Innovations in Turbine Engine Fuel Injection Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Fuel Injection Evolution and Objectives

Turbine engine fuel injection systems have undergone significant evolution since the advent of jet propulsion in the 1940s. Initially, these systems employed rudimentary pressure atomizers that provided limited control over fuel distribution and atomization quality. The 1950s marked the introduction of air-blast atomizers, which leveraged high-velocity air streams to enhance fuel atomization, resulting in improved combustion efficiency and reduced emissions.

The 1970s and 1980s witnessed a paradigm shift with the development of electronic fuel control systems, enabling more precise metering and timing of fuel delivery. This technological advancement coincided with growing concerns about fuel efficiency and environmental impact, driving research toward more sophisticated injection methodologies.

By the 1990s, computational fluid dynamics (CFD) modeling became instrumental in optimizing fuel spray patterns and combustion chamber designs. This computational approach facilitated the development of multi-point injection systems that could adapt to varying engine operating conditions, significantly enhancing performance across flight envelopes.

The early 2000s saw the emergence of lean-burn combustion technologies, necessitating advanced fuel staging capabilities. These systems required precise control over fuel-air mixtures to maintain stable combustion while minimizing NOx formation. Concurrently, materials science advancements enabled the creation of more durable injector components capable of withstanding increasingly harsh operating environments.

Current technological trajectories point toward several key objectives in fuel injection system development. Primary among these is the pursuit of ultra-low emission combustion, requiring unprecedented levels of atomization quality and mixture homogeneity. This goal aligns with global regulatory pressures to reduce aviation's environmental footprint.

Another critical objective is enhancing fuel flexibility to accommodate sustainable alternative fuels, including biofuels and synthetic fuels with varying physical and chemical properties. This adaptability requires injection systems capable of maintaining optimal performance across diverse fuel compositions.

Operational efficiency remains paramount, with research focused on reducing system weight while improving reliability and maintenance intervals. Advanced manufacturing techniques, including additive manufacturing, are enabling more complex injector geometries that were previously impossible to produce.

The integration of real-time adaptive control systems represents perhaps the most ambitious objective, wherein injection parameters continuously adjust based on sensor feedback and predictive algorithms. Such systems promise to optimize combustion across all flight regimes, from idle to maximum thrust, while accommodating variations in ambient conditions and fuel properties.

The 1970s and 1980s witnessed a paradigm shift with the development of electronic fuel control systems, enabling more precise metering and timing of fuel delivery. This technological advancement coincided with growing concerns about fuel efficiency and environmental impact, driving research toward more sophisticated injection methodologies.

By the 1990s, computational fluid dynamics (CFD) modeling became instrumental in optimizing fuel spray patterns and combustion chamber designs. This computational approach facilitated the development of multi-point injection systems that could adapt to varying engine operating conditions, significantly enhancing performance across flight envelopes.

The early 2000s saw the emergence of lean-burn combustion technologies, necessitating advanced fuel staging capabilities. These systems required precise control over fuel-air mixtures to maintain stable combustion while minimizing NOx formation. Concurrently, materials science advancements enabled the creation of more durable injector components capable of withstanding increasingly harsh operating environments.

Current technological trajectories point toward several key objectives in fuel injection system development. Primary among these is the pursuit of ultra-low emission combustion, requiring unprecedented levels of atomization quality and mixture homogeneity. This goal aligns with global regulatory pressures to reduce aviation's environmental footprint.

Another critical objective is enhancing fuel flexibility to accommodate sustainable alternative fuels, including biofuels and synthetic fuels with varying physical and chemical properties. This adaptability requires injection systems capable of maintaining optimal performance across diverse fuel compositions.

Operational efficiency remains paramount, with research focused on reducing system weight while improving reliability and maintenance intervals. Advanced manufacturing techniques, including additive manufacturing, are enabling more complex injector geometries that were previously impossible to produce.

The integration of real-time adaptive control systems represents perhaps the most ambitious objective, wherein injection parameters continuously adjust based on sensor feedback and predictive algorithms. Such systems promise to optimize combustion across all flight regimes, from idle to maximum thrust, while accommodating variations in ambient conditions and fuel properties.

