Innovation Analysis in Metal Mesh Structural Applications

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Mesh Technology Background and Objectives

Metal mesh technology has evolved significantly over the past decades, transforming from simple wire structures to sophisticated engineered materials with diverse applications across multiple industries. The historical development of metal mesh began in traditional manufacturing sectors where basic woven wire products served functional purposes in filtration, separation, and reinforcement applications. As materials science advanced, particularly in metallurgy and manufacturing processes, metal mesh structures gained enhanced properties including improved strength-to-weight ratios, corrosion resistance, and thermal stability.

The current technological landscape shows metal mesh applications expanding beyond traditional uses into advanced structural systems, architectural elements, aerospace components, and even biomedical implants. This expansion has been driven by innovations in mesh design, material composition, and manufacturing techniques that allow for precise control of physical and mechanical properties. Computer-aided design and simulation tools have further accelerated development by enabling optimization of mesh structures for specific performance requirements.

Market trends indicate growing demand for lightweight yet strong materials in construction and transportation sectors, positioning metal mesh as a promising solution for next-generation structural applications. The sustainability advantages of metal mesh structures—including material efficiency, recyclability, and potential energy savings through optimized designs—align with global movements toward greener building practices and manufacturing processes.

Key technological objectives in metal mesh innovation include developing novel geometrical configurations that maximize structural performance while minimizing material usage, creating hybrid mesh systems that combine metals with other materials for enhanced functionality, and advancing manufacturing methods to enable cost-effective production of complex mesh architectures at various scales.

Research priorities focus on understanding the mechanical behavior of different mesh typologies under various loading conditions, exploring the potential of additive manufacturing for creating customized mesh structures, and investigating surface treatments that can enhance durability and performance in challenging environments. Computational modeling approaches are increasingly important for predicting structural responses and optimizing designs before physical prototyping.

The convergence of digital design tools, advanced materials, and innovative manufacturing processes presents unprecedented opportunities for metal mesh technology. Future developments aim to create adaptive and responsive mesh structures that can adjust their properties based on environmental conditions or loading requirements, potentially revolutionizing structural applications across industries.

The current technological landscape shows metal mesh applications expanding beyond traditional uses into advanced structural systems, architectural elements, aerospace components, and even biomedical implants. This expansion has been driven by innovations in mesh design, material composition, and manufacturing techniques that allow for precise control of physical and mechanical properties. Computer-aided design and simulation tools have further accelerated development by enabling optimization of mesh structures for specific performance requirements.

Market trends indicate growing demand for lightweight yet strong materials in construction and transportation sectors, positioning metal mesh as a promising solution for next-generation structural applications. The sustainability advantages of metal mesh structures—including material efficiency, recyclability, and potential energy savings through optimized designs—align with global movements toward greener building practices and manufacturing processes.

Key technological objectives in metal mesh innovation include developing novel geometrical configurations that maximize structural performance while minimizing material usage, creating hybrid mesh systems that combine metals with other materials for enhanced functionality, and advancing manufacturing methods to enable cost-effective production of complex mesh architectures at various scales.

Research priorities focus on understanding the mechanical behavior of different mesh typologies under various loading conditions, exploring the potential of additive manufacturing for creating customized mesh structures, and investigating surface treatments that can enhance durability and performance in challenging environments. Computational modeling approaches are increasingly important for predicting structural responses and optimizing designs before physical prototyping.

The convergence of digital design tools, advanced materials, and innovative manufacturing processes presents unprecedented opportunities for metal mesh technology. Future developments aim to create adaptive and responsive mesh structures that can adjust their properties based on environmental conditions or loading requirements, potentially revolutionizing structural applications across industries.

Market Demand Analysis for Metal Mesh Structures

The global market for metal mesh structures has witnessed substantial growth in recent years, driven by increasing applications across diverse industries. The construction sector represents the largest market segment, with metal mesh structures being extensively utilized in facades, ceilings, partitions, and decorative elements. According to industry reports, the global architectural metal fabric market was valued at approximately $4.8 billion in 2022 and is projected to grow at a compound annual growth rate of 5.7% through 2030.

