Evaluating Compliance with Metal Mesh Safety Standards

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Safety Standards Background and Objectives

Metal mesh safety standards have evolved significantly over the past several decades, driven by increasing industrial applications and growing awareness of workplace safety requirements. Initially developed in the mid-20th century for basic industrial screening applications, these standards have progressively expanded to encompass a wide range of applications including architectural elements, industrial machinery guards, security barriers, and electronic device shielding. The evolution has been marked by a shift from purely mechanical considerations to a more comprehensive approach that addresses multiple safety dimensions.

The technical landscape of metal mesh safety has been shaped by several key milestones, including the establishment of the first international standards in the 1970s, the integration of ergonomic considerations in the 1990s, and the recent incorporation of advanced material science principles. Current technical trends indicate a movement toward performance-based standards rather than prescriptive requirements, allowing for greater innovation while maintaining safety outcomes.

The primary objective of metal mesh safety standards evaluation is to ensure that products and installations provide adequate protection against identified hazards while maintaining functionality. This involves assessing compliance with dimensional specifications, structural integrity requirements, durability under environmental stressors, and performance under impact or load conditions. Additionally, modern evaluation frameworks increasingly consider human factors, such as visibility through barriers and ergonomic interaction with protected equipment.

Regulatory frameworks governing metal mesh safety vary significantly across regions, with notable differences between European EN standards, North American ASTM and ANSI requirements, and Asian regulatory approaches. These variations create challenges for global manufacturers and necessitate sophisticated compliance strategies. The harmonization of these standards represents an ongoing technical challenge and opportunity.

Recent technological advancements have introduced new considerations into metal mesh safety evaluation, including the integration of smart materials, embedded sensors for real-time monitoring, and advanced coating technologies that enhance durability and performance. These innovations are pushing traditional standards to evolve and accommodate emerging capabilities while ensuring that fundamental safety principles remain intact.

The evaluation of compliance with metal mesh safety standards ultimately aims to balance multiple competing factors: maximizing protection, ensuring visibility and accessibility where needed, maintaining structural integrity over time, accommodating environmental conditions, and enabling cost-effective implementation. This multifaceted approach reflects the complex interplay between technical requirements, practical applications, and safety outcomes that characterizes the field.

The technical landscape of metal mesh safety has been shaped by several key milestones, including the establishment of the first international standards in the 1970s, the integration of ergonomic considerations in the 1990s, and the recent incorporation of advanced material science principles. Current technical trends indicate a movement toward performance-based standards rather than prescriptive requirements, allowing for greater innovation while maintaining safety outcomes.

The primary objective of metal mesh safety standards evaluation is to ensure that products and installations provide adequate protection against identified hazards while maintaining functionality. This involves assessing compliance with dimensional specifications, structural integrity requirements, durability under environmental stressors, and performance under impact or load conditions. Additionally, modern evaluation frameworks increasingly consider human factors, such as visibility through barriers and ergonomic interaction with protected equipment.

Regulatory frameworks governing metal mesh safety vary significantly across regions, with notable differences between European EN standards, North American ASTM and ANSI requirements, and Asian regulatory approaches. These variations create challenges for global manufacturers and necessitate sophisticated compliance strategies. The harmonization of these standards represents an ongoing technical challenge and opportunity.

Recent technological advancements have introduced new considerations into metal mesh safety evaluation, including the integration of smart materials, embedded sensors for real-time monitoring, and advanced coating technologies that enhance durability and performance. These innovations are pushing traditional standards to evolve and accommodate emerging capabilities while ensuring that fundamental safety principles remain intact.

The evaluation of compliance with metal mesh safety standards ultimately aims to balance multiple competing factors: maximizing protection, ensuring visibility and accessibility where needed, maintaining structural integrity over time, accommodating environmental conditions, and enabling cost-effective implementation. This multifaceted approach reflects the complex interplay between technical requirements, practical applications, and safety outcomes that characterizes the field.

Market Demand for Compliant Metal Mesh Products

The global market for compliant metal mesh products has experienced significant growth in recent years, driven primarily by increasing safety regulations across various industries and growing awareness of workplace safety standards. The metal mesh market, valued at approximately $4.2 billion in 2022, is projected to reach $6.8 billion by 2028, with safety-compliant products representing over 70% of this market share.