Market Demand Analysis for Advanced Fuel Injection Systems

The global market for advanced fuel injection systems in turbine engines is experiencing robust growth, driven primarily by the aviation and power generation sectors. Current market analysis indicates that the demand for more efficient, reliable, and environmentally friendly fuel injection systems continues to rise as industries face stricter emission regulations and cost pressures. The commercial aviation segment represents the largest market share, with military aviation and industrial gas turbines following closely behind.

Fuel efficiency remains a paramount concern across all sectors utilizing turbine engines. Airlines are particularly sensitive to fuel costs, which typically constitute 20-30% of their operating expenses. This economic pressure has created a strong market pull for injection systems that can deliver even marginal improvements in fuel consumption. Each percentage point of efficiency gain translates to significant operational savings over an engine's service life.

Environmental regulations have emerged as another major market driver. The International Civil Aviation Organization (ICAO) has established increasingly stringent standards for NOx, CO, and particulate matter emissions. Similarly, power generation facilities face tightening regulations from environmental protection agencies worldwide. These regulatory frameworks have accelerated demand for injection systems capable of more precise fuel atomization and distribution, which directly impacts combustion efficiency and emissions profiles.

The market is also witnessing a shift toward fuel-flexible injection systems. As alternative fuels including sustainable aviation fuels (SAFs), hydrogen, and various biofuels gain traction, operators require injection systems that can accommodate varying fuel properties without performance degradation. This adaptability requirement represents a growing market segment with significant future potential.

Maintenance considerations form another dimension of market demand. The total cost of ownership has become increasingly important to operators, creating market opportunities for injection systems with extended service intervals, improved reliability, and simplified maintenance procedures. Systems offering real-time monitoring capabilities and predictive maintenance features command premium pricing in the market.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced fuel injection technologies, primarily due to stricter environmental regulations and higher labor costs that incentivize efficiency improvements. However, the Asia-Pacific region is projected to show the highest growth rate, driven by expanding aviation markets in China and India, along with significant investments in power generation infrastructure.

The aftermarket segment for replacement and upgrade of existing fuel injection systems represents a substantial portion of the overall market value. As fleet operators seek to extend the service life of existing turbine engines while improving their performance characteristics, retrofit solutions have gained significant market traction.

Fuel efficiency remains a paramount concern across all sectors utilizing turbine engines. Airlines are particularly sensitive to fuel costs, which typically constitute 20-30% of their operating expenses. This economic pressure has created a strong market pull for injection systems that can deliver even marginal improvements in fuel consumption. Each percentage point of efficiency gain translates to significant operational savings over an engine's service life.

Environmental regulations have emerged as another major market driver. The International Civil Aviation Organization (ICAO) has established increasingly stringent standards for NOx, CO, and particulate matter emissions. Similarly, power generation facilities face tightening regulations from environmental protection agencies worldwide. These regulatory frameworks have accelerated demand for injection systems capable of more precise fuel atomization and distribution, which directly impacts combustion efficiency and emissions profiles.

The market is also witnessing a shift toward fuel-flexible injection systems. As alternative fuels including sustainable aviation fuels (SAFs), hydrogen, and various biofuels gain traction, operators require injection systems that can accommodate varying fuel properties without performance degradation. This adaptability requirement represents a growing market segment with significant future potential.

Maintenance considerations form another dimension of market demand. The total cost of ownership has become increasingly important to operators, creating market opportunities for injection systems with extended service intervals, improved reliability, and simplified maintenance procedures. Systems offering real-time monitoring capabilities and predictive maintenance features command premium pricing in the market.

Regional analysis reveals that North America and Europe currently lead in adoption of advanced fuel injection technologies, primarily due to stricter environmental regulations and higher labor costs that incentivize efficiency improvements. However, the Asia-Pacific region is projected to show the highest growth rate, driven by expanding aviation markets in China and India, along with significant investments in power generation infrastructure.

