What Factors Affect Metal Mesh Heat Dissipation Efficiency

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Thermal Management Background and Objectives

Metal mesh thermal management has evolved significantly over the past decades, transitioning from simple wire mesh structures to sophisticated engineered thermal solutions. The concept originated in aerospace applications during the 1960s, where lightweight yet effective heat dissipation was critical. Since then, metal mesh technology has expanded into electronics cooling, industrial heat exchangers, and energy systems, demonstrating remarkable versatility across multiple sectors.

The fundamental principle behind metal mesh heat dissipation leverages the high thermal conductivity of metals combined with the increased surface area provided by mesh structures. This combination facilitates enhanced convective and radiative heat transfer, making it particularly effective in applications where size, weight, and power constraints are significant considerations.

Recent technological advancements have focused on optimizing mesh geometries, material compositions, and manufacturing techniques. The introduction of additive manufacturing has revolutionized the design possibilities, enabling complex three-dimensional mesh structures with precisely engineered thermal pathways that were previously impossible to fabricate using traditional methods.

Market trends indicate a growing demand for more efficient thermal management solutions, driven primarily by the miniaturization of electronic devices, increasing power densities, and the push toward sustainable energy systems. This has accelerated research into metal mesh thermal solutions that can operate effectively under extreme conditions while maintaining reliability and performance consistency.

The primary objective of current metal mesh thermal management research is to identify and quantify the critical factors affecting heat dissipation efficiency. These include mesh geometry (wire diameter, spacing, pattern), material properties (thermal conductivity, specific heat capacity), surface treatments (coatings, texturing), fluid dynamics (air or liquid flow rates, turbulence), and environmental conditions (ambient temperature, pressure, humidity).

Secondary objectives include developing predictive models that can accurately simulate thermal performance across various operating conditions, establishing standardized testing methodologies for consistent performance evaluation, and exploring hybrid solutions that combine metal mesh structures with other thermal management technologies such as phase change materials or thermoelectric elements.

Understanding these factors comprehensively will enable the development of next-generation thermal management solutions capable of addressing the increasingly demanding requirements of modern applications. The ultimate goal is to establish design principles and engineering guidelines that optimize metal mesh heat dissipation efficiency while considering practical constraints such as cost, manufacturability, and environmental impact.

The fundamental principle behind metal mesh heat dissipation leverages the high thermal conductivity of metals combined with the increased surface area provided by mesh structures. This combination facilitates enhanced convective and radiative heat transfer, making it particularly effective in applications where size, weight, and power constraints are significant considerations.

Recent technological advancements have focused on optimizing mesh geometries, material compositions, and manufacturing techniques. The introduction of additive manufacturing has revolutionized the design possibilities, enabling complex three-dimensional mesh structures with precisely engineered thermal pathways that were previously impossible to fabricate using traditional methods.

Market trends indicate a growing demand for more efficient thermal management solutions, driven primarily by the miniaturization of electronic devices, increasing power densities, and the push toward sustainable energy systems. This has accelerated research into metal mesh thermal solutions that can operate effectively under extreme conditions while maintaining reliability and performance consistency.

The primary objective of current metal mesh thermal management research is to identify and quantify the critical factors affecting heat dissipation efficiency. These include mesh geometry (wire diameter, spacing, pattern), material properties (thermal conductivity, specific heat capacity), surface treatments (coatings, texturing), fluid dynamics (air or liquid flow rates, turbulence), and environmental conditions (ambient temperature, pressure, humidity).

Secondary objectives include developing predictive models that can accurately simulate thermal performance across various operating conditions, establishing standardized testing methodologies for consistent performance evaluation, and exploring hybrid solutions that combine metal mesh structures with other thermal management technologies such as phase change materials or thermoelectric elements.

Understanding these factors comprehensively will enable the development of next-generation thermal management solutions capable of addressing the increasingly demanding requirements of modern applications. The ultimate goal is to establish design principles and engineering guidelines that optimize metal mesh heat dissipation efficiency while considering practical constraints such as cost, manufacturability, and environmental impact.

