Apply Predictive Maintenance to Improve Turbine Engine Lifespan

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Predictive Maintenance Background and Objectives

Predictive maintenance for turbine engines represents a significant evolution in industrial maintenance strategies, transitioning from reactive and preventive approaches to more sophisticated, data-driven methodologies. The development of this technology can be traced back to the early 2000s when condition-based monitoring began incorporating digital sensors and basic analytics. Over the past decade, advancements in IoT, big data analytics, and machine learning have accelerated this field dramatically, enabling real-time monitoring and increasingly accurate failure predictions.

The technological trajectory shows a clear progression from simple threshold-based alerts to complex machine learning models capable of identifying subtle patterns that precede component failures. Recent innovations have focused on integrating physics-based models with data-driven approaches, creating hybrid systems that leverage both theoretical understanding of turbine mechanics and empirical operational data.

The primary objective of predictive maintenance in turbine engines is to maximize operational efficiency while minimizing downtime and maintenance costs. Specifically, this technology aims to accurately predict potential failures before they occur, optimize maintenance scheduling, extend engine lifespan, and reduce unplanned downtime that can cost millions in lost production and emergency repairs.

Secondary objectives include reducing spare parts inventory by enabling just-in-time procurement, improving fuel efficiency through optimal engine performance, enhancing safety by preventing catastrophic failures, and generating valuable data insights for future engine design improvements. The technology also seeks to establish a framework for continuous improvement in maintenance practices through machine learning models that become increasingly accurate over time.

Current research trends indicate movement toward more sophisticated sensor integration, edge computing for real-time analysis, and the application of deep learning techniques for more nuanced pattern recognition. The integration of digital twin technology is emerging as a particularly promising direction, allowing for virtual simulation of engine performance under various conditions.

The ultimate goal is to achieve a maintenance paradigm that approaches "zero unplanned downtime" while maximizing the useful life of each component. This represents a fundamental shift from the traditional time-based maintenance approach to one that is truly condition-based and predictive, potentially extending turbine engine lifespan by 15-30% while reducing maintenance costs by up to 25%.

The technological trajectory shows a clear progression from simple threshold-based alerts to complex machine learning models capable of identifying subtle patterns that precede component failures. Recent innovations have focused on integrating physics-based models with data-driven approaches, creating hybrid systems that leverage both theoretical understanding of turbine mechanics and empirical operational data.

The primary objective of predictive maintenance in turbine engines is to maximize operational efficiency while minimizing downtime and maintenance costs. Specifically, this technology aims to accurately predict potential failures before they occur, optimize maintenance scheduling, extend engine lifespan, and reduce unplanned downtime that can cost millions in lost production and emergency repairs.

Secondary objectives include reducing spare parts inventory by enabling just-in-time procurement, improving fuel efficiency through optimal engine performance, enhancing safety by preventing catastrophic failures, and generating valuable data insights for future engine design improvements. The technology also seeks to establish a framework for continuous improvement in maintenance practices through machine learning models that become increasingly accurate over time.

Current research trends indicate movement toward more sophisticated sensor integration, edge computing for real-time analysis, and the application of deep learning techniques for more nuanced pattern recognition. The integration of digital twin technology is emerging as a particularly promising direction, allowing for virtual simulation of engine performance under various conditions.

The ultimate goal is to achieve a maintenance paradigm that approaches "zero unplanned downtime" while maximizing the useful life of each component. This represents a fundamental shift from the traditional time-based maintenance approach to one that is truly condition-based and predictive, potentially extending turbine engine lifespan by 15-30% while reducing maintenance costs by up to 25%.

Market Demand Analysis for Engine Lifespan Extension

The global market for turbine engine lifespan extension technologies is experiencing significant growth, driven primarily by the aviation, power generation, and industrial sectors. Current market analysis indicates that the predictive maintenance segment within this space is expanding at a compound annual growth rate of approximately 25-30%, reflecting the urgent need for solutions that can extend equipment life while reducing operational costs.

