Metal Mesh Impact on New Energy Vehicle Weight Reduction

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Technology Background and Objectives

Metal mesh technology has evolved significantly over the past decades, transitioning from traditional industrial applications to becoming a critical component in lightweight vehicle design. Originally developed for electromagnetic shielding and filtration purposes in the 1960s, metal mesh has undergone substantial refinement in material composition, manufacturing techniques, and structural design to meet the demanding requirements of modern automotive engineering.

The evolution trajectory of metal mesh technology shows a clear trend toward higher strength-to-weight ratios, enhanced formability, and improved corrosion resistance. Early iterations primarily utilized stainless steel and aluminum alloys, while contemporary metal mesh solutions incorporate advanced materials such as titanium alloys, magnesium composites, and hybrid metal-polymer structures. This progression has been driven by the automotive industry's persistent pursuit of weight reduction without compromising structural integrity.

In the context of new energy vehicles (NEVs), metal mesh technology assumes heightened significance due to the unique challenges posed by battery integration and range optimization. The additional weight of battery systems in electric vehicles creates an imperative for compensatory weight reduction in other vehicle components. Industry data indicates that a 10% reduction in vehicle weight can improve energy efficiency by approximately 6-8%, translating to extended range capabilities.

The primary technical objective for metal mesh applications in NEVs centers on achieving optimal weight reduction while maintaining or enhancing structural performance. This involves developing metal mesh configurations that provide sufficient strength and stiffness for crash protection, while minimizing mass. Secondary objectives include improving thermal management characteristics, enhancing electromagnetic compatibility, and ensuring cost-effective manufacturability at scale.

Current research focuses on multi-functional metal mesh designs that simultaneously address multiple engineering challenges. These include sandwich structures with variable density cores, topologically optimized mesh patterns, and gradient structures that concentrate material only where mechanical loads demand it. Computational modeling and simulation tools have become instrumental in predicting the performance of these complex geometries before physical prototyping.

The technological trajectory points toward increasingly sophisticated metal mesh solutions that leverage advanced manufacturing methods such as additive manufacturing, precision stamping, and automated assembly. The ultimate goal is to develop standardized, modular metal mesh components that can be readily integrated into various NEV platforms, providing predictable weight savings while meeting stringent safety and performance requirements across diverse vehicle categories.

The evolution trajectory of metal mesh technology shows a clear trend toward higher strength-to-weight ratios, enhanced formability, and improved corrosion resistance. Early iterations primarily utilized stainless steel and aluminum alloys, while contemporary metal mesh solutions incorporate advanced materials such as titanium alloys, magnesium composites, and hybrid metal-polymer structures. This progression has been driven by the automotive industry's persistent pursuit of weight reduction without compromising structural integrity.

In the context of new energy vehicles (NEVs), metal mesh technology assumes heightened significance due to the unique challenges posed by battery integration and range optimization. The additional weight of battery systems in electric vehicles creates an imperative for compensatory weight reduction in other vehicle components. Industry data indicates that a 10% reduction in vehicle weight can improve energy efficiency by approximately 6-8%, translating to extended range capabilities.

The primary technical objective for metal mesh applications in NEVs centers on achieving optimal weight reduction while maintaining or enhancing structural performance. This involves developing metal mesh configurations that provide sufficient strength and stiffness for crash protection, while minimizing mass. Secondary objectives include improving thermal management characteristics, enhancing electromagnetic compatibility, and ensuring cost-effective manufacturability at scale.

Current research focuses on multi-functional metal mesh designs that simultaneously address multiple engineering challenges. These include sandwich structures with variable density cores, topologically optimized mesh patterns, and gradient structures that concentrate material only where mechanical loads demand it. Computational modeling and simulation tools have become instrumental in predicting the performance of these complex geometries before physical prototyping.

The technological trajectory points toward increasingly sophisticated metal mesh solutions that leverage advanced manufacturing methods such as additive manufacturing, precision stamping, and automated assembly. The ultimate goal is to develop standardized, modular metal mesh components that can be readily integrated into various NEV platforms, providing predictable weight savings while meeting stringent safety and performance requirements across diverse vehicle categories.

