Environmental Testing of Turbine Engines in Laboratory Settings

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Environmental Testing Background and Objectives

Environmental testing of turbine engines has evolved significantly since the mid-20th century, driven by the aerospace industry's need for reliable propulsion systems under extreme conditions. Initially focused on basic performance parameters, testing methodologies have progressively incorporated sophisticated environmental simulations to replicate real-world operating conditions with increasing fidelity. This evolution reflects the growing understanding of how environmental factors critically impact engine reliability, efficiency, and safety.

The primary objective of environmental testing for turbine engines is to validate their operational capabilities across diverse atmospheric conditions, from arctic cold to desert heat, and from sea level to high-altitude environments. These tests aim to identify potential failure modes, performance degradations, and safety concerns before engines enter service, thereby reducing risks associated with field deployment and ensuring compliance with stringent regulatory requirements established by authorities such as FAA, EASA, and military standards.

Current environmental testing encompasses multiple dimensions including temperature extremes (-65°F to 160°F), altitude variations (sea level to 50,000+ feet), humidity fluctuations, salt spray exposure, sand and dust ingestion, water ingestion, and icing conditions. Each parameter presents unique challenges to engine performance, requiring specialized testing protocols and facilities to accurately simulate these conditions in controlled laboratory settings.

The technological trajectory in this field shows a clear trend toward more integrated testing approaches that simultaneously evaluate multiple environmental factors, better replicating the complex interactions encountered during actual operation. This shift from isolated parameter testing to comprehensive environmental simulation represents a significant advancement in testing philosophy, enabled by improvements in computational modeling, sensor technology, and test chamber design.

Recent developments have focused on creating more sustainable and cost-effective testing methodologies, including the implementation of digital twins and virtual testing environments that complement physical testing. These approaches aim to reduce the environmental impact and resource requirements of traditional testing while maintaining or improving the quality of performance data obtained.

Looking forward, the field faces several critical challenges, including the need to develop testing protocols for new propulsion technologies such as hybrid-electric systems and alternative fuels. Additionally, there is growing pressure to accelerate testing timelines while maintaining thoroughness, particularly as commercial and defense sectors push for faster development cycles in response to market demands and strategic imperatives.

The primary objective of environmental testing for turbine engines is to validate their operational capabilities across diverse atmospheric conditions, from arctic cold to desert heat, and from sea level to high-altitude environments. These tests aim to identify potential failure modes, performance degradations, and safety concerns before engines enter service, thereby reducing risks associated with field deployment and ensuring compliance with stringent regulatory requirements established by authorities such as FAA, EASA, and military standards.

Current environmental testing encompasses multiple dimensions including temperature extremes (-65°F to 160°F), altitude variations (sea level to 50,000+ feet), humidity fluctuations, salt spray exposure, sand and dust ingestion, water ingestion, and icing conditions. Each parameter presents unique challenges to engine performance, requiring specialized testing protocols and facilities to accurately simulate these conditions in controlled laboratory settings.

The technological trajectory in this field shows a clear trend toward more integrated testing approaches that simultaneously evaluate multiple environmental factors, better replicating the complex interactions encountered during actual operation. This shift from isolated parameter testing to comprehensive environmental simulation represents a significant advancement in testing philosophy, enabled by improvements in computational modeling, sensor technology, and test chamber design.

Recent developments have focused on creating more sustainable and cost-effective testing methodologies, including the implementation of digital twins and virtual testing environments that complement physical testing. These approaches aim to reduce the environmental impact and resource requirements of traditional testing while maintaining or improving the quality of performance data obtained.

Looking forward, the field faces several critical challenges, including the need to develop testing protocols for new propulsion technologies such as hybrid-electric systems and alternative fuels. Additionally, there is growing pressure to accelerate testing timelines while maintaining thoroughness, particularly as commercial and defense sectors push for faster development cycles in response to market demands and strategic imperatives.