Infrastructure development, particularly in emerging economies, has significantly contributed to market expansion. Countries across Asia-Pacific, especially China and India, are investing heavily in urban infrastructure projects that incorporate metal mesh solutions for both functional and aesthetic purposes. The demand is further amplified by the growing trend toward sustainable and energy-efficient building designs, where metal mesh serves as an effective solution for solar shading while maintaining visual connectivity.

The automotive and aerospace industries represent rapidly growing segments for metal mesh applications. In automotive manufacturing, metal mesh components are increasingly replacing traditional materials due to their superior strength-to-weight ratio, contributing to vehicle lightweighting efforts and improved fuel efficiency. The aerospace sector similarly values these properties, with metal mesh structures finding applications in engine components, cabin interiors, and cargo systems.

Industrial applications constitute another significant market segment, with metal mesh structures being utilized in filtration systems, conveyor belts, and protective screens. The chemical processing industry particularly benefits from the corrosion resistance and durability of specialized metal mesh products, driving steady demand growth in this sector.

Consumer preferences are evolving toward more sustainable and visually distinctive architectural solutions, creating new market opportunities for innovative metal mesh designs. The growing emphasis on biophilic design in architecture has led to increased interest in metal mesh structures that can support vertical gardens or create semi-transparent boundaries between indoor and outdoor spaces.

Market analysis indicates that customization capabilities are becoming increasingly important to consumers, with architects and designers seeking bespoke metal mesh solutions that can be tailored to specific project requirements. This trend has prompted manufacturers to invest in advanced fabrication technologies that enable greater design flexibility and precision.

The COVID-19 pandemic temporarily disrupted supply chains and construction activities, impacting market growth in 2020. However, the market has demonstrated resilience, with recovery beginning in late 2021 and accelerating through 2022. Post-pandemic infrastructure stimulus packages in several major economies have further bolstered demand for metal mesh structural applications.

Infrastructure development, particularly in emerging economies, has significantly contributed to market expansion. Countries across Asia-Pacific, especially China and India, are investing heavily in urban infrastructure projects that incorporate metal mesh solutions for both functional and aesthetic purposes. The demand is further amplified by the growing trend toward sustainable and energy-efficient building designs, where metal mesh serves as an effective solution for solar shading while maintaining visual connectivity.

The automotive and aerospace industries represent rapidly growing segments for metal mesh applications. In automotive manufacturing, metal mesh components are increasingly replacing traditional materials due to their superior strength-to-weight ratio, contributing to vehicle lightweighting efforts and improved fuel efficiency. The aerospace sector similarly values these properties, with metal mesh structures finding applications in engine components, cabin interiors, and cargo systems.

Industrial applications constitute another significant market segment, with metal mesh structures being utilized in filtration systems, conveyor belts, and protective screens. The chemical processing industry particularly benefits from the corrosion resistance and durability of specialized metal mesh products, driving steady demand growth in this sector.

Consumer preferences are evolving toward more sustainable and visually distinctive architectural solutions, creating new market opportunities for innovative metal mesh designs. The growing emphasis on biophilic design in architecture has led to increased interest in metal mesh structures that can support vertical gardens or create semi-transparent boundaries between indoor and outdoor spaces.

Market analysis indicates that customization capabilities are becoming increasingly important to consumers, with architects and designers seeking bespoke metal mesh solutions that can be tailored to specific project requirements. This trend has prompted manufacturers to invest in advanced fabrication technologies that enable greater design flexibility and precision.

The COVID-19 pandemic temporarily disrupted supply chains and construction activities, impacting market growth in 2020. However, the market has demonstrated resilience, with recovery beginning in late 2021 and accelerating through 2022. Post-pandemic infrastructure stimulus packages in several major economies have further bolstered demand for metal mesh structural applications.

Current Status and Technical Challenges in Metal Mesh Applications

Metal mesh structures have evolved significantly over the past decade, with applications spanning from architectural facades to aerospace components. Currently, the global market for metal mesh applications is estimated at $12.5 billion, with a compound annual growth rate of 5.7%. The technological landscape is characterized by a dichotomy between traditional manufacturing methods and emerging advanced fabrication techniques that promise enhanced performance characteristics.