NEV Market Demand Analysis

The global new energy vehicle (NEV) market has experienced unprecedented growth in recent years, driven by increasing environmental concerns, government regulations, and technological advancements. This growth has created a significant demand for lightweight materials and solutions that can extend vehicle range, improve performance, and enhance overall efficiency. According to recent market analyses, the global NEV market reached approximately 10.5 million units in 2022, with projections indicating a compound annual growth rate of 21.7% through 2030.

Weight reduction has emerged as a critical factor in NEV development, with manufacturers actively seeking innovative solutions to address this challenge. For every 10% reduction in vehicle weight, energy efficiency can improve by 6-8%, directly translating to extended range capabilities. This correlation has positioned lightweight materials and structures, including metal mesh technologies, as high-priority development areas within the automotive industry.

Consumer preferences are increasingly favoring vehicles with longer ranges, faster charging capabilities, and improved performance metrics. Market research indicates that range anxiety remains a significant barrier to NEV adoption, with approximately 45% of potential buyers citing it as their primary concern. This consumer sentiment has intensified the industry focus on weight reduction strategies, creating substantial market pull for technologies like advanced metal mesh applications.

Regulatory frameworks worldwide are simultaneously pushing manufacturers toward more efficient vehicle designs. The European Union's stringent CO2 emission targets, China's dual-credit policy system, and California's zero-emission vehicle mandates all create regulatory environments that incentivize lightweight vehicle construction. These policies have established a market environment where weight reduction technologies command premium valuations and strategic importance.

The economic implications of metal mesh implementation in NEVs extend beyond direct material costs. While lightweight materials may carry higher initial costs, the total cost of ownership analysis reveals significant long-term benefits through improved battery efficiency, reduced energy consumption, and extended component lifespans. Market analysis suggests that consumers are increasingly willing to pay premium prices for vehicles offering superior range and performance characteristics.

Supply chain considerations also influence market demand for metal mesh technologies. As traditional automotive supply chains evolve to accommodate NEV production requirements, manufacturers are seeking materials and components that can be integrated into existing production processes while delivering substantial weight reduction benefits. This has created particular demand for metal mesh solutions that offer compatibility with current manufacturing systems while providing significant weight advantages.

Weight reduction has emerged as a critical factor in NEV development, with manufacturers actively seeking innovative solutions to address this challenge. For every 10% reduction in vehicle weight, energy efficiency can improve by 6-8%, directly translating to extended range capabilities. This correlation has positioned lightweight materials and structures, including metal mesh technologies, as high-priority development areas within the automotive industry.

Consumer preferences are increasingly favoring vehicles with longer ranges, faster charging capabilities, and improved performance metrics. Market research indicates that range anxiety remains a significant barrier to NEV adoption, with approximately 45% of potential buyers citing it as their primary concern. This consumer sentiment has intensified the industry focus on weight reduction strategies, creating substantial market pull for technologies like advanced metal mesh applications.

Regulatory frameworks worldwide are simultaneously pushing manufacturers toward more efficient vehicle designs. The European Union's stringent CO2 emission targets, China's dual-credit policy system, and California's zero-emission vehicle mandates all create regulatory environments that incentivize lightweight vehicle construction. These policies have established a market environment where weight reduction technologies command premium valuations and strategic importance.

The economic implications of metal mesh implementation in NEVs extend beyond direct material costs. While lightweight materials may carry higher initial costs, the total cost of ownership analysis reveals significant long-term benefits through improved battery efficiency, reduced energy consumption, and extended component lifespans. Market analysis suggests that consumers are increasingly willing to pay premium prices for vehicles offering superior range and performance characteristics.

Supply chain considerations also influence market demand for metal mesh technologies. As traditional automotive supply chains evolve to accommodate NEV production requirements, manufacturers are seeking materials and components that can be integrated into existing production processes while delivering substantial weight reduction benefits. This has created particular demand for metal mesh solutions that offer compatibility with current manufacturing systems while providing significant weight advantages.

