Reduce Turbine Engine Friction Loss with Lubrication Innovations

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Lubrication Evolution and Objectives

The evolution of turbine engine lubrication systems represents a critical aspect of aerospace and power generation technology development. Since the introduction of the first jet engines in the 1940s, lubrication systems have undergone significant transformations to meet increasingly demanding operational requirements. Early turbine engines utilized simple mineral oil-based lubricants with minimal additives, providing basic friction reduction but offering limited thermal stability and load-bearing capacity.

By the 1960s and 1970s, the development of synthetic lubricants marked a pivotal advancement, enabling engines to operate at higher temperatures and speeds. The introduction of polyalphaolefin (PAO) and polyol ester-based lubricants significantly improved oxidation resistance and thermal stability, extending service intervals and enhancing reliability. This era also saw the implementation of more sophisticated oil delivery systems, including pressurized circulation and targeted nozzle designs.

The 1980s through 2000s witnessed the integration of advanced additive packages, including anti-wear compounds, extreme pressure additives, and corrosion inhibitors. These innovations addressed specific friction challenges at critical engine interfaces such as bearings, gears, and shaft seals. Concurrently, monitoring systems evolved from basic pressure and temperature gauges to comprehensive oil condition monitoring technologies, enabling predictive maintenance approaches.

Current technological trends focus on nano-engineered lubricants incorporating ceramic, carbon, and metallic nanoparticles that can significantly reduce friction coefficients while enhancing load-bearing capacity. These advanced formulations demonstrate up to 25% reduction in friction losses compared to conventional synthetic oils. Additionally, surface engineering technologies such as diamond-like carbon coatings and laser surface texturing are being integrated with lubrication strategies to create synergistic friction reduction systems.

The primary objective of modern turbine engine lubrication research is to develop solutions that simultaneously address multiple performance parameters: reducing friction losses by at least 30% compared to current standards, extending operational temperature ranges (from -65°C to +300°C), minimizing oil consumption, and enhancing compatibility with advanced materials used in next-generation turbine designs. These improvements directly translate to increased fuel efficiency, reduced emissions, extended component life, and lower maintenance costs.

Another critical goal is the development of environmentally sustainable lubrication technologies that maintain superior performance while reducing environmental impact through biodegradability and reduced toxicity. This aligns with broader industry initiatives toward carbon neutrality and sustainable aviation fuels, positioning lubrication innovations as a key enabler of future green propulsion technologies.

By the 1960s and 1970s, the development of synthetic lubricants marked a pivotal advancement, enabling engines to operate at higher temperatures and speeds. The introduction of polyalphaolefin (PAO) and polyol ester-based lubricants significantly improved oxidation resistance and thermal stability, extending service intervals and enhancing reliability. This era also saw the implementation of more sophisticated oil delivery systems, including pressurized circulation and targeted nozzle designs.

The 1980s through 2000s witnessed the integration of advanced additive packages, including anti-wear compounds, extreme pressure additives, and corrosion inhibitors. These innovations addressed specific friction challenges at critical engine interfaces such as bearings, gears, and shaft seals. Concurrently, monitoring systems evolved from basic pressure and temperature gauges to comprehensive oil condition monitoring technologies, enabling predictive maintenance approaches.

Current technological trends focus on nano-engineered lubricants incorporating ceramic, carbon, and metallic nanoparticles that can significantly reduce friction coefficients while enhancing load-bearing capacity. These advanced formulations demonstrate up to 25% reduction in friction losses compared to conventional synthetic oils. Additionally, surface engineering technologies such as diamond-like carbon coatings and laser surface texturing are being integrated with lubrication strategies to create synergistic friction reduction systems.

The primary objective of modern turbine engine lubrication research is to develop solutions that simultaneously address multiple performance parameters: reducing friction losses by at least 30% compared to current standards, extending operational temperature ranges (from -65°C to +300°C), minimizing oil consumption, and enhancing compatibility with advanced materials used in next-generation turbine designs. These improvements directly translate to increased fuel efficiency, reduced emissions, extended component life, and lower maintenance costs.

