Comparing Turbine Engine Materials: Titanium vs Nickel Alloys

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Materials Evolution and Objectives

The evolution of turbine engine materials has been a critical factor in the advancement of aerospace and power generation technologies over the past century. Initially, early turbine engines utilized relatively simple steel alloys that limited operational temperatures and efficiency. The 1950s marked a significant turning point with the introduction of titanium alloys, which offered superior strength-to-weight ratios compared to steel, enabling lighter and more efficient engine designs.

The 1960s and 1970s witnessed the emergence of nickel-based superalloys as dominant materials for high-temperature components in turbine engines. These alloys demonstrated exceptional resistance to thermal creep and oxidation at elevated temperatures, allowing engines to operate at higher temperatures and achieve greater thermodynamic efficiency. The development of directionally solidified and single-crystal casting techniques in the 1980s further enhanced the high-temperature capabilities of nickel alloys.

Titanium alloys, particularly Ti-6Al-4V and Ti-6242, have maintained their importance in compressor sections where temperatures are moderate but weight considerations are paramount. Their excellent corrosion resistance and fatigue properties make them ideal for rotating components operating below 600°C. Meanwhile, nickel-based superalloys such as Inconel 718, Waspaloy, and René 41 have become the materials of choice for turbine sections where temperatures can exceed 1000°C.

Recent decades have seen the development of more sophisticated alloy compositions and processing techniques for both material families. Titanium aluminides (TiAl) have emerged as promising intermediate-temperature materials, offering density advantages over nickel alloys while providing better temperature capabilities than conventional titanium alloys. For nickel alloys, advances in powder metallurgy and additive manufacturing have enabled more complex geometries and improved material properties.

The primary objective in turbine engine materials development continues to be increasing the temperature capability while maintaining or reducing component weight. Higher operating temperatures directly translate to improved engine efficiency and reduced fuel consumption. Additional objectives include extending component lifespan, reducing manufacturing costs, and minimizing environmental impact through reduced emissions.

Looking forward, research is focused on pushing the temperature limits of both titanium and nickel alloys through novel compositions and processing techniques. Hybrid material systems and advanced coatings are being explored to combine the advantages of both material families. The ultimate goal remains the development of materials that enable more efficient, lighter, and more environmentally friendly turbine engines for next-generation aircraft and power generation systems.

The 1960s and 1970s witnessed the emergence of nickel-based superalloys as dominant materials for high-temperature components in turbine engines. These alloys demonstrated exceptional resistance to thermal creep and oxidation at elevated temperatures, allowing engines to operate at higher temperatures and achieve greater thermodynamic efficiency. The development of directionally solidified and single-crystal casting techniques in the 1980s further enhanced the high-temperature capabilities of nickel alloys.

Titanium alloys, particularly Ti-6Al-4V and Ti-6242, have maintained their importance in compressor sections where temperatures are moderate but weight considerations are paramount. Their excellent corrosion resistance and fatigue properties make them ideal for rotating components operating below 600°C. Meanwhile, nickel-based superalloys such as Inconel 718, Waspaloy, and René 41 have become the materials of choice for turbine sections where temperatures can exceed 1000°C.

Recent decades have seen the development of more sophisticated alloy compositions and processing techniques for both material families. Titanium aluminides (TiAl) have emerged as promising intermediate-temperature materials, offering density advantages over nickel alloys while providing better temperature capabilities than conventional titanium alloys. For nickel alloys, advances in powder metallurgy and additive manufacturing have enabled more complex geometries and improved material properties.

The primary objective in turbine engine materials development continues to be increasing the temperature capability while maintaining or reducing component weight. Higher operating temperatures directly translate to improved engine efficiency and reduced fuel consumption. Additional objectives include extending component lifespan, reducing manufacturing costs, and minimizing environmental impact through reduced emissions.

