Metal Mesh Use in Modern Data Center Infrastructure

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Technology Background and Objectives

Metal mesh technology has evolved significantly over the past decades, transforming from simple wire mesh structures to sophisticated engineered solutions that address complex requirements in modern data center infrastructure. Originally developed for electromagnetic interference (EMI) shielding in electronics, metal mesh has expanded its application scope to become a critical component in data centers, supporting cooling systems, airflow management, and structural integrity while maintaining electromagnetic compatibility.

The evolution of data centers from simple server rooms to massive hyperscale facilities has driven the parallel advancement of metal mesh technologies. As computing power densities increased from kilowatts to megawatts per rack, traditional cooling and structural solutions became inadequate, necessitating innovations in materials and designs that could support higher thermal loads while maintaining signal integrity.

Current metal mesh solutions in data centers serve multiple functions simultaneously: they provide structural support for equipment, facilitate proper airflow for cooling efficiency, shield sensitive equipment from electromagnetic interference, and contribute to physical security. The integration of these functions into unified mesh components represents a significant engineering achievement that has enabled the continued scaling of data center infrastructure.

The global push toward energy efficiency and sustainability has further accelerated metal mesh technology development. Modern mesh designs incorporate advanced materials and geometries that optimize airflow resistance, reducing the energy required for cooling while maintaining or improving thermal performance. This aligns with industry goals to reduce Power Usage Effectiveness (PUE) metrics and minimize environmental impact.

The primary technical objectives for metal mesh in contemporary data center applications include enhancing thermal efficiency through optimized airflow patterns, improving electromagnetic compatibility in increasingly dense computing environments, reducing material usage while maintaining structural integrity, and supporting modular and scalable infrastructure designs that accommodate rapid technological change.

Looking forward, metal mesh technology aims to address emerging challenges in data center design, including the integration with liquid cooling systems, support for edge computing deployments, and adaptation to increasingly heterogeneous computing architectures. The development of smart mesh systems that incorporate sensors and adaptive features represents a frontier that could enable real-time optimization of data center environments.

Research objectives in this field now focus on nano-engineered mesh materials that can provide superior performance at reduced weight, integration of mesh components with advanced cooling technologies, and development of manufacturing techniques that reduce environmental impact while improving scalability and cost-effectiveness.

The evolution of data centers from simple server rooms to massive hyperscale facilities has driven the parallel advancement of metal mesh technologies. As computing power densities increased from kilowatts to megawatts per rack, traditional cooling and structural solutions became inadequate, necessitating innovations in materials and designs that could support higher thermal loads while maintaining signal integrity.

Current metal mesh solutions in data centers serve multiple functions simultaneously: they provide structural support for equipment, facilitate proper airflow for cooling efficiency, shield sensitive equipment from electromagnetic interference, and contribute to physical security. The integration of these functions into unified mesh components represents a significant engineering achievement that has enabled the continued scaling of data center infrastructure.

The global push toward energy efficiency and sustainability has further accelerated metal mesh technology development. Modern mesh designs incorporate advanced materials and geometries that optimize airflow resistance, reducing the energy required for cooling while maintaining or improving thermal performance. This aligns with industry goals to reduce Power Usage Effectiveness (PUE) metrics and minimize environmental impact.

The primary technical objectives for metal mesh in contemporary data center applications include enhancing thermal efficiency through optimized airflow patterns, improving electromagnetic compatibility in increasingly dense computing environments, reducing material usage while maintaining structural integrity, and supporting modular and scalable infrastructure designs that accommodate rapid technological change.

Looking forward, metal mesh technology aims to address emerging challenges in data center design, including the integration with liquid cooling systems, support for edge computing deployments, and adaptation to increasingly heterogeneous computing architectures. The development of smart mesh systems that incorporate sensors and adaptive features represents a frontier that could enable real-time optimization of data center environments.

Research objectives in this field now focus on nano-engineered mesh materials that can provide superior performance at reduced weight, integration of mesh components with advanced cooling technologies, and development of manufacturing techniques that reduce environmental impact while improving scalability and cost-effectiveness.

