Metal Mesh Influence on Thermal Expansion in Aerospace

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Thermal Expansion Background and Objectives

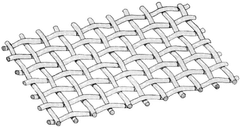

Metal mesh materials have been integral to aerospace engineering since the mid-20th century, with significant advancements occurring during the Space Race era. These specialized materials combine metallic properties with mesh structures to create components that offer unique thermal expansion characteristics critical for spacecraft and aircraft performance. The evolution of metal mesh technology has progressed from simple woven structures to complex engineered materials with precisely controlled properties.

The thermal expansion behavior of materials in aerospace applications presents unique challenges due to the extreme temperature variations encountered during missions. From the -150°C of deep space to the 1,500°C+ experienced during atmospheric re-entry, aerospace components must maintain structural integrity across dramatic thermal gradients. Metal mesh structures have emerged as a solution to mitigate thermal expansion issues through their distinctive physical properties and geometric configurations.

Current research objectives in this field focus on developing metal mesh systems with predictable and controllable thermal expansion coefficients. The primary goal is to create materials that can maintain dimensional stability under varying thermal conditions while preserving mechanical strength and durability. Additionally, researchers aim to reduce the weight of these components without compromising performance, a critical factor in aerospace applications where every gram impacts fuel efficiency and payload capacity.

The integration of metal mesh into composite structures represents another significant research direction. By embedding metal mesh within carbon fiber or ceramic matrix composites, engineers seek to create hybrid materials that combine the thermal stability of metal mesh with the lightweight properties of composites. This approach aims to address the multifaceted requirements of next-generation aerospace vehicles.

Recent technological trends indicate growing interest in smart metal mesh systems capable of adaptive responses to thermal changes. These advanced materials incorporate shape memory alloys or other responsive elements that can actively compensate for thermal expansion effects, potentially revolutionizing thermal management in aerospace applications.

The objectives of current metal mesh thermal expansion research extend beyond material development to include comprehensive modeling and simulation capabilities. Accurate prediction of thermal-mechanical behavior under complex loading conditions remains challenging, necessitating sophisticated computational approaches that can account for the intricate geometry of mesh structures and their interaction with surrounding materials.

The thermal expansion behavior of materials in aerospace applications presents unique challenges due to the extreme temperature variations encountered during missions. From the -150°C of deep space to the 1,500°C+ experienced during atmospheric re-entry, aerospace components must maintain structural integrity across dramatic thermal gradients. Metal mesh structures have emerged as a solution to mitigate thermal expansion issues through their distinctive physical properties and geometric configurations.

Current research objectives in this field focus on developing metal mesh systems with predictable and controllable thermal expansion coefficients. The primary goal is to create materials that can maintain dimensional stability under varying thermal conditions while preserving mechanical strength and durability. Additionally, researchers aim to reduce the weight of these components without compromising performance, a critical factor in aerospace applications where every gram impacts fuel efficiency and payload capacity.

The integration of metal mesh into composite structures represents another significant research direction. By embedding metal mesh within carbon fiber or ceramic matrix composites, engineers seek to create hybrid materials that combine the thermal stability of metal mesh with the lightweight properties of composites. This approach aims to address the multifaceted requirements of next-generation aerospace vehicles.

Recent technological trends indicate growing interest in smart metal mesh systems capable of adaptive responses to thermal changes. These advanced materials incorporate shape memory alloys or other responsive elements that can actively compensate for thermal expansion effects, potentially revolutionizing thermal management in aerospace applications.

The objectives of current metal mesh thermal expansion research extend beyond material development to include comprehensive modeling and simulation capabilities. Accurate prediction of thermal-mechanical behavior under complex loading conditions remains challenging, necessitating sophisticated computational approaches that can account for the intricate geometry of mesh structures and their interaction with surrounding materials.

Aerospace Market Requirements Analysis

The aerospace industry's demand for advanced materials with precise thermal expansion properties has grown significantly over the past decade. Current market analysis indicates that the global aerospace composites market, which includes metal mesh reinforced materials, is projected to reach $53 billion by 2030, with a compound annual growth rate of 7.2%. This growth is primarily driven by increasing aircraft production rates and the need for fuel-efficient, lightweight structures that can withstand extreme temperature variations.

