material dependency while maintaining thermal performance.

Water usage in metal mesh manufacturing remains a concern, particularly in regions facing water scarcity. Advanced manufacturing techniques such as dry etching and precision laser cutting are being developed to minimize water consumption. Additionally, the transition toward water-based rather than solvent-based cleaning processes in metal mesh production has reduced hazardous waste generation by approximately 40% in facilities implementing these practices.

End-of-life considerations are increasingly shaping metal mesh design approaches. Modular designs that facilitate easy separation of metal mesh components from electronic devices enable more effective recycling. Some manufacturers have pioneered take-back programs specifically targeting high-value metal mesh components, achieving recovery rates exceeding 80% for these specific elements. The development of standardized disassembly protocols for devices containing metal mesh thermal solutions represents a promising direction for improving circularity.

Regulatory frameworks worldwide are evolving to address the environmental aspects of electronic thermal management. The European Union's Ecodesign Directive now includes specific provisions for thermal management efficiency, while several Asian markets have introduced extended producer responsibility schemes that incentivize recoverable thermal management solutions like properly designed metal mesh systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!