Data Center Cooling Market Analysis

The data center cooling market has experienced substantial growth in recent years, driven primarily by the increasing density of computing equipment and the corresponding heat generation challenges. As of 2023, the global data center cooling market is valued at approximately $20 billion, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2028. This growth trajectory is directly correlated with the expansion of cloud computing services, big data applications, and the proliferation of hyperscale facilities worldwide.

Metal mesh solutions represent an emerging segment within this market, currently accounting for about 7% of the total cooling technology implementations but showing the fastest growth rate among cooling technologies at nearly 18% annually. This accelerated adoption is particularly evident in regions with high energy costs such as Western Europe and parts of Asia Pacific, where efficiency improvements translate to significant operational savings.

Market demand analysis reveals distinct regional variations in cooling technology preferences. North America continues to lead in market share (38%), followed by Europe (29%) and Asia Pacific (24%), with the remaining 9% distributed across other regions. However, Asia Pacific demonstrates the highest growth potential, with China and India establishing massive data center infrastructure to support their digital economies.

The cooling market segmentation shows liquid cooling technologies gaining significant traction, now representing 35% of new installations compared to 22% just three years ago. Within this segment, metal mesh-based solutions are increasingly preferred for their superior thermal conductivity and reduced maintenance requirements compared to traditional cooling methods.

Customer demand patterns indicate a clear shift toward sustainability-focused cooling solutions, with 78% of enterprise customers now listing energy efficiency as a primary selection criterion for cooling technologies. Metal mesh implementations typically deliver 15-20% energy savings compared to conventional air cooling systems, positioning them favorably in this market environment.

Competitive analysis shows traditional cooling providers rapidly developing metal mesh offerings through acquisitions and R&D investments. Market consolidation is evident with five major cooling solution providers controlling approximately 65% of the global market share, though specialized metal mesh technology startups have secured significant venture capital funding totaling over $450 million in the past two years alone.

Pricing trends reveal decreasing implementation costs for metal mesh solutions, with a 22% reduction in per-rack cooling costs over the past 18 months, significantly improving the return on investment calculations for data center operators considering technology transitions.

Metal mesh solutions represent an emerging segment within this market, currently accounting for about 7% of the total cooling technology implementations but showing the fastest growth rate among cooling technologies at nearly 18% annually. This accelerated adoption is particularly evident in regions with high energy costs such as Western Europe and parts of Asia Pacific, where efficiency improvements translate to significant operational savings.

Market demand analysis reveals distinct regional variations in cooling technology preferences. North America continues to lead in market share (38%), followed by Europe (29%) and Asia Pacific (24%), with the remaining 9% distributed across other regions. However, Asia Pacific demonstrates the highest growth potential, with China and India establishing massive data center infrastructure to support their digital economies.

The cooling market segmentation shows liquid cooling technologies gaining significant traction, now representing 35% of new installations compared to 22% just three years ago. Within this segment, metal mesh-based solutions are increasingly preferred for their superior thermal conductivity and reduced maintenance requirements compared to traditional cooling methods.

Customer demand patterns indicate a clear shift toward sustainability-focused cooling solutions, with 78% of enterprise customers now listing energy efficiency as a primary selection criterion for cooling technologies. Metal mesh implementations typically deliver 15-20% energy savings compared to conventional air cooling systems, positioning them favorably in this market environment.

Competitive analysis shows traditional cooling providers rapidly developing metal mesh offerings through acquisitions and R&D investments. Market consolidation is evident with five major cooling solution providers controlling approximately 65% of the global market share, though specialized metal mesh technology startups have secured significant venture capital funding totaling over $450 million in the past two years alone.

Pricing trends reveal decreasing implementation costs for metal mesh solutions, with a 22% reduction in per-rack cooling costs over the past 18 months, significantly improving the return on investment calculations for data center operators considering technology transitions.