The aftermarket segment for replacement and upgrade of existing fuel injection systems represents a substantial portion of the overall market value. As fleet operators seek to extend the service life of existing turbine engines while improving their performance characteristics, retrofit solutions have gained significant market traction.

Current Technological Landscape and Challenges

The global landscape of turbine engine fuel injection systems has evolved significantly over the past decade, with major advancements in precision engineering, materials science, and computational fluid dynamics. Currently, the industry employs several predominant technologies including pressure atomizers, air blast atomizers, and more recently, direct injection systems. These technologies have reached considerable maturity in conventional applications but face increasing demands for performance in extreme operating conditions.

A significant challenge facing modern fuel injection systems is the need to simultaneously optimize for multiple competing objectives: fuel efficiency, emissions reduction, operational stability across diverse flight envelopes, and durability under extreme thermal conditions. The industry's push toward sustainable aviation fuels (SAFs) introduces additional complexity, as these alternative fuels often exhibit different viscosity, energy density, and atomization characteristics compared to conventional jet fuels.

Geographically, technological development in this field demonstrates distinct regional specialization. North American companies lead in military and high-performance applications, European entities focus on emissions reduction and environmental compliance, while emerging Asian manufacturers increasingly compete on cost-effectiveness and production scalability. This distribution creates both competitive tension and opportunities for cross-regional technology transfer.

Material limitations represent another critical constraint, particularly for components exposed to extreme temperatures exceeding 1600°C in modern high-performance engines. Advanced ceramic matrix composites and thermal barrier coatings show promise but remain costly to implement at scale. Additionally, miniaturization of injection components while maintaining performance creates significant manufacturing challenges, especially for precision features measuring less than 100 microns.

The integration of digital technologies presents both opportunities and challenges. While computational modeling has dramatically improved design capabilities, the validation of these models under actual operating conditions remains difficult. Similarly, the implementation of real-time monitoring and adaptive control systems is constrained by the harsh operating environment within turbine engines.

Regulatory pressures continue to intensify, with increasingly stringent emissions standards driving innovation but also creating compliance challenges. The International Civil Aviation Organization's environmental protection standards have established aggressive targets for NOx and particulate matter reduction, directly impacting fuel injection system requirements and design parameters.

The industry also faces workforce challenges, with specialized knowledge in advanced fuel injection systems concentrated in an aging demographic of engineers. Knowledge transfer and training of new specialists represent a non-technical but nonetheless critical challenge to continued innovation in this field.

A significant challenge facing modern fuel injection systems is the need to simultaneously optimize for multiple competing objectives: fuel efficiency, emissions reduction, operational stability across diverse flight envelopes, and durability under extreme thermal conditions. The industry's push toward sustainable aviation fuels (SAFs) introduces additional complexity, as these alternative fuels often exhibit different viscosity, energy density, and atomization characteristics compared to conventional jet fuels.

Geographically, technological development in this field demonstrates distinct regional specialization. North American companies lead in military and high-performance applications, European entities focus on emissions reduction and environmental compliance, while emerging Asian manufacturers increasingly compete on cost-effectiveness and production scalability. This distribution creates both competitive tension and opportunities for cross-regional technology transfer.

Material limitations represent another critical constraint, particularly for components exposed to extreme temperatures exceeding 1600°C in modern high-performance engines. Advanced ceramic matrix composites and thermal barrier coatings show promise but remain costly to implement at scale. Additionally, miniaturization of injection components while maintaining performance creates significant manufacturing challenges, especially for precision features measuring less than 100 microns.

The integration of digital technologies presents both opportunities and challenges. While computational modeling has dramatically improved design capabilities, the validation of these models under actual operating conditions remains difficult. Similarly, the implementation of real-time monitoring and adaptive control systems is constrained by the harsh operating environment within turbine engines.

Regulatory pressures continue to intensify, with increasingly stringent emissions standards driving innovation but also creating compliance challenges. The International Civil Aviation Organization's environmental protection standards have established aggressive targets for NOx and particulate matter reduction, directly impacting fuel injection system requirements and design parameters.

