Evaluating Metal Mesh Permeability in Filtration Systems

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Filtration Technology Background and Objectives

Metal mesh filtration technology has evolved significantly over the past century, transitioning from simple mechanical sieves to sophisticated engineered materials with precise pore structures. The earliest applications date back to the industrial revolution when basic woven wire meshes were used for rudimentary separation processes. By the mid-20th century, advances in metallurgy and manufacturing techniques enabled the production of more uniform and durable metal mesh filters, expanding their application across multiple industries.

The evolution of metal mesh technology has been driven by increasing demands for filtration efficiency, durability, and specificity. Recent technological breakthroughs have focused on developing metal meshes with controlled permeability characteristics, allowing for precise particle size exclusion while maintaining optimal flow rates. This represents a significant advancement from earlier generations of metal filters that often faced trade-offs between filtration efficiency and throughput capacity.

Current technological trends in metal mesh filtration include the development of multi-layered composite meshes, surface-modified metal filters with enhanced capture capabilities, and smart filtration systems incorporating metal meshes with real-time monitoring capabilities. The integration of nanotechnology has further expanded the potential of metal mesh filters, enabling the creation of structures with sub-micron pore sizes while maintaining mechanical strength and chemical resistance.

The primary objective of evaluating metal mesh permeability in filtration systems is to establish standardized methodologies for characterizing flow behavior through various mesh designs under different operating conditions. This includes quantifying the relationship between mesh structural parameters (wire diameter, weave pattern, pore size distribution) and functional performance metrics such as flow resistance, particle capture efficiency, and clogging behavior.

Additional technical goals include developing predictive models that can accurately simulate fluid-structure interactions within metal mesh filters, enabling more efficient design optimization without extensive physical testing. There is also significant interest in understanding the long-term performance stability of metal mesh filters under challenging environmental conditions, including high temperatures, corrosive media, and high-pressure applications.

The advancement of metal mesh filtration technology aligns with broader industrial trends toward more sustainable and efficient separation processes. As regulatory requirements for emissions control, water purification, and product quality become increasingly stringent, the demand for high-performance filtration solutions continues to grow. Metal mesh filters, with their durability and recyclability, represent an environmentally favorable alternative to disposable polymer-based filtration media in many applications.

The evolution of metal mesh technology has been driven by increasing demands for filtration efficiency, durability, and specificity. Recent technological breakthroughs have focused on developing metal meshes with controlled permeability characteristics, allowing for precise particle size exclusion while maintaining optimal flow rates. This represents a significant advancement from earlier generations of metal filters that often faced trade-offs between filtration efficiency and throughput capacity.

Current technological trends in metal mesh filtration include the development of multi-layered composite meshes, surface-modified metal filters with enhanced capture capabilities, and smart filtration systems incorporating metal meshes with real-time monitoring capabilities. The integration of nanotechnology has further expanded the potential of metal mesh filters, enabling the creation of structures with sub-micron pore sizes while maintaining mechanical strength and chemical resistance.

The primary objective of evaluating metal mesh permeability in filtration systems is to establish standardized methodologies for characterizing flow behavior through various mesh designs under different operating conditions. This includes quantifying the relationship between mesh structural parameters (wire diameter, weave pattern, pore size distribution) and functional performance metrics such as flow resistance, particle capture efficiency, and clogging behavior.

Additional technical goals include developing predictive models that can accurately simulate fluid-structure interactions within metal mesh filters, enabling more efficient design optimization without extensive physical testing. There is also significant interest in understanding the long-term performance stability of metal mesh filters under challenging environmental conditions, including high temperatures, corrosive media, and high-pressure applications.

The advancement of metal mesh filtration technology aligns with broader industrial trends toward more sustainable and efficient separation processes. As regulatory requirements for emissions control, water purification, and product quality become increasingly stringent, the demand for high-performance filtration solutions continues to grow. Metal mesh filters, with their durability and recyclability, represent an environmentally favorable alternative to disposable polymer-based filtration media in many applications.