Metal Mesh Technical Challenges

Despite significant advancements in metal mesh technology for vehicle weight reduction, several critical technical challenges persist that impede widespread implementation in new energy vehicles. The primary challenge lies in achieving optimal balance between structural integrity and weight reduction. Current metal mesh designs often compromise mechanical strength when pursuing extreme lightweighting, creating safety concerns particularly in crash-relevant components.

Manufacturing complexity presents another significant hurdle. The production of advanced metal mesh structures requires sophisticated equipment and precise control over manufacturing parameters. Inconsistencies in mesh geometry, thickness variations, and joining quality can lead to unpredictable mechanical properties and premature failure. These manufacturing challenges directly impact production costs and scalability for mass production.

Corrosion resistance remains problematic for metal mesh applications, especially in exterior and undercarriage components. The increased surface area of mesh structures compared to solid panels creates more potential corrosion sites. This issue is particularly relevant for new energy vehicles operating in diverse environmental conditions, where exposure to road salts, moisture, and temperature fluctuations accelerates degradation processes.

Integration challenges with existing vehicle architectures cannot be overlooked. Current vehicle design methodologies and assembly processes are optimized for traditional materials and structures. Incorporating metal mesh components often requires significant redesign of adjacent components and joining methods, creating cascading engineering challenges throughout the vehicle system.

Noise, vibration, and harshness (NVH) performance presents unique difficulties with metal mesh structures. The inherent resonance characteristics of mesh geometries can amplify certain frequency vibrations, potentially degrading passenger comfort. This challenge is magnified in electric vehicles where the absence of engine noise makes other NVH sources more noticeable to occupants.

Thermal management considerations also pose technical barriers. Metal mesh components conduct heat differently than solid structures, potentially creating thermal hotspots or cold zones that affect battery performance and passenger comfort in electric vehicles. Designing mesh patterns that provide appropriate thermal conductivity while maintaining structural properties requires sophisticated simulation and testing capabilities.

Recyclability and end-of-life considerations present emerging challenges. While metal is inherently recyclable, complex mesh structures with integrated joining methods or hybrid material combinations can complicate disassembly and material separation processes, potentially reducing the sustainability benefits of these lightweight solutions.

Manufacturing complexity presents another significant hurdle. The production of advanced metal mesh structures requires sophisticated equipment and precise control over manufacturing parameters. Inconsistencies in mesh geometry, thickness variations, and joining quality can lead to unpredictable mechanical properties and premature failure. These manufacturing challenges directly impact production costs and scalability for mass production.

Corrosion resistance remains problematic for metal mesh applications, especially in exterior and undercarriage components. The increased surface area of mesh structures compared to solid panels creates more potential corrosion sites. This issue is particularly relevant for new energy vehicles operating in diverse environmental conditions, where exposure to road salts, moisture, and temperature fluctuations accelerates degradation processes.

Integration challenges with existing vehicle architectures cannot be overlooked. Current vehicle design methodologies and assembly processes are optimized for traditional materials and structures. Incorporating metal mesh components often requires significant redesign of adjacent components and joining methods, creating cascading engineering challenges throughout the vehicle system.

Noise, vibration, and harshness (NVH) performance presents unique difficulties with metal mesh structures. The inherent resonance characteristics of mesh geometries can amplify certain frequency vibrations, potentially degrading passenger comfort. This challenge is magnified in electric vehicles where the absence of engine noise makes other NVH sources more noticeable to occupants.

Thermal management considerations also pose technical barriers. Metal mesh components conduct heat differently than solid structures, potentially creating thermal hotspots or cold zones that affect battery performance and passenger comfort in electric vehicles. Designing mesh patterns that provide appropriate thermal conductivity while maintaining structural properties requires sophisticated simulation and testing capabilities.

Recyclability and end-of-life considerations present emerging challenges. While metal is inherently recyclable, complex mesh structures with integrated joining methods or hybrid material combinations can complicate disassembly and material separation processes, potentially reducing the sustainability benefits of these lightweight solutions.