The industry also faces workforce challenges, with specialized knowledge in advanced fuel injection systems concentrated in an aging demographic of engineers. Knowledge transfer and training of new specialists represent a non-technical but nonetheless critical challenge to continued innovation in this field.

Contemporary Fuel Injection Solutions

01 Fuel injection nozzle designs for turbine engines

Various designs of fuel injection nozzles are used in turbine engines to optimize fuel atomization and distribution. These designs include specialized nozzle geometries, spray patterns, and atomization techniques that enhance combustion efficiency and reduce emissions. Advanced nozzle designs can provide better fuel-air mixing, more uniform temperature distribution, and improved combustion stability across different operating conditions.- Fuel injection system design for improved combustion efficiency: Advanced fuel injection systems in turbine engines are designed to optimize fuel atomization and distribution, leading to more efficient combustion. These systems incorporate precise nozzle geometries and spray patterns that ensure proper fuel-air mixing. By controlling the fuel droplet size and distribution, these injection systems can significantly improve combustion efficiency, reduce emissions, and enhance overall engine performance.

- Multi-stage fuel injection technologies: Multi-stage fuel injection systems allow for sequential or staged fuel delivery at different points in the combustion cycle. These systems can adapt to varying engine loads and operating conditions by controlling the timing, quantity, and location of fuel injection. This approach enables more precise combustion control, improved thermal management, and reduced emissions, particularly during transient operations such as startup, acceleration, and power changes.

- Low-emission fuel injection configurations: Specialized fuel injection configurations are designed specifically to reduce harmful emissions from turbine engines. These systems often feature lean premixed combustion techniques, where fuel is thoroughly mixed with air before ignition to minimize hot spots and reduce NOx formation. Some designs incorporate water or steam injection alongside fuel to lower combustion temperatures and further reduce emissions, while maintaining power output and efficiency.

- High-pressure fuel injection systems: High-pressure fuel injection systems deliver fuel at elevated pressures to improve atomization and mixing with combustion air. These systems typically employ robust pumps, precision-engineered injectors, and reinforced fuel lines capable of withstanding extreme pressures. The higher injection pressures result in finer fuel droplets, more complete combustion, improved fuel efficiency, and reduced particulate emissions across various operating conditions.

- Electronic control systems for fuel injection: Modern turbine engine fuel injection systems incorporate sophisticated electronic control systems that continuously adjust fuel delivery based on real-time operating parameters. These systems use sensors to monitor engine conditions such as temperature, pressure, speed, and load, then precisely meter fuel flow accordingly. Advanced control algorithms can optimize fuel-air ratios throughout different operating regimes, enabling adaptive performance, improved fuel economy, and enhanced reliability while maintaining strict emissions compliance.

02 Dual fuel injection systems for gas turbines

Dual fuel injection systems allow turbine engines to operate on different types of fuels, such as liquid fuel and natural gas. These systems incorporate separate injection pathways and control mechanisms for each fuel type, enabling seamless switching between fuels based on availability or operational requirements. The design includes specialized valving, metering systems, and combustion chamber configurations to accommodate the different combustion characteristics of various fuels.Expand Specific Solutions03 Electronic control systems for fuel injection

Advanced electronic control systems are used to precisely manage fuel injection in turbine engines. These systems utilize sensors, actuators, and digital controllers to adjust fuel flow rates, timing, and distribution based on operating conditions. Electronic control enables adaptive fuel management strategies that optimize performance, efficiency, and emissions across various flight regimes, ambient conditions, and power settings.Expand Specific Solutions04 Low emission fuel injection technologies

Specialized fuel injection technologies are developed to reduce emissions from turbine engines. These include staged combustion systems, lean premixed prevaporized (LPP) injection, and rich-quench-lean (RQL) combustion strategies. The injection systems are designed to control flame temperature, residence time, and fuel-air mixing to minimize the formation of pollutants such as nitrogen oxides (NOx), carbon monoxide, and unburned hydrocarbons.Expand Specific Solutions05 High-pressure fuel injection systems