Another critical goal is the development of environmentally sustainable lubrication technologies that maintain superior performance while reducing environmental impact through biodegradability and reduced toxicity. This aligns with broader industry initiatives toward carbon neutrality and sustainable aviation fuels, positioning lubrication innovations as a key enabler of future green propulsion technologies.

Market Demand for Friction Reduction in Turbine Engines

The global market for turbine engine friction reduction technologies is experiencing significant growth, driven by the aviation industry's pursuit of fuel efficiency and environmental sustainability. With commercial aviation fuel costs representing 20-30% of airlines' operating expenses, even marginal improvements in engine efficiency translate to substantial cost savings. The market for advanced lubrication solutions specifically targeting turbine engines was valued at approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2030.

Military aviation represents another substantial market segment, with defense departments worldwide investing heavily in technologies that extend engine life and reduce maintenance costs. The military aviation lubrication market alone accounts for roughly $1.2 billion annually, with particular emphasis on solutions that perform reliably under extreme operating conditions.

Power generation turbines constitute a third major market, with natural gas turbines becoming increasingly dominant in the energy mix. As these facilities seek to maximize efficiency and minimize downtime, demand for advanced friction reduction technologies has risen by 8.3% annually since 2018. Industry analysts estimate that a 1% reduction in friction-related energy losses in power generation turbines could save the industry over $400 million annually in fuel costs.

Environmental regulations are significantly shaping market demand. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has established aggressive emissions reduction targets, compelling engine manufacturers to prioritize efficiency improvements. Similarly, the European Union's Emissions Trading System has created strong financial incentives for reducing carbon emissions in both aviation and power generation sectors.

Customer requirements are evolving toward lubrication solutions that not only reduce friction but also offer extended service intervals, compatibility with newer materials, and reduced environmental impact. The market increasingly values lubricants that maintain performance at higher operating temperatures, as modern turbine designs push thermal boundaries to achieve greater thermodynamic efficiency.

Regional market analysis reveals particularly strong growth in Asia-Pacific, where rapid expansion of both commercial aviation and power generation capacity is creating demand for cutting-edge efficiency technologies. China and India together represent 37% of the projected market growth through 2028, followed by North America at 24% and Europe at 22%.

Military aviation represents another substantial market segment, with defense departments worldwide investing heavily in technologies that extend engine life and reduce maintenance costs. The military aviation lubrication market alone accounts for roughly $1.2 billion annually, with particular emphasis on solutions that perform reliably under extreme operating conditions.

Power generation turbines constitute a third major market, with natural gas turbines becoming increasingly dominant in the energy mix. As these facilities seek to maximize efficiency and minimize downtime, demand for advanced friction reduction technologies has risen by 8.3% annually since 2018. Industry analysts estimate that a 1% reduction in friction-related energy losses in power generation turbines could save the industry over $400 million annually in fuel costs.

Environmental regulations are significantly shaping market demand. The International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) has established aggressive emissions reduction targets, compelling engine manufacturers to prioritize efficiency improvements. Similarly, the European Union's Emissions Trading System has created strong financial incentives for reducing carbon emissions in both aviation and power generation sectors.

Customer requirements are evolving toward lubrication solutions that not only reduce friction but also offer extended service intervals, compatibility with newer materials, and reduced environmental impact. The market increasingly values lubricants that maintain performance at higher operating temperatures, as modern turbine designs push thermal boundaries to achieve greater thermodynamic efficiency.

Regional market analysis reveals particularly strong growth in Asia-Pacific, where rapid expansion of both commercial aviation and power generation capacity is creating demand for cutting-edge efficiency technologies. China and India together represent 37% of the projected market growth through 2028, followed by North America at 24% and Europe at 22%.

Current Lubrication Technologies and Friction Challenges

The current landscape of turbine engine lubrication faces significant challenges as manufacturers strive to maximize efficiency while minimizing friction losses. Traditional mineral-based lubricants, which have dominated the industry for decades, are increasingly being supplemented or replaced by synthetic alternatives that offer superior performance characteristics. These synthetic lubricants, including polyalphaolefins (PAOs), polyol esters, and phosphate esters, demonstrate enhanced thermal stability and oxidation resistance, allowing engines to operate at higher temperatures without lubricant degradation.