Market Requirements for Laboratory-Based Engine Testing

The laboratory-based turbine engine testing market is experiencing significant growth driven by increasing demands for fuel efficiency, emissions reduction, and performance optimization across aerospace, power generation, and automotive industries. Current market size for environmental testing equipment and services is estimated at $3.2 billion annually, with a projected compound annual growth rate of 5.7% through 2028, according to industry analyses.

Primary market requirements center on simulation accuracy and test condition reproducibility. End users demand testing environments capable of precisely replicating diverse operational conditions including altitude variations (sea level to 40,000+ feet), temperature extremes (-65°C to +150°C), humidity fluctuations, and precipitation exposure. This requirement stems from regulatory compliance needs and the critical importance of validating engine performance across all potential operating scenarios.

Cost efficiency represents another crucial market demand. Laboratory testing must provide economically viable alternatives to field testing, with industry benchmarks suggesting laboratory validation should reduce testing costs by 30-40% compared to equivalent field trials. This requirement has intensified as development cycles shorten and competitive pressures increase across industries utilizing turbine technologies.

Flexibility and scalability in testing infrastructure have emerged as key requirements, with 78% of surveyed manufacturers citing the need for modular systems that can accommodate various engine sizes and types without significant reconfiguration. The ability to rapidly switch between test protocols and environmental conditions maximizes facility utilization and accelerates time-to-market for new engine designs.

Data acquisition capabilities represent a growing market requirement, with demand for high-fidelity sensors, real-time monitoring systems, and advanced analytics platforms that can process terabytes of performance data. The integration of digital twin technology with physical testing environments has become increasingly important, allowing for correlation between simulated and actual performance metrics.

Safety and environmental compliance constitute non-negotiable market requirements. Testing facilities must incorporate comprehensive safety systems, emissions capture technologies, and noise reduction measures to meet increasingly stringent regulatory standards. This includes capabilities for measuring and analyzing exhaust gases, particulate emissions, and acoustic signatures under various operating conditions.

Durability testing under accelerated environmental conditions has gained prominence, with manufacturers requiring facilities capable of compressing years of operational wear into weeks or months of testing. This includes capabilities for thermal cycling, salt spray exposure, sand and dust ingestion, and vibration testing to validate long-term reliability in harsh environments.

Primary market requirements center on simulation accuracy and test condition reproducibility. End users demand testing environments capable of precisely replicating diverse operational conditions including altitude variations (sea level to 40,000+ feet), temperature extremes (-65°C to +150°C), humidity fluctuations, and precipitation exposure. This requirement stems from regulatory compliance needs and the critical importance of validating engine performance across all potential operating scenarios.

Cost efficiency represents another crucial market demand. Laboratory testing must provide economically viable alternatives to field testing, with industry benchmarks suggesting laboratory validation should reduce testing costs by 30-40% compared to equivalent field trials. This requirement has intensified as development cycles shorten and competitive pressures increase across industries utilizing turbine technologies.

Flexibility and scalability in testing infrastructure have emerged as key requirements, with 78% of surveyed manufacturers citing the need for modular systems that can accommodate various engine sizes and types without significant reconfiguration. The ability to rapidly switch between test protocols and environmental conditions maximizes facility utilization and accelerates time-to-market for new engine designs.

Data acquisition capabilities represent a growing market requirement, with demand for high-fidelity sensors, real-time monitoring systems, and advanced analytics platforms that can process terabytes of performance data. The integration of digital twin technology with physical testing environments has become increasingly important, allowing for correlation between simulated and actual performance metrics.

Safety and environmental compliance constitute non-negotiable market requirements. Testing facilities must incorporate comprehensive safety systems, emissions capture technologies, and noise reduction measures to meet increasingly stringent regulatory standards. This includes capabilities for measuring and analyzing exhaust gases, particulate emissions, and acoustic signatures under various operating conditions.