Industrial sectors including manufacturing, construction, and automotive remain the largest consumers of metal mesh products, collectively accounting for nearly 65% of market demand. These industries prioritize compliance with international safety standards such as ISO 13857, ANSI/ISEA 105, and EN 1991-1-4, which govern machinery guarding, personal protective equipment, and structural integrity respectively.

Regional analysis reveals that North America and Europe lead in demand for high-compliance metal mesh products, with stringent regulatory frameworks driving adoption. The Asia-Pacific region, particularly China and India, shows the fastest growth rate at 8.7% annually, as industrial safety regulations tighten and manufacturing sectors expand.

Consumer preferences increasingly favor metal mesh products that offer multi-standard compliance, with 78% of procurement managers citing regulatory adherence as their primary purchasing criterion. This represents a significant shift from a decade ago when cost was the predominant factor. The premium for fully compliant products ranges between 15-30% above standard offerings, yet market data indicates willingness to pay this premium has increased by 22% since 2019.

Safety-critical applications in food processing, pharmaceutical manufacturing, and electronics production demonstrate particularly strong demand growth, with compound annual growth rates exceeding 9%. These sectors require specialized metal mesh solutions that comply with both safety and cleanliness standards, creating a premium market segment.

Supply chain considerations have also reshaped market demand patterns, with 63% of end-users now preferring suppliers who provide comprehensive compliance documentation and certification services. This trend has created new value-added service opportunities within the metal mesh industry, with testing and certification services growing at 12% annually.

The COVID-19 pandemic accelerated demand for antimicrobial metal mesh products in healthcare and public spaces, creating a new compliance-focused market segment estimated at $340 million in 2022. This segment combines traditional safety compliance with newer biohazard mitigation standards, demonstrating how market demand continuously evolves alongside regulatory frameworks.

Industrial sectors including manufacturing, construction, and automotive remain the largest consumers of metal mesh products, collectively accounting for nearly 65% of market demand. These industries prioritize compliance with international safety standards such as ISO 13857, ANSI/ISEA 105, and EN 1991-1-4, which govern machinery guarding, personal protective equipment, and structural integrity respectively.

Regional analysis reveals that North America and Europe lead in demand for high-compliance metal mesh products, with stringent regulatory frameworks driving adoption. The Asia-Pacific region, particularly China and India, shows the fastest growth rate at 8.7% annually, as industrial safety regulations tighten and manufacturing sectors expand.

Consumer preferences increasingly favor metal mesh products that offer multi-standard compliance, with 78% of procurement managers citing regulatory adherence as their primary purchasing criterion. This represents a significant shift from a decade ago when cost was the predominant factor. The premium for fully compliant products ranges between 15-30% above standard offerings, yet market data indicates willingness to pay this premium has increased by 22% since 2019.

Safety-critical applications in food processing, pharmaceutical manufacturing, and electronics production demonstrate particularly strong demand growth, with compound annual growth rates exceeding 9%. These sectors require specialized metal mesh solutions that comply with both safety and cleanliness standards, creating a premium market segment.

Supply chain considerations have also reshaped market demand patterns, with 63% of end-users now preferring suppliers who provide comprehensive compliance documentation and certification services. This trend has created new value-added service opportunities within the metal mesh industry, with testing and certification services growing at 12% annually.

The COVID-19 pandemic accelerated demand for antimicrobial metal mesh products in healthcare and public spaces, creating a new compliance-focused market segment estimated at $340 million in 2022. This segment combines traditional safety compliance with newer biohazard mitigation standards, demonstrating how market demand continuously evolves alongside regulatory frameworks.

Current Compliance Challenges and Technical Limitations

The metal mesh safety standards landscape presents significant compliance challenges due to the fragmented regulatory environment across different regions. Organizations must navigate a complex web of standards including ISO 13857, EN 953, ANSI/ISEA 105, and region-specific regulations that often contain conflicting requirements. This regulatory inconsistency creates substantial compliance burdens, especially for global manufacturers who must adapt their products to meet diverse market requirements.