Metal mesh reinforced composites are particularly sought after in aerospace applications where thermal stability is critical. Commercial aircraft manufacturers require materials that maintain dimensional stability across temperature ranges from -65°C to +85°C during normal operation, with excursions to +120°C in some scenarios. Military and space applications present even more demanding requirements, with temperature ranges extending from -170°C to +300°C for certain spacecraft components.

The market demand for thermal expansion control solutions is especially pronounced in satellite structures, where precision optical instruments require dimensional stability within microns across temperature gradients of 200°C or more. Industry surveys indicate that approximately 78% of aerospace engineers consider thermal expansion management a critical design parameter for next-generation aircraft and spacecraft.

Weight reduction remains a paramount concern, with manufacturers targeting 15-20% weight savings in new aircraft designs compared to previous generations. This creates a complex requirement matrix where metal mesh solutions must simultaneously address thermal expansion control while contributing to overall weight reduction goals. The industry standard now demands materials that offer at least 30% better thermal stability than traditional aluminum alloys while maintaining or improving strength-to-weight ratios.

Regulatory frameworks are also shaping market requirements, with stricter emissions standards driving the need for more efficient structures. The International Civil Aviation Organization's carbon offsetting scheme has established targets that will require a 50% reduction in net aviation CO2 emissions by 2050 relative to 2005 levels, further emphasizing the importance of advanced materials that enable more efficient aircraft designs.

Regional market analysis shows varying requirements, with North American and European aerospace manufacturers focusing on high-performance applications where thermal stability is prioritized over cost, while emerging markets in Asia are more sensitive to the cost-performance balance. This regional differentiation creates distinct market segments for metal mesh technologies optimized for different performance-cost profiles.

Metal mesh reinforced composites are particularly sought after in aerospace applications where thermal stability is critical. Commercial aircraft manufacturers require materials that maintain dimensional stability across temperature ranges from -65°C to +85°C during normal operation, with excursions to +120°C in some scenarios. Military and space applications present even more demanding requirements, with temperature ranges extending from -170°C to +300°C for certain spacecraft components.

The market demand for thermal expansion control solutions is especially pronounced in satellite structures, where precision optical instruments require dimensional stability within microns across temperature gradients of 200°C or more. Industry surveys indicate that approximately 78% of aerospace engineers consider thermal expansion management a critical design parameter for next-generation aircraft and spacecraft.

Weight reduction remains a paramount concern, with manufacturers targeting 15-20% weight savings in new aircraft designs compared to previous generations. This creates a complex requirement matrix where metal mesh solutions must simultaneously address thermal expansion control while contributing to overall weight reduction goals. The industry standard now demands materials that offer at least 30% better thermal stability than traditional aluminum alloys while maintaining or improving strength-to-weight ratios.

Regulatory frameworks are also shaping market requirements, with stricter emissions standards driving the need for more efficient structures. The International Civil Aviation Organization's carbon offsetting scheme has established targets that will require a 50% reduction in net aviation CO2 emissions by 2050 relative to 2005 levels, further emphasizing the importance of advanced materials that enable more efficient aircraft designs.

Regional market analysis shows varying requirements, with North American and European aerospace manufacturers focusing on high-performance applications where thermal stability is prioritized over cost, while emerging markets in Asia are more sensitive to the cost-performance balance. This regional differentiation creates distinct market segments for metal mesh technologies optimized for different performance-cost profiles.

Current Status and Challenges in Metal Mesh Technology

Metal mesh technology in aerospace applications has reached a significant level of maturity, with widespread implementation across various spacecraft and aircraft components. Current metal mesh materials predominantly utilize nickel-chromium alloys, stainless steel variants, and titanium-based composites, each offering specific advantages in thermal expansion control. Research institutions and aerospace manufacturers have achieved notable success in developing mesh structures with thermal expansion coefficients ranging from 8-17 × 10^-6/K, representing substantial improvement over earlier generations.