Despite these advancements, friction losses in turbine engines still account for approximately 15-20% of total energy losses, representing a substantial opportunity for efficiency improvements. The primary friction challenges occur at bearing interfaces, gear meshes, and seal contacts, where metal-to-metal contact under high loads and temperatures creates significant wear and energy dissipation. Current lubrication systems struggle to maintain optimal oil film thickness during transient operating conditions, particularly during startup and shutdown phases when boundary lubrication predominates.

Nanomaterial-enhanced lubricants have emerged as a promising innovation, with research showing that properly dispersed nanoparticles can reduce friction coefficients by 20-30% compared to conventional lubricants. However, challenges related to nanoparticle agglomeration and long-term stability have limited widespread commercial adoption. Similarly, solid lubricant coatings such as molybdenum disulfide (MoS2) and tungsten disulfide (WS2) show excellent friction reduction properties but face durability concerns in high-temperature turbine applications.

Another significant challenge is the trade-off between viscosity and friction performance. Higher viscosity oils provide better film strength and component protection but increase pumping losses and fluid friction. Conversely, lower viscosity formulations reduce pumping losses but may compromise wear protection. This balance becomes increasingly difficult to maintain as engine designs push toward higher power densities and operating temperatures.

Environmental and regulatory pressures further complicate lubrication technology development. The industry is moving away from certain additives with environmental concerns, such as zinc dialkyldithiophosphates (ZDDP) and other metal-containing compounds, necessitating the development of equally effective but more environmentally acceptable alternatives. Additionally, biodegradability requirements and reduced toxicity standards are driving research into bio-based lubricants, though these currently fall short of the performance metrics required for advanced turbine applications.

The integration of real-time condition monitoring with adaptive lubrication systems represents the cutting edge of current technology, allowing for optimized lubricant delivery based on actual operating conditions. However, these systems add complexity and cost, and their reliability in harsh operating environments remains a concern for critical applications like aircraft engines.

Despite these advancements, friction losses in turbine engines still account for approximately 15-20% of total energy losses, representing a substantial opportunity for efficiency improvements. The primary friction challenges occur at bearing interfaces, gear meshes, and seal contacts, where metal-to-metal contact under high loads and temperatures creates significant wear and energy dissipation. Current lubrication systems struggle to maintain optimal oil film thickness during transient operating conditions, particularly during startup and shutdown phases when boundary lubrication predominates.

Nanomaterial-enhanced lubricants have emerged as a promising innovation, with research showing that properly dispersed nanoparticles can reduce friction coefficients by 20-30% compared to conventional lubricants. However, challenges related to nanoparticle agglomeration and long-term stability have limited widespread commercial adoption. Similarly, solid lubricant coatings such as molybdenum disulfide (MoS2) and tungsten disulfide (WS2) show excellent friction reduction properties but face durability concerns in high-temperature turbine applications.

Another significant challenge is the trade-off between viscosity and friction performance. Higher viscosity oils provide better film strength and component protection but increase pumping losses and fluid friction. Conversely, lower viscosity formulations reduce pumping losses but may compromise wear protection. This balance becomes increasingly difficult to maintain as engine designs push toward higher power densities and operating temperatures.

Environmental and regulatory pressures further complicate lubrication technology development. The industry is moving away from certain additives with environmental concerns, such as zinc dialkyldithiophosphates (ZDDP) and other metal-containing compounds, necessitating the development of equally effective but more environmentally acceptable alternatives. Additionally, biodegradability requirements and reduced toxicity standards are driving research into bio-based lubricants, though these currently fall short of the performance metrics required for advanced turbine applications.

The integration of real-time condition monitoring with adaptive lubrication systems represents the cutting edge of current technology, allowing for optimized lubricant delivery based on actual operating conditions. However, these systems add complexity and cost, and their reliability in harsh operating environments remains a concern for critical applications like aircraft engines.