Market Analysis of Metal Mesh Filtration Applications

The global metal mesh filtration market has demonstrated robust growth, reaching approximately $3.2 billion in 2022 with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2028. This expansion is primarily driven by increasing industrial applications across diverse sectors including water treatment, chemical processing, food and beverage, pharmaceuticals, and oil and gas industries.

Water treatment represents the largest application segment, accounting for nearly 28% of the total market share. This dominance stems from stringent water quality regulations worldwide and growing concerns about water scarcity. The food and beverage industry follows closely, utilizing metal mesh filtration systems to ensure product quality and safety while meeting regulatory compliance requirements.

Regionally, Asia-Pacific leads the market with approximately 35% share, fueled by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe collectively account for 45% of the market, with established industrial bases and stringent environmental regulations driving adoption of advanced filtration technologies.

The market exhibits notable segmentation based on mesh material types. Stainless steel meshes dominate with approximately 42% market share due to their corrosion resistance and durability. Other significant segments include aluminum, copper, and specialized alloy meshes, each serving specific industrial applications with unique performance characteristics.

End-user analysis reveals that large-scale industrial applications constitute approximately 65% of the market, while smaller commercial and specialized applications make up the remainder. This distribution highlights the critical role of metal mesh filtration in core industrial processes rather than consumer applications.

Market dynamics are increasingly influenced by sustainability concerns, with approximately 38% of new installations focusing on energy-efficient designs and recyclable materials. This trend is particularly pronounced in developed markets where environmental regulations and corporate sustainability goals drive purchasing decisions.

Customer demand patterns show growing preference for customized filtration solutions, with approximately 45% of new orders involving some degree of customization to meet specific process requirements. This trend has created significant opportunities for specialized manufacturers who can provide tailored solutions while maintaining competitive pricing.

Water treatment represents the largest application segment, accounting for nearly 28% of the total market share. This dominance stems from stringent water quality regulations worldwide and growing concerns about water scarcity. The food and beverage industry follows closely, utilizing metal mesh filtration systems to ensure product quality and safety while meeting regulatory compliance requirements.

Regionally, Asia-Pacific leads the market with approximately 35% share, fueled by rapid industrialization in China, India, and Southeast Asian countries. North America and Europe collectively account for 45% of the market, with established industrial bases and stringent environmental regulations driving adoption of advanced filtration technologies.

The market exhibits notable segmentation based on mesh material types. Stainless steel meshes dominate with approximately 42% market share due to their corrosion resistance and durability. Other significant segments include aluminum, copper, and specialized alloy meshes, each serving specific industrial applications with unique performance characteristics.

End-user analysis reveals that large-scale industrial applications constitute approximately 65% of the market, while smaller commercial and specialized applications make up the remainder. This distribution highlights the critical role of metal mesh filtration in core industrial processes rather than consumer applications.

Market dynamics are increasingly influenced by sustainability concerns, with approximately 38% of new installations focusing on energy-efficient designs and recyclable materials. This trend is particularly pronounced in developed markets where environmental regulations and corporate sustainability goals drive purchasing decisions.

Customer demand patterns show growing preference for customized filtration solutions, with approximately 45% of new orders involving some degree of customization to meet specific process requirements. This trend has created significant opportunities for specialized manufacturers who can provide tailored solutions while maintaining competitive pricing.

Current Permeability Evaluation Methods and Challenges

The evaluation of metal mesh permeability in filtration systems currently employs several standardized methodologies, each with specific applications and limitations. The most widely adopted approach is the bubble point test, which determines the largest pore size by measuring the pressure required to force air through a wetted mesh. While this method provides reliable data on maximum pore size, it fails to deliver comprehensive information about pore size distribution or flow characteristics under actual operating conditions.

Darcy's law-based permeability testing represents another fundamental approach, measuring flow rate through mesh samples under controlled pressure differentials. This method yields valuable quantitative permeability data but often requires complex experimental setups and may not accurately reflect performance under variable fluid conditions or with non-Newtonian fluids commonly encountered in industrial applications.