Durability testing under accelerated environmental conditions has gained prominence, with manufacturers requiring facilities capable of compressing years of operational wear into weeks or months of testing. This includes capabilities for thermal cycling, salt spray exposure, sand and dust ingestion, and vibration testing to validate long-term reliability in harsh environments.

Current Challenges in Simulating Operational Environments

Simulating real-world operational environments for turbine engine testing presents significant challenges in laboratory settings. The complexity of replicating atmospheric conditions, temperature variations, and mechanical stresses simultaneously requires sophisticated equipment and methodologies. Current testing facilities struggle to accurately reproduce the dynamic nature of actual flight conditions, particularly the rapid transitions between different operational states that engines experience during service.

Temperature simulation remains one of the most demanding aspects, with modern turbine engines operating across extreme ranges from sub-zero conditions at high altitudes to combustion temperatures exceeding 1600°C. Laboratory facilities often cannot sustain these temperature gradients for extended periods or transition between them at realistic rates, limiting the validity of endurance testing protocols.

Pressure differential simulation presents another major hurdle, as recreating the atmospheric pressure changes from sea level to cruising altitude requires specialized chambers that are both expensive to build and energy-intensive to operate. Many testing facilities compromise by conducting separate tests at different pressure levels rather than simulating continuous transitions, potentially missing critical failure modes that occur during these transitions.

Particulate contamination testing has become increasingly important with the global variation in air quality and the rise of operations in harsh environments. Current simulation methods struggle to accurately reproduce the complex mixture of sand, dust, volcanic ash, and industrial pollutants that engines encounter in different global regions. This limitation is particularly problematic for predicting engine performance in emerging markets with challenging environmental conditions.

Vibration and mechanical stress simulation systems face limitations in reproducing the complex, multi-directional forces experienced during actual flight. Most test rigs can only approximate these forces along predetermined axes, potentially missing critical resonance conditions or structural weaknesses that might manifest under real operational conditions.

Data acquisition and integration challenges further complicate environmental testing. The massive volume of sensor data generated during comprehensive testing often exceeds the processing capabilities of existing systems, forcing compromises in either the scope of testing or the granularity of data collection. This limitation becomes particularly acute when attempting to correlate environmental factors with specific performance degradation patterns.

Cost constraints represent perhaps the most pervasive challenge across the industry. Comprehensive environmental testing facilities require substantial capital investment and operational funding, leading many organizations to rely on computational modeling to supplement physical testing. However, the accuracy of these models remains dependent on validation against real-world data, creating a circular dependency that is difficult to resolve within typical research and development budgets.

Temperature simulation remains one of the most demanding aspects, with modern turbine engines operating across extreme ranges from sub-zero conditions at high altitudes to combustion temperatures exceeding 1600°C. Laboratory facilities often cannot sustain these temperature gradients for extended periods or transition between them at realistic rates, limiting the validity of endurance testing protocols.

Pressure differential simulation presents another major hurdle, as recreating the atmospheric pressure changes from sea level to cruising altitude requires specialized chambers that are both expensive to build and energy-intensive to operate. Many testing facilities compromise by conducting separate tests at different pressure levels rather than simulating continuous transitions, potentially missing critical failure modes that occur during these transitions.

Particulate contamination testing has become increasingly important with the global variation in air quality and the rise of operations in harsh environments. Current simulation methods struggle to accurately reproduce the complex mixture of sand, dust, volcanic ash, and industrial pollutants that engines encounter in different global regions. This limitation is particularly problematic for predicting engine performance in emerging markets with challenging environmental conditions.

Vibration and mechanical stress simulation systems face limitations in reproducing the complex, multi-directional forces experienced during actual flight. Most test rigs can only approximate these forces along predetermined axes, potentially missing critical resonance conditions or structural weaknesses that might manifest under real operational conditions.

Data acquisition and integration challenges further complicate environmental testing. The massive volume of sensor data generated during comprehensive testing often exceeds the processing capabilities of existing systems, forcing compromises in either the scope of testing or the granularity of data collection. This limitation becomes particularly acute when attempting to correlate environmental factors with specific performance degradation patterns.