In the aviation sector, commercial airlines face immense pressure to maximize aircraft utilization while minimizing maintenance-related downtime. With each day of unscheduled maintenance potentially costing airlines between $500,000 and $1 million in lost revenue, the economic incentive for implementing predictive maintenance solutions is substantial. Military aviation faces similar challenges, with defense departments worldwide seeking to extend the service life of expensive engine assets.

The power generation industry represents another major market segment, where gas turbines in particular benefit from lifespan extension technologies. Power plant operators typically aim to extend maintenance intervals by 15-20% while reducing overall maintenance costs by 25-30%. This demand is particularly strong in regions with aging power infrastructure, such as North America and Western Europe.

Market research reveals that industrial customers are increasingly prioritizing total cost of ownership over initial acquisition costs when evaluating turbine technologies. This shift has created a fertile environment for predictive maintenance solutions that can demonstrate clear return on investment through extended equipment life and reduced unplanned downtime.

Geographically, North America currently leads the market for engine lifespan extension technologies, followed closely by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where rapid industrialization is driving demand for more efficient maintenance practices.

Customer surveys indicate that key buying criteria include integration capabilities with existing systems, demonstrated reliability improvements, and quantifiable cost savings. End users consistently express preference for solutions that offer real-time monitoring capabilities and actionable insights rather than just data collection.

The market is also being shaped by regulatory factors, with increasingly stringent emissions and safety standards driving operators to seek more sophisticated maintenance approaches that can ensure compliance while maximizing asset utilization. This regulatory pressure is particularly evident in the aviation sector, where safety considerations make predictive maintenance an attractive alternative to traditional time-based maintenance schedules.

In the aviation sector, commercial airlines face immense pressure to maximize aircraft utilization while minimizing maintenance-related downtime. With each day of unscheduled maintenance potentially costing airlines between $500,000 and $1 million in lost revenue, the economic incentive for implementing predictive maintenance solutions is substantial. Military aviation faces similar challenges, with defense departments worldwide seeking to extend the service life of expensive engine assets.

The power generation industry represents another major market segment, where gas turbines in particular benefit from lifespan extension technologies. Power plant operators typically aim to extend maintenance intervals by 15-20% while reducing overall maintenance costs by 25-30%. This demand is particularly strong in regions with aging power infrastructure, such as North America and Western Europe.

Market research reveals that industrial customers are increasingly prioritizing total cost of ownership over initial acquisition costs when evaluating turbine technologies. This shift has created a fertile environment for predictive maintenance solutions that can demonstrate clear return on investment through extended equipment life and reduced unplanned downtime.

Geographically, North America currently leads the market for engine lifespan extension technologies, followed closely by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where rapid industrialization is driving demand for more efficient maintenance practices.

Customer surveys indicate that key buying criteria include integration capabilities with existing systems, demonstrated reliability improvements, and quantifiable cost savings. End users consistently express preference for solutions that offer real-time monitoring capabilities and actionable insights rather than just data collection.

The market is also being shaped by regulatory factors, with increasingly stringent emissions and safety standards driving operators to seek more sophisticated maintenance approaches that can ensure compliance while maximizing asset utilization. This regulatory pressure is particularly evident in the aviation sector, where safety considerations make predictive maintenance an attractive alternative to traditional time-based maintenance schedules.

Current Predictive Maintenance Technologies and Challenges

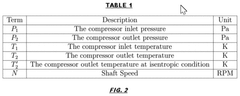

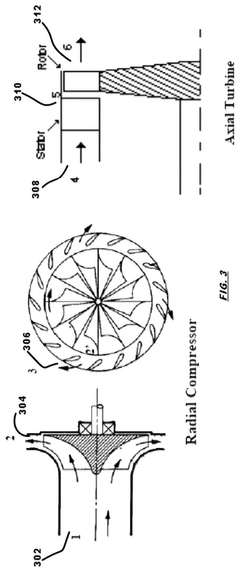

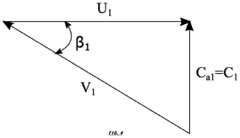

Predictive maintenance technologies for turbine engines have evolved significantly in recent years, driven by advancements in sensor technology, data analytics, and machine learning algorithms. Current solutions primarily rely on condition monitoring systems that collect real-time data from various engine components through embedded sensors measuring parameters such as temperature, pressure, vibration, and fuel flow rates. These systems enable continuous assessment of engine health and performance without requiring physical inspection or shutdown.