Advanced imaging techniques have emerged as powerful complementary methods, with scanning electron microscopy (SEM) and micro-computed tomography (micro-CT) enabling detailed visualization of mesh structures. These technologies provide exceptional insights into mesh geometry and potential flow paths but translate poorly to dynamic performance predictions without supplementary computational modeling.

Computational fluid dynamics (CFD) simulations have gained significant traction in recent years, allowing virtual testing of mesh performance under various conditions. However, the accuracy of these simulations remains heavily dependent on the quality of input parameters and mesh geometry representations, creating a significant challenge in establishing reliable digital twins of physical mesh samples.

A major limitation across current methodologies is the disconnect between laboratory testing and real-world performance. Most standardized tests operate under idealized conditions with clean fluids and controlled temperatures, failing to account for fouling dynamics, temperature fluctuations, and chemical interactions that significantly impact long-term permeability in industrial settings.

Emerging challenges include the need for real-time permeability monitoring in operational systems, particularly for critical applications where performance degradation could lead to system failure. Current sensor technologies and non-invasive monitoring approaches remain inadequate for continuous assessment of mesh condition during operation.

The industry also faces significant standardization challenges, with different sectors employing varied testing protocols that complicate cross-application comparisons. This fragmentation hinders knowledge transfer between industries and slows the development of universal performance metrics that could accelerate innovation in mesh design and material selection.

Darcy's law-based permeability testing represents another fundamental approach, measuring flow rate through mesh samples under controlled pressure differentials. This method yields valuable quantitative permeability data but often requires complex experimental setups and may not accurately reflect performance under variable fluid conditions or with non-Newtonian fluids commonly encountered in industrial applications.

Advanced imaging techniques have emerged as powerful complementary methods, with scanning electron microscopy (SEM) and micro-computed tomography (micro-CT) enabling detailed visualization of mesh structures. These technologies provide exceptional insights into mesh geometry and potential flow paths but translate poorly to dynamic performance predictions without supplementary computational modeling.

Computational fluid dynamics (CFD) simulations have gained significant traction in recent years, allowing virtual testing of mesh performance under various conditions. However, the accuracy of these simulations remains heavily dependent on the quality of input parameters and mesh geometry representations, creating a significant challenge in establishing reliable digital twins of physical mesh samples.

A major limitation across current methodologies is the disconnect between laboratory testing and real-world performance. Most standardized tests operate under idealized conditions with clean fluids and controlled temperatures, failing to account for fouling dynamics, temperature fluctuations, and chemical interactions that significantly impact long-term permeability in industrial settings.

Emerging challenges include the need for real-time permeability monitoring in operational systems, particularly for critical applications where performance degradation could lead to system failure. Current sensor technologies and non-invasive monitoring approaches remain inadequate for continuous assessment of mesh condition during operation.

The industry also faces significant standardization challenges, with different sectors employing varied testing protocols that complicate cross-application comparisons. This fragmentation hinders knowledge transfer between industries and slows the development of universal performance metrics that could accelerate innovation in mesh design and material selection.

Current Methodologies for Measuring Metal Mesh Permeability

01 Metal mesh design factors affecting permeability

The permeability of metal meshes is influenced by various design factors including mesh size, wire diameter, opening area, and weave pattern. These parameters can be optimized to achieve specific permeability requirements for different applications. The relationship between these design factors and the resulting permeability characteristics is critical for engineering applications requiring precise fluid or gas flow control.- Metal mesh design factors affecting permeability: The permeability of metal meshes is influenced by several design factors including mesh size, wire diameter, weave pattern, and open area percentage. By adjusting these parameters, manufacturers can create metal meshes with specific permeability characteristics suitable for various applications. The mesh opening size and wire thickness ratio directly impacts the flow rate of gases or liquids through the mesh structure.