Market Analysis for Advanced Heat Dissipation Solutions

The global market for advanced heat dissipation solutions is experiencing robust growth, driven primarily by the increasing thermal management demands across multiple industries. The metal mesh heat dissipation technology segment specifically has gained significant traction due to its superior performance characteristics compared to traditional cooling methods. Current market valuations place the thermal management industry at approximately 12.8 billion USD in 2023, with projections indicating a compound annual growth rate of 8.2% through 2028.

Electronics and semiconductor industries represent the largest application sectors, accounting for nearly 40% of the total market share. This dominance stems from the continuous miniaturization of electronic components coupled with increasing power densities, creating unprecedented thermal challenges that conventional cooling solutions cannot adequately address. Metal mesh solutions offer particular advantages in these applications due to their high surface-area-to-volume ratio and customizable designs.

The automotive sector presents another substantial market opportunity, particularly with the rapid expansion of electric vehicles. Thermal management systems for battery packs, power electronics, and electric motors are critical components affecting vehicle performance, safety, and longevity. Metal mesh heat dissipation technologies are increasingly being adopted in this sector due to their lightweight properties and efficient heat transfer capabilities, which directly contribute to extended range and improved battery life.

Data center cooling represents a high-growth segment within the market landscape. With global data traffic increasing exponentially and the proliferation of high-performance computing applications, cooling solutions that can efficiently manage extreme heat loads while minimizing energy consumption have become essential. Metal mesh technologies offer promising solutions for these environments, with several major data center operators reporting 15-20% improvements in cooling efficiency after implementation.

Regional analysis reveals that Asia-Pacific currently leads the market with approximately 38% share, followed by North America (29%) and Europe (24%). China, Japan, and South Korea are particularly notable for their advanced manufacturing capabilities in metal mesh technologies, while North American companies tend to focus on innovative design approaches and material science advancements.

Market competition is characterized by a mix of established thermal management companies expanding their portfolios and specialized startups focusing exclusively on advanced metal mesh solutions. Recent merger and acquisition activities suggest industry consolidation, with larger corporations seeking to incorporate innovative metal mesh technologies into their existing product lines.

Customer demand increasingly emphasizes sustainability alongside performance, with energy efficiency and recyclability becoming key purchasing factors. This trend has accelerated development of eco-friendly metal mesh solutions utilizing materials with lower environmental impact while maintaining or improving thermal performance characteristics.

Electronics and semiconductor industries represent the largest application sectors, accounting for nearly 40% of the total market share. This dominance stems from the continuous miniaturization of electronic components coupled with increasing power densities, creating unprecedented thermal challenges that conventional cooling solutions cannot adequately address. Metal mesh solutions offer particular advantages in these applications due to their high surface-area-to-volume ratio and customizable designs.

The automotive sector presents another substantial market opportunity, particularly with the rapid expansion of electric vehicles. Thermal management systems for battery packs, power electronics, and electric motors are critical components affecting vehicle performance, safety, and longevity. Metal mesh heat dissipation technologies are increasingly being adopted in this sector due to their lightweight properties and efficient heat transfer capabilities, which directly contribute to extended range and improved battery life.

Data center cooling represents a high-growth segment within the market landscape. With global data traffic increasing exponentially and the proliferation of high-performance computing applications, cooling solutions that can efficiently manage extreme heat loads while minimizing energy consumption have become essential. Metal mesh technologies offer promising solutions for these environments, with several major data center operators reporting 15-20% improvements in cooling efficiency after implementation.

Regional analysis reveals that Asia-Pacific currently leads the market with approximately 38% share, followed by North America (29%) and Europe (24%). China, Japan, and South Korea are particularly notable for their advanced manufacturing capabilities in metal mesh technologies, while North American companies tend to focus on innovative design approaches and material science advancements.

Market competition is characterized by a mix of established thermal management companies expanding their portfolios and specialized startups focusing exclusively on advanced metal mesh solutions. Recent merger and acquisition activities suggest industry consolidation, with larger corporations seeking to incorporate innovative metal mesh technologies into their existing product lines.

Customer demand increasingly emphasizes sustainability alongside performance, with energy efficiency and recyclability becoming key purchasing factors. This trend has accelerated development of eco-friendly metal mesh solutions utilizing materials with lower environmental impact while maintaining or improving thermal performance characteristics.

