How Do Coating Materials Affect Metal Mesh Durability

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Technology Background and Objectives

Metal mesh structures have become integral components in various industries, from aerospace and automotive to electronics and construction. The durability of these mesh structures is paramount to their functionality and longevity, with coating materials playing a decisive role in determining their performance characteristics. The evolution of coating technologies for metal meshes traces back to the mid-20th century, when basic galvanization and simple polymer coatings represented the state-of-the-art protection methods.

Over the past decades, coating technology has undergone significant transformation, driven by increasing demands for enhanced durability in harsh environments. The 1980s witnessed the emergence of specialized epoxy and polyurethane coatings, while the 1990s introduced advanced ceramic and composite coatings. The early 2000s marked a pivotal shift toward nanotechnology-enhanced coatings, offering unprecedented protection capabilities at the molecular level.

Current technological trends in metal mesh coatings focus on multi-functional properties that extend beyond mere corrosion resistance. These include self-healing capabilities, antimicrobial properties, thermal management, and electrical conductivity modulation. The integration of smart materials into coating formulations represents the cutting edge of this field, enabling responsive protection systems that adapt to environmental changes.

The primary objective of modern coating technology research is to develop solutions that significantly extend the service life of metal meshes while maintaining or enhancing their functional properties. This includes creating coatings that can withstand extreme temperature fluctuations, resist chemical degradation, prevent mechanical wear, and inhibit biological fouling, all while maintaining optimal mesh performance characteristics such as flexibility, weight, and porosity.

Another critical goal is the development of environmentally sustainable coating technologies that eliminate toxic components traditionally used in high-performance coatings. This shift responds to increasingly stringent global regulations and growing market demand for eco-friendly industrial materials. Research aims to replace chromates, cadmium, and volatile organic compounds with equally effective but environmentally benign alternatives.

Cost-effectiveness represents another key objective, as coating processes often constitute a significant portion of total manufacturing costs for metal mesh products. Innovations that reduce application complexity, curing time, and material waste can deliver substantial economic benefits across various industries. The ideal coating technology would combine superior protection with streamlined production requirements.

Looking forward, the field is moving toward predictive modeling capabilities that can accurately forecast coating performance under specific environmental conditions, enabling tailored solutions for diverse applications. This approach promises to optimize the balance between protection, functionality, and cost, ultimately revolutionizing how metal mesh structures are designed and implemented across industries.

Over the past decades, coating technology has undergone significant transformation, driven by increasing demands for enhanced durability in harsh environments. The 1980s witnessed the emergence of specialized epoxy and polyurethane coatings, while the 1990s introduced advanced ceramic and composite coatings. The early 2000s marked a pivotal shift toward nanotechnology-enhanced coatings, offering unprecedented protection capabilities at the molecular level.

Current technological trends in metal mesh coatings focus on multi-functional properties that extend beyond mere corrosion resistance. These include self-healing capabilities, antimicrobial properties, thermal management, and electrical conductivity modulation. The integration of smart materials into coating formulations represents the cutting edge of this field, enabling responsive protection systems that adapt to environmental changes.

The primary objective of modern coating technology research is to develop solutions that significantly extend the service life of metal meshes while maintaining or enhancing their functional properties. This includes creating coatings that can withstand extreme temperature fluctuations, resist chemical degradation, prevent mechanical wear, and inhibit biological fouling, all while maintaining optimal mesh performance characteristics such as flexibility, weight, and porosity.

Another critical goal is the development of environmentally sustainable coating technologies that eliminate toxic components traditionally used in high-performance coatings. This shift responds to increasingly stringent global regulations and growing market demand for eco-friendly industrial materials. Research aims to replace chromates, cadmium, and volatile organic compounds with equally effective but environmentally benign alternatives.

Cost-effectiveness represents another key objective, as coating processes often constitute a significant portion of total manufacturing costs for metal mesh products. Innovations that reduce application complexity, curing time, and material waste can deliver substantial economic benefits across various industries. The ideal coating technology would combine superior protection with streamlined production requirements.

Looking forward, the field is moving toward predictive modeling capabilities that can accurately forecast coating performance under specific environmental conditions, enabling tailored solutions for diverse applications. This approach promises to optimize the balance between protection, functionality, and cost, ultimately revolutionizing how metal mesh structures are designed and implemented across industries.