Cost constraints represent perhaps the most pervasive challenge across the industry. Comprehensive environmental testing facilities require substantial capital investment and operational funding, leading many organizations to rely on computational modeling to supplement physical testing. However, the accuracy of these models remains dependent on validation against real-world data, creating a circular dependency that is difficult to resolve within typical research and development budgets.

Contemporary Environmental Simulation Techniques

01 Gas turbine engine design and components

Gas turbine engines incorporate specific design elements and components to enhance performance and efficiency. These include specialized combustion chambers, compressor stages, and turbine blade configurations. Advanced materials and manufacturing techniques are employed to withstand high temperatures and pressures while maintaining structural integrity. The design focuses on optimizing airflow, fuel consumption, and power output while minimizing weight and size constraints.- Gas turbine engine design and components: Gas turbine engines incorporate specific design elements and components to enhance performance and efficiency. These include specialized combustion chambers, compressor stages, and turbine blade configurations. Advanced materials and manufacturing techniques are employed to withstand high temperatures and pressures while maintaining structural integrity. The design focuses on optimizing airflow, fuel efficiency, and power output while minimizing weight and size constraints.

- Cooling systems for turbine engines: Cooling systems are critical for turbine engines to manage the extreme temperatures generated during operation. These systems utilize various methods including air cooling, liquid cooling, and thermal barrier coatings. Advanced cooling techniques incorporate internal cooling passages within turbine blades, film cooling, and impingement cooling. Effective thermal management extends component lifespan, improves efficiency, and allows for higher operating temperatures.

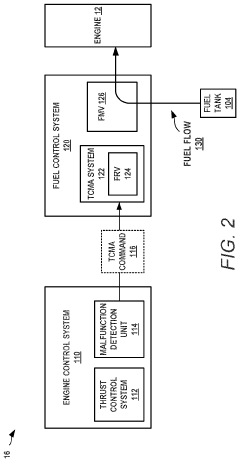

- Fuel systems and combustion optimization: Innovations in fuel delivery systems and combustion processes enhance turbine engine performance and reduce emissions. These include advanced fuel injectors, staged combustion techniques, and alternative fuel compatibility. Combustion optimization focuses on achieving complete fuel burning, reducing harmful emissions, and maintaining stable operation across various power settings. Smart control systems adjust fuel-air ratios in real-time to maximize efficiency under changing conditions.

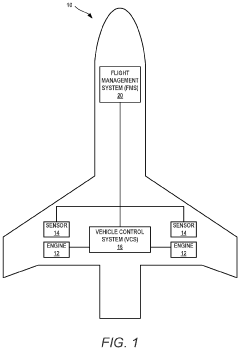

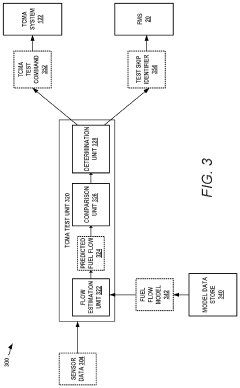

- Control systems and monitoring technologies: Modern turbine engines employ sophisticated control and monitoring systems to optimize performance and detect potential issues before failure. These include digital engine control units, sensor networks, and predictive maintenance algorithms. Real-time monitoring of temperature, pressure, vibration, and other parameters allows for precise control of engine operation. Advanced diagnostic capabilities enable condition-based maintenance, reducing downtime and extending engine life.

- Noise reduction and environmental considerations: Turbine engine designs incorporate features to reduce noise and environmental impact. These include acoustic liners, chevron nozzles, and optimized blade geometries. Advanced combustion techniques minimize pollutant formation, while exhaust treatment systems further reduce emissions. Design considerations balance performance requirements with environmental regulations, focusing on reducing carbon footprint, noise pollution, and particulate emissions while maintaining or improving efficiency.