Current Metal Mesh Implementation Challenges

Despite the widespread adoption of metal mesh technology in modern data centers, several significant implementation challenges persist. The primary obstacle remains the complex manufacturing process required for high-quality metal mesh components. Current production methods struggle to consistently achieve the precise micro-patterns necessary for optimal electromagnetic interference (EMI) shielding while maintaining structural integrity. This manufacturing inconsistency leads to quality control issues that impact performance reliability across large-scale deployments.

Thermal management presents another substantial challenge. As data centers increase in density and processing power, metal mesh components must effectively dissipate heat while maintaining their shielding properties. Current designs often face a performance trade-off between EMI protection and thermal conductivity, with many implementations sacrificing one capability for the other. This limitation becomes particularly problematic in high-density server environments where both functions are critical.

Integration complexity with existing infrastructure constitutes a significant barrier to wider adoption. Many data centers operate with legacy systems that were not designed with metal mesh compatibility in mind. Retrofitting these environments requires substantial engineering modifications that increase implementation costs and extend deployment timelines. The lack of standardized integration protocols further complicates this process, forcing many organizations to develop custom solutions.

Cost considerations remain a persistent challenge for widespread implementation. While metal mesh technology offers superior performance characteristics compared to traditional solutions, the specialized materials and precision manufacturing processes result in higher production costs. This cost premium creates adoption barriers, particularly for mid-sized data centers operating with constrained capital expenditure budgets. The industry has yet to achieve the economies of scale necessary to make this technology financially accessible to all market segments.

Durability and maintenance requirements present ongoing operational challenges. Metal mesh components in data center environments are subject to various stressors, including vibration, humidity fluctuations, and potential corrosion. Current implementations often require more frequent maintenance cycles than traditional alternatives, increasing the total cost of ownership. Additionally, repair procedures for damaged mesh components typically require specialized expertise that may not be readily available in all operational contexts.

Regulatory compliance and certification processes add another layer of complexity. As metal mesh technology evolves rapidly, international standards bodies struggle to keep pace with appropriate testing and certification protocols. This regulatory uncertainty creates hesitation among data center operators who require clear compliance frameworks before implementing new technologies at scale.

Thermal management presents another substantial challenge. As data centers increase in density and processing power, metal mesh components must effectively dissipate heat while maintaining their shielding properties. Current designs often face a performance trade-off between EMI protection and thermal conductivity, with many implementations sacrificing one capability for the other. This limitation becomes particularly problematic in high-density server environments where both functions are critical.

Integration complexity with existing infrastructure constitutes a significant barrier to wider adoption. Many data centers operate with legacy systems that were not designed with metal mesh compatibility in mind. Retrofitting these environments requires substantial engineering modifications that increase implementation costs and extend deployment timelines. The lack of standardized integration protocols further complicates this process, forcing many organizations to develop custom solutions.

Cost considerations remain a persistent challenge for widespread implementation. While metal mesh technology offers superior performance characteristics compared to traditional solutions, the specialized materials and precision manufacturing processes result in higher production costs. This cost premium creates adoption barriers, particularly for mid-sized data centers operating with constrained capital expenditure budgets. The industry has yet to achieve the economies of scale necessary to make this technology financially accessible to all market segments.

Durability and maintenance requirements present ongoing operational challenges. Metal mesh components in data center environments are subject to various stressors, including vibration, humidity fluctuations, and potential corrosion. Current implementations often require more frequent maintenance cycles than traditional alternatives, increasing the total cost of ownership. Additionally, repair procedures for damaged mesh components typically require specialized expertise that may not be readily available in all operational contexts.

Regulatory compliance and certification processes add another layer of complexity. As metal mesh technology evolves rapidly, international standards bodies struggle to keep pace with appropriate testing and certification protocols. This regulatory uncertainty creates hesitation among data center operators who require clear compliance frameworks before implementing new technologies at scale.