Market Analysis for Durable Metal Mesh Applications

The global market for durable metal mesh applications continues to expand significantly, driven by increasing demand across multiple industries including construction, automotive, aerospace, filtration, and electronics. Current market valuation stands at approximately 4.5 billion USD with projections indicating growth to reach 6.7 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is particularly pronounced in regions with robust industrial manufacturing bases such as East Asia, North America, and Western Europe.

Consumer demand patterns reveal a clear shift toward metal mesh products with enhanced durability characteristics, with over 70% of industrial purchasers citing longevity as a primary selection criterion. This trend is especially evident in high-stress application environments where mesh failure results in significant operational disruptions and replacement costs. Market research indicates that customers are increasingly willing to pay premium prices for coated metal mesh products that demonstrate superior corrosion resistance, wear protection, and extended service life.

Industry segmentation analysis shows that the construction sector currently represents the largest market share at 32%, followed by industrial filtration at 24%, and automotive applications at 18%. However, the fastest growing segment is specialized electronics applications, expanding at 12.4% annually due to increasing demand for EMI/RFI shielding solutions in consumer electronics and telecommunications infrastructure.

Regional market analysis reveals significant variations in demand patterns. North American and European markets demonstrate stronger preference for premium coated products with advanced performance characteristics, while developing markets in Asia and Latin America show greater price sensitivity but rapidly increasing quality expectations. The Asia-Pacific region, particularly China and India, represents the fastest growing geographical market with annual growth rates exceeding 10%.

Competitive landscape assessment identifies three distinct market tiers: global industrial conglomerates offering comprehensive metal mesh solutions, specialized coating technology providers, and regional manufacturers competing primarily on price. Market concentration remains moderate with the top five manufacturers controlling approximately 38% of global market share, indicating opportunities for innovative market entrants with differentiated coating technologies.

Customer feedback analysis reveals that performance expectations are evolving beyond basic durability to include additional functional properties such as antimicrobial characteristics, self-cleaning capabilities, and enhanced aesthetic qualities. This trend presents significant opportunities for coating technologies that can deliver multiple performance benefits simultaneously, potentially commanding price premiums 15-25% above standard products.

Consumer demand patterns reveal a clear shift toward metal mesh products with enhanced durability characteristics, with over 70% of industrial purchasers citing longevity as a primary selection criterion. This trend is especially evident in high-stress application environments where mesh failure results in significant operational disruptions and replacement costs. Market research indicates that customers are increasingly willing to pay premium prices for coated metal mesh products that demonstrate superior corrosion resistance, wear protection, and extended service life.

Industry segmentation analysis shows that the construction sector currently represents the largest market share at 32%, followed by industrial filtration at 24%, and automotive applications at 18%. However, the fastest growing segment is specialized electronics applications, expanding at 12.4% annually due to increasing demand for EMI/RFI shielding solutions in consumer electronics and telecommunications infrastructure.

Regional market analysis reveals significant variations in demand patterns. North American and European markets demonstrate stronger preference for premium coated products with advanced performance characteristics, while developing markets in Asia and Latin America show greater price sensitivity but rapidly increasing quality expectations. The Asia-Pacific region, particularly China and India, represents the fastest growing geographical market with annual growth rates exceeding 10%.

Competitive landscape assessment identifies three distinct market tiers: global industrial conglomerates offering comprehensive metal mesh solutions, specialized coating technology providers, and regional manufacturers competing primarily on price. Market concentration remains moderate with the top five manufacturers controlling approximately 38% of global market share, indicating opportunities for innovative market entrants with differentiated coating technologies.

Customer feedback analysis reveals that performance expectations are evolving beyond basic durability to include additional functional properties such as antimicrobial characteristics, self-cleaning capabilities, and enhanced aesthetic qualities. This trend presents significant opportunities for coating technologies that can deliver multiple performance benefits simultaneously, potentially commanding price premiums 15-25% above standard products.

Current Challenges in Metal Mesh Coating Technology

Despite significant advancements in metal mesh coating technologies, several critical challenges persist that impede optimal performance and widespread adoption. The foremost challenge lies in achieving uniform coating distribution across complex mesh geometries. Metal meshes often feature intricate structures with varying surface angles and densities, making it difficult to apply coatings with consistent thickness. This non-uniformity leads to premature coating failure at thinner regions, compromising the overall durability of the mesh system.