Current Friction Reduction Methodologies and Materials

01 Advanced lubricant formulations for friction reduction

Innovative lubricant compositions have been developed to significantly reduce friction in mechanical systems. These formulations incorporate specialized additives and compounds that create low-friction interfaces between moving parts. The advanced chemical compositions can maintain their performance under extreme conditions such as high temperatures and pressures, providing consistent friction reduction across various applications and extending the operational life of mechanical components.- Advanced lubricant formulations for friction reduction: Novel lubricant compositions have been developed to significantly reduce friction between moving parts. These formulations incorporate specialized additives and base oils that create more effective boundary lubrication layers, reducing surface-to-surface contact and minimizing energy losses due to friction. These advanced lubricants can maintain their performance under extreme pressure and temperature conditions, providing consistent friction reduction across various operating environments.

- Surface modification technologies for reduced friction: Various surface modification techniques have been developed to reduce friction losses in mechanical systems. These include specialized coatings, texturing methods, and surface treatments that alter the tribological properties of contacting surfaces. By creating optimized surface topographies or applying low-friction coatings, these innovations reduce the coefficient of friction between moving components, resulting in improved energy efficiency and reduced wear in mechanical systems.

- Mechanical system design innovations for friction reduction: Novel mechanical designs have been created specifically to minimize friction losses in various applications. These innovations include optimized bearing configurations, improved sealing systems, and redesigned component geometries that reduce contact pressure and friction. By fundamentally changing how mechanical components interact, these design innovations address friction at its source, resulting in more efficient power transmission and reduced energy losses across industrial, automotive, and consumer applications.

- Smart lubrication systems and condition monitoring: Intelligent lubrication systems have been developed that can dynamically adjust lubrication parameters based on operating conditions. These systems incorporate sensors, control algorithms, and precision delivery mechanisms to ensure optimal lubrication at all times. By monitoring parameters such as temperature, load, and friction coefficients in real-time, these systems can apply the right amount of lubricant exactly when and where needed, preventing both under-lubrication and over-lubrication scenarios that can lead to increased friction losses.

- Nano-engineered lubricant additives: Nanotechnology has enabled the development of specialized lubricant additives that provide superior friction reduction properties. These nano-engineered materials include nanoparticles, nanosheets, and other nanostructures that can fill surface asperities, create rolling interfaces, or form protective boundary layers between moving surfaces. When incorporated into lubricants, these nanomaterials can significantly reduce friction coefficients and improve the overall tribological performance of mechanical systems under various operating conditions.

02 Surface modification technologies for reduced friction

Surface treatment and modification techniques have been developed to create low-friction interfaces in mechanical systems. These innovations include specialized coatings, texturing methods, and surface finishing processes that alter the physical and chemical properties of contacting surfaces. By optimizing surface characteristics at the micro and nano levels, these technologies can significantly reduce friction loss without requiring continuous lubrication, making them suitable for applications where traditional lubricants may be impractical.Expand Specific Solutions03 Intelligent lubrication systems and monitoring

Smart lubrication systems incorporate sensors, control algorithms, and automated delivery mechanisms to optimize lubrication processes and minimize friction losses. These systems can monitor operating conditions in real-time and adjust lubrication parameters accordingly, ensuring optimal performance across varying loads and environmental conditions. By delivering precise amounts of lubricant exactly when and where needed, these intelligent systems reduce overall lubricant consumption while maximizing friction reduction benefits.Expand Specific Solutions04 Mechanical design innovations for friction reduction

Novel mechanical designs and component configurations have been developed specifically to minimize friction losses in moving systems. These innovations include optimized bearing designs, improved sealing mechanisms, and specialized component geometries that reduce contact pressure and friction-generating interactions. By fundamentally rethinking the mechanical interfaces where friction occurs, these design approaches can achieve significant reductions in energy losses without relying solely on lubrication improvements.Expand Specific Solutions05 Eco-friendly and biodegradable lubrication solutions