Looking forward, research is focused on pushing the temperature limits of both titanium and nickel alloys through novel compositions and processing techniques. Hybrid material systems and advanced coatings are being explored to combine the advantages of both material families. The ultimate goal remains the development of materials that enable more efficient, lighter, and more environmentally friendly turbine engines for next-generation aircraft and power generation systems.

Market Requirements for Advanced Turbine Materials

The aerospace and power generation industries are experiencing unprecedented demand for advanced turbine materials that can withstand increasingly extreme operating conditions. Current market requirements are primarily driven by the need for higher operating temperatures to improve thermal efficiency, with every 50°C increase in operating temperature potentially yielding 1-3% improvement in fuel efficiency. This translates to significant cost savings and emissions reductions over the lifecycle of turbine engines.

Weight reduction remains a critical market requirement, particularly in aerospace applications where the industry standard dictates that each kilogram reduced from an aircraft can save approximately 2,900 liters of fuel annually per aircraft. This creates strong market pull for titanium alloys despite their temperature limitations compared to nickel-based superalloys.

Durability under extreme conditions is becoming increasingly non-negotiable as maintenance costs and downtime represent major expenses for operators. The market demands materials that can maintain structural integrity under thermal cycling, with resistance to creep deformation at high temperatures (above 540°C) and excellent fatigue resistance under variable loading conditions.

Cost-effectiveness considerations are shifting from purely acquisition costs to total lifecycle expenses. While nickel alloys typically command premium prices (30-50% higher than titanium alloys), their superior high-temperature performance often justifies the investment through extended service life and reduced maintenance intervals in high-temperature applications.

Environmental regulations and sustainability goals are reshaping material requirements, with the aviation industry committed to carbon-neutral growth from 2020 and a 50% reduction in CO2 emissions by 2050 compared to 2005 levels. This drives demand for materials enabling more efficient combustion at higher temperatures.

Manufacturing scalability has emerged as a significant market requirement, with OEMs seeking materials that can be processed using advanced manufacturing techniques such as additive manufacturing. The market increasingly values alloys that maintain their performance advantages while being compatible with these cost-effective production methods.

Certification and regulatory compliance represent substantial market barriers, with new materials facing rigorous testing requirements. Materials with established performance data and certification histories hold significant market advantages, explaining the continued dominance of well-characterized nickel superalloys in critical high-temperature applications despite the weight advantages of titanium alternatives.

Weight reduction remains a critical market requirement, particularly in aerospace applications where the industry standard dictates that each kilogram reduced from an aircraft can save approximately 2,900 liters of fuel annually per aircraft. This creates strong market pull for titanium alloys despite their temperature limitations compared to nickel-based superalloys.

Durability under extreme conditions is becoming increasingly non-negotiable as maintenance costs and downtime represent major expenses for operators. The market demands materials that can maintain structural integrity under thermal cycling, with resistance to creep deformation at high temperatures (above 540°C) and excellent fatigue resistance under variable loading conditions.

Cost-effectiveness considerations are shifting from purely acquisition costs to total lifecycle expenses. While nickel alloys typically command premium prices (30-50% higher than titanium alloys), their superior high-temperature performance often justifies the investment through extended service life and reduced maintenance intervals in high-temperature applications.

Environmental regulations and sustainability goals are reshaping material requirements, with the aviation industry committed to carbon-neutral growth from 2020 and a 50% reduction in CO2 emissions by 2050 compared to 2005 levels. This drives demand for materials enabling more efficient combustion at higher temperatures.

Manufacturing scalability has emerged as a significant market requirement, with OEMs seeking materials that can be processed using advanced manufacturing techniques such as additive manufacturing. The market increasingly values alloys that maintain their performance advantages while being compatible with these cost-effective production methods.

Certification and regulatory compliance represent substantial market barriers, with new materials facing rigorous testing requirements. Materials with established performance data and certification histories hold significant market advantages, explaining the continued dominance of well-characterized nickel superalloys in critical high-temperature applications despite the weight advantages of titanium alternatives.