Technical limitations in current compliance testing methodologies represent another major challenge. Traditional testing procedures often fail to adequately simulate real-world conditions, leading to potential gaps between certified safety levels and actual performance in field applications. The static nature of many testing protocols does not account for dynamic forces, environmental degradation, or long-term material fatigue that metal mesh barriers encounter during their operational lifecycle.

Material science constraints further complicate compliance efforts. Current metal mesh materials face an inherent trade-off between strength, flexibility, and weight. High-strength meshes typically sacrifice flexibility and add significant weight, while more lightweight solutions may not provide adequate protection against high-impact forces. This fundamental materials challenge limits the ability to design optimal safety solutions that meet all regulatory requirements while maintaining practical usability.

Measurement and verification technologies present additional technical limitations. Current inspection methods often rely on manual visual assessment, which introduces human error and inconsistency. More advanced automated inspection systems struggle with detecting subtle defects in mesh structures, particularly when dealing with complex geometrical patterns or specialized coatings that may affect both safety performance and compliance status.

Implementation challenges at the manufacturing level further exacerbate compliance difficulties. Achieving consistent quality across production batches remains problematic, with variations in material properties, welding quality, and dimensional accuracy potentially compromising safety performance. These manufacturing inconsistencies make it difficult to guarantee that every produced unit meets the required safety standards, creating liability concerns and market access barriers.

Cost considerations represent a significant practical limitation in compliance efforts. The expense of comprehensive testing, certification processes, and potential product redesigns to meet evolving standards creates economic pressure, particularly for smaller manufacturers. This cost burden can lead to compromises in safety margins or attempts to find regulatory loopholes, ultimately undermining the protective intent of safety standards.

Technical limitations in current compliance testing methodologies represent another major challenge. Traditional testing procedures often fail to adequately simulate real-world conditions, leading to potential gaps between certified safety levels and actual performance in field applications. The static nature of many testing protocols does not account for dynamic forces, environmental degradation, or long-term material fatigue that metal mesh barriers encounter during their operational lifecycle.

Material science constraints further complicate compliance efforts. Current metal mesh materials face an inherent trade-off between strength, flexibility, and weight. High-strength meshes typically sacrifice flexibility and add significant weight, while more lightweight solutions may not provide adequate protection against high-impact forces. This fundamental materials challenge limits the ability to design optimal safety solutions that meet all regulatory requirements while maintaining practical usability.

Measurement and verification technologies present additional technical limitations. Current inspection methods often rely on manual visual assessment, which introduces human error and inconsistency. More advanced automated inspection systems struggle with detecting subtle defects in mesh structures, particularly when dealing with complex geometrical patterns or specialized coatings that may affect both safety performance and compliance status.

Implementation challenges at the manufacturing level further exacerbate compliance difficulties. Achieving consistent quality across production batches remains problematic, with variations in material properties, welding quality, and dimensional accuracy potentially compromising safety performance. These manufacturing inconsistencies make it difficult to guarantee that every produced unit meets the required safety standards, creating liability concerns and market access barriers.

Cost considerations represent a significant practical limitation in compliance efforts. The expense of comprehensive testing, certification processes, and potential product redesigns to meet evolving standards creates economic pressure, particularly for smaller manufacturers. This cost burden can lead to compromises in safety margins or attempts to find regulatory loopholes, ultimately undermining the protective intent of safety standards.

Current Compliance Testing Methodologies

01 Metal mesh design for flexibility and compliance

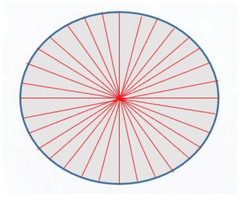

Metal mesh structures can be designed with specific patterns and configurations to enhance flexibility and compliance. These designs often incorporate geometric arrangements that allow the mesh to bend, stretch, or conform to various surfaces while maintaining structural integrity. The compliance characteristics can be optimized through variations in mesh density, wire diameter, and pattern geometry to meet specific application requirements.- Metal mesh design for flexibility and compliance: Metal mesh structures can be designed with specific patterns and geometries to enhance flexibility and compliance. These designs often incorporate interconnected metal traces or wires arranged in patterns that allow for stretching, bending, or conforming to irregular surfaces. The compliance characteristics can be controlled through mesh density, wire thickness, and pattern configuration, enabling applications in flexible electronics, wearable devices, and curved displays.