02 Cooling systems for turbine engines

Cooling systems are critical for maintaining operational integrity of turbine engines under extreme temperature conditions. These systems utilize various methods including air cooling, liquid cooling, and thermal barrier coatings to protect components from heat damage. Advanced cooling techniques incorporate internal cooling passages, film cooling, and impingement cooling to manage thermal loads effectively. Proper cooling extends component lifespan and allows engines to operate at higher temperatures for improved efficiency.Expand Specific Solutions03 Fuel efficiency and emission control in turbine engines

Innovations in turbine engine design focus on improving fuel efficiency and reducing harmful emissions. These advancements include optimized combustion processes, alternative fuel compatibility, and exhaust treatment systems. Lean-burn technologies, staged combustion, and precise fuel injection control help maximize energy extraction while minimizing environmental impact. Advanced sensors and control systems continuously monitor and adjust engine parameters to maintain optimal performance under varying operational conditions.Expand Specific Solutions04 Control systems and monitoring for turbine engines

Sophisticated control and monitoring systems are essential for safe and efficient turbine engine operation. These systems incorporate sensors, actuators, and electronic control units that regulate fuel flow, air intake, and other critical parameters. Advanced diagnostic capabilities enable real-time performance monitoring, predictive maintenance, and fault detection. Digital twin technology and machine learning algorithms enhance operational reliability by predicting potential failures before they occur and optimizing engine performance across various operating conditions.Expand Specific Solutions05 Novel turbine engine configurations and applications

Innovative turbine engine configurations are being developed for specialized applications across various industries. These include hybrid propulsion systems, distributed propulsion architectures, and compact turbine designs for urban air mobility. Adaptations of traditional turbine technology enable new applications in marine propulsion, power generation, and aerospace. Research focuses on scalability, noise reduction, and integration with other power systems to meet emerging market demands and environmental regulations.Expand Specific Solutions

Leading Organizations in Engine Testing Technology

Environmental testing of turbine engines in laboratory settings is currently in a growth phase, with the market expanding due to increasing demand for more efficient and reliable engine technologies. The global market size is estimated to exceed $3 billion, driven by aerospace, power generation, and automotive applications. Leading players demonstrate varying levels of technical maturity: Rolls-Royce, GE, and Southwest Research Institute possess advanced capabilities with comprehensive testing facilities; US Air Force and academic institutions like Tsinghua University and Beihang University contribute significant research infrastructure; while specialized companies like HORIBA Instruments and Solar Turbines offer targeted testing solutions. The competitive landscape features collaboration between industry leaders and research institutions to address increasingly complex environmental simulation requirements.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed comprehensive environmental testing capabilities for turbine engines through their Propulsion and Energy Machinery Section. Their approach integrates multiple environmental factors simultaneously, including temperature cycling (-65°F to +350°F), altitude simulation (up to 100,000 feet), humidity control (10-98%), and vibration testing. SwRI's proprietary HEDGE (High-Efficiency Durability and Greenhouse gas Emissions) testing methodology evaluates engine performance under various environmental conditions while monitoring emissions. Their facilities feature specialized test cells with advanced instrumentation capable of capturing over 1,500 data points per second, enabling real-time analysis of engine response to environmental stressors. SwRI has pioneered accelerated life testing protocols that compress years of environmental exposure into weeks of testing through carefully calibrated stress amplification. Their test facilities include capabilities for foreign object damage (FOD) simulation, salt fog exposure for corrosion testing, and electromagnetic interference (EMI) evaluation to ensure engine control systems remain reliable under adverse environmental conditions.