In the architectural sector, metal mesh applications have reached a mature stage with standardized solutions for facades, sunscreens, and decorative elements. However, the integration of smart technologies and responsive systems remains in early development phases. Leading manufacturers have successfully implemented basic sensor integration, but comprehensive systems that adapt to environmental conditions in real-time face significant technical hurdles related to durability and power management.

The aerospace and automotive industries represent the cutting edge of metal mesh applications, where weight reduction while maintaining structural integrity presents the primary technical challenge. Current solutions employ titanium and aluminum alloys, but these materials often struggle to meet the increasingly demanding performance requirements. Research into metal-composite hybrid meshes shows promise but faces challenges in joining dissimilar materials and preventing galvanic corrosion at interface points.

From a manufacturing perspective, traditional weaving and expanded metal techniques remain dominant due to their cost-effectiveness and established supply chains. Advanced methods such as 3D metal printing and selective laser melting offer unprecedented design freedom but suffer from scalability limitations, inconsistent material properties, and high production costs. The technology readiness level (TRL) for these advanced manufacturing methods ranges from 5-7, indicating they are not yet fully commercialized for large-scale applications.

Geographically, innovation in metal mesh technologies is concentrated in Western Europe, North America, and East Asia, with Germany, the United States, and Japan leading patent filings. Emerging research clusters in China and South Korea are rapidly closing the innovation gap through substantial R&D investments and government support programs.

The most pressing technical challenges include achieving multi-functional performance (combining structural, thermal, and electromagnetic properties), developing standardized testing protocols for novel mesh configurations, and creating computational models that accurately predict long-term performance under complex loading conditions. Additionally, sustainability concerns have emerged as critical constraints, with increasing pressure to develop recyclable and low-carbon footprint solutions without compromising mechanical properties.

Recent breakthroughs in nano-coating technologies offer potential solutions to corrosion and wear issues, but their industrial implementation remains limited by cost factors and process complexity. Similarly, advances in topology optimization algorithms have enabled more efficient mesh designs, though translating these theoretical optimizations into manufacturable products continues to challenge engineers across the industry.

In the architectural sector, metal mesh applications have reached a mature stage with standardized solutions for facades, sunscreens, and decorative elements. However, the integration of smart technologies and responsive systems remains in early development phases. Leading manufacturers have successfully implemented basic sensor integration, but comprehensive systems that adapt to environmental conditions in real-time face significant technical hurdles related to durability and power management.

The aerospace and automotive industries represent the cutting edge of metal mesh applications, where weight reduction while maintaining structural integrity presents the primary technical challenge. Current solutions employ titanium and aluminum alloys, but these materials often struggle to meet the increasingly demanding performance requirements. Research into metal-composite hybrid meshes shows promise but faces challenges in joining dissimilar materials and preventing galvanic corrosion at interface points.

From a manufacturing perspective, traditional weaving and expanded metal techniques remain dominant due to their cost-effectiveness and established supply chains. Advanced methods such as 3D metal printing and selective laser melting offer unprecedented design freedom but suffer from scalability limitations, inconsistent material properties, and high production costs. The technology readiness level (TRL) for these advanced manufacturing methods ranges from 5-7, indicating they are not yet fully commercialized for large-scale applications.

Geographically, innovation in metal mesh technologies is concentrated in Western Europe, North America, and East Asia, with Germany, the United States, and Japan leading patent filings. Emerging research clusters in China and South Korea are rapidly closing the innovation gap through substantial R&D investments and government support programs.

The most pressing technical challenges include achieving multi-functional performance (combining structural, thermal, and electromagnetic properties), developing standardized testing protocols for novel mesh configurations, and creating computational models that accurately predict long-term performance under complex loading conditions. Additionally, sustainability concerns have emerged as critical constraints, with increasing pressure to develop recyclable and low-carbon footprint solutions without compromising mechanical properties.

Recent breakthroughs in nano-coating technologies offer potential solutions to corrosion and wear issues, but their industrial implementation remains limited by cost factors and process complexity. Similarly, advances in topology optimization algorithms have enabled more efficient mesh designs, though translating these theoretical optimizations into manufacturable products continues to challenge engineers across the industry.