- Electromagnetic shielding applications of metal mesh: Metal meshes are used in electromagnetic shielding applications where permeability to electromagnetic waves needs to be controlled. The mesh structure allows for selective filtering of electromagnetic radiation while maintaining optical transparency or airflow. These meshes can be designed with specific aperture sizes and patterns to block certain frequencies while allowing others to pass through, making them valuable in electronic devices, communication equipment, and sensitive instrumentation.

- Fluid filtration and separation using metal mesh: Metal meshes are employed in fluid filtration and separation processes where their permeability characteristics enable the selective passage of certain particles while blocking others. The mesh structure can be engineered with precise pore sizes to achieve specific filtration requirements. Applications include industrial filtration systems, water treatment, oil and gas processing, and chemical processing where durability and resistance to harsh environments are required.

- Advanced manufacturing techniques for metal mesh permeability control: Innovative manufacturing techniques have been developed to precisely control the permeability of metal meshes. These include advanced weaving methods, etching processes, additive manufacturing, and micro-perforation technologies. Such techniques allow for the creation of complex mesh structures with gradient permeability, multi-layered designs, or region-specific flow characteristics that can be tailored for specific applications requiring controlled fluid or gas flow.

- Testing and measurement methods for metal mesh permeability: Various testing and measurement methods have been developed to accurately characterize the permeability of metal meshes. These include standardized flow testing, pressure drop analysis, bubble point testing, and computational fluid dynamics simulations. These methods help in quality control during manufacturing and ensure that the metal mesh meets the required permeability specifications for its intended application.

02 Electromagnetic shielding applications of permeable metal meshes

Metal meshes with controlled permeability are used in electromagnetic shielding applications where both electromagnetic isolation and airflow are required. These meshes can block electromagnetic interference while allowing for heat dissipation and ventilation. The balance between electromagnetic shielding effectiveness and permeability is achieved through specific mesh designs that consider aperture size, material conductivity, and thickness.Expand Specific Solutions03 Filtration and separation technologies using metal meshes

Metal meshes are employed in filtration and separation processes where permeability to certain substances while blocking others is required. Applications include industrial filtration, water treatment, and gas separation. The permeability characteristics can be tailored by controlling pore size distribution, surface treatments, and mesh layering to achieve specific filtration efficiency and flow rates.Expand Specific Solutions04 Testing and measurement methods for metal mesh permeability

Various methods and apparatus are used to measure and characterize the permeability of metal meshes. These include pressure drop tests, flow rate measurements, and specialized permeability testing equipment. Standardized testing procedures ensure consistent evaluation of mesh performance across different applications and enable quality control in manufacturing processes.Expand Specific Solutions05 Advanced manufacturing techniques for permeable metal meshes

Innovative manufacturing techniques are employed to create metal meshes with precisely controlled permeability characteristics. These include additive manufacturing, micro-perforation, electroforming, and advanced weaving technologies. These methods allow for the production of complex mesh structures with tailored permeability profiles that cannot be achieved through conventional manufacturing processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Metal Filtration

The metal mesh permeability filtration systems market is currently in a growth phase, with increasing demand driven by stringent filtration requirements across industries. The global market size is estimated to exceed $3 billion, expanding at a CAGR of 5-7% due to industrial automation and environmental regulations. Technologically, the field shows varying maturity levels, with companies like HYDAC Filtertechnik and Bekaert leading with advanced metal mesh solutions for industrial applications. Chengdu Yitai and SiTration are developing innovative materials like porous TiAl intermetallic compounds and specialized membranes, while established players such as 3M, Asahi Kasei Medical, and NGK Insulators are leveraging their manufacturing expertise to enhance permeability performance. Research institutions including Harbin Institute of Technology and Helmholtz-Zentrum Dresden-Rossendorf are advancing fundamental understanding of metal mesh behavior in filtration systems.