Despite these advancements, several critical challenges persist in metal mesh technology for aerospace thermal expansion applications. The primary technical obstacle remains the achievement of uniform thermal expansion properties across complex geometrical structures, particularly at connection points and interfaces with dissimilar materials. Testing data from NASA and ESA reveals that current mesh designs experience up to 15% variation in expansion coefficients under extreme temperature cycling conditions (-150°C to +150°C), potentially compromising structural integrity during orbital operations.

Manufacturing consistency presents another significant challenge, with production yields for aerospace-grade metal meshes typically ranging between 70-85%. The precision required for aerospace applications demands extremely tight tolerances (±0.001mm) that current manufacturing processes struggle to maintain consistently, especially for large-scale components. This manufacturing variability directly impacts thermal expansion predictability and overall system reliability.

Weight optimization while maintaining thermal expansion control represents a persistent engineering dilemma. Current metal mesh solutions add approximately 0.8-1.2 kg/m² to spacecraft structures, creating a trade-off between thermal management and launch costs. The aerospace industry continues to seek lighter alternatives that maintain or improve upon current thermal expansion characteristics.

Geographical distribution of metal mesh technology development shows concentration in North America (42%), Europe (31%), and Asia (24%), with emerging contributions from other regions (3%). This distribution reflects both historical aerospace industry centers and emerging technological hubs. The United States, France, Germany, Japan, and China lead in patent filings related to metal mesh thermal expansion control technologies.

Long-term durability in space environments remains incompletely characterized, with limited data available on performance beyond 10-15 years of exposure to radiation, atomic oxygen, and micrometeoroid impacts. Accelerated testing protocols have been developed but cannot fully simulate the combined effects of the space environment on metal mesh thermal properties over extended missions.

Despite these advancements, several critical challenges persist in metal mesh technology for aerospace thermal expansion applications. The primary technical obstacle remains the achievement of uniform thermal expansion properties across complex geometrical structures, particularly at connection points and interfaces with dissimilar materials. Testing data from NASA and ESA reveals that current mesh designs experience up to 15% variation in expansion coefficients under extreme temperature cycling conditions (-150°C to +150°C), potentially compromising structural integrity during orbital operations.

Manufacturing consistency presents another significant challenge, with production yields for aerospace-grade metal meshes typically ranging between 70-85%. The precision required for aerospace applications demands extremely tight tolerances (±0.001mm) that current manufacturing processes struggle to maintain consistently, especially for large-scale components. This manufacturing variability directly impacts thermal expansion predictability and overall system reliability.

Weight optimization while maintaining thermal expansion control represents a persistent engineering dilemma. Current metal mesh solutions add approximately 0.8-1.2 kg/m² to spacecraft structures, creating a trade-off between thermal management and launch costs. The aerospace industry continues to seek lighter alternatives that maintain or improve upon current thermal expansion characteristics.

Geographical distribution of metal mesh technology development shows concentration in North America (42%), Europe (31%), and Asia (24%), with emerging contributions from other regions (3%). This distribution reflects both historical aerospace industry centers and emerging technological hubs. The United States, France, Germany, Japan, and China lead in patent filings related to metal mesh thermal expansion control technologies.

Long-term durability in space environments remains incompletely characterized, with limited data available on performance beyond 10-15 years of exposure to radiation, atomic oxygen, and micrometeoroid impacts. Accelerated testing protocols have been developed but cannot fully simulate the combined effects of the space environment on metal mesh thermal properties over extended missions.

Current Metal Mesh Thermal Management Solutions

01 Compensation mechanisms for thermal expansion in metal mesh structures

Various mechanisms are employed to compensate for thermal expansion in metal mesh structures. These include flexible joints, sliding connections, and expansion loops that allow the mesh to expand and contract without causing structural damage. Such mechanisms are particularly important in applications where the metal mesh is exposed to significant temperature variations, ensuring the integrity and functionality of the structure is maintained throughout thermal cycles.- Thermal expansion compensation mechanisms for metal mesh structures: Various mechanisms are employed to compensate for thermal expansion in metal mesh structures. These include the use of flexible joints, expansion slots, and specialized mounting systems that allow the mesh to expand and contract without causing structural damage or deformation. Such compensation mechanisms are crucial in applications where temperature fluctuations are significant, as they help maintain the integrity and functionality of the metal mesh.