Current Status and Challenges in Titanium and Nickel Alloys

The global landscape of turbine engine materials is currently dominated by titanium and nickel-based alloys, each with distinct advantages and limitations. Titanium alloys have achieved significant market penetration in compressor sections where temperatures remain below 600°C, while nickel-based superalloys dominate the high-temperature turbine sections operating above 700°C. This temperature-based segmentation reflects the fundamental material properties that define their application boundaries.

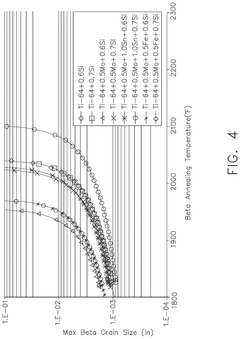

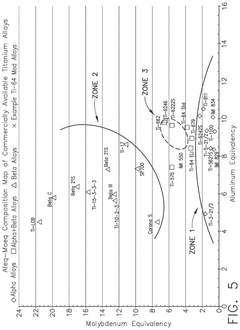

Recent advancements in titanium alloys have focused on improving their temperature resistance through alloying with elements such as aluminum, vanadium, and molybdenum. Despite these efforts, the inherent oxidation susceptibility of titanium at elevated temperatures remains a significant technical barrier. Current-generation titanium alloys typically exhibit rapid strength degradation above 550-600°C, limiting their application in hotter engine sections.

Nickel-based superalloys, particularly those strengthened by gamma prime precipitates, maintain structural integrity at substantially higher temperatures but face challenges in weight reduction and raw material costs. The global supply chain for nickel has experienced volatility, with prices fluctuating by over 300% in the past decade, creating economic uncertainties for engine manufacturers.

A critical technical challenge facing both material systems is the balance between mechanical properties and manufacturability. Advanced manufacturing techniques such as additive manufacturing (AM) have shown promise for complex geometries but often result in microstructural variations that can compromise performance. Approximately 65% of new alloy developments fail to transition from laboratory to production due to scalability issues.

Geographically, the development of advanced titanium alloys is concentrated in the United States, Russia, and China, with these countries controlling approximately 70% of global titanium production capacity. Nickel-based superalloy development is more distributed, with significant research centers in the United States, United Kingdom, Germany, Japan, and increasingly China.

Environmental regulations present another significant challenge, particularly for titanium processing, which is energy-intensive and produces considerable emissions. The carbon footprint of titanium production is approximately 35-40 kg CO₂ per kg of material, significantly higher than many competing structural materials.

The integration of computational materials engineering has accelerated in recent years, with approximately 40% of new alloy formulations now leveraging machine learning approaches. However, the predictive accuracy of these models remains limited for complex microstructural evolution during service, particularly for nickel alloys under thermomechanical fatigue conditions.

Recycling and sustainable material usage represent emerging challenges, with the aviation industry targeting 50% reduction in material waste by 2030. Current recycling rates for specialized turbine alloys remain below 30% due to contamination concerns and the complex nature of engine components.

Recent advancements in titanium alloys have focused on improving their temperature resistance through alloying with elements such as aluminum, vanadium, and molybdenum. Despite these efforts, the inherent oxidation susceptibility of titanium at elevated temperatures remains a significant technical barrier. Current-generation titanium alloys typically exhibit rapid strength degradation above 550-600°C, limiting their application in hotter engine sections.

Nickel-based superalloys, particularly those strengthened by gamma prime precipitates, maintain structural integrity at substantially higher temperatures but face challenges in weight reduction and raw material costs. The global supply chain for nickel has experienced volatility, with prices fluctuating by over 300% in the past decade, creating economic uncertainties for engine manufacturers.

A critical technical challenge facing both material systems is the balance between mechanical properties and manufacturability. Advanced manufacturing techniques such as additive manufacturing (AM) have shown promise for complex geometries but often result in microstructural variations that can compromise performance. Approximately 65% of new alloy developments fail to transition from laboratory to production due to scalability issues.