HYDAC Filtertechnik GmbH

Technical Solution: HYDAC has developed advanced metal mesh filtration systems that utilize precisely engineered wire mesh structures with controlled pore sizes ranging from 1 to 100 microns. Their technology employs multi-layer sintered metal mesh configurations that optimize both filtration efficiency and flow characteristics. The company's proprietary weaving techniques create uniform apertures that maintain consistent permeability under varying pressure conditions. HYDAC's metal mesh filters incorporate computational fluid dynamics (CFD) modeling to predict and enhance flow distribution across the filter surface, resulting in up to 30% improved dirt-holding capacity compared to conventional designs. Their systems feature self-cleaning capabilities through reverse flow mechanisms that extend operational lifetimes in demanding industrial applications. HYDAC also implements specialized surface treatments to enhance chemical resistance and prevent clogging in challenging environments.

Strengths: Superior mechanical strength allowing operation under high differential pressures; excellent thermal stability for high-temperature applications; precise pore size control enabling consistent filtration performance. Weaknesses: Higher initial cost compared to polymer-based alternatives; potential for metal ion leaching in certain chemical environments; greater weight than non-metallic filtration media.

Bekaert SA

Technical Solution: Bekaert has pioneered advanced metal fiber filtration technology through their Bekipor® product line, specifically engineered to evaluate and optimize metal mesh permeability in filtration systems. Their approach utilizes sintered stainless steel fibers with diameters as small as 2 microns to create three-dimensional porous structures with porosity levels reaching 85-90%. This technology enables precise control of pore size distribution between 1-100 microns while maintaining high mechanical integrity. Bekaert's proprietary sintering process creates metallurgical bonds between fibers, resulting in a robust structure that withstands high temperatures (up to 1000°C) and pressure differentials exceeding 20 bar. Their metal mesh filters incorporate gradient density structures that progressively filter particles while optimizing flow characteristics and minimizing pressure drop. Bekaert has also developed computational models that accurately predict permeability based on fiber diameter, density, and orientation, allowing customized solutions for specific filtration requirements.

Strengths: Exceptional thermal and chemical resistance making them suitable for extreme environments; high mechanical strength allowing backwashing and regeneration; customizable porosity and permeability profiles. Weaknesses: Higher production costs compared to conventional filter media; potential for metal contamination in ultra-pure applications; more complex manufacturing process requiring specialized equipment.

Key Patents and Research in Permeability Measurement

Filter material, in particular for hydraulic filters

PatentInactiveEP2945723A1

Innovation

- A filter material design featuring warp and weft threads arranged to form channel guides within the filter layer, allowing undisturbed flow without the need for large mesh widths, maintaining mechanical strength while optimizing flow conditions through specific thread orientations and configurations.

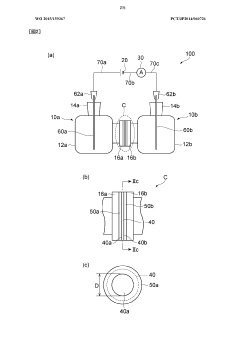

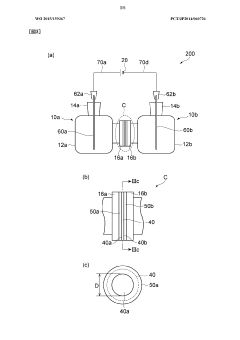

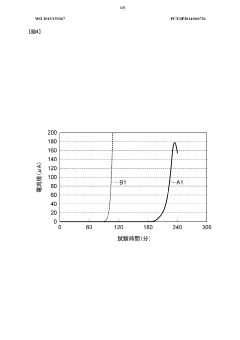

Permeability evaluation method

PatentWO2015159367A1

Innovation

- A permeability evaluation method involving a test piece with an insulating material, where a voltage is applied between two liquids separated by the test piece, allowing for the measurement of current flow and heavy metal ion concentration, using a first liquid with copper ions and a second liquid containing water and an organic solvent, such as N-methyl-2-pyrrolidone, to assess the permeability of heavy metal ions without the need for special devices.