Current Technical Solutions for Metal Mesh Structures

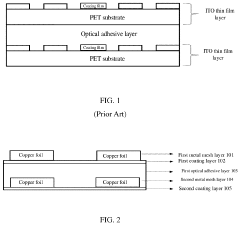

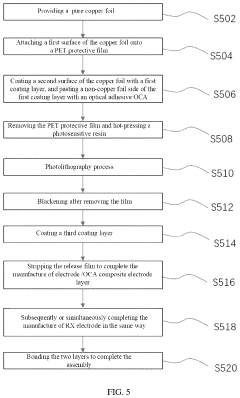

01 Touch screen applications with metal mesh structures

Metal mesh structures are utilized in touch screen technologies to create transparent conductive patterns. These structures offer advantages such as high conductivity, flexibility, and optical transparency, making them suitable for various touch-sensitive display applications. The metal mesh can be designed with specific patterns to optimize touch sensitivity while maintaining visibility of the underlying display.- Touch screen metal mesh structures: Metal mesh structures are used in touch screen technologies to create transparent conductive patterns. These innovations focus on improving touch sensitivity, reducing visibility of the mesh pattern, and enhancing durability while maintaining optical transparency. Advanced manufacturing techniques allow for ultra-fine metal mesh patterns that provide excellent conductivity without compromising the display quality, making them suitable for various electronic devices.

- Metal mesh for electromagnetic shielding: Metal mesh structures are designed for electromagnetic interference (EMI) shielding applications. These innovations involve specialized mesh geometries and materials that effectively block or attenuate electromagnetic radiation while allowing for other desirable properties such as light transmission, heat dissipation, or flexibility. These shielding solutions are critical for electronic devices, medical equipment, and communication systems where signal integrity must be maintained.

- Flexible and stretchable metal mesh structures: Innovations in flexible and stretchable metal mesh structures focus on creating conductive networks that can withstand bending, folding, and stretching while maintaining electrical performance. These structures typically employ novel geometric patterns, substrate materials, and bonding techniques to achieve mechanical flexibility without compromising electrical conductivity. Applications include wearable electronics, flexible displays, and medical devices that conform to body contours.

- Metal mesh for filtration and separation: Metal mesh structures designed for filtration and separation processes feature precisely controlled pore sizes, surface treatments, and material compositions to achieve specific separation capabilities. These innovations enhance filtration efficiency, reduce clogging, improve durability in harsh environments, and enable selective separation of particles, molecules, or cells based on size, charge, or other properties. Applications span industrial processing, water treatment, and biomedical separations.

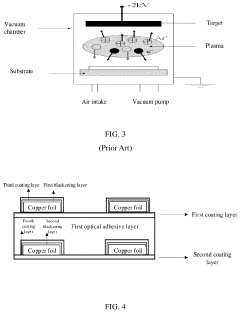

- Advanced manufacturing of metal mesh structures: Innovations in manufacturing techniques for metal mesh structures include novel fabrication methods such as nanoimprint lithography, electroforming, laser patterning, and additive manufacturing. These approaches enable the creation of complex three-dimensional mesh architectures with precisely controlled features at micro and nano scales. The manufacturing innovations focus on improving production efficiency, reducing costs, enhancing structural precision, and enabling mass production of high-performance metal mesh components.

02 Manufacturing techniques for metal mesh structures

Various manufacturing methods are employed to create metal mesh structures, including photolithography, etching, printing, and deposition techniques. These processes allow for precise control over mesh geometry, line width, and spacing. Advanced manufacturing approaches enable the creation of ultra-fine metal mesh patterns with optimized electrical and optical properties for specific applications.Expand Specific Solutions03 Metal mesh for electromagnetic shielding

Metal mesh structures are designed for electromagnetic interference (EMI) shielding applications. These meshes can block or attenuate electromagnetic radiation while allowing for airflow, light transmission, or visibility. The geometry, material composition, and connectivity of the mesh determine its effectiveness across different frequency ranges, making it suitable for electronic devices, communication equipment, and sensitive instruments.Expand Specific Solutions04 Flexible and stretchable metal mesh structures