Geographically, the development of advanced titanium alloys is concentrated in the United States, Russia, and China, with these countries controlling approximately 70% of global titanium production capacity. Nickel-based superalloy development is more distributed, with significant research centers in the United States, United Kingdom, Germany, Japan, and increasingly China.

Environmental regulations present another significant challenge, particularly for titanium processing, which is energy-intensive and produces considerable emissions. The carbon footprint of titanium production is approximately 35-40 kg CO₂ per kg of material, significantly higher than many competing structural materials.

The integration of computational materials engineering has accelerated in recent years, with approximately 40% of new alloy formulations now leveraging machine learning approaches. However, the predictive accuracy of these models remains limited for complex microstructural evolution during service, particularly for nickel alloys under thermomechanical fatigue conditions.

Recycling and sustainable material usage represent emerging challenges, with the aviation industry targeting 50% reduction in material waste by 2030. Current recycling rates for specialized turbine alloys remain below 30% due to contamination concerns and the complex nature of engine components.

Comparative Analysis of Titanium and Nickel Alloy Solutions

01 Titanium alloy compositions for turbine engines

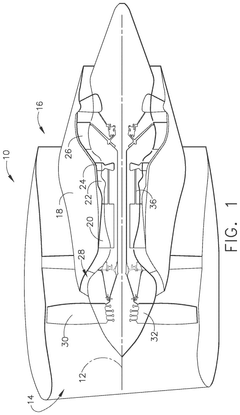

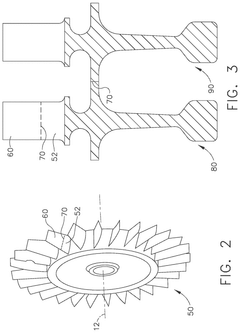

Specialized titanium alloy compositions are developed specifically for turbine engine applications, offering an optimal balance of high strength, low weight, and thermal stability. These alloys typically contain specific proportions of elements such as aluminum, vanadium, molybdenum, and zirconium to enhance mechanical properties at elevated temperatures. The microstructure of these alloys is carefully controlled through processing techniques to achieve the desired combination of properties required for turbine components such as blades, discs, and casings.- Titanium alloy compositions for turbine engines: Specialized titanium alloy compositions are developed specifically for turbine engine applications, offering an optimal balance of high strength, low weight, and thermal stability. These alloys typically contain specific proportions of elements like aluminum, vanadium, molybdenum, and zirconium to enhance mechanical properties at elevated temperatures. The microstructure of these alloys is carefully controlled through processing techniques to achieve the desired combination of creep resistance, fatigue strength, and oxidation resistance required in turbine engine components.

- Nickel-based superalloys for high-temperature turbine components: Nickel-based superalloys are formulated for extreme high-temperature applications in turbine engines, particularly in the hot section components like turbine blades and vanes. These superalloys contain carefully balanced amounts of chromium, cobalt, aluminum, titanium, and refractory elements to form strengthening precipitates and provide oxidation resistance. Advanced processing techniques including directional solidification and single crystal growth are employed to enhance creep resistance and thermal fatigue properties, allowing these materials to withstand the severe operating conditions in modern turbine engines.

- Manufacturing processes for turbine engine components: Specialized manufacturing processes are developed for producing complex turbine engine components from titanium and nickel alloys. These include advanced casting techniques, powder metallurgy, additive manufacturing, and precision machining methods tailored to the unique properties of these materials. Heat treatment protocols are designed to optimize microstructure and mechanical properties, while surface treatments and coatings are applied to enhance wear resistance, corrosion protection, and thermal barrier properties. These manufacturing processes are critical for ensuring the structural integrity and performance of turbine engine components under extreme operating conditions.