Adhesion between coating materials and metal substrates remains problematic, particularly in applications involving thermal cycling or mechanical stress. The coefficient of thermal expansion mismatch between coating materials and metal substrates creates interfacial stresses during temperature fluctuations, leading to coating delamination and subsequent corrosion of the underlying metal. This issue is especially pronounced in high-temperature applications where thermal cycling is frequent.

Environmental resistance presents another significant challenge. While many coating systems perform adequately in controlled environments, they often deteriorate rapidly when exposed to harsh conditions such as marine environments, industrial atmospheres, or extreme weather. The development of coating materials that can simultaneously resist multiple environmental stressors (UV radiation, chemical exposure, moisture, and temperature variations) without compromising other performance attributes remains elusive.

Cost-effectiveness and scalability of advanced coating technologies constitute major barriers to industrial implementation. Many high-performance coating materials that demonstrate excellent laboratory results involve expensive precursors or complex application processes that are difficult to scale for commercial production. This economic constraint often forces manufacturers to compromise on coating quality or durability to maintain competitive pricing.

Regulatory compliance adds another layer of complexity to coating material selection. The progressive phase-out of certain chemicals due to environmental or health concerns (such as chromates, certain VOCs, and PFAS compounds) necessitates the development of alternative coating systems that can match or exceed the performance of traditional materials while meeting increasingly stringent regulations.

Wear resistance under dynamic conditions presents unique challenges for metal mesh applications subject to abrasion, impact, or friction. Many coating systems that excel in corrosion protection lack adequate mechanical durability, resulting in premature coating failure in high-wear applications. Developing multi-functional coatings that simultaneously address corrosion protection and mechanical durability remains a significant technical hurdle.

Quality control and performance prediction constitute additional challenges. Current testing methodologies often fail to accurately predict real-world performance, leading to unexpected coating failures in field applications. The development of accelerated testing protocols that reliably correlate with long-term performance would significantly advance the field.

Adhesion between coating materials and metal substrates remains problematic, particularly in applications involving thermal cycling or mechanical stress. The coefficient of thermal expansion mismatch between coating materials and metal substrates creates interfacial stresses during temperature fluctuations, leading to coating delamination and subsequent corrosion of the underlying metal. This issue is especially pronounced in high-temperature applications where thermal cycling is frequent.

Environmental resistance presents another significant challenge. While many coating systems perform adequately in controlled environments, they often deteriorate rapidly when exposed to harsh conditions such as marine environments, industrial atmospheres, or extreme weather. The development of coating materials that can simultaneously resist multiple environmental stressors (UV radiation, chemical exposure, moisture, and temperature variations) without compromising other performance attributes remains elusive.

Cost-effectiveness and scalability of advanced coating technologies constitute major barriers to industrial implementation. Many high-performance coating materials that demonstrate excellent laboratory results involve expensive precursors or complex application processes that are difficult to scale for commercial production. This economic constraint often forces manufacturers to compromise on coating quality or durability to maintain competitive pricing.

Regulatory compliance adds another layer of complexity to coating material selection. The progressive phase-out of certain chemicals due to environmental or health concerns (such as chromates, certain VOCs, and PFAS compounds) necessitates the development of alternative coating systems that can match or exceed the performance of traditional materials while meeting increasingly stringent regulations.

Wear resistance under dynamic conditions presents unique challenges for metal mesh applications subject to abrasion, impact, or friction. Many coating systems that excel in corrosion protection lack adequate mechanical durability, resulting in premature coating failure in high-wear applications. Developing multi-functional coatings that simultaneously address corrosion protection and mechanical durability remains a significant technical hurdle.

Quality control and performance prediction constitute additional challenges. Current testing methodologies often fail to accurately predict real-world performance, leading to unexpected coating failures in field applications. The development of accelerated testing protocols that reliably correlate with long-term performance would significantly advance the field.