Current Challenges in Metal Mesh Heat Transfer Technology

Despite significant advancements in metal mesh heat transfer technology, several critical challenges continue to impede optimal performance and widespread adoption. The primary obstacle remains the complex balance between mesh porosity and thermal conductivity. While higher porosity enhances fluid flow and increases convective heat transfer, it simultaneously reduces the effective thermal conductivity of the mesh structure. This fundamental trade-off creates significant design constraints that engineers struggle to overcome, particularly in applications requiring both high heat flux dissipation and minimal pressure drop.

Material limitations present another substantial challenge. Current metal mesh technologies predominantly utilize copper, aluminum, and stainless steel, each with inherent limitations. Copper offers excellent thermal conductivity but suffers from oxidation and high cost. Aluminum, while lightweight and cost-effective, provides lower thermal performance. Stainless steel offers durability but exhibits relatively poor thermal conductivity. The development of advanced alloys or composite materials that combine optimal thermal properties with mechanical stability remains an ongoing challenge.

Manufacturing inconsistencies significantly impact performance reliability. Current production methods often result in non-uniform mesh structures, including variations in wire diameter, mesh opening size, and overall porosity. These inconsistencies create unpredictable heat transfer patterns and hotspots that compromise system efficiency. Advanced manufacturing techniques like precision additive manufacturing show promise but face scalability and cost barriers for mass production.

Surface wettability issues present particular challenges in phase-change heat transfer applications. The interaction between the metal mesh surface and working fluid significantly affects bubble nucleation, growth, and departure dynamics in boiling heat transfer. Controlling surface characteristics at the micro and nano scales to optimize wettability remains technically challenging and application-specific.

Integration challenges with existing thermal management systems constitute a significant barrier to adoption. Metal mesh heat exchangers often require specialized mounting, bonding, or attachment methods that may not be compatible with conventional thermal solutions. The thermal contact resistance at interfaces between the mesh and heat source or heat sink can substantially degrade overall system performance.

Fouling and clogging represent long-term operational challenges, particularly in open systems or those with particulate-laden fluids. The intricate structure of metal meshes makes them susceptible to performance degradation over time as deposits accumulate within the mesh openings, reducing effective porosity and increasing flow resistance.

Modeling and simulation limitations further complicate development efforts. Current computational models struggle to accurately predict the complex fluid-structure interactions within metal mesh systems, particularly under transient conditions or with phase-change heat transfer. This gap between theoretical predictions and actual performance creates uncertainty in design optimization and system sizing.

Material limitations present another substantial challenge. Current metal mesh technologies predominantly utilize copper, aluminum, and stainless steel, each with inherent limitations. Copper offers excellent thermal conductivity but suffers from oxidation and high cost. Aluminum, while lightweight and cost-effective, provides lower thermal performance. Stainless steel offers durability but exhibits relatively poor thermal conductivity. The development of advanced alloys or composite materials that combine optimal thermal properties with mechanical stability remains an ongoing challenge.

Manufacturing inconsistencies significantly impact performance reliability. Current production methods often result in non-uniform mesh structures, including variations in wire diameter, mesh opening size, and overall porosity. These inconsistencies create unpredictable heat transfer patterns and hotspots that compromise system efficiency. Advanced manufacturing techniques like precision additive manufacturing show promise but face scalability and cost barriers for mass production.

Surface wettability issues present particular challenges in phase-change heat transfer applications. The interaction between the metal mesh surface and working fluid significantly affects bubble nucleation, growth, and departure dynamics in boiling heat transfer. Controlling surface characteristics at the micro and nano scales to optimize wettability remains technically challenging and application-specific.

Integration challenges with existing thermal management systems constitute a significant barrier to adoption. Metal mesh heat exchangers often require specialized mounting, bonding, or attachment methods that may not be compatible with conventional thermal solutions. The thermal contact resistance at interfaces between the mesh and heat source or heat sink can substantially degrade overall system performance.

Fouling and clogging represent long-term operational challenges, particularly in open systems or those with particulate-laden fluids. The intricate structure of metal meshes makes them susceptible to performance degradation over time as deposits accumulate within the mesh openings, reducing effective porosity and increasing flow resistance.

Modeling and simulation limitations further complicate development efforts. Current computational models struggle to accurately predict the complex fluid-structure interactions within metal mesh systems, particularly under transient conditions or with phase-change heat transfer. This gap between theoretical predictions and actual performance creates uncertainty in design optimization and system sizing.