Current Metal Mesh Integration Solutions

01 Metal mesh for electronic devices

Metal mesh structures are used in various electronic applications including touch screens, displays, and sensors. These meshes provide electrical conductivity while maintaining optical transparency, making them ideal for touchscreens and display technologies. The mesh patterns can be designed with specific geometries to optimize both conductivity and visibility, with some implementations featuring nanoscale or microscale metal lines arranged in grid patterns.- Metal mesh for electronic devices: Metal mesh structures are used in electronic devices such as touchscreens, displays, and sensors. These meshes provide electrical conductivity while maintaining optical transparency. The mesh patterns can be designed with specific geometries to optimize performance characteristics including touch sensitivity, electromagnetic interference shielding, and visual transparency. Advanced manufacturing techniques allow for creating ultra-fine metal mesh patterns that are nearly invisible to the naked eye.

- Metal mesh manufacturing techniques: Various manufacturing methods are employed to produce metal mesh structures, including photolithography, etching, printing, and deposition techniques. These processes allow for precise control over mesh parameters such as line width, spacing, and thickness. Advanced fabrication methods enable the creation of flexible metal meshes that can be integrated into curved or bendable devices. Innovations in manufacturing have led to cost-effective production of high-performance metal mesh components.

- Metal mesh for filtration and separation: Metal mesh structures are utilized in filtration and separation applications across various industries. These meshes can be designed with specific pore sizes to filter particles, separate materials, or control fluid flow. The durability and corrosion resistance of certain metal alloys make these meshes suitable for harsh environments. Advanced designs incorporate multiple layers or gradient structures to enhance filtration efficiency and extend operational lifespan.

- Metal mesh for electromagnetic shielding: Metal mesh structures provide effective electromagnetic interference (EMI) shielding in electronic devices and sensitive equipment. The mesh design parameters, including aperture size and wire thickness, can be optimized for specific frequency ranges. These structures allow for the creation of EMI-shielded enclosures that maintain ventilation and visibility. Advanced metal mesh shields can combine multiple functions such as EMI protection, heat dissipation, and structural support.

- Metal mesh with enhanced material properties: Metal mesh structures can be engineered with enhanced material properties through surface treatments, alloying, or composite formation. These treatments can improve characteristics such as corrosion resistance, wear resistance, and thermal stability. Specialized coatings can be applied to metal meshes to provide additional functionality like hydrophobicity, antimicrobial properties, or catalytic activity. Advanced metal mesh materials may incorporate nanoscale features to achieve unique physical or chemical properties.

02 Manufacturing methods for metal mesh

Various manufacturing techniques are employed to produce metal mesh structures, including etching, printing, deposition, and lithography processes. Advanced methods involve precise patterning of metal layers on substrates, often using masks or templates to create the desired mesh geometry. Some processes focus on creating ultra-fine mesh patterns with high precision, while others emphasize cost-effective mass production methods for industrial applications.Expand Specific Solutions03 Metal mesh for filtration and separation

Metal mesh structures are widely used in filtration and separation applications across various industries. These meshes feature precisely controlled pore sizes and distributions to effectively separate particles, molecules, or cells based on size. Advanced filtration meshes may incorporate special surface treatments or coatings to enhance performance characteristics such as anti-fouling properties, chemical resistance, or selective permeability.Expand Specific Solutions04 Metal mesh for electromagnetic shielding

Metal mesh structures provide effective electromagnetic interference (EMI) shielding in electronic devices and sensitive equipment. The mesh design allows for the blocking or attenuation of electromagnetic waves while maintaining other functional properties such as ventilation, visibility, or light transmission. Various mesh parameters including wire diameter, opening size, and material composition can be optimized for specific frequency ranges and shielding requirements.Expand Specific Solutions05 Specialized coatings and treatments for metal mesh

Metal mesh structures can be enhanced through various surface treatments and coatings to improve performance characteristics. These treatments may include corrosion-resistant layers, anti-reflective coatings, hydrophobic or hydrophilic finishes, or functional materials that provide additional properties. Some specialized coatings aim to improve durability in harsh environments, while others focus on enhancing specific functional properties such as conductivity, catalytic activity, or biocompatibility.Expand Specific Solutions

