Machining Techniques for Precision Turbine Engine Components

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Component Precision Machining Background and Objectives

Precision machining of turbine engine components has evolved significantly over the past seven decades, driven by the aerospace industry's relentless pursuit of higher performance, efficiency, and reliability. The journey began in the 1950s with conventional machining methods and has progressed through various technological revolutions including the introduction of Computer Numerical Control (CNC) in the 1970s, advanced multi-axis machining in the 1990s, and the integration of digital manufacturing concepts in the 2000s.

The technological trajectory has been characterized by continuous improvements in dimensional accuracy, surface finish quality, and material removal rates. Modern precision machining techniques now routinely achieve tolerances measured in microns, representing a hundredfold improvement over early manufacturing capabilities. This evolution has been essential to support the development of increasingly sophisticated turbine designs with complex geometries and tighter specifications.

Current industry objectives focus on addressing the challenges posed by next-generation turbine engine designs, which demand components with unprecedented precision, complex geometries, and superior surface integrity. These components must withstand extreme operating conditions including temperatures exceeding 1,600°C, high rotational speeds, and aggressive environmental factors.

The primary technical goals in this field include developing machining processes capable of consistently achieving sub-micron tolerances on superalloy components, reducing production cycle times while maintaining quality standards, and minimizing material waste in the manufacturing process. Additionally, there is significant emphasis on enhancing the surface integrity of machined components to improve fatigue resistance and extend service life.

Another critical objective is the development of adaptive machining techniques that can compensate for material variations and tool wear in real-time, ensuring consistent quality across production batches. This includes the integration of in-process measurement systems and closed-loop control mechanisms that can make instantaneous adjustments to machining parameters.

The industry is also pursuing sustainable manufacturing practices through the optimization of cutting parameters to reduce energy consumption, the implementation of minimum quantity lubrication (MQL) systems to decrease coolant usage, and the development of recycling processes for expensive superalloy materials. These environmental considerations are becoming increasingly important as regulatory pressures mount and manufacturers seek to reduce their ecological footprint.

Looking forward, the field is moving toward the integration of digital twin technology, artificial intelligence, and machine learning algorithms to predict and optimize machining outcomes. The ultimate goal is to establish fully autonomous manufacturing systems capable of self-optimization and adaptation to changing conditions, representing the next frontier in precision turbine component manufacturing.

The technological trajectory has been characterized by continuous improvements in dimensional accuracy, surface finish quality, and material removal rates. Modern precision machining techniques now routinely achieve tolerances measured in microns, representing a hundredfold improvement over early manufacturing capabilities. This evolution has been essential to support the development of increasingly sophisticated turbine designs with complex geometries and tighter specifications.

Current industry objectives focus on addressing the challenges posed by next-generation turbine engine designs, which demand components with unprecedented precision, complex geometries, and superior surface integrity. These components must withstand extreme operating conditions including temperatures exceeding 1,600°C, high rotational speeds, and aggressive environmental factors.

The primary technical goals in this field include developing machining processes capable of consistently achieving sub-micron tolerances on superalloy components, reducing production cycle times while maintaining quality standards, and minimizing material waste in the manufacturing process. Additionally, there is significant emphasis on enhancing the surface integrity of machined components to improve fatigue resistance and extend service life.

Another critical objective is the development of adaptive machining techniques that can compensate for material variations and tool wear in real-time, ensuring consistent quality across production batches. This includes the integration of in-process measurement systems and closed-loop control mechanisms that can make instantaneous adjustments to machining parameters.

The industry is also pursuing sustainable manufacturing practices through the optimization of cutting parameters to reduce energy consumption, the implementation of minimum quantity lubrication (MQL) systems to decrease coolant usage, and the development of recycling processes for expensive superalloy materials. These environmental considerations are becoming increasingly important as regulatory pressures mount and manufacturers seek to reduce their ecological footprint.

Looking forward, the field is moving toward the integration of digital twin technology, artificial intelligence, and machine learning algorithms to predict and optimize machining outcomes. The ultimate goal is to establish fully autonomous manufacturing systems capable of self-optimization and adaptation to changing conditions, representing the next frontier in precision turbine component manufacturing.