Current Coating Solutions for Metal Mesh Durability

01 Corrosion-resistant coatings for metal mesh

Various corrosion-resistant coatings can be applied to metal mesh to enhance durability in harsh environments. These coatings typically include anti-corrosive compounds that form protective barriers against moisture, chemicals, and environmental factors. Advanced formulations may incorporate multiple layers or specialized polymers that bond strongly to the metal substrate while providing flexibility to withstand mechanical stress and temperature variations.- Corrosion-resistant coatings for metal mesh: Various corrosion-resistant coatings can be applied to metal mesh to enhance durability in harsh environments. These coatings typically include anti-corrosive compounds that form protective barriers against moisture, chemicals, and environmental factors. The application methods may involve dipping, spraying, or electroplating processes to ensure uniform coverage across the mesh surface, resulting in extended service life and maintained structural integrity.

- Polymer-based protective coatings: Polymer-based coatings provide excellent durability for metal mesh applications through their flexibility, adhesion properties, and resistance to environmental degradation. These coatings can include fluoropolymers, epoxies, polyurethanes, and silicone-based materials that create protective barriers against moisture, UV radiation, and chemical exposure. The polymer coatings can be formulated with additives to enhance specific properties such as impact resistance, weatherability, and thermal stability.

- Ceramic and inorganic coating technologies: Ceramic and inorganic coatings provide exceptional heat resistance and durability for metal mesh exposed to high-temperature environments. These coatings typically include materials such as silicon carbide, aluminum oxide, or zirconium compounds that form protective layers with excellent thermal stability and wear resistance. Application methods may include plasma spraying, chemical vapor deposition, or sol-gel processes to achieve optimal adhesion and coverage on the metal mesh surface.

- Nanostructured and composite coatings: Advanced nanostructured and composite coatings combine multiple materials at the nanoscale to achieve superior durability properties for metal mesh applications. These innovative coatings may incorporate nanoparticles, carbon nanotubes, or graphene to enhance mechanical strength, wear resistance, and self-healing capabilities. The multi-layered structure of these coatings provides synergistic protection against various degradation mechanisms while maintaining the flexibility and permeability required for mesh applications.

- Environmental and weathering resistance treatments: Specialized treatments can be applied to metal mesh to enhance resistance against environmental factors such as UV radiation, moisture, salt spray, and temperature fluctuations. These treatments may include passivation processes, hydrophobic coatings, or UV stabilizers that protect the mesh from degradation in outdoor applications. The treatments can be tailored to specific environmental conditions, providing long-term durability and maintaining the functional properties of the metal mesh throughout its service life.

02 Polymer-based protective coatings

Polymer-based coatings provide excellent durability for metal mesh applications through their ability to form continuous, flexible films that adhere strongly to metal surfaces. These coatings often incorporate specialized additives to enhance UV resistance, weatherability, and mechanical strength. The polymer matrices can be engineered to maintain integrity under various environmental conditions while providing barrier properties against moisture and chemicals that would otherwise degrade the metal substrate.Expand Specific Solutions03 Heat-resistant and thermal barrier coatings

Specialized coatings designed to withstand high temperatures are critical for metal mesh applications in extreme thermal environments. These formulations typically incorporate ceramic components, refractory materials, or specialized binders that maintain structural integrity at elevated temperatures. Multi-layer systems may be employed to provide both thermal insulation and oxidation resistance, extending the service life of metal mesh in high-temperature industrial applications, furnaces, or exhaust systems.Expand Specific Solutions04 Nano-enhanced coating technologies

Advanced coating systems incorporating nanomaterials offer superior durability for metal mesh through enhanced mechanical properties and surface interactions. These coatings utilize nanoparticles or nanostructured materials to create more uniform and defect-free protective layers. The nanoscale components can significantly improve adhesion to the metal substrate, increase scratch and abrasion resistance, and provide self-healing capabilities that extend coating lifetime under mechanical stress and environmental exposure.Expand Specific Solutions05 Environmental and weathering resistant coatings

Specialized coating formulations designed to withstand outdoor exposure and harsh environmental conditions provide extended durability for metal mesh applications. These coatings typically incorporate UV stabilizers, antioxidants, and moisture-resistant components to prevent degradation from sunlight, precipitation, and atmospheric pollutants. Advanced systems may feature multi-layer architectures with primers for adhesion, middle layers for protection, and topcoats that provide specific surface properties while maintaining flexibility during thermal cycling.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The metal mesh durability coating materials market is in a growth phase, driven by increasing demand across automotive, energy, and electronics sectors. The market is expanding due to rising applications in protective coatings that enhance corrosion resistance and extend product lifespan. Technologically, companies like Nippon Steel, Bridgestone, and Sumitomo Electric are leading with advanced coating solutions, while Geobrugg AG specializes in high-tensile steel wire protection systems. Research institutions such as Tsinghua University and Shandong University are advancing fundamental coating science. Emerging players like Xiamen Yanjan and Lumotive are introducing innovative materials, while established corporations including Mitsubishi Heavy Industries, Siemens Energy, and NEC are integrating these technologies into their industrial applications, creating a competitive landscape balanced between specialized coating developers and end-use implementers.