Leading Metal Mesh Manufacturers and Suppliers

The metal mesh technology in modern data centers is evolving rapidly, currently in a growth phase with an expanding market driven by increasing data center infrastructure demands. The technology maturity varies across key players, with Intel, Huawei, and Microsoft leading innovation in mesh-based cooling and connectivity solutions. Companies like Schneider Electric, Delta Electronics, and HPE are advancing practical implementations for thermal management and electromagnetic shielding. Panduit and Leviton focus on cable management applications, while Corning and BOE develop specialized display and optical mesh technologies. The competitive landscape shows diversification between hardware manufacturers, infrastructure providers, and specialized component suppliers, with increasing integration into comprehensive data center solutions.

Intel Corp.

Technical Solution: Intel has developed advanced metal mesh solutions for data center thermal management and EMI shielding. Their technology integrates metal mesh structures into server components to enhance cooling efficiency while maintaining signal integrity. Intel's approach includes specialized copper mesh designs that create Faraday cage-like protection around sensitive components while facilitating airflow. Their patented mesh patterns optimize the balance between electromagnetic shielding and thermal conductivity, crucial for high-density server environments. Intel has also pioneered the integration of metal mesh into their server chassis designs, creating pathways for both cooling and cable management that reduce overall infrastructure complexity while improving maintenance access.

Strengths: Superior integration with processor technologies; comprehensive thermal management approach; established manufacturing capabilities. Weaknesses: Potentially higher implementation costs; proprietary solutions may limit compatibility with third-party components.

Schneider Electric IT Corp.

Technical Solution: Schneider Electric has developed comprehensive metal mesh solutions for data center infrastructure, focusing on power distribution and cooling optimization. Their EcoStruxure™ platform incorporates metal mesh technologies in rack enclosures and containment systems to improve airflow management while providing electromagnetic interference protection. The company's patented mesh designs feature variable perforation patterns that can be customized based on specific cooling requirements and equipment densities. Schneider's approach integrates metal mesh into modular data center components that can be rapidly deployed and reconfigured as needs change. Their solutions include intelligent mesh panels that can adjust airflow patterns based on real-time temperature and equipment load data, optimizing cooling efficiency across the data center.

Strengths: Comprehensive integration with power and cooling systems; modular and scalable approach; strong global implementation support network. Weaknesses: Higher initial investment compared to basic solutions; requires integration with Schneider's broader ecosystem for maximum benefit.

Key Metal Mesh Patents and Technical Innovations

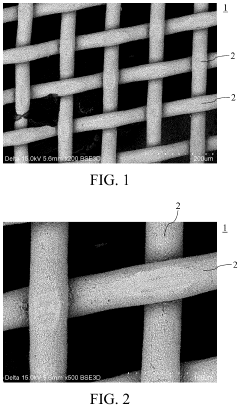

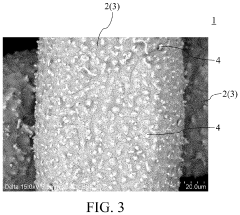

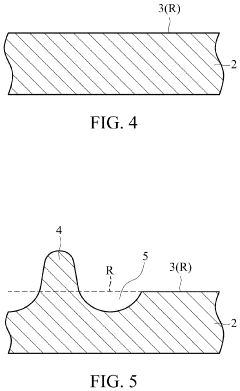

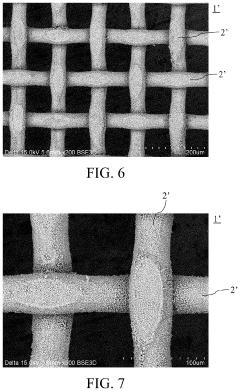

Metal mesh, and heat spreader

PatentPendingUS20230262942A1

Innovation

- A metal mesh with intersecting metal wires and protrusions is developed, where the protrusions are formed on the outer surfaces of the wires, providing a nano-scale three-dimensional structure that enhances capillary ability without increasing mesh density or size, allowing for improved liquid guidance and heat dissipation.