Market Analysis for High-Precision Aerospace Components

The global market for high-precision aerospace components, particularly those used in turbine engine manufacturing, has experienced substantial growth over the past decade. This expansion is primarily driven by increasing aircraft production rates, rising defense budgets worldwide, and the growing emphasis on fuel-efficient engines requiring more complex precision components. The market value for precision-machined aerospace components reached approximately $29.5 billion in 2022, with projections indicating growth to $42.3 billion by 2028, representing a compound annual growth rate of 6.2%.

The demand for high-precision turbine components is particularly strong in regions with established aerospace manufacturing hubs. North America continues to dominate the market with a 38% share, followed by Europe at 31% and Asia-Pacific at 24%. The remaining 7% is distributed across other regions. This geographic distribution closely aligns with the locations of major aircraft and engine manufacturers.

Commercial aviation represents the largest market segment, accounting for 52% of demand for precision components, while military applications constitute 36%. The remaining 12% serves space exploration and other specialized aerospace applications. The commercial segment is expected to maintain its dominant position due to increasing air travel demands and fleet modernization initiatives by major airlines globally.

Key demand drivers include the industry-wide push toward more fuel-efficient engines, which require components manufactured to tighter tolerances and more complex geometries. Additionally, the trend toward lighter materials, including titanium alloys and advanced composites, is creating new challenges and opportunities in precision machining techniques. The market is also influenced by increasing requirements for components that can withstand higher operating temperatures, allowing engines to run more efficiently.

Customer requirements are evolving toward components with longer service life, reduced maintenance needs, and improved reliability. This shift is creating premium market segments for ultra-precision components that can deliver superior performance under extreme operating conditions. Engine manufacturers are willing to pay premium prices for components that can demonstrably improve engine efficiency or reduce maintenance costs.

Market barriers include the high capital investment required for advanced machining equipment, stringent certification requirements, and the specialized expertise needed for precision manufacturing of aerospace components. These factors have created a relatively concentrated supplier market, with approximately 75% of production controlled by the top 20 global manufacturers.

The demand for high-precision turbine components is particularly strong in regions with established aerospace manufacturing hubs. North America continues to dominate the market with a 38% share, followed by Europe at 31% and Asia-Pacific at 24%. The remaining 7% is distributed across other regions. This geographic distribution closely aligns with the locations of major aircraft and engine manufacturers.

Commercial aviation represents the largest market segment, accounting for 52% of demand for precision components, while military applications constitute 36%. The remaining 12% serves space exploration and other specialized aerospace applications. The commercial segment is expected to maintain its dominant position due to increasing air travel demands and fleet modernization initiatives by major airlines globally.

Key demand drivers include the industry-wide push toward more fuel-efficient engines, which require components manufactured to tighter tolerances and more complex geometries. Additionally, the trend toward lighter materials, including titanium alloys and advanced composites, is creating new challenges and opportunities in precision machining techniques. The market is also influenced by increasing requirements for components that can withstand higher operating temperatures, allowing engines to run more efficiently.

Customer requirements are evolving toward components with longer service life, reduced maintenance needs, and improved reliability. This shift is creating premium market segments for ultra-precision components that can deliver superior performance under extreme operating conditions. Engine manufacturers are willing to pay premium prices for components that can demonstrably improve engine efficiency or reduce maintenance costs.

Market barriers include the high capital investment required for advanced machining equipment, stringent certification requirements, and the specialized expertise needed for precision manufacturing of aerospace components. These factors have created a relatively concentrated supplier market, with approximately 75% of production controlled by the top 20 global manufacturers.

Current Challenges in Turbine Engine Component Manufacturing

The manufacturing of precision turbine engine components faces significant challenges due to the extreme operating conditions these parts must withstand. Current manufacturing processes struggle with the complex geometries, tight tolerances, and advanced materials required for modern turbine engines. Material machinability presents a primary obstacle, as manufacturers increasingly utilize nickel-based superalloys, titanium alloys, and ceramic matrix composites that resist conventional cutting methods due to their high-temperature strength and work-hardening properties.

Thermal management during machining represents another critical challenge. The heat generated during high-speed cutting operations can cause dimensional inaccuracies, tool wear, and microstructural changes in the workpiece. This is particularly problematic for thin-walled components where thermal distortion can lead to rejection rates exceeding 15% in some production environments.