Contemporary Metal Mesh Heat Sink Design Approaches

01 Metal mesh structure design for enhanced heat dissipation

The design of metal mesh structures significantly impacts heat dissipation efficiency. Optimized mesh patterns, including grid size, thickness, and arrangement, can maximize surface area for heat transfer while maintaining structural integrity. Advanced designs incorporate variable density patterns that concentrate mesh elements in high-heat areas while reducing material in cooler zones, improving overall thermal management efficiency.- Metal mesh structure design for enhanced heat dissipation: The design of metal mesh structures significantly impacts heat dissipation efficiency. Optimized mesh patterns, including grid size, thickness, and arrangement, can maximize surface area for heat exchange while maintaining structural integrity. Advanced designs incorporate variable density patterns that concentrate mesh elements in high-heat areas while reducing material in cooler zones, improving overall thermal management efficiency.

- Metal mesh materials and coatings for thermal conductivity: The selection of metal materials and surface treatments for mesh heat sinks directly affects thermal performance. High thermal conductivity metals like copper and aluminum alloys are commonly used, while specialized coatings can enhance emissivity and prevent oxidation. Composite metal meshes combining different materials can optimize both weight and thermal properties, creating more efficient heat dissipation systems for electronic devices.

- Integration of metal mesh in electronic cooling systems: Metal mesh components are strategically integrated into electronic cooling systems to enhance thermal management. These meshes can be incorporated into heat sinks, thermal interface materials, or as standalone cooling elements. The integration approach considers airflow patterns, device architecture, and heat generation profiles to optimize placement and configuration of the mesh structures, resulting in more efficient heat transfer from critical components.

- Airflow optimization through metal mesh design: The relationship between metal mesh design and airflow dynamics is crucial for maximizing heat dissipation. Engineered mesh patterns create turbulent airflow that breaks thermal boundary layers while minimizing pressure drop. Strategic perforations and three-dimensional mesh structures can direct air toward hotspots and create vortices that enhance convective heat transfer, significantly improving cooling efficiency in passive and active cooling systems.

- Hybrid cooling solutions incorporating metal mesh: Advanced thermal management systems combine metal mesh structures with complementary cooling technologies to achieve superior heat dissipation. These hybrid approaches may integrate metal meshes with heat pipes, liquid cooling channels, phase change materials, or thermoelectric elements. The synergistic combination leverages the high surface area and thermal conductivity of metal meshes while addressing limitations through supplementary cooling mechanisms, resulting in more effective thermal solutions for high-power applications.

02 Material selection for metal mesh heat sinks

The choice of metal materials for mesh heat sinks directly affects thermal conductivity and dissipation performance. High thermal conductivity metals like copper and aluminum are commonly used, with copper offering superior heat transfer properties despite higher weight and cost. Composite and alloy materials can provide balanced performance characteristics, while surface treatments and coatings can further enhance radiation properties and corrosion resistance.Expand Specific Solutions03 Integration of metal mesh in electronic device cooling systems

Metal mesh structures are effectively integrated into electronic cooling systems through various mounting and attachment techniques. These include direct bonding to heat-generating components, incorporation into fan-assisted cooling assemblies, and integration with heat pipes or vapor chambers. The mesh can be strategically positioned to create optimal airflow channels while maintaining electrical isolation where necessary, resulting in compact yet efficient thermal management solutions for electronic devices.Expand Specific Solutions04 Hybrid cooling solutions combining metal mesh with other technologies

Hybrid cooling systems leverage metal mesh in combination with other cooling technologies to achieve superior thermal management. These systems may incorporate liquid cooling channels within or adjacent to metal mesh structures, phase-change materials embedded in mesh frameworks, or thermoelectric elements integrated with mesh heat sinks. Such combinations capitalize on the strengths of each cooling method while mitigating individual limitations, resulting in more effective heat dissipation for high-power applications.Expand Specific Solutions05 Manufacturing techniques for optimized metal mesh heat dissipation