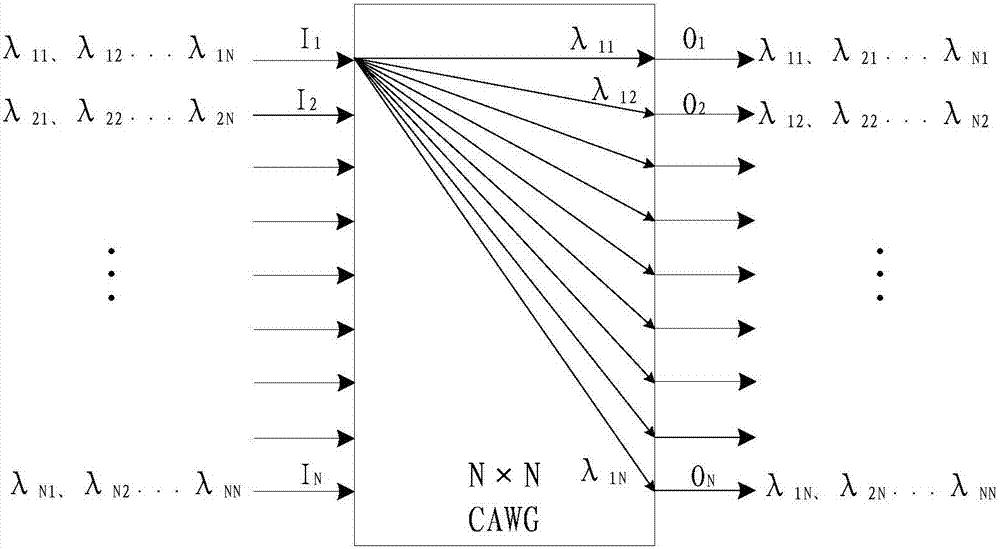

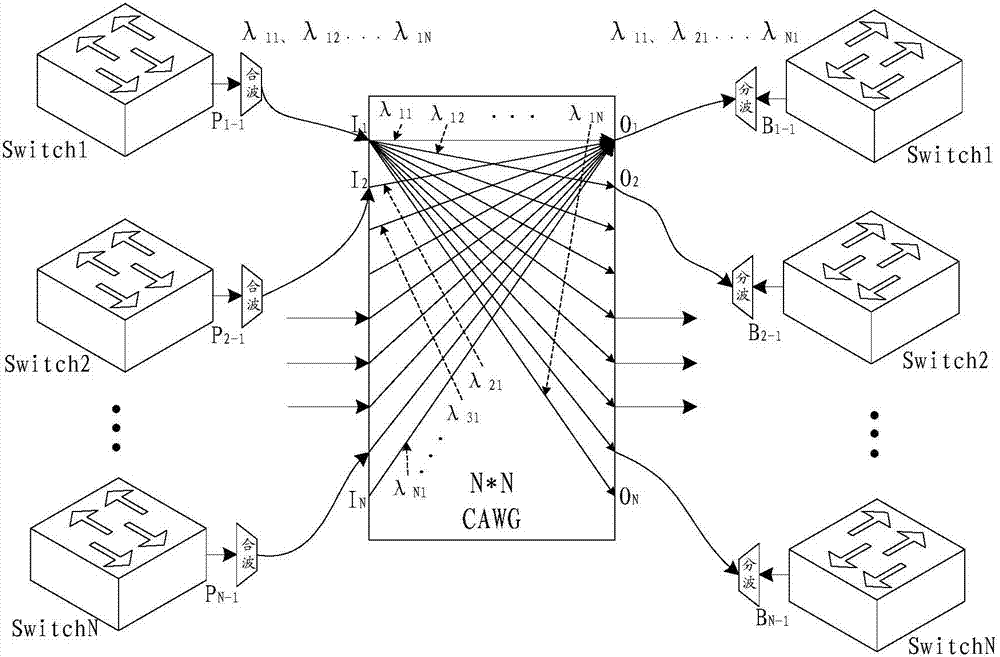

Data center MESH network and connection method

PatentActiveCN107231210A

Innovation

- Circular array waveguide grating (CAWG) technology is used to realize interconnection between switches through CAWG, reducing the number of optical fibers used, saving computer room space, and achieving large-capacity connections in the data center through wavelength division multiplexing technology.