Current Metal Mesh Solutions

01 Metal mesh weight reduction techniques

Various techniques are employed to reduce the weight of metal meshes while maintaining structural integrity. These include using lightweight alloys, optimizing mesh geometry, reducing wire diameter while maintaining strength, and implementing strategic perforation patterns. Weight reduction is particularly important in applications where the overall mass of the component affects performance, such as in aerospace, automotive, and portable electronic devices.- Lightweight metal mesh design techniques: Various techniques are employed to reduce the weight of metal meshes while maintaining structural integrity. These include using thinner wire diameters, optimizing mesh patterns, and incorporating lightweight alloys. The design focuses on achieving a balance between weight reduction and maintaining necessary strength properties for specific applications.

- Weight optimization for specific applications: Metal mesh weight is optimized differently based on the intended application. For electromagnetic shielding, a balance between conductivity and weight is crucial. For architectural applications, structural support requirements determine the minimum weight. For filtration systems, the mesh weight is optimized to handle pressure differentials while maintaining porosity.

- Composite metal mesh structures: Composite structures incorporating metal mesh with other materials can achieve significant weight reduction. These composites often combine metal mesh with polymers, ceramics, or other metals to create lightweight yet strong structures. The integration of different materials allows for customized weight distribution and enhanced performance characteristics.

- Manufacturing processes affecting mesh weight: Various manufacturing processes significantly impact the final weight of metal meshes. Techniques such as expanded metal processing, wire weaving, etching, and advanced additive manufacturing all produce meshes with different weight characteristics. The choice of manufacturing method depends on the required mesh specifications and weight constraints.

- Weight measurement and standardization methods: Standardized methods for measuring and specifying metal mesh weight are essential for quality control and application suitability. Weight is typically expressed in grams per square meter or similar units. Testing protocols ensure consistency across production batches, with weight verification being a critical quality control parameter for metal mesh products.

02 Weight distribution in metal mesh structures

Proper weight distribution in metal mesh structures is crucial for maintaining balance and stability. This involves strategic placement of reinforcement elements, graduated mesh density, and calculated weight distribution across the structure. Techniques include varying wire thickness in different areas, incorporating support structures at stress points, and designing mesh patterns that distribute loads evenly across the entire structure.Expand Specific Solutions03 Metal mesh weight measurement methods

Accurate measurement of metal mesh weight involves specialized techniques and equipment. These include precision scales for finished products, computational methods to calculate theoretical weights based on material density and dimensions, non-destructive testing methods for quality control, and in-line weighing systems for production monitoring. These measurements are essential for quality assurance, material cost calculation, and performance prediction.Expand Specific Solutions04 Material selection for optimized metal mesh weight

The selection of appropriate materials significantly impacts the weight of metal meshes. Lightweight metals and alloys such as aluminum, titanium, and magnesium alloys are commonly used when weight reduction is a priority. Advanced materials including metal-polymer composites, high-strength low-density alloys, and specialized surface treatments can further optimize the weight-to-strength ratio while maintaining necessary properties like corrosion resistance and durability.Expand Specific Solutions05 Applications requiring specific metal mesh weight considerations

Different applications have unique requirements for metal mesh weight. In electromagnetic shielding, the weight must be balanced with conductivity and coverage. For filtration systems, the mesh weight affects flow rates and structural integrity. In architectural applications, weight considerations impact installation methods and structural support requirements. Transportation and aerospace industries require ultra-lightweight meshes that maintain strength under dynamic loads and environmental stresses.Expand Specific Solutions