Advanced manufacturing methods enable the production of high-performance metal mesh structures for thermal management. Techniques include precision stamping, additive manufacturing for complex geometries, micro-etching for ultra-fine mesh patterns, and sintering processes for porous metal structures. Post-processing treatments such as surface texturing can further enhance thermal performance by increasing effective surface area and modifying emissivity properties, resulting in more efficient heat dissipation components.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermal Solutions

The metal mesh heat dissipation market is currently in a growth phase, driven by increasing demand for efficient thermal management solutions across electronics, automotive, and industrial sectors. The global market size is estimated to exceed $3 billion, with projected annual growth of 6-8% through 2028. Technical maturity varies across applications, with companies like Delta Electronics, Mitsubishi Electric, and Sony Group leading innovation in advanced mesh designs. Key players including TDK Corp, Sumitomo Electric Industries, and LG Innotek are developing proprietary metal mesh technologies with enhanced thermal conductivity and reduced weight. Research institutions such as Toyota Central R&D Labs and Korea Institute of Machinery & Materials are advancing fundamental understanding of mesh geometry, material composition, and surface treatments that significantly impact heat dissipation efficiency.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed innovative metal mesh heat dissipation solutions focusing on material science and manufacturing precision. Their approach addresses efficiency factors through advanced metallurgy and structural optimization. Sumitomo's technology utilizes high-purity copper meshes (99.9%+) with thermal conductivities approaching 400 W/m·K, enhanced through proprietary annealing processes that optimize grain structure and reduce defects. Their research has identified mesh weave pattern as a critical factor, with their designs featuring specialized weave configurations that increase surface area by up to 40% compared to standard weaves. Sumitomo has pioneered gradient mesh structures where mesh density varies across the component to address specific thermal requirements. Their solutions incorporate precision-controlled wire diameters (typically 40-120μm) and mesh counts (80-250 per inch) tailored to application requirements. Sumitomo has also developed specialized sintering techniques that create metallurgical bonds between mesh layers, reducing internal thermal resistance by up to 50% compared to mechanical bonding methods.

Strengths: Superior material quality and purity leading to excellent thermal conductivity; highly precise manufacturing tolerances; excellent mechanical strength and durability. Weaknesses: Higher material costs due to high-purity metals; limited flexibility in some designs; more complex manufacturing process increasing production time.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced metal mesh heat dissipation technology focusing on optimizing the relationship between mesh structure and thermal performance. Their research has identified key efficiency factors including material composition, surface area, and fluid dynamics interactions. Mitsubishi's approach utilizes copper-based meshes with thermal conductivities exceeding 380 W/m·K, enhanced through proprietary alloying techniques. Their designs feature precisely controlled mesh aperture sizes (typically 50-300μm) with variable density distributions to address uneven heat generation. Mitsubishi has conducted extensive research on the impact of mesh layer count, demonstrating that multi-layer configurations with 3-5 layers can improve thermal performance by up to 35% compared to single-layer designs. Their technology incorporates specialized surface treatments that enhance both radiation heat transfer and corrosion resistance. Mitsubishi's solutions also feature optimized bonding methods that minimize thermal interface resistance, achieving thermal contact resistances below 0.05°C·cm²/W in their premium offerings.

Strengths: Exceptional thermal performance in high-power density applications; excellent long-term reliability and corrosion resistance; sophisticated multi-layer designs for complex thermal profiles. Weaknesses: Premium pricing compared to conventional solutions; higher weight in some configurations; requires specialized manufacturing processes.

Critical Parameters Affecting Metal Mesh Thermal Performance

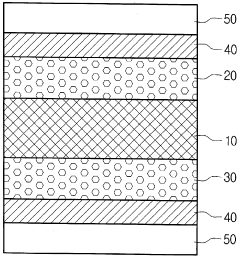

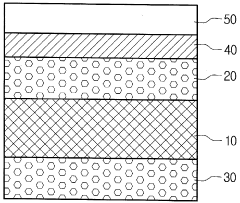

Heat-dissipating tape and method for manufacturing same

PatentWO2011119007A2

Innovation

- A heat dissipation tape featuring a metal mesh substrate with heat dissipation paint layers on both sides and a thermally conductive adhesive layer, allowing for efficient vertical and horizontal heat conduction, thereby overcoming the limitations of conventional tapes by maintaining high thermal conductivity even at thin thicknesses.