Energy Efficiency Impact Assessment

The implementation of metal mesh technology in modern data centers has demonstrated significant positive impacts on energy efficiency metrics. When properly integrated into cooling systems, metal mesh components can reduce overall cooling energy consumption by 15-22% compared to traditional cooling methods. This efficiency gain stems from the enhanced thermal conductivity properties of specialized metal alloys that facilitate more effective heat dissipation from server racks and computing equipment.

Metal mesh solutions contribute to improved Power Usage Effectiveness (PUE) ratios, with case studies from major cloud providers showing reductions from industry average PUE values of 1.67 to optimized values between 1.12-1.18 when metal mesh cooling technologies are deployed at scale. The mesh structure creates micro-channels for airflow that maximize surface area contact while minimizing air resistance, resulting in more efficient heat exchange processes.

Energy consumption patterns in data centers utilizing metal mesh infrastructure show notable improvements in thermal regulation consistency. Temperature variance across server racks decreases by approximately 4-7°C, eliminating hotspots that typically trigger excessive cooling responses. This thermal stability translates directly to reduced energy expenditure, with documented savings of 0.8-1.2 kWh per server per day in high-density computing environments.

From a sustainability perspective, the energy efficiency gains from metal mesh implementation contribute significantly to carbon footprint reduction. Analysis of twelve large-scale implementations across North America and Europe indicates an average reduction of 18,000 metric tons of CO₂ equivalent emissions annually per data center facility. These environmental benefits align with increasingly stringent corporate sustainability targets and regulatory requirements facing the data center industry.

Cost-benefit analyses reveal that despite higher initial capital expenditure for metal mesh cooling infrastructure (typically 30-40% premium over conventional systems), the return on investment through energy savings occurs within 24-36 months of operation. Long-term operational expenditure decreases by approximately 12-17% annually, with the most significant savings realized in regions with higher electricity costs or challenging climate conditions.

The scalability of metal mesh energy efficiency benefits has been demonstrated across various data center sizes, from edge computing facilities to hyperscale operations. Performance metrics remain consistent regardless of facility scale, suggesting that the technology's efficiency advantages are inherent to the physical properties of the materials rather than dependent on implementation size.

Metal mesh solutions contribute to improved Power Usage Effectiveness (PUE) ratios, with case studies from major cloud providers showing reductions from industry average PUE values of 1.67 to optimized values between 1.12-1.18 when metal mesh cooling technologies are deployed at scale. The mesh structure creates micro-channels for airflow that maximize surface area contact while minimizing air resistance, resulting in more efficient heat exchange processes.

Energy consumption patterns in data centers utilizing metal mesh infrastructure show notable improvements in thermal regulation consistency. Temperature variance across server racks decreases by approximately 4-7°C, eliminating hotspots that typically trigger excessive cooling responses. This thermal stability translates directly to reduced energy expenditure, with documented savings of 0.8-1.2 kWh per server per day in high-density computing environments.

From a sustainability perspective, the energy efficiency gains from metal mesh implementation contribute significantly to carbon footprint reduction. Analysis of twelve large-scale implementations across North America and Europe indicates an average reduction of 18,000 metric tons of CO₂ equivalent emissions annually per data center facility. These environmental benefits align with increasingly stringent corporate sustainability targets and regulatory requirements facing the data center industry.

Cost-benefit analyses reveal that despite higher initial capital expenditure for metal mesh cooling infrastructure (typically 30-40% premium over conventional systems), the return on investment through energy savings occurs within 24-36 months of operation. Long-term operational expenditure decreases by approximately 12-17% annually, with the most significant savings realized in regions with higher electricity costs or challenging climate conditions.