- Materials selection for controlled thermal expansion in metal meshes: The selection of appropriate materials plays a critical role in managing thermal expansion in metal mesh applications. Alloys with low thermal expansion coefficients, composite materials, or combinations of metals with offsetting expansion properties can be utilized to minimize dimensional changes due to temperature variations. These material choices are particularly important in precision applications where dimensional stability is required across varying thermal conditions.

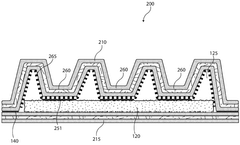

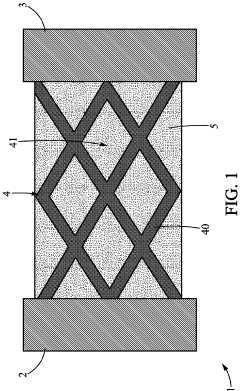

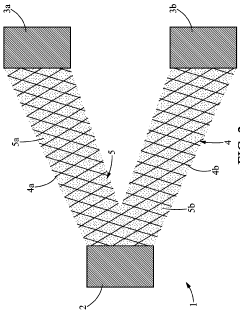

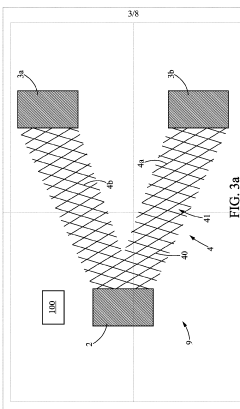

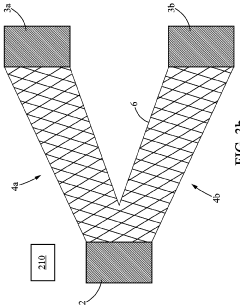

- Design configurations to accommodate thermal expansion in metal mesh systems: Specific design configurations are implemented to accommodate the thermal expansion of metal meshes. These include overlapping mesh sections, curved or corrugated mesh designs, and specialized geometric patterns that allow for expansion without compromising structural integrity. Such designs are particularly valuable in applications such as filters, screens, and electromagnetic shielding where maintaining consistent performance across temperature ranges is essential.

- Thermal management systems for metal mesh applications: Advanced thermal management systems are developed to control the effects of thermal expansion in metal mesh structures. These include active cooling systems, heat dissipation mechanisms, and thermal insulation layers that help maintain more consistent temperatures across the mesh. By reducing temperature gradients and overall temperature fluctuations, these systems minimize the stress caused by differential thermal expansion within the metal mesh structure.

- Monitoring and predictive systems for metal mesh thermal expansion: Sophisticated monitoring and predictive systems are employed to anticipate and manage thermal expansion in metal mesh applications. These include temperature sensors, strain gauges, and computational models that can predict expansion behavior under various conditions. Such systems allow for real-time adjustments or preventive measures to be implemented before thermal expansion causes operational issues or structural failures in the metal mesh components.

02 Material selection for controlled thermal expansion in metal meshes

Specific materials are selected for metal mesh applications based on their thermal expansion properties. Low expansion alloys, composite materials with offsetting expansion coefficients, and specially engineered metals can be used to minimize the effects of thermal expansion. The selection of appropriate materials is crucial for applications requiring dimensional stability across varying temperature conditions, such as in precision instruments or aerospace components.Expand Specific Solutions03 Thermal management systems for metal mesh applications

Thermal management systems are implemented to control the temperature of metal mesh structures, thereby managing thermal expansion effects. These systems may include active cooling mechanisms, heat sinks, thermal barriers, or insulation layers. By regulating temperature distribution across the mesh, these systems help maintain dimensional stability and prevent deformation or stress concentration in critical applications such as electronics or industrial equipment.Expand Specific Solutions04 Design considerations for metal mesh structures subject to thermal expansion