Data acquisition systems have become increasingly sophisticated, with modern turbines featuring hundreds of sensors generating terabytes of operational data. This data is transmitted through secure networks to centralized monitoring centers where it undergoes preliminary processing and analysis. The integration of edge computing capabilities has further enhanced this process by enabling preliminary data processing directly at the source, reducing latency and bandwidth requirements.

Analytics platforms employ various techniques to identify patterns and anomalies in turbine performance data. Traditional statistical methods such as regression analysis and time series forecasting remain valuable for establishing baseline performance metrics and identifying deviations. However, machine learning algorithms including random forests, support vector machines, and neural networks have demonstrated superior capabilities in detecting subtle patterns that might indicate impending failures.

Digital twin technology represents another significant advancement, creating virtual replicas of physical turbine engines that simulate performance under various operating conditions. These models are continuously updated with real-time data, allowing engineers to predict how components will behave over time and under different stress scenarios. This approach enables more accurate remaining useful life (RUL) predictions and optimization of maintenance schedules.

Despite these technological advances, significant challenges persist in implementing effective predictive maintenance systems for turbine engines. Data quality issues, including sensor drift, calibration errors, and missing values, can compromise the accuracy of predictive models. The heterogeneity of data formats and protocols across different turbine models and manufacturers creates integration difficulties when implementing enterprise-wide maintenance solutions.

Model accuracy and reliability remain ongoing concerns, particularly in complex operational environments where multiple variables interact in non-linear ways. False positives can lead to unnecessary maintenance interventions and costs, while false negatives might result in catastrophic failures. Additionally, the computational requirements for processing massive datasets and running sophisticated models in real-time present infrastructure challenges for many organizations.

Workforce adaptation represents another significant hurdle, as maintenance teams must transition from traditional schedule-based approaches to data-driven decision-making processes. This requires substantial investment in training and organizational change management to ensure that technical staff can effectively interpret and act upon the insights generated by predictive maintenance systems.

Data acquisition systems have become increasingly sophisticated, with modern turbines featuring hundreds of sensors generating terabytes of operational data. This data is transmitted through secure networks to centralized monitoring centers where it undergoes preliminary processing and analysis. The integration of edge computing capabilities has further enhanced this process by enabling preliminary data processing directly at the source, reducing latency and bandwidth requirements.

Analytics platforms employ various techniques to identify patterns and anomalies in turbine performance data. Traditional statistical methods such as regression analysis and time series forecasting remain valuable for establishing baseline performance metrics and identifying deviations. However, machine learning algorithms including random forests, support vector machines, and neural networks have demonstrated superior capabilities in detecting subtle patterns that might indicate impending failures.

Digital twin technology represents another significant advancement, creating virtual replicas of physical turbine engines that simulate performance under various operating conditions. These models are continuously updated with real-time data, allowing engineers to predict how components will behave over time and under different stress scenarios. This approach enables more accurate remaining useful life (RUL) predictions and optimization of maintenance schedules.

Despite these technological advances, significant challenges persist in implementing effective predictive maintenance systems for turbine engines. Data quality issues, including sensor drift, calibration errors, and missing values, can compromise the accuracy of predictive models. The heterogeneity of data formats and protocols across different turbine models and manufacturers creates integration difficulties when implementing enterprise-wide maintenance solutions.

Model accuracy and reliability remain ongoing concerns, particularly in complex operational environments where multiple variables interact in non-linear ways. False positives can lead to unnecessary maintenance interventions and costs, while false negatives might result in catastrophic failures. Additionally, the computational requirements for processing massive datasets and running sophisticated models in real-time present infrastructure challenges for many organizations.

Workforce adaptation represents another significant hurdle, as maintenance teams must transition from traditional schedule-based approaches to data-driven decision-making processes. This requires substantial investment in training and organizational change management to ensure that technical staff can effectively interpret and act upon the insights generated by predictive maintenance systems.