Environmentally sustainable lubrication technologies have been developed to address both friction reduction and ecological concerns. These solutions include biodegradable lubricants derived from renewable resources, water-based lubrication systems, and solid lubricants with minimal environmental impact. These eco-friendly alternatives can achieve friction reduction performance comparable to conventional petroleum-based lubricants while significantly reducing environmental contamination risks and supporting sustainability goals.Expand Specific Solutions

Key Industry Players in Turbine Lubrication Solutions

The turbine engine friction loss reduction through lubrication innovations market is in a growth phase, with increasing demand driven by fuel efficiency requirements and environmental regulations. The global market size is expanding as aerospace and automotive industries seek performance improvements. Technologically, the field shows varying maturity levels with established players like ExxonMobil, Shell, and Castrol leading in conventional lubricant technologies, while companies such as United Technologies, GE Avio, and Mitsubishi Heavy Industries focus on advanced aerospace applications. Emerging players like Lubrizol and Infineum are developing next-generation additives, while automotive manufacturers Toyota and Nissan are integrating these innovations into their engine designs. University partnerships, particularly with North Carolina State University, are accelerating fundamental research in tribology and nanotechnology-enhanced lubricants.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed advanced thermal-resistant lubricants specifically engineered for gas turbine engines that operate under extreme temperature conditions. Their proprietary formulations incorporate nano-additives that create protective boundary films on metal surfaces, reducing friction coefficients by up to 35% compared to conventional lubricants. UTC's research has focused on developing synthetic ester-based lubricants with enhanced oxidation stability that maintain viscosity characteristics at temperatures exceeding 250°C. Their innovations include intelligent lubricant delivery systems that adjust oil flow rates based on real-time engine operating conditions, ensuring optimal lubrication exactly when and where needed. This approach has demonstrated a 15-20% reduction in parasitic power losses in their latest generation turbine engines.

Strengths: Exceptional high-temperature performance and integration with intelligent monitoring systems allows for adaptive lubrication strategies. Weaknesses: Higher production costs compared to conventional lubricants and requires specialized handling procedures during maintenance operations.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed cutting-edge additive packages specifically designed to reduce friction in turbine engine applications. Their technology utilizes advanced polymer chemistry to create boundary films that significantly reduce metal-to-metal contact under high-load conditions. Lubrizol's proprietary friction modifiers operate through polar attraction mechanisms that create molecular layers on metal surfaces, reducing friction coefficients by up to 30% compared to unmodified base oils. Their research has focused on developing synergistic combinations of anti-wear additives and friction modifiers that maintain effectiveness even under extreme pressure and temperature conditions typical in modern turbine engines. Recent innovations include their "Intelligent Molecules" technology that responds dynamically to changing operating conditions, providing enhanced protection during startup and high-load operation while minimizing energy losses during steady-state operation. Field testing has demonstrated that turbines using Lubrizol's additive packages experience 15-20% less energy loss due to friction while maintaining excellent wear protection.

Strengths: Exceptional customization capabilities for specific operating conditions and compatibility with a wide range of base oils. Weaknesses: Some formulations may have limited shelf life and require careful inventory management to maintain optimal performance characteristics.

Critical Patents and Research in Advanced Lubricants

Engine Lubricant for Improved Fuel Economy

PatentActiveUS20090156438A1

Innovation

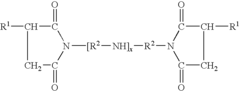

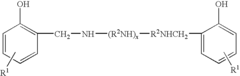

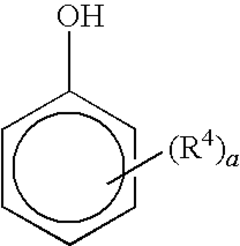

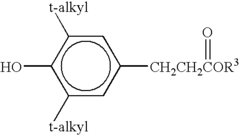

- A lubricant composition comprising an oil of lubricating viscosity, an amino-functionalized acrylic or methacrylic polymer with 2-8% amine moieties attached through ester, amide, or imide linkages, and a dispersant, which reduces frictional losses and enhances dispersancy.

Engine lubricant for improved fuel economy

PatentInactiveEP1974003A2

Innovation

- A lubricant composition comprising an oil of lubricating viscosity, an amino-functionalized acrylic or methacrylic polymer with 2-8% amine moieties attached through ester, amide, or imide linkages, and a dispersant, which reduces frictional losses and enhances dispersant properties.