Patent

Innovation

- Design optimization of metal mesh structure with specific pore size, density, and arrangement patterns to maximize surface area for heat exchange while maintaining structural integrity.

- Integration of multi-layer metal mesh configurations with varying mesh densities to create gradient heat transfer pathways that efficiently move heat from source to ambient environment.

- Development of adaptive metal mesh structures that can dynamically adjust their configuration based on thermal load requirements to optimize heat dissipation under varying operating conditions.

Material Science Advancements for Enhanced Thermal Conductivity

Recent advancements in material science have significantly contributed to enhancing the thermal conductivity of metal mesh heat dissipation systems. The development of novel alloys and composite materials has been particularly impactful, with researchers focusing on optimizing the microstructure and composition of metals to maximize heat transfer capabilities.

Copper-based alloys have seen substantial improvements through the incorporation of nano-particles that enhance thermal conductivity while maintaining structural integrity. These advanced copper composites can achieve thermal conductivity values up to 20% higher than traditional copper meshes, making them increasingly valuable for high-performance cooling applications.

Aluminum-based materials have also undergone significant evolution, with the development of specialized aluminum alloys containing silicon carbide or graphene additives. These materials exhibit superior thermal properties while maintaining the lightweight characteristics that make aluminum desirable for portable electronic applications.

Surface treatment technologies have emerged as another critical area of advancement. Techniques such as plasma electrolytic oxidation and micro-arc oxidation create specialized surface structures that increase the effective surface area of metal meshes without compromising their mechanical properties. These treatments can enhance heat dissipation efficiency by up to 30% compared to untreated surfaces.

Nano-coating technologies represent perhaps the most promising frontier in thermal conductivity enhancement. Carbon nanotube coatings, graphene layers, and diamond-like carbon films applied to metal mesh surfaces have demonstrated remarkable improvements in thermal interface conductance. Research indicates that these nano-scale modifications can reduce thermal resistance at material interfaces by as much as 45%.

Additive manufacturing has revolutionized the production of metal meshes with complex geometries previously impossible to achieve through traditional manufacturing methods. 3D-printed metal meshes with optimized lattice structures can now be designed with precisely controlled porosity and surface characteristics, allowing for customized thermal performance based on specific application requirements.

Hybrid material systems combining metals with ceramics or polymers have also shown promise for specialized applications. These composites leverage the high thermal conductivity of metals while incorporating the beneficial properties of other materials, such as electrical insulation or chemical resistance, creating multifunctional heat dissipation solutions.

Copper-based alloys have seen substantial improvements through the incorporation of nano-particles that enhance thermal conductivity while maintaining structural integrity. These advanced copper composites can achieve thermal conductivity values up to 20% higher than traditional copper meshes, making them increasingly valuable for high-performance cooling applications.

Aluminum-based materials have also undergone significant evolution, with the development of specialized aluminum alloys containing silicon carbide or graphene additives. These materials exhibit superior thermal properties while maintaining the lightweight characteristics that make aluminum desirable for portable electronic applications.

Surface treatment technologies have emerged as another critical area of advancement. Techniques such as plasma electrolytic oxidation and micro-arc oxidation create specialized surface structures that increase the effective surface area of metal meshes without compromising their mechanical properties. These treatments can enhance heat dissipation efficiency by up to 30% compared to untreated surfaces.

Nano-coating technologies represent perhaps the most promising frontier in thermal conductivity enhancement. Carbon nanotube coatings, graphene layers, and diamond-like carbon films applied to metal mesh surfaces have demonstrated remarkable improvements in thermal interface conductance. Research indicates that these nano-scale modifications can reduce thermal resistance at material interfaces by as much as 45%.

Additive manufacturing has revolutionized the production of metal meshes with complex geometries previously impossible to achieve through traditional manufacturing methods. 3D-printed metal meshes with optimized lattice structures can now be designed with precisely controlled porosity and surface characteristics, allowing for customized thermal performance based on specific application requirements.

Hybrid material systems combining metals with ceramics or polymers have also shown promise for specialized applications. These composites leverage the high thermal conductivity of metals while incorporating the beneficial properties of other materials, such as electrical insulation or chemical resistance, creating multifunctional heat dissipation solutions.