Innovations in flexible and stretchable metal mesh structures enable applications in wearable electronics, flexible displays, and conformable sensors. These meshes maintain electrical conductivity under bending, stretching, and other deformations. Special design patterns, substrate materials, and fabrication techniques are employed to enhance mechanical durability while preserving electrical performance under strain.Expand Specific Solutions05 Metal mesh for energy applications

Metal mesh structures are utilized in energy-related applications such as batteries, fuel cells, solar cells, and catalytic systems. The mesh design provides high surface area, controlled porosity, and efficient electron transport pathways. These structures can serve as current collectors, electrodes, or structural supports in energy generation, storage, and conversion devices, enhancing performance through optimized material utilization and improved reaction kinetics.Expand Specific Solutions

Key Industry Players in Metal Mesh Structural Solutions

The metal mesh structural applications market is currently in a growth phase, characterized by increasing adoption across architectural, aerospace, and telecommunications sectors. The global market size is estimated to exceed $5 billion, with projected annual growth of 7-8% driven by demand for lightweight, high-strength materials. Technologically, the field shows varying maturity levels, with established players like Zhejiang Southeast Space Frame and Officine Maccaferri leading in traditional applications, while innovation frontiers are being pushed by research institutions including Zhejiang University and Harbin Institute of Technology. Companies like ANSYS and AUTODESK are advancing simulation capabilities, while manufacturers such as BOE Technology and OPPO are exploring novel applications in consumer electronics. Industrial players including Battelle Memorial Institute and Taiwan Semiconductor are developing specialized implementations for high-performance environments.

Airbus Espana SL

Technical Solution: Airbus España has developed cutting-edge metal mesh structural applications specifically for aerospace requirements. Their technology centers on lightweight aluminum and titanium alloy mesh structures that provide exceptional strength-to-weight ratios critical for aircraft components. The company has pioneered advanced manufacturing techniques including selective laser melting (SLM) and direct metal laser sintering (DMLS) to create complex mesh geometries with precisely controlled node connections and strut thicknesses (typically 0.3-2.0mm). These additive manufacturing processes enable the production of optimized lattice structures that can reduce component weight by 30-50% while maintaining structural integrity. Airbus's metal mesh designs incorporate variable density patterns that place material only where needed for load-bearing, resulting in biomimetic structures that efficiently distribute stresses. Their proprietary mesh topologies have been implemented in aircraft structural components including wing ribs, fuselage frames, and engine mounting brackets. Testing has demonstrated these mesh structures can withstand operating temperatures from -55°C to 350°C while maintaining mechanical properties and providing superior fatigue resistance compared to traditional solid structures[5][7].

Strengths: Exceptional weight reduction capabilities critical for aerospace applications; ability to create complex geometries impossible with traditional manufacturing; excellent thermal management properties. Weaknesses: High production costs compared to conventional structures; longer manufacturing times; requires specialized design expertise and advanced simulation capabilities.

AUTODESK INC

Technical Solution: Autodesk has developed advanced computational design and simulation technologies specifically for metal mesh structural applications. Their generative design platform enables the creation of optimized metal mesh structures by defining performance requirements and constraints, allowing AI algorithms to explore thousands of design possibilities. The software can generate complex lattice and mesh structures with variable density patterns that place material only where needed for structural integrity, potentially reducing material usage by 30-60% compared to traditional designs. Autodesk's simulation tools provide accurate prediction of mechanical behavior under various loading conditions, including static, dynamic, and thermal stresses. Their Netfabb software specifically addresses metal additive manufacturing challenges for mesh structures, with tools for lattice optimization, support structure generation, and build preparation. The company has pioneered topology optimization algorithms that can create mesh structures with optimized node connections and strut thicknesses based on specific loading conditions. These tools have been applied across industries including aerospace, automotive, and medical device manufacturing, enabling the production of lightweight yet strong components with complex geometries impossible to achieve through traditional manufacturing methods[9][11].

Strengths: Comprehensive end-to-end solution from design to manufacturing preparation; powerful optimization algorithms that create highly efficient structures; extensive material simulation capabilities. Weaknesses: Steep learning curve for effective implementation; high computational requirements for complex simulations; optimization results sometimes require significant manual refinement for manufacturability.