- Composite materials with metal mesh for enhanced compliance: Incorporating metal meshes into composite materials creates structures with both electrical conductivity and mechanical compliance. These composites typically combine metal mesh with polymers, elastomers, or other flexible substrates. The resulting materials maintain electrical functionality while allowing for deformation, making them suitable for applications requiring both conductivity and flexibility, such as electromagnetic shielding in flexible devices or compliant electrodes.

- Thermal compliance and stress management in metal mesh structures: Metal mesh designs can be optimized to manage thermal expansion and mechanical stress. By incorporating specific geometrical features like serpentine patterns, expansion joints, or variable thickness regions, these meshes can accommodate thermal cycling without failure. This approach is particularly important in applications where temperature fluctuations could otherwise cause deformation, cracking, or delamination of the metal mesh from its substrate.

- Manufacturing techniques for compliant metal mesh: Various manufacturing processes can be employed to create compliant metal mesh structures, including photolithography, etching, electroplating, and advanced printing techniques. These methods allow for precise control over mesh geometry, thickness, and material composition. Post-processing treatments can further enhance compliance characteristics through annealing, surface modification, or selective reinforcement of critical regions.

- Testing and standardization of metal mesh compliance: Standardized methods for testing and characterizing the compliance of metal mesh structures are essential for quality control and performance validation. These include mechanical testing for flexibility, durability under repeated deformation, adhesion strength to substrates, and electrical performance during bending or stretching. Compliance metrics may include bend radius tolerance, elastic recovery after deformation, and maintenance of electrical conductivity under strain.

02 Composite materials incorporating metal mesh

Metal mesh can be integrated with other materials to create composite structures with enhanced compliance properties. These composites often combine the strength and conductivity of metal mesh with the flexibility of polymers, elastomers, or other substrates. The resulting materials exhibit improved mechanical properties, including better stress distribution, impact resistance, and conformability to complex geometries.Expand Specific Solutions03 Manufacturing techniques for compliant metal mesh

Various manufacturing processes can be employed to produce metal mesh with specific compliance characteristics. These techniques include etching, weaving, knitting, and advanced deposition methods. The manufacturing approach significantly influences the mesh's mechanical properties, with parameters such as annealing temperature, material selection, and post-processing treatments affecting the final compliance behavior of the metal mesh structure.Expand Specific Solutions04 Applications of compliant metal mesh in electronic devices

Compliant metal mesh structures are widely used in electronic devices where flexibility and conformability are required. Applications include touch sensors, flexible displays, electromagnetic interference (EMI) shielding, and stretchable electronics. The mesh's ability to maintain electrical conductivity while undergoing deformation makes it particularly valuable for wearable technology and curved display surfaces.Expand Specific Solutions05 Testing and characterization of metal mesh compliance

Specialized methods and equipment are used to evaluate the compliance characteristics of metal mesh structures. These testing approaches measure properties such as elastic deformation, fatigue resistance, and recovery behavior under various loading conditions. Characterization techniques may include mechanical cycling tests, stress-strain analysis, and microscopic examination to assess structural integrity after repeated deformation cycles.Expand Specific Solutions

Key Industry Players and Certification Bodies

The metal mesh safety standards compliance landscape is currently in a growth phase, with increasing market demand driven by industrial safety regulations. The market is expanding at a moderate pace, estimated to reach significant value as industries prioritize worker protection and regulatory adherence. Technologically, the field shows varying maturity levels across different applications. Leading players like Shanghai Baosight Software and Industrial Technology Research Institute have developed advanced compliance monitoring systems, while educational institutions such as Harbin Institute of Technology and California Institute of Technology contribute valuable research. State Grid Corp. of China and Leister Technologies AG are implementing comprehensive safety protocols, with specialized expertise from organizations like the Fifth Institute of Electronics. The competitive environment features both established industrial conglomerates and specialized safety technology providers working to address evolving standards.