High-pressure fuel injection systems are employed in modern turbine engines to improve atomization and combustion efficiency. These systems utilize advanced pumps, pressure regulators, and reinforced delivery components to inject fuel at elevated pressures. The higher injection pressures result in finer fuel droplets, more rapid vaporization, and better mixing with combustion air, leading to more complete combustion, improved thermal efficiency, and reduced specific fuel consumption.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The turbine engine fuel injection systems market is in a growth phase, characterized by increasing demand for more efficient and environmentally friendly propulsion technologies. The market is projected to expand significantly due to rising aviation traffic, stringent emission regulations, and the push for fuel efficiency. Leading players include established aerospace giants like General Electric Technology, Rolls-Royce, Pratt & Whitney Canada, and Safran Aircraft Engines, who possess advanced technological capabilities in high-precision fuel delivery systems. Automotive powerhouses such as Robert Bosch, DENSO, and Woodward are leveraging their expertise in precision injection to enter this space. The technology is approaching maturity in conventional applications but continues to evolve rapidly for alternative fuels and advanced combustion techniques, with companies like Solar Turbines and Ansaldo Energia driving innovations in industrial gas turbine applications.

General Electric Technology GmbH

Technical Solution: GE has pioneered the Twin Annular Pre-mixing Swirler (TAPS) fuel injection system for turbine engines, representing a significant advancement in combustion technology. This system features a main mixer for high-power operation and a pilot mixer for low-power stability, allowing for optimized performance across all flight regimes. GE's latest TAPS III iteration incorporates advanced ceramic matrix composite (CMC) materials that can withstand temperatures up to 2400°F, significantly higher than traditional metal alloys. The system utilizes sophisticated computational fluid dynamics to optimize fuel-air mixing, resulting in more complete combustion and lower emissions. GE has also integrated additive manufacturing techniques to create complex internal geometries that enhance fuel atomization and distribution. Their fuel nozzles contain up to 20 parts fewer than conventional designs, reducing potential failure points while improving reliability. Testing has shown TAPS technology achieves approximately 40% lower NOx emissions compared to conventional combustors while maintaining high combustion efficiency.

Strengths: Exceptional durability with CMC materials; simplified design with fewer components improves reliability; superior emissions performance across wide operating range; excellent fuel atomization characteristics. Weaknesses: Higher initial manufacturing costs; requires specialized maintenance expertise; complex control systems add weight to the overall engine package.

SNECMA SA

Technical Solution: SNECMA (now part of Safran Aircraft Engines) has developed the LEAP (Leading Edge Aviation Propulsion) fuel injection system for turbine engines, representing a significant technological advancement. Their system utilizes a multipoint fuel injection architecture that precisely distributes fuel across the combustion chamber for optimal mixing and combustion efficiency. A key innovation is their implementation of piloted airblast atomizers that use high-velocity air streams to create exceptionally fine fuel droplets, enhancing vaporization and reducing emissions. SNECMA's fuel injectors incorporate advanced cooling techniques, including effusion cooling with thousands of laser-drilled microscopic holes that create a protective air film around critical components. Their system features staged combustion with multiple injection zones that activate based on power requirements, optimizing the combustion process across all operating conditions. The company has pioneered the use of ceramic matrix composites in fuel injector components, allowing operation at temperatures exceeding 2200°F while reducing weight. Testing has demonstrated that their technology achieves approximately 50% lower NOx emissions compared to previous generation engines while improving fuel efficiency by up to 15%.

Strengths: Industry-leading emissions reduction performance; excellent fuel atomization characteristics; superior durability with advanced materials; significant weight reduction compared to conventional systems. Weaknesses: Higher manufacturing complexity increases production costs; requires sophisticated electronic control systems; more complex maintenance procedures compared to conventional systems.