Surface integrity requirements have become increasingly stringent, with Ra values below 0.4μm now standard for critical airflow surfaces. Achieving these finishes while maintaining subsurface material properties presents significant technical difficulties. Residual stress management is essential, as improper machining can introduce tensile stresses that compromise fatigue life in high-cycle applications.

Tool wear acceleration in these difficult-to-machine materials dramatically impacts production economics. Advanced cutting tools, including polycrystalline diamond (PCD) and ceramic inserts, typically experience tool life reductions of 60-80% when machining superalloys compared to conventional steels. This necessitates frequent tool changes, increasing production costs and reducing manufacturing efficiency.

Complex cooling passage geometries in modern turbine blades require advanced five-axis machining capabilities with positional accuracies of ±0.005mm. The industry faces a significant skills gap in programming and operating these sophisticated machine tools, with training cycles often exceeding 18 months for full competency.

Quality verification presents additional challenges, as traditional coordinate measuring machines (CMMs) struggle with deep internal features and complex freeform surfaces. Non-destructive testing methods must evolve to detect subsurface defects without compromising component integrity.

Supply chain vulnerabilities have been exposed by recent global disruptions, with specialized tooling and machine components facing lead times extending beyond 12 months in some cases. This has forced manufacturers to reconsider vertical integration strategies and regional manufacturing capabilities to ensure production continuity.

Environmental and regulatory pressures are mounting, with cutting fluid management and disposal costs increasing by approximately 30% over the past five years. Sustainable manufacturing practices must be developed while maintaining the exacting quality standards required for safety-critical aerospace components.

Thermal management during machining represents another critical challenge. The heat generated during high-speed cutting operations can cause dimensional inaccuracies, tool wear, and microstructural changes in the workpiece. This is particularly problematic for thin-walled components where thermal distortion can lead to rejection rates exceeding 15% in some production environments.

Surface integrity requirements have become increasingly stringent, with Ra values below 0.4μm now standard for critical airflow surfaces. Achieving these finishes while maintaining subsurface material properties presents significant technical difficulties. Residual stress management is essential, as improper machining can introduce tensile stresses that compromise fatigue life in high-cycle applications.

Tool wear acceleration in these difficult-to-machine materials dramatically impacts production economics. Advanced cutting tools, including polycrystalline diamond (PCD) and ceramic inserts, typically experience tool life reductions of 60-80% when machining superalloys compared to conventional steels. This necessitates frequent tool changes, increasing production costs and reducing manufacturing efficiency.

Complex cooling passage geometries in modern turbine blades require advanced five-axis machining capabilities with positional accuracies of ±0.005mm. The industry faces a significant skills gap in programming and operating these sophisticated machine tools, with training cycles often exceeding 18 months for full competency.

Quality verification presents additional challenges, as traditional coordinate measuring machines (CMMs) struggle with deep internal features and complex freeform surfaces. Non-destructive testing methods must evolve to detect subsurface defects without compromising component integrity.

Supply chain vulnerabilities have been exposed by recent global disruptions, with specialized tooling and machine components facing lead times extending beyond 12 months in some cases. This has forced manufacturers to reconsider vertical integration strategies and regional manufacturing capabilities to ensure production continuity.

Environmental and regulatory pressures are mounting, with cutting fluid management and disposal costs increasing by approximately 30% over the past five years. Sustainable manufacturing practices must be developed while maintaining the exacting quality standards required for safety-critical aerospace components.

Advanced Machining Methodologies for Turbine Components

01 Advanced CNC machining techniques for precision components

Computer Numerical Control (CNC) machining techniques have evolved to achieve high precision in manufacturing complex components. These techniques utilize advanced programming algorithms and multi-axis machining centers to produce parts with tight tolerances. The integration of real-time monitoring systems allows for continuous adjustment during the machining process, ensuring dimensional accuracy and surface quality. These advanced CNC techniques are particularly valuable in industries requiring high-precision components such as aerospace and medical device manufacturing.- CNC Machining for High Precision Components: Computer Numerical Control (CNC) machining techniques enable the production of high-precision components with tight tolerances. These systems use computerized controls to operate machine tools with exceptional accuracy, allowing for complex geometries and consistent results. Advanced CNC technologies incorporate multi-axis capabilities, real-time monitoring, and adaptive control systems to maintain precision throughout the machining process, making them suitable for aerospace, medical, and other industries requiring extreme precision.