California Institute of Technology

Technical Solution: Caltech has developed the Quantitative Metal Mesh Integrity Assessment (QMMIA) system, a cutting-edge approach to evaluating compliance with metal mesh safety standards. Their methodology leverages advanced materials characterization techniques combined with computational modeling to provide comprehensive safety assessments. The QMMIA system employs high-resolution X-ray computed tomography to create detailed 3D models of metal mesh structures, enabling non-destructive evaluation of internal defects and structural integrity. Caltech researchers have developed proprietary algorithms that can predict mesh failure modes based on microstructural analysis, incorporating factors such as grain boundary characteristics and crystallographic orientation. Their approach includes multi-scale modeling that bridges atomic-level simulations with macroscopic performance predictions, allowing for more accurate safety margin calculations. The system incorporates machine learning techniques trained on extensive experimental datasets to identify subtle patterns that may indicate potential compliance issues. Additionally, Caltech has pioneered the use of digital twin technology for metal mesh applications, creating virtual replicas that can be subjected to simulated extreme conditions beyond physical testing limitations.

Strengths: Cutting-edge scientific approach with strong theoretical foundation; advanced predictive capabilities; integration of multiple characterization techniques for comprehensive evaluation. Weaknesses: Highly specialized approach requiring significant expertise to implement; potentially higher cost and complexity compared to more standardized testing methods; less focus on regulatory documentation aspects.

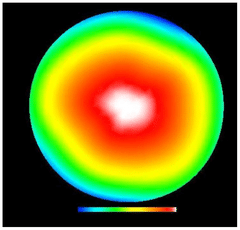

China Institute of Electronic Product Reliability and Environmental Testing

Technical Solution: The China Institute of Electronic Product Reliability and Environmental Testing has developed a comprehensive metal mesh safety compliance evaluation system that integrates multi-dimensional testing methodologies. Their approach combines physical inspection, electrical performance testing, and environmental stress testing specifically designed for metal mesh structures used in electronic products. The institute employs advanced scanning electron microscopy (SEM) to detect micro-fractures and structural defects in metal meshes at nanometer scale. Their proprietary MESH-Safe protocol evaluates compliance across five key dimensions: mechanical integrity, electrical conductivity stability, electromagnetic interference shielding effectiveness, thermal cycling resilience, and environmental hazard containment. The system includes automated testing equipment capable of performing accelerated life testing that simulates 5-10 years of operational wear in controlled laboratory conditions, providing manufacturers with predictive compliance data.

Strengths: Comprehensive testing methodology covering multiple safety aspects; advanced detection capabilities at nanometer scale; established reputation as a national testing authority. Weaknesses: Testing procedures may be time-consuming and costly; primarily focused on Chinese national standards which may differ from international requirements.

Critical Technical Requirements and Specifications

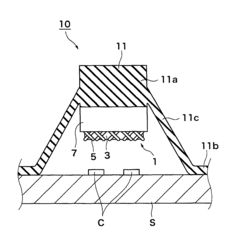

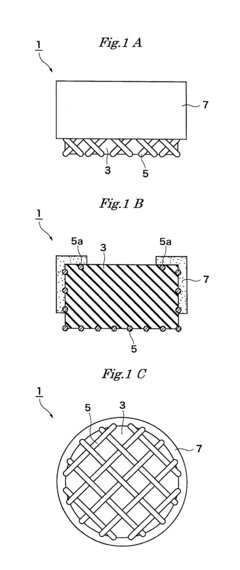

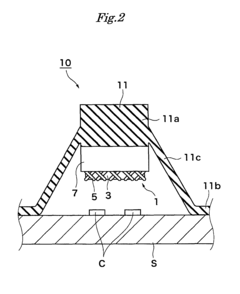

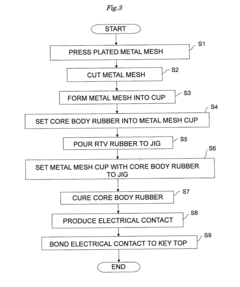

Metal mesh contact and switch and method for producing the same

PatentActiveUS8686307B2

Innovation

- An electrical contact with a metal mesh layer covering the outer and side surfaces of an elastic core body, combined with a bonding layer to prevent rust and enhance bonding, forms a conductive uneven surface for reliable contact and reduces exposure of cut edges to air.