Xiamen Yanjan New Material Co., Ltd.

Technical Solution: Xiamen Yanjan New Material has developed specialized coating solutions for metal mesh applications with their YJ-Coat series. Their primary innovation lies in multi-layer coating systems that combine inorganic zinc-rich primers with organic topcoats to provide comprehensive protection. The base layer typically consists of a zinc-rich epoxy primer (containing 80-85% zinc by weight in the dry film) that provides cathodic protection, while subsequent layers include epoxy intermediates and fluoropolymer or polyurethane topcoats that resist UV degradation and chemical exposure. Their research indicates this system provides protection exceeding 5,000 hours in salt spray testing (ASTM B117). For applications requiring electromagnetic properties, Yanjan has developed conductive coatings incorporating carbon nanotubes or silver nanoparticles that maintain electrical conductivity while providing corrosion protection. Their coating application process employs electrostatic spray technology to ensure uniform coverage across complex mesh geometries, with controlled curing protocols that optimize cross-linking and adhesion properties. This results in mesh products that maintain both functional and structural integrity in demanding environments such as chemical processing facilities and offshore installations.

Strengths: Exceptional chemical resistance against acids, alkalis and solvents; excellent UV stability for outdoor applications; ability to maintain electrical properties while providing corrosion protection; customizable appearance including transparent options. Weaknesses: More complex application process requiring multiple coating layers; higher material costs compared to simple metallic coatings; potential for coating damage at mesh intersection points during flexing; requires careful surface preparation for optimal adhesion.

GEOBRUGG AG

Technical Solution: GEOBRUGG AG has developed advanced coating technologies specifically designed for high-tensile steel wire mesh systems used in rockfall protection, slope stabilization, and debris flow barriers. Their SUPERCOATING® technology applies a zinc-aluminum coating (95% zinc, 5% aluminum) that provides superior corrosion protection compared to traditional galvanization. This coating creates a self-healing effect where zinc sacrificially corrodes to protect the underlying steel, while the aluminum forms a passive barrier against environmental factors. Their research shows this coating extends service life by up to 4 times compared to conventional hot-dip galvanized coatings in aggressive environments. GEOBRUGG's coating process involves precise temperature control and immersion timing to ensure optimal coating thickness (typically 150-300 g/m²) and adhesion to the wire substrate, resulting in mesh systems that maintain structural integrity even after decades of exposure to harsh weather conditions.

Strengths: Superior corrosion resistance in aggressive environments including coastal areas with salt spray exposure; self-healing properties that extend service life; maintains flexibility of the mesh without compromising mechanical properties. Weaknesses: Higher production costs compared to standard galvanization; requires specialized equipment for application; potential for coating damage during installation if not handled properly.

Key Innovations in Protective Coating Materials

Metal material, and coating film and wiring for semiconductor integrated circuitry utilizing the metal material

PatentInactiveUS7759749B2

Innovation

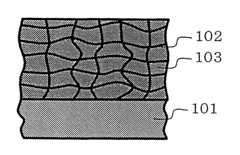

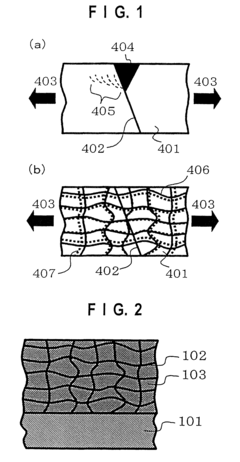

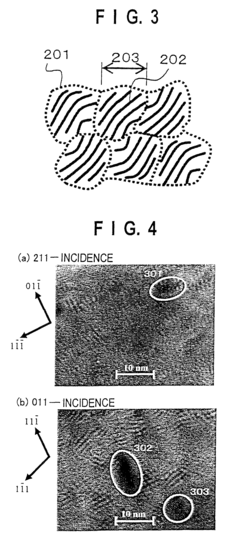

- A metallic material with a three-dimensional mesh structure formed by crosslinking or tangling of polymer chains, where metal is densely filled into gaps, creating a moiré pattern observed under transmission electron microscopy, enhancing mechanical strength and abrasion resistance while maintaining chemical and electric properties.