- Joining and repair techniques for turbine engine materials: Specialized joining and repair techniques are developed for titanium and nickel alloy components in turbine engines. These include advanced welding methods, brazing, diffusion bonding, and mechanical fastening systems designed to maintain material properties at the joint interface. Repair methodologies for damaged components include additive manufacturing-based restoration, specialized heat treatments, and surface engineering techniques. These joining and repair approaches extend component service life while maintaining structural integrity and performance characteristics under the demanding conditions of turbine engine operation.

- Protective coatings and surface treatments for turbine engine alloys: Advanced protective coatings and surface treatments are developed to enhance the performance and durability of titanium and nickel alloys in turbine engines. These include thermal barrier coatings, oxidation-resistant overlays, diffusion coatings, and environmental barrier systems that protect against high-temperature oxidation, hot corrosion, and erosion. Surface modification techniques such as shot peening, laser shock peening, and nitriding are employed to improve fatigue resistance and mechanical properties. These protective systems significantly extend component life and enable operation at higher temperatures, improving overall engine efficiency and performance.

02 Nickel-based superalloys for high-temperature turbine components

Nickel-based superalloys are formulated for extreme high-temperature applications in turbine engines, particularly in the hot sections where operating temperatures can exceed 1000°C. These superalloys contain carefully balanced amounts of chromium, cobalt, aluminum, titanium, and other elements to form strengthening precipitates and provide oxidation resistance. Advanced processing techniques such as directional solidification and single crystal growth are employed to enhance creep resistance and thermal fatigue properties, making these materials ideal for combustion chambers, turbine blades, and vanes.Expand Specific Solutions03 Manufacturing processes for turbine engine components

Specialized manufacturing processes are developed for producing complex turbine engine components from titanium and nickel alloys. These include precision casting, powder metallurgy, additive manufacturing, and advanced joining techniques such as diffusion bonding and friction welding. These processes are designed to maintain the integrity of the alloy microstructure while achieving the complex geometries required for turbine components. Post-processing treatments such as hot isostatic pressing and heat treatments are employed to optimize mechanical properties and eliminate defects in the final components.Expand Specific Solutions04 Protective coatings for turbine engine materials

Protective coating systems are developed to enhance the durability of titanium and nickel alloy components in turbine engines. These include thermal barrier coatings, oxidation-resistant coatings, and wear-resistant surface treatments. Multi-layer coating systems typically consist of a bond coat that adheres to the base metal and a ceramic top coat that provides thermal insulation. Advanced coating technologies such as physical vapor deposition, chemical vapor deposition, and plasma spraying are employed to apply these protective layers, significantly extending the service life of turbine components operating in extreme environments.Expand Specific Solutions05 Alloy development for improved performance characteristics

Ongoing research focuses on developing new titanium and nickel alloy compositions with enhanced performance characteristics for specific turbine engine applications. This includes alloys with improved high-temperature strength, better fatigue resistance, enhanced corrosion resistance, and reduced density. Novel alloying elements and processing techniques are investigated to achieve specific property combinations. Computational modeling and simulation tools are increasingly used to predict alloy behavior and optimize compositions before experimental validation, accelerating the development of next-generation materials for more efficient and durable turbine engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Alloy Development

The turbine engine materials market, particularly the competition between titanium and nickel alloys, is in a mature growth phase with increasing specialization. The global market size exceeds $5 billion annually, driven by aerospace and power generation applications. Technologically, nickel alloys have reached higher maturity for high-temperature applications, while titanium alloys continue evolving for weight-critical components. Key players demonstrate distinct positioning: GE and Rolls-Royce lead in comprehensive material development; Honeywell, RTX (formerly United Technologies), and Safran focus on aerospace applications; while Siemens Energy and BorgWarner emphasize industrial turbine solutions. Specialized materials developers like Haynes International and Alloyed Ltd provide cutting-edge alloy innovations to address specific performance requirements.