Environmental Impact and Sustainability Considerations

The environmental impact of metal mesh filtration systems extends far beyond their immediate operational efficiency. These systems interact with ecosystems through their manufacturing processes, operational lifespan, and eventual disposal. The production of metal meshes typically involves resource-intensive mining operations and energy-consuming manufacturing processes that contribute significantly to carbon emissions and environmental degradation. Different mesh materials—such as stainless steel, aluminum, or copper—present varying environmental footprints, with considerations ranging from extraction impacts to processing energy requirements.

Water consumption represents another critical environmental factor in metal mesh filtration applications. While these systems are designed to filter and purify, their cleaning and maintenance often require substantial water resources. Advanced designs incorporating self-cleaning mechanisms or optimized backwash systems can significantly reduce this water footprint, presenting opportunities for more sustainable operational practices.

The durability and longevity of metal mesh filters directly influence their sustainability profile. High-quality meshes that resist corrosion and mechanical wear typically offer extended service lives, reducing replacement frequency and associated resource consumption. This durability factor must be balanced against initial manufacturing impacts when assessing overall environmental performance. Furthermore, the recyclability of metal mesh materials presents significant sustainability advantages compared to disposable filtration media, creating opportunities for closed-loop material systems.

Energy efficiency during operation constitutes another crucial environmental consideration. The relationship between mesh permeability and pressure drop directly affects energy consumption in pumping systems. Optimized mesh designs that maintain effective filtration while minimizing flow resistance can substantially reduce operational energy requirements, particularly in large-scale industrial applications where filtration systems operate continuously.

Emerging sustainable innovations in metal mesh technology include bio-inspired designs that mimic natural filtration systems, advanced surface treatments that enhance performance while reducing environmental impact, and hybrid systems that combine metal meshes with other sustainable materials. Additionally, life cycle assessment methodologies are increasingly being applied to evaluate the comprehensive environmental impact of different mesh configurations across their entire lifespan, from raw material extraction through manufacturing, use, and end-of-life management.

The regulatory landscape surrounding filtration systems continues to evolve, with increasing emphasis on environmental performance metrics beyond traditional efficiency measures. Forward-thinking manufacturers are proactively addressing these considerations through sustainable design practices, material selection strategies, and transparent environmental impact reporting.

Water consumption represents another critical environmental factor in metal mesh filtration applications. While these systems are designed to filter and purify, their cleaning and maintenance often require substantial water resources. Advanced designs incorporating self-cleaning mechanisms or optimized backwash systems can significantly reduce this water footprint, presenting opportunities for more sustainable operational practices.

The durability and longevity of metal mesh filters directly influence their sustainability profile. High-quality meshes that resist corrosion and mechanical wear typically offer extended service lives, reducing replacement frequency and associated resource consumption. This durability factor must be balanced against initial manufacturing impacts when assessing overall environmental performance. Furthermore, the recyclability of metal mesh materials presents significant sustainability advantages compared to disposable filtration media, creating opportunities for closed-loop material systems.

Energy efficiency during operation constitutes another crucial environmental consideration. The relationship between mesh permeability and pressure drop directly affects energy consumption in pumping systems. Optimized mesh designs that maintain effective filtration while minimizing flow resistance can substantially reduce operational energy requirements, particularly in large-scale industrial applications where filtration systems operate continuously.

Emerging sustainable innovations in metal mesh technology include bio-inspired designs that mimic natural filtration systems, advanced surface treatments that enhance performance while reducing environmental impact, and hybrid systems that combine metal meshes with other sustainable materials. Additionally, life cycle assessment methodologies are increasingly being applied to evaluate the comprehensive environmental impact of different mesh configurations across their entire lifespan, from raw material extraction through manufacturing, use, and end-of-life management.

The regulatory landscape surrounding filtration systems continues to evolve, with increasing emphasis on environmental performance metrics beyond traditional efficiency measures. Forward-thinking manufacturers are proactively addressing these considerations through sustainable design practices, material selection strategies, and transparent environmental impact reporting.