Key Industry Players

The metal mesh technology for new energy vehicle weight reduction is currently in a growth phase, with increasing market adoption driven by stringent emissions regulations and consumer demand for extended range. The market is projected to expand significantly as automotive manufacturers prioritize lightweight materials to improve energy efficiency. Technologically, companies like BYD, CATL, and BMW are leading innovation in metal mesh applications, while traditional automotive players such as Ford, Mercedes-Benz, and GM are integrating these solutions into production vehicles. Steel manufacturers like NIPPON STEEL and aluminum specialists including Guangdong Hoshion are developing specialized alloys optimized for EV applications. Research institutions such as Battelle Memorial Institute and Kunming University of Science & Technology are advancing fundamental technologies, creating a competitive ecosystem balancing established manufacturers and emerging technology providers.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative metal mesh technology for their new energy vehicles called "Dragon Face" body structure. This technology utilizes high-strength aluminum alloys and steel in a mesh configuration that creates a lightweight yet rigid vehicle frame. The design incorporates aluminum-steel hybrid structures with optimized topology, achieving weight reductions of approximately 15-20% compared to traditional steel structures. BYD's approach includes specialized joining techniques for dissimilar metals, using advanced adhesives and mechanical fastening systems that maintain structural integrity while reducing overall mass. Their e-platform 3.0 specifically incorporates metal mesh designs in critical load-bearing areas, allowing for better energy absorption during impacts while maintaining passenger safety. The company has also developed specialized coating technologies to prevent galvanic corrosion between different metals in the mesh structure.

Strengths: Excellent weight-to-strength ratio, superior crash performance, and compatibility with existing manufacturing infrastructure. The technology enables BYD to reduce vehicle weight while maintaining or improving safety standards. Weaknesses: Higher initial production costs compared to traditional steel structures, and requires specialized joining techniques that may increase manufacturing complexity.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered the Multi-Material Lightweight Vehicle (MMLV) concept, incorporating advanced metal mesh structures in their new energy vehicle designs. Their technology utilizes high-strength aluminum and ultra-high-strength steel in a strategic mesh configuration, particularly in the vehicle's "safety cage" areas. Ford's approach includes proprietary spot-welding and adhesive bonding techniques that enable joining dissimilar metals without compromising structural integrity. The company has achieved weight reductions of up to 25% in body structures through their metal mesh implementations. Ford's metal mesh technology features variable density patterns that place material precisely where needed for structural support, while minimizing it in non-critical areas. This optimization is achieved through advanced computer modeling that simulates crash scenarios and structural loads. Ford has also developed specialized coating systems to prevent galvanic corrosion between different metals in their mesh structures, ensuring long-term durability.

Strengths: Significant weight reduction while maintaining or improving crash safety performance, scalable manufacturing processes compatible with existing production lines, and proven durability in real-world applications. Weaknesses: Higher material costs compared to traditional steel structures, and requires sophisticated design and simulation capabilities to optimize mesh patterns effectively.

Core Metal Mesh Patents

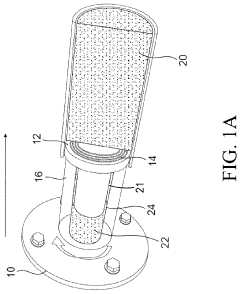

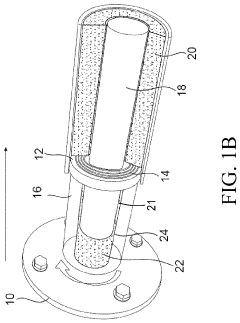

Extrusion processes, feedstock materials, conductive materials and/or assemblies

PatentPendingUS20230234115A1

Innovation

- The Shear Assisted Processing and Extrusion (ShAPE) technique uses a rotating ram or die to apply both rotational shearing and axial extrusion forces, allowing for the production of metal-NanoCrystalline Carbon Forms (NCCF) extrusions with improved strength, conductivity, and corrosion resistance without the need for additional processing steps or rare earth elements.

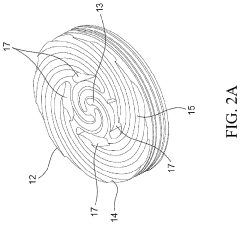

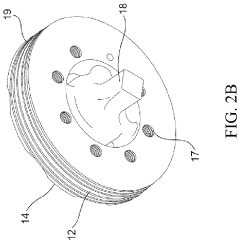

Duplex nano-structured low-density steel sheet with strength ductility product exceeding 50 gpa% and preparation method thereof