Strengths: Independent third-party testing capabilities providing unbiased validation; extensive experience across multiple industries beyond aerospace; advanced emissions testing integrated with environmental simulation. Weaknesses: Limited production testing capacity compared to OEMs; challenges in replicating proprietary OEM control systems in test environments; geographic limitations requiring transport of engines to testing facilities.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced Accelerated Mission Testing (AMT) facilities for turbine engine environmental testing. Their approach combines physical testing with digital simulation in "digital twins" to replicate extreme operational conditions. Their Testbed 80, the world's largest indoor aerospace testbed, can simulate diverse environmental conditions including altitude, temperature (-60°C to +100°C), humidity, and precipitation. Rolls-Royce employs specialized acoustic chambers for noise testing and has pioneered the use of sustainable aviation fuels (SAF) in their testing protocols. Their Intelligent Engine concept incorporates extensive sensor networks that collect real-time data during environmental testing, enabling predictive maintenance capabilities and reducing testing time by approximately 30%. Their environmental testing capabilities extend to icing conditions, bird strike simulations, and volcanic ash exposure tests critical for certification and safety validation.

Strengths: Industry-leading integration of digital and physical testing environments; comprehensive testing capabilities across all environmental variables; advanced data analytics for test optimization. Weaknesses: High capital investment requirements for test facilities; complex testing protocols requiring specialized expertise; challenges in perfectly replicating all real-world environmental conditions simultaneously.

Critical Testing Technologies and Standards Analysis

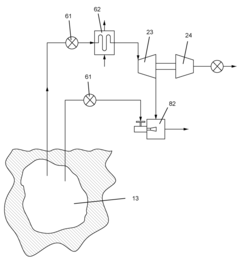

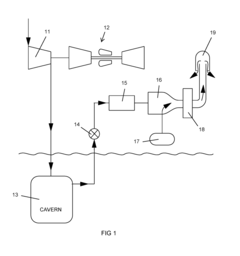

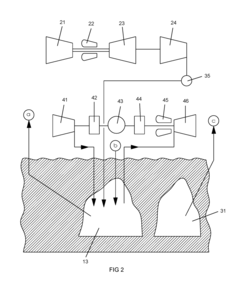

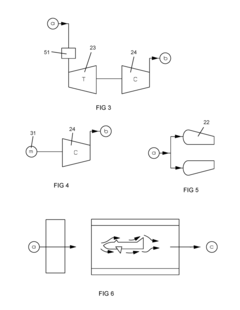

Process for testing a compressor or a combustor of a gas turbine engine using a large compressed air storage reservoir

PatentActiveUS9654161B2

Innovation

- Utilizing a compressed air energy storage (CAES) facility with underground caverns to supply and store compressed air for testing, allowing for efficient energy use, reduced equipment costs, and increased testing duration, and incorporating a non-vitiating heat exchanger or air turbine to preheat air for accurate component testing.

Turbine engine operational testing

PatentActiveUS20210372295A1

Innovation

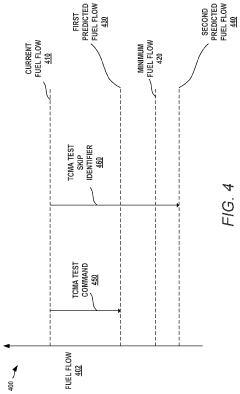

- A computer-implemented method and system that determines a predicted fuel flow rate using sensor data and engine models, comparing it to thresholds to selectively initiate engine operational tests, thereby avoiding lean blowout by ensuring a minimum fuel flow margin is maintained.

Sustainability Considerations in Engine Testing Facilities

The integration of sustainability principles into engine testing facilities has become increasingly critical as environmental regulations tighten and corporate social responsibility gains prominence. Modern turbine engine testing laboratories must balance technical performance requirements with environmental impact considerations. This dual focus necessitates innovative approaches to facility design, operation, and waste management.

Energy consumption represents the most significant environmental challenge in engine testing environments. Traditional facilities often require massive power inputs for test operations, climate control, and auxiliary systems. Leading facilities are now implementing energy recovery systems that capture and repurpose thermal energy generated during engine tests. These systems can reduce overall energy consumption by 15-30%, depending on facility scale and test protocols. Additionally, the integration of renewable energy sources, particularly solar arrays and wind turbines, is becoming standard practice for supplementing conventional power supplies.