General Electric Company

Technical Solution: General Electric has developed advanced nickel-based superalloys like René N5 and René N6 for turbine engine hot sections, featuring precise control of elemental composition with 3-6% aluminum, 8-12% cobalt, and 5-7% tantalum. Their proprietary directional solidification and single crystal casting processes create components with superior creep resistance at temperatures exceeding 1000°C. GE's TiAl (titanium aluminide) alloys are implemented in low-pressure turbine blades of the GEnx and LEAP engines, reducing weight by up to 50% compared to traditional nickel alloys. Their materials engineering includes specialized thermal barrier coatings with yttria-stabilized zirconia that extends component life by 2-3x under extreme thermal cycling conditions. GE has pioneered additive manufacturing techniques specifically optimized for both titanium and nickel alloy turbine components, enabling complex cooling geometries impossible with conventional manufacturing.

Strengths: Industry-leading expertise in single crystal superalloy development; integrated manufacturing capabilities from powder metallurgy to finished components; extensive operational data from global fleet. Weaknesses: Higher production costs for advanced nickel superalloys; longer development cycles for new materials; greater weight compared to titanium alternatives in certain applications.

Safran SA

Technical Solution: Safran has developed the AM1 and MC-NG nickel-based single crystal superalloys specifically optimized for high-pressure turbine blades, featuring carefully controlled rhenium content (3-6%) to enhance creep resistance at temperatures exceeding 1050°C. Their titanium implementation strategy focuses on advanced Ti-Al-V alloys with precise microstructural control for compressor applications, achieving 15-20% weight reduction compared to conventional materials while maintaining required mechanical properties. Safran's proprietary ceramic core technology enables the creation of complex cooling channels within nickel superalloy turbine blades, improving thermal efficiency by up to 30% in critical hot section components. For intermediate temperature zones (500-700°C), they've pioneered dual-material solutions that leverage the advantages of both titanium alloys (lower weight, good corrosion resistance) and nickel alloys (superior high-temperature strength) through advanced joining technologies including inertia welding and diffusion bonding. Their materials engineering includes specialized surface treatments like HVOF (High Velocity Oxygen Fuel) thermal spray coatings for nickel components and titanium-specific anti-oxidation treatments that extend component life by 25-40% under typical operating conditions.

Strengths: Extensive experience in single crystal casting technologies; integrated supply chain for specialized alloy production; advanced non-destructive testing capabilities for quality assurance. Weaknesses: Higher production costs for specialized alloys; longer lead times for complex components; challenges in recycling mixed-material assemblies.

Key Innovations in High-Temperature Alloy Technology

Optimized nickel alloy and turbine blade made thereof

PatentInactiveEP2976439A1

Innovation

- A nickel alloy with specific weight proportions of chromium (12.3-12.7%), aluminum (4.3-4.7%), and tantalum to titanium ratio (2-3.5) is developed to achieve balanced high creep resistance and hot corrosion resistance, suitable for temperatures up to 900°C, enabling a 30°C increase in permissible temperature and 10% performance boost in gas turbines.

Titanium alloys and their methods of production

PatentActiveUS12104239B2

Innovation

- A new titanium alloy composition with 5-8 wt% aluminum, 2.5-5.5 wt% vanadium, 0.1-2 wt% iron or molybdenum, 0.01-0.2 wt% carbon, and up to 0.3 wt% oxygen or nitrogen, along with silicon and copper, is developed to maintain the isotropic properties and low cost of Ti-64 while enhancing thick section strength and fatigue resistance, utilizing a beta transus temperature and titanium silicide solvus temperature processing to refine microstructure and improve manufacturing efficiency.

Environmental Impact and Sustainability Considerations

The environmental impact of turbine engine materials has become increasingly significant as the aviation and power generation industries face growing pressure to reduce their carbon footprint. When comparing titanium and nickel alloys from a sustainability perspective, several critical factors must be considered throughout their lifecycle.