Metal surface coating, especially for micro electronics

PatentInactiveEP1042534A1

Innovation

- A substance with a first head group and a second head group connected via a spacer group is used to create a durable bond between polymers and metals, providing a hydrophobic layer that prevents water accumulation and corrosion, and can be deposited as a monomolecular layer on metal surfaces using chemisorption, ensuring strong adhesion even under mechanical stress.

Environmental Impact of Coating Materials

The environmental impact of coating materials used on metal meshes extends far beyond their primary function of enhancing durability. These coatings, while essential for protecting metal meshes from corrosion and wear, introduce significant environmental considerations throughout their lifecycle.

Traditional coating materials often contain volatile organic compounds (VOCs), heavy metals, and other toxic substances that pose serious environmental hazards. During manufacturing processes, these compounds can be released into the atmosphere, contributing to air pollution and potentially affecting local ecosystems. For instance, chromium-based coatings, while excellent for corrosion resistance, contain hexavalent chromium—a known carcinogen that can contaminate soil and water systems when improperly disposed.

Water-based coating alternatives have emerged as more environmentally friendly options, reducing VOC emissions by up to 80% compared to solvent-based counterparts. However, these coatings may require more energy for curing processes, creating a different environmental trade-off that must be carefully evaluated in lifecycle assessments.

The disposal and end-of-life management of coated metal meshes present additional environmental challenges. When these materials reach landfills, coating degradation can lead to leaching of harmful substances into groundwater. Recycling processes for coated metals often require additional energy and chemical treatments to separate the coating from the base metal, further increasing the environmental footprint.

Recent advancements in green coating technologies show promising developments. Bio-based coatings derived from renewable resources such as plant oils and agricultural byproducts demonstrate comparable performance to conventional coatings while significantly reducing environmental impact. These sustainable alternatives typically biodegrade more readily and contain fewer toxic components.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials. The European Union's REACH regulation and similar initiatives globally have restricted the use of certain harmful substances in coatings, driving innovation toward more sustainable formulations. Companies adopting environmentally responsible coating practices often gain competitive advantages through improved brand reputation and compliance with evolving regulations.

Life cycle assessment (LCA) studies indicate that the environmental impact of coating materials extends beyond their application and use phases. The extraction of raw materials for coating production, energy consumption during manufacturing, and transportation all contribute to the overall environmental footprint. Comprehensive sustainability evaluations must therefore consider these upstream and downstream factors when selecting coating materials for metal mesh applications.

Traditional coating materials often contain volatile organic compounds (VOCs), heavy metals, and other toxic substances that pose serious environmental hazards. During manufacturing processes, these compounds can be released into the atmosphere, contributing to air pollution and potentially affecting local ecosystems. For instance, chromium-based coatings, while excellent for corrosion resistance, contain hexavalent chromium—a known carcinogen that can contaminate soil and water systems when improperly disposed.

Water-based coating alternatives have emerged as more environmentally friendly options, reducing VOC emissions by up to 80% compared to solvent-based counterparts. However, these coatings may require more energy for curing processes, creating a different environmental trade-off that must be carefully evaluated in lifecycle assessments.

The disposal and end-of-life management of coated metal meshes present additional environmental challenges. When these materials reach landfills, coating degradation can lead to leaching of harmful substances into groundwater. Recycling processes for coated metals often require additional energy and chemical treatments to separate the coating from the base metal, further increasing the environmental footprint.

Recent advancements in green coating technologies show promising developments. Bio-based coatings derived from renewable resources such as plant oils and agricultural byproducts demonstrate comparable performance to conventional coatings while significantly reducing environmental impact. These sustainable alternatives typically biodegrade more readily and contain fewer toxic components.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating materials. The European Union's REACH regulation and similar initiatives globally have restricted the use of certain harmful substances in coatings, driving innovation toward more sustainable formulations. Companies adopting environmentally responsible coating practices often gain competitive advantages through improved brand reputation and compliance with evolving regulations.