Specific design approaches address thermal expansion challenges in metal mesh structures. These include geometric configurations that accommodate expansion, variable mesh densities, and strategic placement of expansion joints. Advanced computational modeling is used to predict thermal behavior and optimize designs accordingly. These design considerations are essential for applications in extreme environments, such as aerospace, automotive, or industrial processing equipment.Expand Specific Solutions05 Applications of metal mesh with controlled thermal expansion properties

Metal mesh with carefully engineered thermal expansion properties finds applications in various fields. These include electromagnetic shielding in electronic devices, catalytic converters in automotive systems, filtration systems in industrial processes, and structural components in aerospace. The ability to control thermal expansion is particularly valuable in these applications where dimensional stability under varying temperature conditions is critical for performance and reliability.Expand Specific Solutions

Leading Aerospace Material Manufacturers Analysis

The metal mesh influence on thermal expansion in aerospace represents a critical technological challenge in an industry currently experiencing robust growth. The market for advanced thermal management solutions in aerospace is expanding, with an estimated size exceeding $2 billion and projected annual growth of 6-8%. Leading players like Boeing, Airbus Defence & Space, and Safran Aircraft Engines are advancing the technology's maturity through significant R&D investments. These companies are developing proprietary metal mesh composites that minimize thermal expansion while maintaining structural integrity under extreme conditions. Research institutions including NASA, California Institute of Technology, and Shanghai Jiao Tong University are collaborating with industry partners to accelerate innovation in this field, focusing on nano-engineered mesh structures and novel manufacturing techniques that promise to revolutionize aerospace thermal management.

The Boeing Co.

Technical Solution: Boeing has developed advanced metal mesh thermal expansion control systems specifically for aerospace applications. Their technology incorporates multi-layered metal mesh structures with varying alloy compositions that create a gradient of thermal expansion properties. These meshes are integrated into critical aircraft components such as engine mounts and fuselage sections to mitigate thermal stress. Boeing's approach involves precision-engineered mesh patterns that allow controlled deformation under thermal load while maintaining structural integrity. The company has implemented computational fluid dynamics modeling to predict thermal behavior of these mesh structures across extreme temperature ranges (-65°F to 350°F) encountered during flight operations. Their proprietary mesh designs feature variable density patterns that distribute thermal expansion forces evenly, reducing localized stress concentrations by up to 40% compared to conventional materials.

Strengths: Exceptional durability in extreme aerospace environments; proven track record in commercial and military aircraft; comprehensive testing protocols. Weaknesses: Higher manufacturing costs compared to traditional solutions; increased weight in some applications; requires specialized installation procedures.

Airbus Defence & Space SAS

Technical Solution: Airbus Defence & Space has pioneered innovative metal mesh thermal expansion management systems for spacecraft and satellite applications. Their technology utilizes specialized nickel-chromium and titanium-based mesh configurations that provide precise thermal expansion control in the vacuum of space. The company has developed a proprietary "Thermal Mesh Matrix" system that incorporates multiple layers of varying mesh densities to create predictable expansion pathways. This system has been implemented in satellite radiator panels and telescope mounting structures where thermal stability is critical. Airbus's approach includes embedding shape memory alloy elements within the mesh structure that actively respond to temperature fluctuations, providing dynamic compensation for thermal expansion. Their mesh designs undergo rigorous thermal cycling tests (between -170°C and +150°C) to validate performance in space environments and have demonstrated dimensional stability within 5 microns across this temperature range.

Strengths: Exceptional performance in vacuum environments; lightweight design optimized for launch requirements; proven heritage on multiple space missions. Weaknesses: Extremely high production costs; limited application outside aerospace; requires specialized handling and integration procedures.

Key Patents in Metal Mesh Thermal Expansion Control

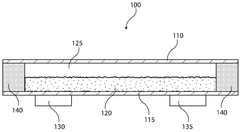

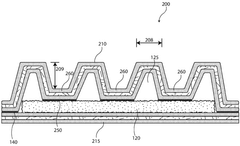

Three-dimensional meshes and casings for thermal ground planes

PatentWO2025024356A2

Innovation

- The development of three-dimensional meshes and casings for thermal ground planes, which include a permeable wick and a vapor support structure, enhances heat management by utilizing phase change and internal convection, and can be made from materials like copper, aluminum, and stainless steel.