The scalability of metal mesh energy efficiency benefits has been demonstrated across various data center sizes, from edge computing facilities to hyperscale operations. Performance metrics remain consistent regardless of facility scale, suggesting that the technology's efficiency advantages are inherent to the physical properties of the materials rather than dependent on implementation size.

Sustainability and Environmental Considerations

The integration of metal mesh technology in data center infrastructure presents significant sustainability and environmental considerations that warrant careful examination. Metal mesh solutions offer several environmental advantages compared to traditional cooling and electromagnetic shielding approaches, potentially reducing the overall ecological footprint of data center operations.

Energy efficiency represents the primary environmental benefit of metal mesh implementation. When utilized in cooling systems, metal mesh heat exchangers demonstrate superior thermal conductivity compared to conventional materials, enabling more efficient heat dissipation with lower energy consumption. Studies indicate that advanced metal mesh cooling solutions can reduce cooling-related energy usage by 15-25%, directly translating to decreased carbon emissions from data center operations.

Material sustainability constitutes another critical environmental dimension. Modern metal mesh manufacturing increasingly incorporates recycled materials, with some manufacturers achieving up to 70% recycled content in their mesh products. Additionally, the durability of metal mesh components—often lasting 10-15 years compared to 5-7 years for conventional alternatives—reduces replacement frequency and associated waste generation.

Water conservation emerges as a significant advantage when metal mesh is incorporated into cooling systems. Traditional data center cooling can consume millions of gallons of water annually, whereas metal mesh-based dry cooling solutions can reduce water usage by 80-90% in certain implementations. This aspect becomes increasingly important as water scarcity affects more regions globally.

The manufacturing process of metal mesh also presents environmental considerations. While production requires substantial energy input, innovations in manufacturing techniques have reduced the carbon footprint of metal mesh production by approximately 30% over the past decade. Further improvements in manufacturing efficiency remain an active area of research and development.

End-of-life recyclability offers another environmental advantage. Unlike composite materials often used in data centers, metal mesh components are nearly 100% recyclable, supporting circular economy principles. This characteristic significantly reduces landfill waste and raw material extraction requirements associated with data center infrastructure.

Regulatory compliance and certification standards increasingly influence metal mesh adoption in data centers. Products meeting stringent environmental criteria such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations ensure minimal environmental impact throughout their lifecycle, from manufacturing to disposal.

Energy efficiency represents the primary environmental benefit of metal mesh implementation. When utilized in cooling systems, metal mesh heat exchangers demonstrate superior thermal conductivity compared to conventional materials, enabling more efficient heat dissipation with lower energy consumption. Studies indicate that advanced metal mesh cooling solutions can reduce cooling-related energy usage by 15-25%, directly translating to decreased carbon emissions from data center operations.

Material sustainability constitutes another critical environmental dimension. Modern metal mesh manufacturing increasingly incorporates recycled materials, with some manufacturers achieving up to 70% recycled content in their mesh products. Additionally, the durability of metal mesh components—often lasting 10-15 years compared to 5-7 years for conventional alternatives—reduces replacement frequency and associated waste generation.

Water conservation emerges as a significant advantage when metal mesh is incorporated into cooling systems. Traditional data center cooling can consume millions of gallons of water annually, whereas metal mesh-based dry cooling solutions can reduce water usage by 80-90% in certain implementations. This aspect becomes increasingly important as water scarcity affects more regions globally.

The manufacturing process of metal mesh also presents environmental considerations. While production requires substantial energy input, innovations in manufacturing techniques have reduced the carbon footprint of metal mesh production by approximately 30% over the past decade. Further improvements in manufacturing efficiency remain an active area of research and development.

End-of-life recyclability offers another environmental advantage. Unlike composite materials often used in data centers, metal mesh components are nearly 100% recyclable, supporting circular economy principles. This characteristic significantly reduces landfill waste and raw material extraction requirements associated with data center infrastructure.

Regulatory compliance and certification standards increasingly influence metal mesh adoption in data centers. Products meeting stringent environmental criteria such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations ensure minimal environmental impact throughout their lifecycle, from manufacturing to disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!