Industry Standards and Compliance Requirements

The filtration industry operates under a complex framework of standards and regulations designed to ensure product quality, safety, and performance consistency. ISO 16889 serves as the cornerstone standard for evaluating filtration efficiency, providing a globally recognized methodology for testing and rating metal mesh filters. This standard establishes uniform procedures for measuring beta ratios and particle retention capabilities, enabling meaningful comparisons between different filtration products across international markets.

In the United States, ASTM E2016 specifically addresses test methods for measuring the permeability of metal mesh materials, while ASTM F1215 focuses on determining the bubble point and pore size distribution—critical parameters for filtration applications. These standards provide manufacturers with precise protocols for quality control and performance verification. Additionally, the American National Standards Institute (ANSI) collaborates with industry associations to develop specialized standards for sector-specific applications of metal mesh filtration.

European regulations impose stringent requirements through the EN 1822 standard for high-efficiency particulate air filters, which includes provisions for metal mesh components. The European Pressure Equipment Directive (PED) further regulates filtration systems operating under pressure, mandating compliance with safety standards and material specifications for metal mesh elements used in such environments.

For pharmaceutical and food processing applications, FDA 21 CFR Part 177 regulates materials that contact food products, including metal mesh filters. These regulations specify acceptable materials, manufacturing processes, and testing protocols to prevent contamination. Similarly, the pharmaceutical industry must adhere to USP <788> standards for particulate matter in injections, which influences the design and validation of metal mesh filtration systems used in drug production.

Environmental compliance represents another critical dimension, with the EPA's Clean Air Act and Clean Water Act establishing permissible emission and discharge levels that directly impact filtration system specifications. These regulations often necessitate specific mesh permeability characteristics to achieve mandated filtration efficiencies.

International harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) to develop unified global standards for filtration technologies. The ISO/TC 131/SC 6 subcommittee specifically focuses on filtration and separation devices for hydraulic systems, working to establish consistent testing methodologies and performance criteria across borders.

Compliance certification processes typically involve third-party testing by accredited laboratories that verify conformance to relevant standards. Documentation requirements include detailed technical specifications, performance test results, and material certifications that must be maintained throughout the product lifecycle to demonstrate ongoing compliance.

In the United States, ASTM E2016 specifically addresses test methods for measuring the permeability of metal mesh materials, while ASTM F1215 focuses on determining the bubble point and pore size distribution—critical parameters for filtration applications. These standards provide manufacturers with precise protocols for quality control and performance verification. Additionally, the American National Standards Institute (ANSI) collaborates with industry associations to develop specialized standards for sector-specific applications of metal mesh filtration.

European regulations impose stringent requirements through the EN 1822 standard for high-efficiency particulate air filters, which includes provisions for metal mesh components. The European Pressure Equipment Directive (PED) further regulates filtration systems operating under pressure, mandating compliance with safety standards and material specifications for metal mesh elements used in such environments.

For pharmaceutical and food processing applications, FDA 21 CFR Part 177 regulates materials that contact food products, including metal mesh filters. These regulations specify acceptable materials, manufacturing processes, and testing protocols to prevent contamination. Similarly, the pharmaceutical industry must adhere to USP <788> standards for particulate matter in injections, which influences the design and validation of metal mesh filtration systems used in drug production.

Environmental compliance represents another critical dimension, with the EPA's Clean Air Act and Clean Water Act establishing permissible emission and discharge levels that directly impact filtration system specifications. These regulations often necessitate specific mesh permeability characteristics to achieve mandated filtration efficiencies.

International harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) to develop unified global standards for filtration technologies. The ISO/TC 131/SC 6 subcommittee specifically focuses on filtration and separation devices for hydraulic systems, working to establish consistent testing methodologies and performance criteria across borders.

Compliance certification processes typically involve third-party testing by accredited laboratories that verify conformance to relevant standards. Documentation requirements include detailed technical specifications, performance test results, and material certifications that must be maintained throughout the product lifecycle to demonstrate ongoing compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!