Titanium alloys generally require more energy during initial extraction and processing compared to nickel alloys, with titanium production consuming approximately 361 MJ/kg versus nickel's 159 MJ/kg. However, titanium's lower density offers significant weight reduction in engine components, potentially reducing fuel consumption by 1-3% over the operational lifetime of an aircraft engine. This translates to substantial reductions in greenhouse gas emissions during the use phase, which typically constitutes over 80% of a turbine engine's environmental impact.

Nickel alloys, while more energy-efficient to produce initially, contain various elements like chromium and cobalt that present environmental concerns during mining and processing. These elements can lead to soil and water contamination if not properly managed. Additionally, some nickel mining operations have been associated with deforestation and habitat destruction in biodiversity-rich regions, particularly in countries with less stringent environmental regulations.

Recyclability represents another important sustainability consideration. Titanium alloys maintain excellent recyclability rates of up to 95% with minimal property degradation, creating a viable circular economy pathway. Nickel-based superalloys, while also recyclable, often face challenges in separating alloying elements during the recycling process, resulting in downcycling rather than true recycling in many cases.

End-of-life toxicity profiles differ significantly between these materials. Titanium is biologically inert and poses minimal environmental hazards when disposed of. Conversely, nickel compounds can be carcinogenic and may leach into groundwater from improperly managed waste sites, creating long-term environmental liabilities.

Recent advancements in manufacturing technologies, particularly additive manufacturing, have improved the sustainability profile of both materials by reducing waste during production. For titanium components, powder bed fusion techniques can reduce material waste by up to 90% compared to traditional subtractive manufacturing methods, while similar improvements are being realized for nickel alloy components.

As environmental regulations tighten globally, manufacturers are increasingly required to consider the full lifecycle environmental impact of material choices. This has prompted research into hybrid material solutions and surface treatments that optimize the environmental benefits of both titanium and nickel alloys while minimizing their respective drawbacks.

Titanium alloys generally require more energy during initial extraction and processing compared to nickel alloys, with titanium production consuming approximately 361 MJ/kg versus nickel's 159 MJ/kg. However, titanium's lower density offers significant weight reduction in engine components, potentially reducing fuel consumption by 1-3% over the operational lifetime of an aircraft engine. This translates to substantial reductions in greenhouse gas emissions during the use phase, which typically constitutes over 80% of a turbine engine's environmental impact.

Nickel alloys, while more energy-efficient to produce initially, contain various elements like chromium and cobalt that present environmental concerns during mining and processing. These elements can lead to soil and water contamination if not properly managed. Additionally, some nickel mining operations have been associated with deforestation and habitat destruction in biodiversity-rich regions, particularly in countries with less stringent environmental regulations.

Recyclability represents another important sustainability consideration. Titanium alloys maintain excellent recyclability rates of up to 95% with minimal property degradation, creating a viable circular economy pathway. Nickel-based superalloys, while also recyclable, often face challenges in separating alloying elements during the recycling process, resulting in downcycling rather than true recycling in many cases.

End-of-life toxicity profiles differ significantly between these materials. Titanium is biologically inert and poses minimal environmental hazards when disposed of. Conversely, nickel compounds can be carcinogenic and may leach into groundwater from improperly managed waste sites, creating long-term environmental liabilities.

Recent advancements in manufacturing technologies, particularly additive manufacturing, have improved the sustainability profile of both materials by reducing waste during production. For titanium components, powder bed fusion techniques can reduce material waste by up to 90% compared to traditional subtractive manufacturing methods, while similar improvements are being realized for nickel alloy components.

As environmental regulations tighten globally, manufacturers are increasingly required to consider the full lifecycle environmental impact of material choices. This has prompted research into hybrid material solutions and surface treatments that optimize the environmental benefits of both titanium and nickel alloys while minimizing their respective drawbacks.