Existing Predictive Maintenance Implementation Strategies

01 Data-driven predictive maintenance models

Advanced algorithms and machine learning techniques are used to analyze historical equipment data, operational parameters, and failure patterns to predict maintenance needs and estimate remaining useful life. These models can identify early warning signs of potential failures, allowing for timely interventions before critical breakdowns occur. By continuously learning from new data, these systems improve prediction accuracy over time, optimizing maintenance schedules and extending equipment lifespan.- Data-driven predictive maintenance models: Advanced algorithms and machine learning techniques are used to analyze historical equipment data, operational parameters, and failure patterns to predict maintenance needs and estimate remaining useful life. These models can identify early warning signs of potential failures, allowing for timely interventions before critical breakdowns occur. By continuously learning from new data, these systems improve prediction accuracy over time, optimizing maintenance schedules and extending equipment lifespan.

- Sensor-based condition monitoring systems: Real-time monitoring systems utilize various sensors to continuously track equipment health indicators such as vibration, temperature, pressure, and acoustic emissions. These systems collect and process data to detect anomalies and deviations from normal operating conditions. By establishing baseline performance metrics and monitoring trends over time, these systems can accurately predict when components are likely to fail, enabling proactive maintenance interventions and extending the operational lifespan of industrial assets.

- Lifecycle management and optimization frameworks: Comprehensive frameworks for managing the entire lifecycle of assets incorporate predictive maintenance as a key component. These frameworks integrate maintenance history, operational data, and manufacturer specifications to optimize maintenance strategies and extend equipment lifespan. By balancing maintenance costs against performance requirements and failure risks, these systems help organizations make informed decisions about when to repair, refurbish, or replace assets, maximizing return on investment while minimizing downtime.

- IoT and cloud-based predictive maintenance platforms: Internet of Things (IoT) technologies enable the collection and transmission of equipment data to cloud-based platforms for advanced analytics. These platforms leverage connectivity between machines, sensors, and maintenance systems to create comprehensive predictive maintenance solutions. By centralizing data storage and processing, these systems can identify patterns across multiple assets and facilities, providing scalable predictive maintenance capabilities that adapt to changing operational conditions and extend equipment lifespan.

- Digital twin technology for lifespan prediction: Digital twin technology creates virtual replicas of physical assets that simulate their behavior under various conditions. These models incorporate real-time operational data, historical performance metrics, and engineering specifications to accurately predict component degradation and failure points. By running simulations and what-if scenarios, digital twins help maintenance teams understand how different operational parameters affect equipment lifespan, enabling optimization of both performance and longevity through targeted maintenance interventions.

02 IoT and sensor-based condition monitoring

Internet of Things (IoT) devices and advanced sensors continuously monitor equipment health parameters such as temperature, vibration, pressure, and acoustic emissions in real-time. These sensors collect and transmit data to centralized systems for analysis, enabling the detection of anomalies and deterioration patterns before they lead to failures. This approach transforms traditional time-based maintenance into condition-based maintenance, significantly improving equipment lifespan prediction accuracy and reducing unnecessary maintenance interventions.Expand Specific Solutions03 Digital twin technology for lifespan simulation

Digital twin technology creates virtual replicas of physical assets that simulate their behavior under various operating conditions. These models incorporate real-time data from the actual equipment to predict performance degradation and estimate remaining useful life. By running simulations with different operational scenarios, maintenance teams can identify optimal operating parameters to extend equipment lifespan and develop more effective maintenance strategies tailored to specific usage patterns and environmental conditions.Expand Specific Solutions04 Integrated maintenance management systems

Comprehensive software platforms integrate predictive maintenance capabilities with inventory management, work order processing, and resource allocation. These systems analyze equipment health data alongside maintenance history and replacement part availability to optimize maintenance scheduling and resource allocation. By considering multiple factors including operational criticality, failure consequences, and maintenance costs, these platforms enable organizations to implement risk-based maintenance approaches that maximize equipment lifespan while minimizing total ownership costs.Expand Specific Solutions05 Lifecycle assessment and optimization frameworks