Life cycle assessment (LCA) studies indicate that the environmental impact of coating materials extends beyond their application and use phases. The extraction of raw materials for coating production, energy consumption during manufacturing, and transportation all contribute to the overall environmental footprint. Comprehensive sustainability evaluations must therefore consider these upstream and downstream factors when selecting coating materials for metal mesh applications.

Cost-Benefit Analysis of Advanced Coating Technologies

When evaluating advanced coating technologies for metal mesh applications, a comprehensive cost-benefit analysis reveals significant economic implications across the product lifecycle. Initial investment in premium coating materials such as ceramic-based composites or advanced polymer systems typically increases upfront manufacturing costs by 15-30% compared to standard options. However, this investment often yields substantial returns through extended service life, with high-performance coatings demonstrating durability improvements of 2-5 times over uncoated or conventionally coated meshes.

Operational cost savings represent a critical benefit, particularly in harsh environmental applications. Field data indicates that advanced ceramic coatings can reduce maintenance frequency by up to 70% in marine environments, while fluoropolymer coatings demonstrate similar advantages in chemical processing facilities. These maintenance reductions translate to decreased downtime, with associated cost savings often exceeding $10,000 per day in industrial settings.

The environmental impact considerations further influence the cost-benefit equation. Modern eco-friendly coating technologies may command a 10-20% premium but offer compliance with increasingly stringent regulations, avoiding potential non-compliance penalties that can reach millions in severe cases. Additionally, reduced replacement frequency minimizes waste generation and resource consumption, aligning with sustainability objectives that increasingly carry financial incentives.

Application-specific performance enhancements must be quantified in any thorough analysis. For filtration applications, hydrophobic coatings that maintain consistent flow rates can improve process efficiency by 8-15%, while in electromagnetic shielding, conductive coatings preserve signal integrity, reducing interference-related failures by up to 40% according to industry benchmarks.

Long-term return on investment calculations demonstrate that despite higher initial costs, premium coating technologies typically achieve break-even within 12-36 months depending on application severity. For instance, in offshore oil platforms, corrosion-resistant nanocomposite coatings costing 25% more initially have shown ROI periods averaging 18 months due to dramatically reduced replacement requirements.

Market differentiation value, though less quantifiable, represents another significant benefit. Products featuring advanced coating technologies command premium pricing, with market research indicating price premiums of 15-40% for coated metal mesh products with documented performance advantages, particularly in aerospace, medical, and high-precision manufacturing sectors.

Operational cost savings represent a critical benefit, particularly in harsh environmental applications. Field data indicates that advanced ceramic coatings can reduce maintenance frequency by up to 70% in marine environments, while fluoropolymer coatings demonstrate similar advantages in chemical processing facilities. These maintenance reductions translate to decreased downtime, with associated cost savings often exceeding $10,000 per day in industrial settings.

The environmental impact considerations further influence the cost-benefit equation. Modern eco-friendly coating technologies may command a 10-20% premium but offer compliance with increasingly stringent regulations, avoiding potential non-compliance penalties that can reach millions in severe cases. Additionally, reduced replacement frequency minimizes waste generation and resource consumption, aligning with sustainability objectives that increasingly carry financial incentives.

Application-specific performance enhancements must be quantified in any thorough analysis. For filtration applications, hydrophobic coatings that maintain consistent flow rates can improve process efficiency by 8-15%, while in electromagnetic shielding, conductive coatings preserve signal integrity, reducing interference-related failures by up to 40% according to industry benchmarks.

Long-term return on investment calculations demonstrate that despite higher initial costs, premium coating technologies typically achieve break-even within 12-36 months depending on application severity. For instance, in offshore oil platforms, corrosion-resistant nanocomposite coatings costing 25% more initially have shown ROI periods averaging 18 months due to dramatically reduced replacement requirements.

Market differentiation value, though less quantifiable, represents another significant benefit. Products featuring advanced coating technologies command premium pricing, with market research indicating price premiums of 15-40% for coated metal mesh products with documented performance advantages, particularly in aerospace, medical, and high-precision manufacturing sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!