- Precision Grinding and Surface Finishing Techniques: Specialized grinding and surface finishing techniques are employed to achieve superior surface quality and dimensional accuracy. These methods include precision grinding, honing, lapping, and polishing processes that can achieve surface finishes in the nanometer range. Advanced abrasive technologies and machine designs enable the removal of minimal material while maintaining geometric accuracy, resulting in components with excellent wear resistance, reduced friction, and improved functional performance.

- Micro and Nano-Machining Technologies: Micro and nano-machining technologies enable the fabrication of extremely small features with high precision. These techniques include micro-milling, micro-EDM (Electrical Discharge Machining), laser micro-machining, and focused ion beam processing. They allow for the creation of miniature components with micro and nano-scale features while maintaining tight tolerances. These technologies are particularly important in the production of microelectronics, MEMS (Micro-Electro-Mechanical Systems), medical devices, and optical components.

- Advanced Tool Materials and Coatings: The development of advanced cutting tool materials and coatings significantly enhances machining precision. Materials such as cemented carbides, ceramics, cubic boron nitride, and polycrystalline diamond provide superior hardness, wear resistance, and thermal stability. Specialized coatings like TiAlN, TiCN, and diamond-like carbon further improve tool performance by reducing friction, preventing built-up edge formation, and extending tool life. These advancements enable higher cutting speeds, better surface finishes, and more precise dimensional control during machining operations.

- Intelligent Machining Systems and Error Compensation: Intelligent machining systems incorporate sensors, real-time monitoring, and adaptive control to achieve higher precision. These systems use in-process measurement, thermal compensation, and vibration control to detect and correct errors during machining. Machine learning algorithms analyze process data to optimize cutting parameters and predict tool wear. Advanced error compensation techniques account for geometric errors, thermal expansion, and tool deflection, ensuring consistent precision even under varying conditions. These technologies are particularly valuable for high-value components where dimensional accuracy is critical.

02 Micro-machining technologies for ultra-precision applications

Micro-machining technologies enable the fabrication of extremely small features with sub-micron precision. These technologies include micro-milling, micro-drilling, and micro-grinding processes that utilize specialized tooling and equipment designed specifically for small-scale operations. Ultra-precision machining systems incorporate vibration isolation, temperature control, and high-resolution positioning systems to achieve nanometer-level accuracy. These techniques are essential for manufacturing microelectronic components, optical devices, and miniaturized medical instruments where conventional machining methods cannot achieve the required precision.Expand Specific Solutions03 Precision grinding and polishing methods for surface finishing

Advanced grinding and polishing methods are crucial for achieving superior surface finishes in precision components. These techniques include centerless grinding, creep-feed grinding, and electrolytic in-process dressing (ELID) grinding, which can produce mirror-like surfaces with roughness values in the nanometer range. Computer-controlled polishing systems utilize specialized abrasives and precisely controlled pressure to remove material at the molecular level. These finishing methods are particularly important in optical component manufacturing, precision mold making, and high-performance mechanical parts where surface quality directly impacts functionality.Expand Specific Solutions04 Hybrid manufacturing combining additive and subtractive techniques

Hybrid manufacturing processes integrate additive manufacturing (3D printing) with precision machining techniques to leverage the advantages of both approaches. Components are first built using additive methods to create near-net shapes, followed by precision machining operations to achieve final dimensions and surface finishes. This combination allows for the creation of complex internal geometries while maintaining tight tolerances and excellent surface quality on critical features. Hybrid systems often incorporate in-process inspection to verify dimensional accuracy throughout the manufacturing sequence, enabling the production of high-precision components with geometries that would be impossible to create using traditional methods alone.Expand Specific Solutions05 Precision fixturing and workholding systems

Advanced fixturing and workholding systems are essential for achieving high precision in machining operations. These systems include modular fixturing, vacuum workholding, magnetic chucks, and specialized clamping mechanisms designed to secure workpieces without distortion. Precision fixtures incorporate kinematic principles to ensure repeatable positioning and minimize setup errors. Some advanced systems feature active compensation for thermal expansion and vibration damping to maintain dimensional stability during machining. Proper workholding is critical for precision machining as it directly affects the ability to achieve and maintain tight tolerances throughout the manufacturing process.Expand Specific Solutions