Water management presents another critical sustainability challenge. Engine testing typically requires substantial water volumes for cooling systems and emissions scrubbing. Closed-loop water recycling systems have emerged as the industry standard, reducing freshwater consumption by up to 85% compared to traditional once-through cooling methods. Advanced filtration technologies and chemical treatment processes enable water reuse across multiple test cycles without compromising test integrity or equipment safety.

Emissions control technologies have evolved significantly to address air quality concerns. Modern facilities incorporate multi-stage filtration systems, catalytic converters, and scrubbers specifically designed for the unique exhaust profiles of turbine engines. These systems can capture over 95% of particulate matter and substantially reduce nitrogen oxide and sulfur dioxide emissions. Real-time emissions monitoring systems provide continuous data for regulatory compliance and process optimization.

Noise pollution, often overlooked in sustainability discussions, receives increasing attention in facility design. Advanced acoustic engineering, including specialized wall constructions, vibration isolation systems, and strategic facility placement, can reduce community noise impact by 20-30 decibels. These measures not only improve community relations but also enhance working conditions for facility personnel.

Material selection and waste management protocols further enhance sustainability profiles. The use of recyclable materials in test fixtures, preference for non-toxic chemicals in maintenance operations, and comprehensive waste segregation systems minimize environmental footprint. Leading facilities achieve waste diversion rates exceeding 80% through careful planning and partnership with specialized recycling services.

Return on investment calculations increasingly incorporate sustainability metrics, recognizing that environmental improvements often yield operational cost reductions. The initial capital investment in sustainable technologies typically shows payback periods of 3-7 years, with ongoing operational savings thereafter.

Energy consumption represents the most significant environmental challenge in engine testing environments. Traditional facilities often require massive power inputs for test operations, climate control, and auxiliary systems. Leading facilities are now implementing energy recovery systems that capture and repurpose thermal energy generated during engine tests. These systems can reduce overall energy consumption by 15-30%, depending on facility scale and test protocols. Additionally, the integration of renewable energy sources, particularly solar arrays and wind turbines, is becoming standard practice for supplementing conventional power supplies.

Water management presents another critical sustainability challenge. Engine testing typically requires substantial water volumes for cooling systems and emissions scrubbing. Closed-loop water recycling systems have emerged as the industry standard, reducing freshwater consumption by up to 85% compared to traditional once-through cooling methods. Advanced filtration technologies and chemical treatment processes enable water reuse across multiple test cycles without compromising test integrity or equipment safety.

Emissions control technologies have evolved significantly to address air quality concerns. Modern facilities incorporate multi-stage filtration systems, catalytic converters, and scrubbers specifically designed for the unique exhaust profiles of turbine engines. These systems can capture over 95% of particulate matter and substantially reduce nitrogen oxide and sulfur dioxide emissions. Real-time emissions monitoring systems provide continuous data for regulatory compliance and process optimization.

Noise pollution, often overlooked in sustainability discussions, receives increasing attention in facility design. Advanced acoustic engineering, including specialized wall constructions, vibration isolation systems, and strategic facility placement, can reduce community noise impact by 20-30 decibels. These measures not only improve community relations but also enhance working conditions for facility personnel.

Material selection and waste management protocols further enhance sustainability profiles. The use of recyclable materials in test fixtures, preference for non-toxic chemicals in maintenance operations, and comprehensive waste segregation systems minimize environmental footprint. Leading facilities achieve waste diversion rates exceeding 80% through careful planning and partnership with specialized recycling services.

Return on investment calculations increasingly incorporate sustainability metrics, recognizing that environmental improvements often yield operational cost reductions. The initial capital investment in sustainable technologies typically shows payback periods of 3-7 years, with ongoing operational savings thereafter.