Holistic frameworks evaluate equipment throughout its entire lifecycle, from installation to decommissioning. These approaches incorporate factors such as usage patterns, environmental conditions, maintenance history, and component degradation rates to provide comprehensive lifespan assessments. By analyzing the interdependencies between different components and systems, these frameworks can identify critical failure paths and recommend targeted interventions to extend overall equipment life. They also enable better long-term planning for capital expenditures and replacement strategies.Expand Specific Solutions

Leading Players in Predictive Maintenance Solutions

The predictive maintenance market for turbine engines is in a growth phase, characterized by increasing adoption across aviation, power generation, and industrial sectors. The market size is expanding rapidly, driven by the need to reduce downtime and extend equipment lifespan. Technologically, the field is maturing with major players like General Electric, Siemens AG, and Mitsubishi Heavy Industries leading innovation through AI and IoT integration. Aviation specialists including Pratt & Whitney and MTU Aero Engines are developing sophisticated algorithms for early failure detection, while newer entrants like Averroes.ai are bringing specialized AI solutions. IBM's data analytics capabilities and Caterpillar's industrial expertise further diversify the competitive landscape, creating a robust ecosystem of solutions ranging from established enterprise platforms to emerging specialized technologies.

General Electric Company

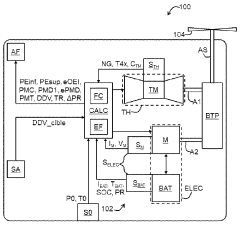

Technical Solution: GE's predictive maintenance solution for turbine engines leverages their Digital Twin technology combined with advanced analytics. Their system collects real-time operational data from sensors embedded throughout turbine engines, monitoring parameters such as temperature, pressure, vibration, and fuel flow. This data is processed through machine learning algorithms that can detect anomalies and predict potential failures weeks or months before they occur. GE's Predix platform serves as the foundation for their predictive maintenance capabilities, enabling continuous monitoring across fleets of engines. The system incorporates historical maintenance records and operational data to refine predictive models over time, achieving up to 99.5% prediction accuracy in some applications. GE has demonstrated that their predictive maintenance solutions can reduce unplanned downtime by up to 60% and extend turbine engine lifespan by 10-15% through optimized maintenance scheduling and early intervention protocols.

Strengths: Extensive experience with turbine technology; proprietary Digital Twin technology provides highly accurate modeling; comprehensive sensor integration capabilities; global service network for implementation. Weaknesses: Solutions can be costly to implement; may require significant infrastructure upgrades; high dependency on connectivity for real-time monitoring; potential vendor lock-in with proprietary systems.

Siemens AG

Technical Solution: Siemens has developed an integrated predictive maintenance approach for turbine engines that combines physics-based models with AI-driven analytics. Their solution utilizes MindSphere, Siemens' cloud-based IoT operating system, to collect and analyze operational data from turbines. The system employs a multi-layered approach to failure prediction, incorporating vibration analysis, thermal imaging, oil analysis, and acoustic monitoring. Siemens' predictive algorithms can identify developing issues such as bearing wear, blade deterioration, and combustion inefficiencies before they cause significant damage. Their solution includes automated workflow generation for maintenance teams, with specific repair recommendations and priority levels based on predicted failure impacts. Siemens has implemented this technology across power generation facilities worldwide, reporting maintenance cost reductions of up to 30% and turbine availability improvements of 5-8%. The system continuously evolves through machine learning, becoming more accurate as it processes more operational data and maintenance outcomes.

Strengths: Comprehensive integration with existing industrial control systems; strong physics-based modeling capabilities; extensive experience with power generation equipment; scalable solutions for different turbine sizes. Weaknesses: Complex implementation requiring specialized expertise; significant initial investment; requires substantial historical data for optimal performance; challenges in retrofitting older turbine systems.

Key Algorithms and Sensor Technologies Analysis

Monitoring of an aircraft propulsion system

PatentWO2024023461A1

Innovation

- A method for monitoring the turbine engine's propulsion system, involving the calculation of maximum increment speeds for damage counters based on target lifespan, with thresholds set to prevent exceeding predefined limits, and transmitting current operating quantities to a display device for pilot management.