Leading Manufacturers and Suppliers in Aerospace Machining

The precision turbine engine components machining market is in a mature growth phase, characterized by established technologies and steady expansion driven by aerospace and power generation demands. The global market size exceeds $15 billion annually with consistent 4-6% growth. Leading players include established Western aerospace giants (GE, Rolls-Royce, RTX, Safran, MTU Aero Engines) with advanced multi-axis machining capabilities and emerging Chinese competitors (AVIC Shenyang Liming, AECC South Industry) rapidly developing technical expertise. The competitive landscape features increasing technological sophistication in areas like adaptive machining, high-precision grinding, and advanced cooling hole drilling techniques, with companies investing heavily in automation and digital manufacturing to maintain competitive advantages.

General Electric Company

Technical Solution: GE has pioneered advanced machining techniques for turbine components through their Brilliant Factory initiative. Their approach integrates adaptive machining with digital twins to achieve micron-level precision. GE utilizes multi-axis CNC machining centers with in-process measurement systems that continuously adjust parameters based on real-time feedback. Their proprietary Blue Arc™ Electro-Erosion Machining technology enables high-speed material removal for hard alloys like titanium aluminides and single-crystal superalloys, reducing machining time by up to 80% compared to conventional methods[1]. GE also employs Electrical Discharge Machining (EDM) with adaptive control algorithms to create complex cooling channels in turbine blades with tolerances as tight as ±0.0005 inches. Their integrated manufacturing execution systems maintain digital thread continuity throughout the production process, ensuring traceability and consistency.

Strengths: Industry-leading integration of digital and physical manufacturing systems; proprietary high-speed machining technologies for superalloys; comprehensive quality control systems. Weaknesses: High capital investment requirements; complex implementation requiring specialized expertise; technologies primarily optimized for their own engine designs.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a comprehensive suite of precision machining techniques focused on their "Manufacturing of the Future" strategy. Their approach centers on adaptive machining systems that combine on-machine measurement with automated compensation algorithms to achieve tolerances below 10 microns on complex geometries. Rolls-Royce employs robotic super-finishing processes for turbine blade surfaces, achieving surface roughness values below Ra 0.2μm. Their proprietary "Blue Sky" machining centers incorporate cryogenic cooling technology that maintains thermal stability during high-speed cutting of nickel-based superalloys, reducing tool wear by approximately 40%[2]. For turbine discs, Rolls-Royce utilizes specialized broaching techniques with instrumented tooling that provides real-time feedback on cutting forces, allowing for immediate adjustments to maintain dimensional accuracy. Their manufacturing facilities implement closed-loop quality systems that feed measurement data back to design teams, enabling continuous refinement of both components and processes.

Strengths: Exceptional surface finish capabilities; advanced cryogenic machining expertise; strong integration between design and manufacturing. Weaknesses: Higher production costs compared to conventional techniques; specialized equipment with limited flexibility for diverse component types; significant training requirements for operators.

Critical Patents and Innovations in Precision Machining

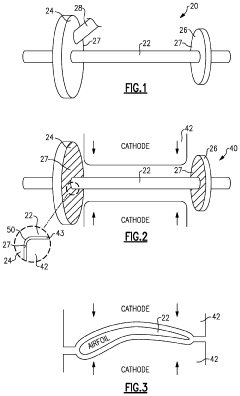

Method of machining gas turbine engine components

PatentActiveUS11623290B2

Innovation

- A method combining conventional machining with ECM, where the gas path surfaces of the shrouds are initially machined using a non-ECM process, followed by a pulsed or precise ECM process on the airfoil, with cathode oscillations and angled feeding to optimize the input geometry and minimize surface mismatch.

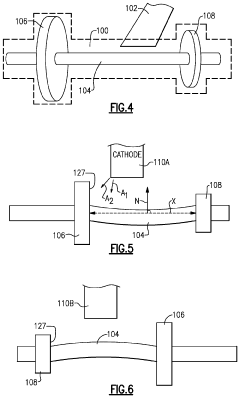

Control of a machining operation

PatentInactiveUS20090319077A1

Innovation

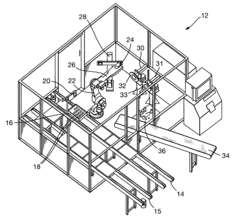

- A machining cell equipped with a computer-controlled system that uses optical readers, robot manipulators, and sensors to measure and adjust machining parameters in real-time, ensuring precise material removal and surface finish, while monitoring tool wear and environmental conditions to maintain consistency with design intent.