Risk Management and Safety Protocols for Laboratory Testing

Laboratory testing of turbine engines involves significant risks that require comprehensive management protocols. The primary hazards include high-temperature operations, rotating machinery, combustible fuels, and high-pressure systems. These elements create potential for catastrophic failures, fires, explosions, and toxic gas emissions if not properly controlled. Effective risk management begins with thorough hazard identification through systematic risk assessment methodologies such as FMEA (Failure Mode and Effects Analysis) and HAZOP (Hazard and Operability Study).

Implementation of engineering controls represents the first line of defense in laboratory safety. These include blast-resistant test cells, reinforced observation areas, automated fire suppression systems, and emergency shutdown mechanisms. Modern facilities increasingly incorporate real-time monitoring systems that can detect abnormal operating conditions and initiate protective measures before catastrophic failures occur.

Administrative controls complement engineering safeguards through strict operational procedures. These include detailed pre-test checklists, clear communication protocols, and defined emergency response plans. Personnel certification requirements ensure that only qualified technicians operate equipment, while mandatory rest periods prevent fatigue-related errors during extended testing campaigns.

Environmental considerations form a critical component of safety protocols. Emissions control systems must capture and treat exhaust gases to prevent release of harmful pollutants. Noise abatement measures protect both laboratory personnel and surrounding communities from the extreme acoustic energy generated during engine testing. Specialized containment systems for fuel and lubricants prevent ground contamination in case of leaks.

Documentation and traceability systems maintain comprehensive records of all safety-related activities. This includes equipment maintenance logs, calibration certificates for measurement instruments, and detailed test plans with explicit risk mitigation strategies. Post-test analysis procedures identify near-misses and potential safety improvements, creating a continuous improvement cycle.

Emergency preparedness requires specialized training for laboratory personnel in firefighting techniques appropriate for engine fires, evacuation procedures, and first aid for thermal injuries. Regular drills ensure that response actions become automatic during actual emergencies. Coordination with local emergency services familiarizes first responders with the unique hazards present in engine testing facilities.

International standards such as ISO 45001 and industry-specific guidelines from organizations like SAE International provide frameworks for safety management systems. These standards emphasize the importance of leadership commitment, worker involvement, and systematic approaches to risk reduction. Compliance with these standards not only enhances safety but also facilitates international collaboration on engine development programs.

Implementation of engineering controls represents the first line of defense in laboratory safety. These include blast-resistant test cells, reinforced observation areas, automated fire suppression systems, and emergency shutdown mechanisms. Modern facilities increasingly incorporate real-time monitoring systems that can detect abnormal operating conditions and initiate protective measures before catastrophic failures occur.

Administrative controls complement engineering safeguards through strict operational procedures. These include detailed pre-test checklists, clear communication protocols, and defined emergency response plans. Personnel certification requirements ensure that only qualified technicians operate equipment, while mandatory rest periods prevent fatigue-related errors during extended testing campaigns.

Environmental considerations form a critical component of safety protocols. Emissions control systems must capture and treat exhaust gases to prevent release of harmful pollutants. Noise abatement measures protect both laboratory personnel and surrounding communities from the extreme acoustic energy generated during engine testing. Specialized containment systems for fuel and lubricants prevent ground contamination in case of leaks.

Documentation and traceability systems maintain comprehensive records of all safety-related activities. This includes equipment maintenance logs, calibration certificates for measurement instruments, and detailed test plans with explicit risk mitigation strategies. Post-test analysis procedures identify near-misses and potential safety improvements, creating a continuous improvement cycle.

Emergency preparedness requires specialized training for laboratory personnel in firefighting techniques appropriate for engine fires, evacuation procedures, and first aid for thermal injuries. Regular drills ensure that response actions become automatic during actual emergencies. Coordination with local emergency services familiarizes first responders with the unique hazards present in engine testing facilities.

International standards such as ISO 45001 and industry-specific guidelines from organizations like SAE International provide frameworks for safety management systems. These standards emphasize the importance of leadership commitment, worker involvement, and systematic approaches to risk reduction. Compliance with these standards not only enhances safety but also facilitates international collaboration on engine development programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!