Core Patents and Technical Literature in Metal Mesh Innovation

Metal mesh structure, touch display device and mobile terminal

PatentActiveUS11914830B2

Innovation

- A metal mesh structure for capacitive touch screens is developed, comprising multiple layers with specific thicknesses and materials, including coating layers on metal mesh layers, eliminating the need for a polymer substrate, which enhances conductivity, reduces surface resistance, and improves transmittance and thinness.

Material Science Advancements for Enhanced Metal Mesh Performance

Recent advancements in material science have significantly transformed the landscape of metal mesh structural applications. The evolution of metallurgical processes has enabled the development of high-performance alloys specifically engineered for mesh structures, offering unprecedented combinations of strength, flexibility, and corrosion resistance. These innovations have expanded the functional capabilities of metal mesh beyond traditional applications.

Nano-engineering techniques have emerged as a revolutionary approach to enhancing metal mesh performance. By manipulating material properties at the nanoscale, researchers have successfully created mesh structures with self-healing capabilities, improved fatigue resistance, and enhanced load-bearing capacity. Surface modification technologies, including advanced coating systems and controlled oxidation processes, have further extended the durability and environmental adaptability of metal mesh structures.

Composite metal mesh systems represent another significant breakthrough, combining different metal alloys or integrating metal with non-metallic materials to achieve synergistic performance benefits. These hybrid structures demonstrate superior mechanical properties while maintaining essential characteristics such as electrical conductivity and thermal stability. The integration of smart materials into metal mesh designs has introduced responsive capabilities, allowing structures to adapt to changing environmental conditions or applied forces.

Additive manufacturing has revolutionized the production of complex metal mesh geometries that were previously impossible to fabricate using conventional methods. This technology enables precise control over porosity, node configuration, and structural gradients, resulting in optimized performance characteristics for specific applications. The ability to create biomimetic designs inspired by natural structures has led to metal mesh systems with exceptional strength-to-weight ratios and novel functional properties.

Computational materials science has accelerated innovation through predictive modeling and simulation of metal mesh behavior under various conditions. These digital tools allow researchers to explore virtual prototypes and optimize material compositions before physical fabrication, significantly reducing development cycles and costs. Machine learning algorithms have further enhanced this capability by identifying non-intuitive material combinations and processing parameters that yield superior performance metrics.

Sustainable manufacturing approaches have gained prominence in metal mesh development, focusing on recyclable alloys, energy-efficient production methods, and reduced material waste. These environmentally conscious innovations address growing market demands for responsible material usage while maintaining or improving technical performance. The emergence of closed-loop material systems for metal mesh production represents a promising direction for future development in this field.

Nano-engineering techniques have emerged as a revolutionary approach to enhancing metal mesh performance. By manipulating material properties at the nanoscale, researchers have successfully created mesh structures with self-healing capabilities, improved fatigue resistance, and enhanced load-bearing capacity. Surface modification technologies, including advanced coating systems and controlled oxidation processes, have further extended the durability and environmental adaptability of metal mesh structures.

Composite metal mesh systems represent another significant breakthrough, combining different metal alloys or integrating metal with non-metallic materials to achieve synergistic performance benefits. These hybrid structures demonstrate superior mechanical properties while maintaining essential characteristics such as electrical conductivity and thermal stability. The integration of smart materials into metal mesh designs has introduced responsive capabilities, allowing structures to adapt to changing environmental conditions or applied forces.

Additive manufacturing has revolutionized the production of complex metal mesh geometries that were previously impossible to fabricate using conventional methods. This technology enables precise control over porosity, node configuration, and structural gradients, resulting in optimized performance characteristics for specific applications. The ability to create biomimetic designs inspired by natural structures has led to metal mesh systems with exceptional strength-to-weight ratios and novel functional properties.

Computational materials science has accelerated innovation through predictive modeling and simulation of metal mesh behavior under various conditions. These digital tools allow researchers to explore virtual prototypes and optimize material compositions before physical fabrication, significantly reducing development cycles and costs. Machine learning algorithms have further enhanced this capability by identifying non-intuitive material combinations and processing parameters that yield superior performance metrics.