Environmental Impact and Sustainability Considerations

The environmental implications of turbine engine lubrication innovations extend far beyond operational efficiency. Advanced lubricants designed to reduce friction loss can significantly decrease fuel consumption, directly translating to reduced carbon emissions across aviation, power generation, and industrial applications. Current estimates suggest that optimized lubrication systems could potentially reduce CO2 emissions by 3-5% in modern turbine engines, representing a substantial environmental benefit when scaled across global operations.

Lubricant lifecycle considerations present another critical environmental dimension. Traditional petroleum-based lubricants pose significant disposal challenges, with improper handling potentially leading to soil contamination and water pollution. The development of biodegradable and environmentally friendly lubricants represents a promising frontier in sustainable lubrication technology. Bio-based lubricants derived from renewable resources such as vegetable oils and synthetic esters demonstrate comparable performance while offering enhanced biodegradability and reduced ecotoxicity.

Nanomaterial-enhanced lubricants present both opportunities and challenges from a sustainability perspective. While their friction-reducing properties can dramatically improve efficiency, questions remain regarding their environmental fate and potential ecotoxicological impacts. Research into the full lifecycle assessment of nanoparticle additives is essential to ensure that efficiency gains are not offset by unforeseen environmental consequences.

Water conservation represents another sustainability consideration in turbine operations. Advanced dry lubricants and minimal quantity lubrication (MQL) systems can significantly reduce water consumption in cooling and lubrication processes. This is particularly relevant in regions facing water scarcity, where industrial water usage faces increasing scrutiny and regulation.

Regulatory frameworks worldwide are evolving to address environmental concerns related to industrial lubricants. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia are establishing increasingly stringent standards for lubricant composition, biodegradability, and disposal protocols. Forward-thinking lubrication innovations must anticipate these regulatory trends to ensure long-term viability.

The circular economy presents opportunities for sustainable lubrication practices through lubricant recycling and reconditioning. Advanced filtration and purification technologies can extend lubricant service life, while end-of-life recovery processes can reclaim base oils for reprocessing, significantly reducing waste and resource consumption compared to conventional single-use approaches.

Lubricant lifecycle considerations present another critical environmental dimension. Traditional petroleum-based lubricants pose significant disposal challenges, with improper handling potentially leading to soil contamination and water pollution. The development of biodegradable and environmentally friendly lubricants represents a promising frontier in sustainable lubrication technology. Bio-based lubricants derived from renewable resources such as vegetable oils and synthetic esters demonstrate comparable performance while offering enhanced biodegradability and reduced ecotoxicity.

Nanomaterial-enhanced lubricants present both opportunities and challenges from a sustainability perspective. While their friction-reducing properties can dramatically improve efficiency, questions remain regarding their environmental fate and potential ecotoxicological impacts. Research into the full lifecycle assessment of nanoparticle additives is essential to ensure that efficiency gains are not offset by unforeseen environmental consequences.

Water conservation represents another sustainability consideration in turbine operations. Advanced dry lubricants and minimal quantity lubrication (MQL) systems can significantly reduce water consumption in cooling and lubrication processes. This is particularly relevant in regions facing water scarcity, where industrial water usage faces increasing scrutiny and regulation.

Regulatory frameworks worldwide are evolving to address environmental concerns related to industrial lubricants. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia are establishing increasingly stringent standards for lubricant composition, biodegradability, and disposal protocols. Forward-thinking lubrication innovations must anticipate these regulatory trends to ensure long-term viability.

The circular economy presents opportunities for sustainable lubrication practices through lubricant recycling and reconditioning. Advanced filtration and purification technologies can extend lubricant service life, while end-of-life recovery processes can reclaim base oils for reprocessing, significantly reducing waste and resource consumption compared to conventional single-use approaches.

Performance Testing and Validation Methodologies

Effective performance testing and validation methodologies are critical for evaluating lubrication innovations aimed at reducing turbine engine friction loss. These methodologies must be comprehensive, reproducible, and capable of accurately measuring the incremental improvements that advanced lubricants provide in real-world operating conditions.