Material Science Advancements for Turbine Applications

The evolution of turbine engine technology is intrinsically linked to advancements in material science. Modern turbine components operate under extreme conditions, with temperatures exceeding 1200°C and significant mechanical stresses, necessitating materials with exceptional thermal stability and mechanical properties.

Nickel-based superalloys remain the cornerstone of turbine component manufacturing, with continuous improvements in their composition and microstructure. Recent developments include the incorporation of rhenium, ruthenium, and hafnium to enhance creep resistance and high-temperature stability. These third and fourth-generation superalloys demonstrate up to 30% improvement in temperature capability compared to their predecessors.

Ceramic matrix composites (CMCs) represent a significant breakthrough for turbine applications. Silicon carbide (SiC) fiber-reinforced SiC matrix composites offer superior temperature resistance up to 1400°C while weighing approximately one-third of traditional superalloys. General Electric's implementation of CMCs in the LEAP engine has demonstrated 5% improved fuel efficiency and reduced cooling requirements.

Thermal barrier coatings (TBCs) have evolved from simple yttria-stabilized zirconia (YSZ) systems to complex multilayer structures. Advanced TBCs incorporate gadolinium zirconate and other rare earth elements, providing improved phase stability and reduced thermal conductivity. These coatings extend component life by up to 40% under cyclic thermal conditions.

Single-crystal manufacturing techniques have progressed significantly, allowing for larger and more complex geometries with controlled crystallographic orientations. This advancement enables the elimination of grain boundaries—traditionally weak points in high-temperature applications—resulting in components with superior creep resistance and thermal fatigue properties.

Additive manufacturing has revolutionized material possibilities for turbine components. Selective laser melting and electron beam melting processes enable the creation of previously impossible internal cooling geometries and functionally graded materials. These techniques allow for localized property optimization and reduced material waste, with some components showing 40-60% weight reduction while maintaining mechanical integrity.

Environmental barrier coatings (EBCs) have become essential for protecting CMCs and other advanced materials from water vapor and other combustion byproducts. Multilayer rare earth silicates and hafnium-based compounds provide protection against chemical degradation while maintaining thermal stability, extending component life in aggressive environments by factors of 3-5 times.

Nickel-based superalloys remain the cornerstone of turbine component manufacturing, with continuous improvements in their composition and microstructure. Recent developments include the incorporation of rhenium, ruthenium, and hafnium to enhance creep resistance and high-temperature stability. These third and fourth-generation superalloys demonstrate up to 30% improvement in temperature capability compared to their predecessors.

Ceramic matrix composites (CMCs) represent a significant breakthrough for turbine applications. Silicon carbide (SiC) fiber-reinforced SiC matrix composites offer superior temperature resistance up to 1400°C while weighing approximately one-third of traditional superalloys. General Electric's implementation of CMCs in the LEAP engine has demonstrated 5% improved fuel efficiency and reduced cooling requirements.

Thermal barrier coatings (TBCs) have evolved from simple yttria-stabilized zirconia (YSZ) systems to complex multilayer structures. Advanced TBCs incorporate gadolinium zirconate and other rare earth elements, providing improved phase stability and reduced thermal conductivity. These coatings extend component life by up to 40% under cyclic thermal conditions.

Single-crystal manufacturing techniques have progressed significantly, allowing for larger and more complex geometries with controlled crystallographic orientations. This advancement enables the elimination of grain boundaries—traditionally weak points in high-temperature applications—resulting in components with superior creep resistance and thermal fatigue properties.

Additive manufacturing has revolutionized material possibilities for turbine components. Selective laser melting and electron beam melting processes enable the creation of previously impossible internal cooling geometries and functionally graded materials. These techniques allow for localized property optimization and reduced material waste, with some components showing 40-60% weight reduction while maintaining mechanical integrity.

Environmental barrier coatings (EBCs) have become essential for protecting CMCs and other advanced materials from water vapor and other combustion byproducts. Multilayer rare earth silicates and hafnium-based compounds provide protection against chemical degradation while maintaining thermal stability, extending component life in aggressive environments by factors of 3-5 times.