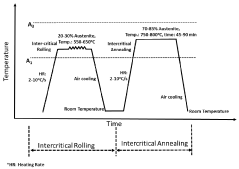

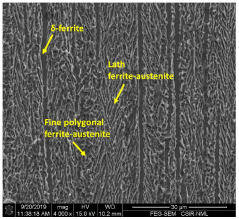

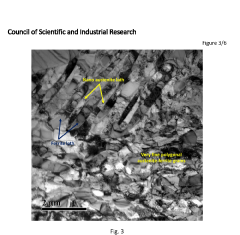

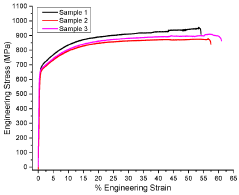

PatentPendingIN202011039587A

Innovation

- A duplex nano-structured steel sheet is developed through an innovative intercritical rolling and annealing process, utilizing a lower Mn content (<9 wt.%) and optimized alloy chemistry, resulting in a steel sheet with a strength-elongation product exceeding 50 GPa% and a density 4-6% lower than conventional steels.

Environmental Impact Assessment

The environmental impact of metal mesh technology in new energy vehicle (NEV) weight reduction extends far beyond the immediate benefits of improved fuel efficiency. When evaluating the full lifecycle environmental footprint, metal mesh components demonstrate significant advantages compared to traditional materials.

Manufacturing metal mesh structures requires approximately 30-40% less energy than producing conventional solid metal components of equivalent strength. This energy reduction translates directly to lower carbon emissions during the production phase. Additionally, the manufacturing process generates fewer waste byproducts, with approximately 85% of metal scrap being immediately recyclable within the same production facility.

The environmental benefits continue throughout the vehicle's operational lifespan. Studies indicate that for every 10% reduction in vehicle weight, fuel consumption decreases by 6-8% in conventional vehicles and energy consumption by 5-7% in electric vehicles. A typical implementation of metal mesh technology can reduce component weight by 15-25%, potentially extending EV range by 8-12% without requiring larger batteries.

End-of-life considerations further highlight the environmental advantages of metal mesh components. Unlike composite materials that often present recycling challenges, metal mesh structures maintain nearly 100% recyclability. The homogeneous metal composition facilitates straightforward separation and reprocessing, contributing to circular economy principles.

Water usage represents another critical environmental factor. Metal mesh manufacturing processes typically consume 25-35% less water compared to traditional metal forming techniques. This reduction is particularly significant in regions facing water scarcity challenges.

However, certain environmental challenges must be acknowledged. The production of specialized metal alloys sometimes used in advanced mesh designs may involve rare earth elements with their own extraction impacts. Additionally, some coating processes used to enhance corrosion resistance can introduce potentially harmful chemicals if not properly managed.

Life cycle assessment (LCA) studies comparing metal mesh components to traditional alternatives show a 15-20% reduction in overall environmental impact scores. These assessments consider factors including global warming potential, acidification, eutrophication, and resource depletion across the entire product lifecycle.

Manufacturing metal mesh structures requires approximately 30-40% less energy than producing conventional solid metal components of equivalent strength. This energy reduction translates directly to lower carbon emissions during the production phase. Additionally, the manufacturing process generates fewer waste byproducts, with approximately 85% of metal scrap being immediately recyclable within the same production facility.

The environmental benefits continue throughout the vehicle's operational lifespan. Studies indicate that for every 10% reduction in vehicle weight, fuel consumption decreases by 6-8% in conventional vehicles and energy consumption by 5-7% in electric vehicles. A typical implementation of metal mesh technology can reduce component weight by 15-25%, potentially extending EV range by 8-12% without requiring larger batteries.

End-of-life considerations further highlight the environmental advantages of metal mesh components. Unlike composite materials that often present recycling challenges, metal mesh structures maintain nearly 100% recyclability. The homogeneous metal composition facilitates straightforward separation and reprocessing, contributing to circular economy principles.

Water usage represents another critical environmental factor. Metal mesh manufacturing processes typically consume 25-35% less water compared to traditional metal forming techniques. This reduction is particularly significant in regions facing water scarcity challenges.

However, certain environmental challenges must be acknowledged. The production of specialized metal alloys sometimes used in advanced mesh designs may involve rare earth elements with their own extraction impacts. Additionally, some coating processes used to enhance corrosion resistance can introduce potentially harmful chemicals if not properly managed.