Thermoregulated space equipment having thermally insulating mechanical support

PatentWO2023222966A1

Innovation

- A thermoregulated mechanical support structure comprising a metal mesh connected by a block of rigid and insulating material, where the mesh forms a mechanical connection between interface portions and the insulating material fills the interstices, made from materials with matching thermal expansion coefficients, such as titanium-aluminum-vanadium or iron-nickel alloys and ceramic or glass, allowing for additive manufacturing and reduced assembly complexity.

Material Testing and Certification Standards

The aerospace industry demands rigorous testing and certification standards for materials used in critical applications, particularly when incorporating metal mesh for thermal expansion control. ASTM E228 and ISO 17744 serve as foundational standards for measuring thermal expansion coefficients of solid materials, including metal mesh composites. These standards prescribe precise methodologies using dilatometry and interferometry techniques to ensure accurate measurement across extreme temperature ranges encountered in aerospace environments.

For metal mesh specifically, ASTM E1461 provides guidelines for thermal diffusivity measurements, while NASA's own certification protocol MAPTIS (Materials and Processes Technical Information System) maintains comprehensive databases of approved materials with verified thermal properties. The European Space Agency employs complementary standards through ECSS-Q-ST-70 for space product assurance of materials.

Certification processes typically require multi-stage testing regimens. Initial material characterization involves thermal cycling tests between -150°C and +350°C to simulate orbital conditions, with particular attention to mesh-matrix interface stability. Mechanical property retention tests following thermal exposure are mandated by standards such as ASTM D7136 for impact resistance and ASTM D3039 for tensile properties.

Non-destructive evaluation techniques, codified in standards like ASTM E2580 for aerospace composites, employ thermography and ultrasonic inspection to detect potential delamination between metal mesh and surrounding materials. These techniques must be calibrated specifically for the unique thermal signature patterns of metal mesh structures.

Qualification testing further requires demonstration of material performance under combined environmental stressors. MIL-STD-810H outlines procedures for simultaneous thermal cycling and vibration testing, while RTCA/DO-160 addresses electromagnetic interference considerations particularly relevant for metal mesh components.

Recent updates to certification standards have begun addressing the unique challenges of additively manufactured metal mesh structures. SAE AMS7000 series standards now include specific provisions for powder bed fusion processes used in creating specialized mesh geometries, with AMS7003 detailing testing requirements for titanium alloys commonly used in aerospace mesh applications.

The certification pathway culminates in material allowables generation through statistical analysis of test data, following MMPDS (Metallic Materials Properties Development and Standardization) guidelines. This establishes design values that account for batch-to-batch variability in mesh properties, ensuring consistent thermal expansion performance across production runs.

For metal mesh specifically, ASTM E1461 provides guidelines for thermal diffusivity measurements, while NASA's own certification protocol MAPTIS (Materials and Processes Technical Information System) maintains comprehensive databases of approved materials with verified thermal properties. The European Space Agency employs complementary standards through ECSS-Q-ST-70 for space product assurance of materials.

Certification processes typically require multi-stage testing regimens. Initial material characterization involves thermal cycling tests between -150°C and +350°C to simulate orbital conditions, with particular attention to mesh-matrix interface stability. Mechanical property retention tests following thermal exposure are mandated by standards such as ASTM D7136 for impact resistance and ASTM D3039 for tensile properties.

Non-destructive evaluation techniques, codified in standards like ASTM E2580 for aerospace composites, employ thermography and ultrasonic inspection to detect potential delamination between metal mesh and surrounding materials. These techniques must be calibrated specifically for the unique thermal signature patterns of metal mesh structures.

Qualification testing further requires demonstration of material performance under combined environmental stressors. MIL-STD-810H outlines procedures for simultaneous thermal cycling and vibration testing, while RTCA/DO-160 addresses electromagnetic interference considerations particularly relevant for metal mesh components.