Quality Assurance and Certification Standards

Quality assurance and certification standards play a pivotal role in the manufacturing of precision turbine engine components, establishing the foundation for reliability, safety, and performance in aerospace and power generation applications. The aerospace industry, in particular, has developed rigorous certification frameworks such as AS9100 for quality management systems, which extends ISO 9000 standards with additional requirements specific to aviation, space, and defense organizations. These standards ensure that machining processes consistently meet the exacting specifications required for critical turbine components.

Non-destructive testing (NDT) methodologies constitute an essential element of quality assurance protocols for turbine components. Techniques including ultrasonic testing, radiographic inspection, eddy current testing, and dye penetrant inspection are systematically employed to detect surface and subsurface defects without compromising the structural integrity of the components. The implementation of these testing regimes is governed by standards such as ASTM E1417 for liquid penetrant testing and ASTM E1444 for magnetic particle examination.

Material certification standards, including those established by organizations like SAE, ASTM, and API, define the chemical composition, mechanical properties, and heat treatment requirements for superalloys and other advanced materials used in turbine components. These standards ensure that materials can withstand the extreme thermal and mechanical stresses encountered during turbine operation. Traceability requirements mandate comprehensive documentation of material provenance from raw material to finished component.

Statistical process control (SPC) methodologies have become increasingly integrated into quality assurance frameworks for precision machining operations. Standards such as ANSI/ASQ Z1.4 provide guidelines for sampling procedures and acceptance criteria, enabling manufacturers to monitor process stability and capability. Advanced measurement systems analysis (MSA) techniques, conforming to standards like AIAG MSA, ensure that measurement processes themselves are reliable and accurate.

International certification bodies, including Nadcap (National Aerospace and Defense Contractors Accreditation Program), provide specialized accreditation for critical manufacturing processes such as heat treatment, welding, and non-destructive testing. Nadcap certification has become a de facto requirement for suppliers to major aerospace OEMs, establishing a standardized approach to special process qualification across the global supply chain. This certification ensures that suppliers adhere to industry-best practices and maintain consistent quality levels.

Environmental and sustainability standards are increasingly influencing quality assurance frameworks in precision machining. Standards such as ISO 14001 for environmental management systems and emerging standards for sustainable manufacturing practices are being integrated into comprehensive quality management approaches, reflecting growing industry commitment to environmental responsibility while maintaining the highest levels of component performance and reliability.

Non-destructive testing (NDT) methodologies constitute an essential element of quality assurance protocols for turbine components. Techniques including ultrasonic testing, radiographic inspection, eddy current testing, and dye penetrant inspection are systematically employed to detect surface and subsurface defects without compromising the structural integrity of the components. The implementation of these testing regimes is governed by standards such as ASTM E1417 for liquid penetrant testing and ASTM E1444 for magnetic particle examination.

Material certification standards, including those established by organizations like SAE, ASTM, and API, define the chemical composition, mechanical properties, and heat treatment requirements for superalloys and other advanced materials used in turbine components. These standards ensure that materials can withstand the extreme thermal and mechanical stresses encountered during turbine operation. Traceability requirements mandate comprehensive documentation of material provenance from raw material to finished component.

Statistical process control (SPC) methodologies have become increasingly integrated into quality assurance frameworks for precision machining operations. Standards such as ANSI/ASQ Z1.4 provide guidelines for sampling procedures and acceptance criteria, enabling manufacturers to monitor process stability and capability. Advanced measurement systems analysis (MSA) techniques, conforming to standards like AIAG MSA, ensure that measurement processes themselves are reliable and accurate.

International certification bodies, including Nadcap (National Aerospace and Defense Contractors Accreditation Program), provide specialized accreditation for critical manufacturing processes such as heat treatment, welding, and non-destructive testing. Nadcap certification has become a de facto requirement for suppliers to major aerospace OEMs, establishing a standardized approach to special process qualification across the global supply chain. This certification ensures that suppliers adhere to industry-best practices and maintain consistent quality levels.

Environmental and sustainability standards are increasingly influencing quality assurance frameworks in precision machining. Standards such as ISO 14001 for environmental management systems and emerging standards for sustainable manufacturing practices are being integrated into comprehensive quality management approaches, reflecting growing industry commitment to environmental responsibility while maintaining the highest levels of component performance and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!