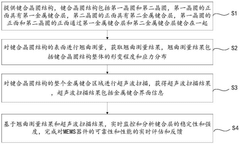

MEMS metal bonding stability and strength monitoring method

PatentPendingCN119409139A

Innovation

- The bonded wafer structure of MEMS devices is comprehensively evaluated by combining two methods: Warpage measurement and ultrasonic (C-SAM) measurement. First, warpage measurement is performed to obtain the overall deformation degree and stress distribution, and then ultrasonic scanning is performed to obtain the metal bonding interface information, and the stability and strength of the bonding layer are monitored and analyzed in real time.

Risk Assessment Framework for Metal Mesh Applications

The Risk Assessment Framework for Metal Mesh Applications provides a structured methodology for evaluating safety compliance across various industrial implementations. This framework integrates quantitative risk analysis with qualitative assessment techniques to create a comprehensive evaluation system specifically tailored for metal mesh installations. By establishing a multi-tiered approach, organizations can systematically identify potential hazards, assess their severity and likelihood, and implement appropriate mitigation strategies.

The framework consists of four interconnected components: hazard identification, risk quantification, compliance verification, and continuous monitoring. Hazard identification employs both historical incident analysis and predictive modeling to catalog potential failure modes specific to metal mesh applications, including structural integrity issues, corrosion vulnerabilities, and installation defects. This component utilizes industry databases and expert consultation to ensure comprehensive coverage of known and emerging risks.

Risk quantification transforms identified hazards into measurable parameters through a combination of statistical analysis and engineering principles. The framework employs a standardized scoring system (1-5) for both severity and probability factors, creating a risk priority matrix that enables objective comparison across different applications and environments. This quantitative approach facilitates resource allocation decisions by highlighting high-priority risk areas requiring immediate attention.

Compliance verification forms the core evaluation component, mapping identified risks against applicable regulatory standards including ISO 14120, ANSI/ISEA 102, and regional safety codes. The framework incorporates a compliance checklist methodology that documents evidence of conformity while identifying potential gaps. This systematic approach ensures that all relevant safety requirements are addressed while providing clear documentation for regulatory inspections and internal audits.

Continuous monitoring represents the framework's dynamic element, establishing protocols for regular reassessment based on operational changes, incident reports, and regulatory updates. This component includes defined inspection schedules, performance indicators, and feedback mechanisms to ensure ongoing compliance. The framework recommends technology-enabled monitoring solutions such as IoT sensors and automated inspection systems to enhance detection capabilities and reduce human error in the assessment process.

Implementation guidance accompanies the framework, providing organizations with practical steps for integration into existing safety management systems. This includes role definitions, training requirements, and documentation templates to facilitate adoption across different organizational structures and technical capabilities.

The framework consists of four interconnected components: hazard identification, risk quantification, compliance verification, and continuous monitoring. Hazard identification employs both historical incident analysis and predictive modeling to catalog potential failure modes specific to metal mesh applications, including structural integrity issues, corrosion vulnerabilities, and installation defects. This component utilizes industry databases and expert consultation to ensure comprehensive coverage of known and emerging risks.

Risk quantification transforms identified hazards into measurable parameters through a combination of statistical analysis and engineering principles. The framework employs a standardized scoring system (1-5) for both severity and probability factors, creating a risk priority matrix that enables objective comparison across different applications and environments. This quantitative approach facilitates resource allocation decisions by highlighting high-priority risk areas requiring immediate attention.

Compliance verification forms the core evaluation component, mapping identified risks against applicable regulatory standards including ISO 14120, ANSI/ISEA 102, and regional safety codes. The framework incorporates a compliance checklist methodology that documents evidence of conformity while identifying potential gaps. This systematic approach ensures that all relevant safety requirements are addressed while providing clear documentation for regulatory inspections and internal audits.