Gas turbine engine lifecycle digital-twin design, monitoring and maintenance

PatentPendingUS20250225297A1

Innovation

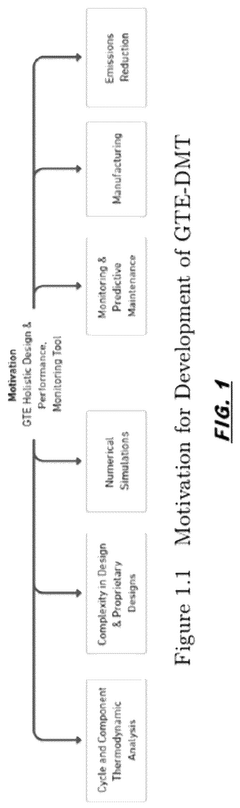

- A digital twin system integrated with a graphical user interface and machine learning algorithms to predict performance, optimize design, and provide real-time monitoring and maintenance indicators, utilizing operational data and physics-based models to enhance efficiency and reliability.

ROI Assessment of Predictive Maintenance Implementation

Implementing predictive maintenance for turbine engines presents a compelling financial case when properly analyzed. The return on investment (ROI) assessment reveals that organizations typically achieve payback within 12-18 months of implementation, with ROI rates ranging from 200% to 500% over a five-year period, depending on fleet size and implementation scope.

Initial implementation costs include sensor hardware ($1,000-$5,000 per turbine), data infrastructure development ($50,000-$200,000), predictive analytics software licensing ($75,000-$150,000 annually), and staff training ($25,000-$50,000). While these figures represent significant upfront investment, they are substantially offset by the resulting benefits.

The most significant financial gains come from unplanned downtime reduction, typically decreasing by 30-45% within the first year of implementation. For power generation facilities, this translates to approximately $50,000-$100,000 saved per avoided day of downtime per turbine. Aviation applications show even more dramatic savings, with unplanned maintenance events costing $10,000-$50,000 per hour depending on aircraft type.

Maintenance cost reductions represent another major benefit, with parts and labor expenses decreasing by 20-30% through condition-based maintenance rather than time-based approaches. The extended turbine lifespan—typically 15-25% longer—creates substantial long-term value, particularly for assets with high replacement costs.

Energy efficiency improvements of 2-5% may seem modest but accumulate significantly over time. For a 100MW turbine operating at 75% capacity, this efficiency gain represents approximately $500,000-$1.3 million in additional annual revenue.

Risk mitigation benefits, while harder to quantify, include reduced safety incidents, regulatory compliance improvements, and enhanced operational reliability. Insurance providers increasingly offer premium discounts of 5-15% for organizations implementing comprehensive predictive maintenance programs.

The scalability factor significantly impacts ROI calculations. Organizations implementing predictive maintenance across multiple turbines or facilities achieve economies of scale, with per-unit costs decreasing as the program expands. Data collected from one turbine type can often inform maintenance strategies for similar equipment, creating a network effect that enhances the overall value proposition.

Initial implementation costs include sensor hardware ($1,000-$5,000 per turbine), data infrastructure development ($50,000-$200,000), predictive analytics software licensing ($75,000-$150,000 annually), and staff training ($25,000-$50,000). While these figures represent significant upfront investment, they are substantially offset by the resulting benefits.

The most significant financial gains come from unplanned downtime reduction, typically decreasing by 30-45% within the first year of implementation. For power generation facilities, this translates to approximately $50,000-$100,000 saved per avoided day of downtime per turbine. Aviation applications show even more dramatic savings, with unplanned maintenance events costing $10,000-$50,000 per hour depending on aircraft type.

Maintenance cost reductions represent another major benefit, with parts and labor expenses decreasing by 20-30% through condition-based maintenance rather than time-based approaches. The extended turbine lifespan—typically 15-25% longer—creates substantial long-term value, particularly for assets with high replacement costs.

Energy efficiency improvements of 2-5% may seem modest but accumulate significantly over time. For a 100MW turbine operating at 75% capacity, this efficiency gain represents approximately $500,000-$1.3 million in additional annual revenue.

Risk mitigation benefits, while harder to quantify, include reduced safety incidents, regulatory compliance improvements, and enhanced operational reliability. Insurance providers increasingly offer premium discounts of 5-15% for organizations implementing comprehensive predictive maintenance programs.