Laboratory bench testing represents the first tier of validation, utilizing tribometers to measure coefficient of friction, wear rates, and film thickness under controlled conditions. These tests typically employ standardized protocols such as ASTM D5183 for high-temperature bearing tests or ASTM D4172 for wear prevention characteristics. Advanced techniques including interferometry and acoustic emission analysis provide deeper insights into lubricant behavior at the microscopic level.

Component-level testing forms the second validation tier, where individual engine components like bearings, gears, and seals are evaluated with candidate lubricants. These tests measure torque reduction, temperature profiles, and wear patterns under simulated operating conditions. High-precision dynamometers capable of detecting friction differences as small as 0.1% are essential for quantifying performance improvements accurately.

Full engine testing constitutes the most comprehensive validation approach, involving instrumented engines in test cells that replicate actual operating conditions. These tests measure overall efficiency gains, fuel consumption reduction, and power output improvements. Thermal imaging and oil analysis during testing provide additional data on heat distribution and lubricant degradation patterns. Industry standards such as SAE J1321 for fuel consumption testing offer standardized protocols for consistent evaluation.

Accelerated aging and durability testing expose lubricants to extreme conditions to predict long-term performance. These tests include thermal cycling, contamination resistance, and oxidation stability evaluations. The correlation between accelerated testing and real-world performance requires careful validation through field testing programs.

Field validation in operational turbine engines represents the final and most definitive testing methodology. This involves carefully monitored trials in commercial or industrial settings, with comprehensive data collection on performance metrics, maintenance intervals, and component longevity. Statistical analysis of multiple installations ensures that performance improvements are consistent across different operating environments and conditions.

Computational validation through advanced modeling complements physical testing. Computational fluid dynamics (CFD) simulations predict lubricant flow patterns and pressure distributions, while molecular dynamics models explore interactions between lubricant additives and metal surfaces. These computational approaches help optimize formulations before expensive physical testing and provide insights into mechanisms that are difficult to observe experimentally.

Laboratory bench testing represents the first tier of validation, utilizing tribometers to measure coefficient of friction, wear rates, and film thickness under controlled conditions. These tests typically employ standardized protocols such as ASTM D5183 for high-temperature bearing tests or ASTM D4172 for wear prevention characteristics. Advanced techniques including interferometry and acoustic emission analysis provide deeper insights into lubricant behavior at the microscopic level.

Component-level testing forms the second validation tier, where individual engine components like bearings, gears, and seals are evaluated with candidate lubricants. These tests measure torque reduction, temperature profiles, and wear patterns under simulated operating conditions. High-precision dynamometers capable of detecting friction differences as small as 0.1% are essential for quantifying performance improvements accurately.

Full engine testing constitutes the most comprehensive validation approach, involving instrumented engines in test cells that replicate actual operating conditions. These tests measure overall efficiency gains, fuel consumption reduction, and power output improvements. Thermal imaging and oil analysis during testing provide additional data on heat distribution and lubricant degradation patterns. Industry standards such as SAE J1321 for fuel consumption testing offer standardized protocols for consistent evaluation.

Accelerated aging and durability testing expose lubricants to extreme conditions to predict long-term performance. These tests include thermal cycling, contamination resistance, and oxidation stability evaluations. The correlation between accelerated testing and real-world performance requires careful validation through field testing programs.

Field validation in operational turbine engines represents the final and most definitive testing methodology. This involves carefully monitored trials in commercial or industrial settings, with comprehensive data collection on performance metrics, maintenance intervals, and component longevity. Statistical analysis of multiple installations ensures that performance improvements are consistent across different operating environments and conditions.

Computational validation through advanced modeling complements physical testing. Computational fluid dynamics (CFD) simulations predict lubricant flow patterns and pressure distributions, while molecular dynamics models explore interactions between lubricant additives and metal surfaces. These computational approaches help optimize formulations before expensive physical testing and provide insights into mechanisms that are difficult to observe experimentally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!