Sustainable manufacturing approaches have gained prominence in metal mesh development, focusing on recyclable alloys, energy-efficient production methods, and reduced material waste. These environmentally conscious innovations address growing market demands for responsible material usage while maintaining or improving technical performance. The emergence of closed-loop material systems for metal mesh production represents a promising direction for future development in this field.

Sustainability and Environmental Impact of Metal Mesh Structures

Metal mesh structures have emerged as significant contributors to sustainable construction and design practices. The environmental impact of these structures begins with their material composition, where the use of recycled metals can reduce the carbon footprint by up to 70% compared to virgin material production. Additionally, the manufacturing process of metal meshes has evolved to incorporate energy-efficient technologies, reducing overall emissions by approximately 30% over the past decade.

The lifecycle assessment of metal mesh structures reveals impressive sustainability credentials. These structures typically demonstrate a lifespan of 50-75 years with minimal maintenance requirements, significantly outperforming many alternative materials. This longevity translates directly into reduced resource consumption and waste generation over time. Furthermore, at end-of-life, metal mesh components maintain a recycling rate exceeding 90%, creating a nearly closed-loop material system.

Energy efficiency represents another critical environmental advantage of metal mesh applications. When implemented as building facades, these structures can reduce solar heat gain by 40-60% while maintaining natural light transmission, resulting in decreased cooling loads and associated energy consumption. Studies from the Building Research Establishment indicate that properly designed metal mesh shading systems can contribute to energy savings of 15-25% in commercial buildings across various climate zones.

Water management capabilities further enhance the sustainability profile of metal mesh structures. Innovative designs incorporate rainwater collection and filtration systems, with some installations demonstrating capacity to capture and repurpose up to 80% of incident precipitation. This feature proves particularly valuable in urban environments where stormwater management presents significant challenges.

The biodiversity impact of metal mesh structures also warrants consideration. Green wall systems utilizing metal mesh frameworks support vertical gardens that can increase urban biodiversity while improving air quality. Research indicates that such installations can capture particulate matter and absorb gaseous pollutants, with some designs filtering up to 20% of airborne particulates in their immediate vicinity.

Carbon sequestration potential represents an emerging area of research, with metal mesh structures serving as frameworks for algae cultivation or specialized carbon-capturing coatings. Preliminary studies suggest that bioreactive metal mesh facades could potentially absorb 5-8 times more carbon dioxide than equivalent areas of conventional tree planting, though these technologies remain in developmental stages.

The lifecycle assessment of metal mesh structures reveals impressive sustainability credentials. These structures typically demonstrate a lifespan of 50-75 years with minimal maintenance requirements, significantly outperforming many alternative materials. This longevity translates directly into reduced resource consumption and waste generation over time. Furthermore, at end-of-life, metal mesh components maintain a recycling rate exceeding 90%, creating a nearly closed-loop material system.

Energy efficiency represents another critical environmental advantage of metal mesh applications. When implemented as building facades, these structures can reduce solar heat gain by 40-60% while maintaining natural light transmission, resulting in decreased cooling loads and associated energy consumption. Studies from the Building Research Establishment indicate that properly designed metal mesh shading systems can contribute to energy savings of 15-25% in commercial buildings across various climate zones.

Water management capabilities further enhance the sustainability profile of metal mesh structures. Innovative designs incorporate rainwater collection and filtration systems, with some installations demonstrating capacity to capture and repurpose up to 80% of incident precipitation. This feature proves particularly valuable in urban environments where stormwater management presents significant challenges.

The biodiversity impact of metal mesh structures also warrants consideration. Green wall systems utilizing metal mesh frameworks support vertical gardens that can increase urban biodiversity while improving air quality. Research indicates that such installations can capture particulate matter and absorb gaseous pollutants, with some designs filtering up to 20% of airborne particulates in their immediate vicinity.

Carbon sequestration potential represents an emerging area of research, with metal mesh structures serving as frameworks for algae cultivation or specialized carbon-capturing coatings. Preliminary studies suggest that bioreactive metal mesh facades could potentially absorb 5-8 times more carbon dioxide than equivalent areas of conventional tree planting, though these technologies remain in developmental stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!