Environmental Impact of Metal Mesh Cooling Technologies

The environmental impact of metal mesh cooling technologies extends beyond their primary function of heat dissipation, encompassing various ecological and sustainability dimensions. Metal mesh cooling systems generally demonstrate lower environmental footprints compared to traditional cooling methods due to their passive operational nature, which requires minimal or no energy input for basic functionality.

Material selection plays a crucial role in determining the environmental profile of these technologies. Aluminum meshes, while lightweight and effective, have high embodied energy from production processes. Copper meshes offer superior thermal conductivity but involve more resource-intensive extraction and processing. Stainless steel presents a middle ground with moderate environmental impact and good durability, potentially extending product lifecycles.

Manufacturing processes for metal meshes also contribute significantly to their environmental footprint. Traditional manufacturing methods often generate substantial waste and consume considerable energy. However, advanced techniques like additive manufacturing can reduce material waste by up to 40% while enabling more complex and efficient mesh designs that maximize heat dissipation performance.

The recyclability of metal mesh materials represents a significant environmental advantage. Most metals used in cooling applications maintain their properties through multiple recycling cycles, with aluminum and copper recovery rates exceeding 90% in efficient recycling systems. This circular economy potential substantially reduces the need for virgin material extraction and associated environmental degradation.

End-of-life considerations reveal that metal mesh cooling technologies generally outperform plastic-based alternatives in biodegradability and ecosystem impact. While metals do not biodegrade, their recyclability prevents accumulation in landfills or natural environments. Non-recycled components typically remain inert rather than releasing harmful substances into ecosystems.

Energy efficiency improvements enabled by optimized metal mesh designs translate directly to reduced carbon footprints in electronic devices and industrial systems. Studies indicate that advanced metal mesh heat sinks can improve overall system efficiency by 15-30% compared to conventional cooling solutions, resulting in proportional reductions in operational energy consumption and associated emissions.

Water conservation represents another environmental benefit, as metal mesh cooling systems typically require less or no water compared to liquid cooling alternatives. This advantage becomes particularly significant in water-stressed regions where cooling system water consumption can compete with essential human and ecological needs.

AI-driven design optimization is emerging as a pathway to further enhance the environmental performance of metal mesh cooling technologies, with algorithms capable of identifying mesh configurations that maximize heat dissipation while minimizing material usage and manufacturing complexity.

Material selection plays a crucial role in determining the environmental profile of these technologies. Aluminum meshes, while lightweight and effective, have high embodied energy from production processes. Copper meshes offer superior thermal conductivity but involve more resource-intensive extraction and processing. Stainless steel presents a middle ground with moderate environmental impact and good durability, potentially extending product lifecycles.

Manufacturing processes for metal meshes also contribute significantly to their environmental footprint. Traditional manufacturing methods often generate substantial waste and consume considerable energy. However, advanced techniques like additive manufacturing can reduce material waste by up to 40% while enabling more complex and efficient mesh designs that maximize heat dissipation performance.

The recyclability of metal mesh materials represents a significant environmental advantage. Most metals used in cooling applications maintain their properties through multiple recycling cycles, with aluminum and copper recovery rates exceeding 90% in efficient recycling systems. This circular economy potential substantially reduces the need for virgin material extraction and associated environmental degradation.

End-of-life considerations reveal that metal mesh cooling technologies generally outperform plastic-based alternatives in biodegradability and ecosystem impact. While metals do not biodegrade, their recyclability prevents accumulation in landfills or natural environments. Non-recycled components typically remain inert rather than releasing harmful substances into ecosystems.

Energy efficiency improvements enabled by optimized metal mesh designs translate directly to reduced carbon footprints in electronic devices and industrial systems. Studies indicate that advanced metal mesh heat sinks can improve overall system efficiency by 15-30% compared to conventional cooling solutions, resulting in proportional reductions in operational energy consumption and associated emissions.

Water conservation represents another environmental benefit, as metal mesh cooling systems typically require less or no water compared to liquid cooling alternatives. This advantage becomes particularly significant in water-stressed regions where cooling system water consumption can compete with essential human and ecological needs.

AI-driven design optimization is emerging as a pathway to further enhance the environmental performance of metal mesh cooling technologies, with algorithms capable of identifying mesh configurations that maximize heat dissipation while minimizing material usage and manufacturing complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!