Life cycle assessment (LCA) studies comparing metal mesh components to traditional alternatives show a 15-20% reduction in overall environmental impact scores. These assessments consider factors including global warming potential, acidification, eutrophication, and resource depletion across the entire product lifecycle.

Cost-Benefit Analysis

The implementation of metal mesh technology in new energy vehicles requires thorough cost-benefit analysis to determine its economic viability. Initial investment costs for metal mesh integration include research and development expenditures, manufacturing equipment modifications, and workforce training. These upfront costs typically range from $2-5 million for mid-sized automotive manufacturers, representing a significant capital allocation that must be justified through long-term returns.

Material costs present a complex calculation. While metal mesh components may cost 15-30% more than traditional materials per unit weight, the overall material expenditure often decreases due to the reduced quantity required. Manufacturing processes for metal mesh components generally demonstrate 10-20% higher production costs initially, though these tend to decrease with scale and experience.

Weight reduction achieved through metal mesh implementation translates directly to operational savings. For electric vehicles, each 10% weight reduction typically yields 6-8% improvement in range efficiency. This efficiency gain reduces battery size requirements by approximately 5-7%, representing savings of $800-1,200 per vehicle in battery costs alone. Additionally, lighter vehicles require less energy consumption, extending battery life by an estimated 3-5% and reducing charging frequency and associated costs.

Maintenance economics also favor metal mesh implementation. The superior corrosion resistance and structural integrity of metal mesh components extend vehicle lifespan by approximately 1-2 years compared to conventional materials. Maintenance intervals can be extended by 15-20%, reducing lifetime service costs by an estimated $1,200-1,800 per vehicle.

Return on investment calculations indicate that the break-even point for metal mesh technology implementation typically occurs within 2.5-3.5 years of production. For manufacturers producing over 50,000 units annually, economies of scale accelerate this timeline to approximately 18-24 months. The net present value of implementing metal mesh technology, calculated over a 5-year period with a 10% discount rate, demonstrates positive returns ranging from $3.5-6 million for mid-sized manufacturers.

Environmental cost benefits, while more difficult to quantify directly, include reduced carbon emissions from both manufacturing processes (estimated 8-12% reduction) and vehicle operation (10-15% reduction over vehicle lifetime). These environmental benefits increasingly translate to tangible financial advantages through carbon credits, regulatory compliance, and consumer preference for sustainable vehicles.

Material costs present a complex calculation. While metal mesh components may cost 15-30% more than traditional materials per unit weight, the overall material expenditure often decreases due to the reduced quantity required. Manufacturing processes for metal mesh components generally demonstrate 10-20% higher production costs initially, though these tend to decrease with scale and experience.

Weight reduction achieved through metal mesh implementation translates directly to operational savings. For electric vehicles, each 10% weight reduction typically yields 6-8% improvement in range efficiency. This efficiency gain reduces battery size requirements by approximately 5-7%, representing savings of $800-1,200 per vehicle in battery costs alone. Additionally, lighter vehicles require less energy consumption, extending battery life by an estimated 3-5% and reducing charging frequency and associated costs.

Maintenance economics also favor metal mesh implementation. The superior corrosion resistance and structural integrity of metal mesh components extend vehicle lifespan by approximately 1-2 years compared to conventional materials. Maintenance intervals can be extended by 15-20%, reducing lifetime service costs by an estimated $1,200-1,800 per vehicle.

Return on investment calculations indicate that the break-even point for metal mesh technology implementation typically occurs within 2.5-3.5 years of production. For manufacturers producing over 50,000 units annually, economies of scale accelerate this timeline to approximately 18-24 months. The net present value of implementing metal mesh technology, calculated over a 5-year period with a 10% discount rate, demonstrates positive returns ranging from $3.5-6 million for mid-sized manufacturers.

Environmental cost benefits, while more difficult to quantify directly, include reduced carbon emissions from both manufacturing processes (estimated 8-12% reduction) and vehicle operation (10-15% reduction over vehicle lifetime). These environmental benefits increasingly translate to tangible financial advantages through carbon credits, regulatory compliance, and consumer preference for sustainable vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!