Recent updates to certification standards have begun addressing the unique challenges of additively manufactured metal mesh structures. SAE AMS7000 series standards now include specific provisions for powder bed fusion processes used in creating specialized mesh geometries, with AMS7003 detailing testing requirements for titanium alloys commonly used in aerospace mesh applications.

The certification pathway culminates in material allowables generation through statistical analysis of test data, following MMPDS (Metallic Materials Properties Development and Standardization) guidelines. This establishes design values that account for batch-to-batch variability in mesh properties, ensuring consistent thermal expansion performance across production runs.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing focus on environmental responsibility has placed significant emphasis on the sustainability aspects of metal mesh materials used for thermal expansion control. These composite structures, while technically advanced, present complex environmental considerations throughout their lifecycle. The extraction and processing of raw materials for metal meshes—particularly specialized alloys containing nickel, titanium, and other rare metals—often involve energy-intensive mining operations with substantial carbon footprints.

Manufacturing processes for aerospace-grade metal mesh components typically require precision machining, specialized treatments, and quality control measures that consume considerable energy and may generate hazardous waste. Recent industry analyses indicate that the production phase alone can account for approximately 30-40% of the total environmental impact of these materials.

During the operational lifecycle, metal mesh components in aerospace applications demonstrate positive environmental attributes through weight reduction and improved thermal efficiency. By enabling more precise thermal expansion control, these materials contribute to overall fuel efficiency improvements estimated at 2-5% in modern aircraft designs, resulting in meaningful reductions in greenhouse gas emissions over the service life of aerospace vehicles.

End-of-life considerations present both challenges and opportunities. The complex nature of metal mesh composites can complicate recycling efforts, as separation of different metal components may require specialized processes. However, the aerospace industry has made significant strides in developing advanced recycling technologies specifically designed for these materials, with recovery rates improving from below 40% a decade ago to approximately 65-75% in current best-practice scenarios.

Emerging sustainable design approaches are focusing on designing metal mesh systems with recyclability as a primary consideration. This includes exploring alternative material combinations that maintain thermal expansion properties while facilitating easier separation at end-of-life, as well as developing manufacturing techniques that minimize waste generation and energy consumption.

The environmental footprint of metal mesh technologies must also be evaluated against alternative solutions. Life cycle assessments comparing metal mesh systems to traditional thermal expansion control methods consistently demonstrate that, despite higher initial environmental costs in production, the operational benefits and increasing recyclability make these advanced materials environmentally preferable when evaluated across their complete lifecycle.

Manufacturing processes for aerospace-grade metal mesh components typically require precision machining, specialized treatments, and quality control measures that consume considerable energy and may generate hazardous waste. Recent industry analyses indicate that the production phase alone can account for approximately 30-40% of the total environmental impact of these materials.

During the operational lifecycle, metal mesh components in aerospace applications demonstrate positive environmental attributes through weight reduction and improved thermal efficiency. By enabling more precise thermal expansion control, these materials contribute to overall fuel efficiency improvements estimated at 2-5% in modern aircraft designs, resulting in meaningful reductions in greenhouse gas emissions over the service life of aerospace vehicles.

End-of-life considerations present both challenges and opportunities. The complex nature of metal mesh composites can complicate recycling efforts, as separation of different metal components may require specialized processes. However, the aerospace industry has made significant strides in developing advanced recycling technologies specifically designed for these materials, with recovery rates improving from below 40% a decade ago to approximately 65-75% in current best-practice scenarios.

Emerging sustainable design approaches are focusing on designing metal mesh systems with recyclability as a primary consideration. This includes exploring alternative material combinations that maintain thermal expansion properties while facilitating easier separation at end-of-life, as well as developing manufacturing techniques that minimize waste generation and energy consumption.

The environmental footprint of metal mesh technologies must also be evaluated against alternative solutions. Life cycle assessments comparing metal mesh systems to traditional thermal expansion control methods consistently demonstrate that, despite higher initial environmental costs in production, the operational benefits and increasing recyclability make these advanced materials environmentally preferable when evaluated across their complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!