The scalability factor significantly impacts ROI calculations. Organizations implementing predictive maintenance across multiple turbines or facilities achieve economies of scale, with per-unit costs decreasing as the program expands. Data collected from one turbine type can often inform maintenance strategies for similar equipment, creating a network effect that enhances the overall value proposition.

Data Security and Integration Considerations

Implementing predictive maintenance for turbine engines necessitates robust data security and integration frameworks. The sensitive nature of operational data from turbine engines requires comprehensive security measures to protect against unauthorized access and potential cyber threats. Organizations must establish multi-layered security protocols including encryption of data both at rest and in transit, implementation of role-based access controls, and regular security audits to identify vulnerabilities. Additionally, compliance with industry regulations such as GDPR, HIPAA, or sector-specific standards is essential to avoid legal complications and maintain stakeholder trust.

Data integration presents significant challenges when implementing predictive maintenance systems for turbine engines. These systems typically collect data from diverse sources including sensors, maintenance records, operational logs, and environmental monitoring systems. The heterogeneity of data formats, sampling rates, and quality levels necessitates sophisticated integration strategies. Organizations should implement standardized data pipelines with robust ETL (Extract, Transform, Load) processes to ensure data consistency and reliability. Real-time data integration capabilities are particularly crucial for turbine engines where immediate detection of anomalies can prevent catastrophic failures.

The volume and velocity of data generated by modern turbine engines create additional integration challenges. A typical industrial turbine can generate terabytes of operational data annually through hundreds of sensors monitoring various parameters. Edge computing solutions can help manage this data deluge by performing preliminary processing and filtering at the source, reducing bandwidth requirements and enabling faster response times. Cloud-based storage and processing solutions offer scalability but must be carefully designed to maintain performance and security standards.

Data ownership and sharing considerations also impact predictive maintenance implementations. In multi-stakeholder environments involving OEMs, operators, and maintenance service providers, clear data governance frameworks must define data ownership, usage rights, and sharing protocols. Blockchain technologies are emerging as potential solutions for maintaining secure, transparent records of data transactions between parties while preserving intellectual property rights.

Integration with existing enterprise systems represents another critical consideration. Predictive maintenance solutions must seamlessly connect with enterprise asset management systems, computerized maintenance management systems, and enterprise resource planning platforms to deliver maximum value. API-based integration approaches offer flexibility and modularity, allowing organizations to adapt their predictive maintenance capabilities as technology evolves without disrupting core business operations.

Data integration presents significant challenges when implementing predictive maintenance systems for turbine engines. These systems typically collect data from diverse sources including sensors, maintenance records, operational logs, and environmental monitoring systems. The heterogeneity of data formats, sampling rates, and quality levels necessitates sophisticated integration strategies. Organizations should implement standardized data pipelines with robust ETL (Extract, Transform, Load) processes to ensure data consistency and reliability. Real-time data integration capabilities are particularly crucial for turbine engines where immediate detection of anomalies can prevent catastrophic failures.

The volume and velocity of data generated by modern turbine engines create additional integration challenges. A typical industrial turbine can generate terabytes of operational data annually through hundreds of sensors monitoring various parameters. Edge computing solutions can help manage this data deluge by performing preliminary processing and filtering at the source, reducing bandwidth requirements and enabling faster response times. Cloud-based storage and processing solutions offer scalability but must be carefully designed to maintain performance and security standards.

Data ownership and sharing considerations also impact predictive maintenance implementations. In multi-stakeholder environments involving OEMs, operators, and maintenance service providers, clear data governance frameworks must define data ownership, usage rights, and sharing protocols. Blockchain technologies are emerging as potential solutions for maintaining secure, transparent records of data transactions between parties while preserving intellectual property rights.

Integration with existing enterprise systems represents another critical consideration. Predictive maintenance solutions must seamlessly connect with enterprise asset management systems, computerized maintenance management systems, and enterprise resource planning platforms to deliver maximum value. API-based integration approaches offer flexibility and modularity, allowing organizations to adapt their predictive maintenance capabilities as technology evolves without disrupting core business operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!