Cost-Benefit Analysis of Material Selection

When evaluating turbine engine materials, particularly titanium versus nickel alloys, a comprehensive cost-benefit analysis reveals significant economic implications across the entire product lifecycle. Initial material costs show that titanium alloys typically command a 30-45% price premium over nickel-based superalloys per unit weight. However, titanium's lower density (approximately 4.5 g/cm³ compared to nickel's 8.9 g/cm³) means that components can be manufactured with less material by volume, partially offsetting the higher per-unit cost.

Manufacturing expenses present another critical dimension. Titanium alloys require specialized processing techniques due to their reactivity with oxygen at elevated temperatures, necessitating vacuum or inert atmosphere processing that increases production costs by 20-25%. Nickel alloys, while also requiring precision manufacturing, generally have more established and economical processing routes, resulting in 15-20% lower fabrication costs compared to titanium components of similar complexity.

Operational economics strongly favor titanium in specific applications. The superior strength-to-weight ratio of titanium alloys contributes to fuel efficiency improvements of 2-3% in aircraft engines, translating to millions in operational savings over an aircraft's service life. Conversely, nickel alloys demonstrate superior performance in the hottest sections of turbines where temperatures exceed 600°C, enabling higher operating temperatures and consequently greater thermodynamic efficiency.

Maintenance economics reveal that titanium components typically exhibit excellent corrosion resistance, reducing replacement frequency by approximately 30% compared to some nickel alloys in corrosive environments. However, nickel-based superalloys generally demonstrate superior creep resistance at elevated temperatures, extending service intervals in high-temperature applications by up to 25%.

Lifecycle cost modeling indicates that despite higher initial investment, titanium components may offer 15-20% lower total ownership costs in applications where weight reduction and corrosion resistance are paramount. Conversely, nickel alloys provide 10-15% better economic value in high-temperature applications where thermal stability and creep resistance are critical performance factors.

Environmental considerations also factor into the economic equation. Titanium production is energy-intensive, requiring approximately 50% more energy per kilogram than nickel alloy production, though this is partially offset by titanium's longer service life and recyclability. Recent market volatility has seen titanium prices fluctuate by up to 35% over five-year periods, while nickel has experienced even greater price variations of up to 50%, introducing significant risk factors into long-term procurement strategies.

Manufacturing expenses present another critical dimension. Titanium alloys require specialized processing techniques due to their reactivity with oxygen at elevated temperatures, necessitating vacuum or inert atmosphere processing that increases production costs by 20-25%. Nickel alloys, while also requiring precision manufacturing, generally have more established and economical processing routes, resulting in 15-20% lower fabrication costs compared to titanium components of similar complexity.

Operational economics strongly favor titanium in specific applications. The superior strength-to-weight ratio of titanium alloys contributes to fuel efficiency improvements of 2-3% in aircraft engines, translating to millions in operational savings over an aircraft's service life. Conversely, nickel alloys demonstrate superior performance in the hottest sections of turbines where temperatures exceed 600°C, enabling higher operating temperatures and consequently greater thermodynamic efficiency.

Maintenance economics reveal that titanium components typically exhibit excellent corrosion resistance, reducing replacement frequency by approximately 30% compared to some nickel alloys in corrosive environments. However, nickel-based superalloys generally demonstrate superior creep resistance at elevated temperatures, extending service intervals in high-temperature applications by up to 25%.

Lifecycle cost modeling indicates that despite higher initial investment, titanium components may offer 15-20% lower total ownership costs in applications where weight reduction and corrosion resistance are paramount. Conversely, nickel alloys provide 10-15% better economic value in high-temperature applications where thermal stability and creep resistance are critical performance factors.

Environmental considerations also factor into the economic equation. Titanium production is energy-intensive, requiring approximately 50% more energy per kilogram than nickel alloy production, though this is partially offset by titanium's longer service life and recyclability. Recent market volatility has seen titanium prices fluctuate by up to 35% over five-year periods, while nickel has experienced even greater price variations of up to 50%, introducing significant risk factors into long-term procurement strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!