Continuous monitoring represents the framework's dynamic element, establishing protocols for regular reassessment based on operational changes, incident reports, and regulatory updates. This component includes defined inspection schedules, performance indicators, and feedback mechanisms to ensure ongoing compliance. The framework recommends technology-enabled monitoring solutions such as IoT sensors and automated inspection systems to enhance detection capabilities and reduce human error in the assessment process.

Implementation guidance accompanies the framework, providing organizations with practical steps for integration into existing safety management systems. This includes role definitions, training requirements, and documentation templates to facilitate adoption across different organizational structures and technical capabilities.

International Regulatory Variations and Harmonization

Metal mesh safety standards exhibit significant variations across different global regulatory frameworks, creating a complex landscape for manufacturers operating in international markets. The European Union implements the EN 15611 standard, which specifies rigorous testing methodologies for metal mesh products, emphasizing both structural integrity and material composition requirements. In contrast, the United States relies on ASTM F2267, which places greater emphasis on impact resistance and durability under extreme conditions, while incorporating different measurement parameters for compliance verification.

Asian regulatory frameworks present additional complexity, with Japan's JIS standards implementing unique requirements for corrosion resistance in high-humidity environments, while China's GB standards focus more heavily on manufacturing process controls and raw material certifications. These regional differences create significant compliance challenges for global manufacturers, often necessitating market-specific product modifications.

The International Organization for Standardization (ISO) has initiated efforts toward harmonization through ISO 14120, which attempts to establish universal safety principles for protective mesh systems. However, adoption remains inconsistent, with many countries maintaining their sovereign standards alongside ISO guidelines. This dual-standard approach creates additional compliance burdens for manufacturers seeking global market access.

Recent developments in harmonization efforts include the establishment of mutual recognition agreements (MRAs) between major economic regions. The EU-US MRA for certain industrial products represents progress in this direction, though metal mesh standards remain only partially covered under these frameworks. Industry stakeholders have formed working groups through organizations like the International Federation of Standards Users (IFAN) to accelerate harmonization efforts.

Compliance verification methodologies also differ substantially across jurisdictions. The EU typically employs a CE marking system with third-party certification requirements, while the US often permits self-declaration of conformity with periodic regulatory oversight. These procedural differences further complicate international compliance strategies, particularly for small and medium enterprises with limited regulatory resources.

The economic impact of these regulatory variations is substantial, with studies indicating compliance costs representing 5-8% of total production expenses for manufacturers serving multiple international markets. This has led to increasing industry advocacy for accelerated harmonization initiatives and simplified conformity assessment procedures that maintain safety standards while reducing redundant testing requirements.

Asian regulatory frameworks present additional complexity, with Japan's JIS standards implementing unique requirements for corrosion resistance in high-humidity environments, while China's GB standards focus more heavily on manufacturing process controls and raw material certifications. These regional differences create significant compliance challenges for global manufacturers, often necessitating market-specific product modifications.

The International Organization for Standardization (ISO) has initiated efforts toward harmonization through ISO 14120, which attempts to establish universal safety principles for protective mesh systems. However, adoption remains inconsistent, with many countries maintaining their sovereign standards alongside ISO guidelines. This dual-standard approach creates additional compliance burdens for manufacturers seeking global market access.

Recent developments in harmonization efforts include the establishment of mutual recognition agreements (MRAs) between major economic regions. The EU-US MRA for certain industrial products represents progress in this direction, though metal mesh standards remain only partially covered under these frameworks. Industry stakeholders have formed working groups through organizations like the International Federation of Standards Users (IFAN) to accelerate harmonization efforts.

Compliance verification methodologies also differ substantially across jurisdictions. The EU typically employs a CE marking system with third-party certification requirements, while the US often permits self-declaration of conformity with periodic regulatory oversight. These procedural differences further complicate international compliance strategies, particularly for small and medium enterprises with limited regulatory resources.

The economic impact of these regulatory variations is substantial, with studies indicating compliance costs representing 5-8% of total production expenses for manufacturers serving multiple international markets. This has led to increasing industry advocacy for accelerated harmonization initiatives and simplified conformity assessment procedures that maintain safety standards while reducing redundant testing requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!