Key Patents and Technical Breakthroughs

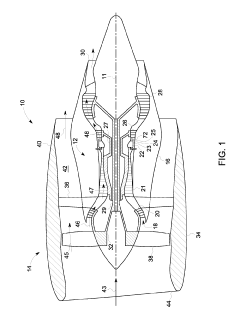

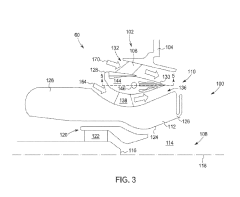

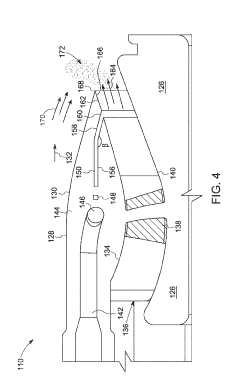

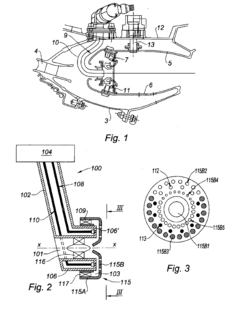

Turbine engine fuel injection system and methods of assembling the same

PatentActiveUS10352570B2

Innovation

- A fuel injection system featuring a fuel nozzle assembly with a substantially annular main fuel injector, a swirl chamber, and circumferentially-spaced fuel metering slots that impart swirl to the fuel, forming a thin sheet which interacts with air flows to achieve radial and circumferential uniformity of the fuel-air mixture.

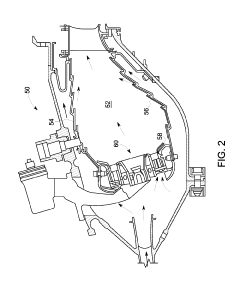

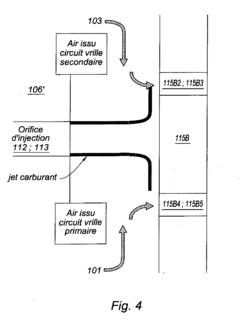

Fuel injector for the combustion chamber of a gas turbine engine

PatentActiveEP1909031A1

Innovation

- A fuel injector with staged combustion capabilities, featuring a first fuel supply conduit for idle operation and a second main fuel supply conduit for full throttle, with injection orifices arranged in a ring configuration, ensuring efficient premixing of fuel and air through a central primary air channel and annular secondary air supply, promoting efficient flame propagation and reduced pollutant formation.

Emissions Regulations Impact on Design

Environmental regulations have become a primary driver for innovation in turbine engine fuel injection systems over the past two decades. The International Civil Aviation Organization (ICAO) has progressively tightened emissions standards through its Committee on Aviation Environmental Protection (CAEP), with each new standard (CAEP/6, CAEP/8, and most recently CAEP/11) requiring significant reductions in nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter.

These increasingly stringent regulations have fundamentally altered the design philosophy of fuel injection systems. Traditional designs prioritized performance and reliability, whereas modern systems must balance these requirements with emissions reduction capabilities. This has led to the development of lean-burn combustion technologies, which operate at lower flame temperatures to reduce NOx formation but require more sophisticated fuel atomization and distribution.

The European Union's Clean Sky initiative and the FAA's Continuous Lower Energy, Emissions and Noise (CLEEN) program have further accelerated innovation by providing funding frameworks specifically targeting emissions reduction technologies. These programs have resulted in rapid advancement of staged injection systems that can optimize fuel delivery across different operating conditions.

Regional variations in emissions regulations have created additional design challenges. For instance, airport-specific emissions charges in Europe have prompted manufacturers to develop injection systems with specialized low-emission ground idle modes, while maintaining high-altitude cruise efficiency. This has driven the adoption of multi-point injection architectures capable of dynamically adjusting spray patterns based on flight phase.

Material selection for injector components has also evolved in response to regulatory pressures. Traditional nickel-based alloys are increasingly being replaced with advanced ceramics and ceramic matrix composites that can withstand higher temperatures while enabling more precise fuel metering and atomization. These materials support leaner combustion while maintaining durability requirements.

The timeline for implementing new emissions standards has compressed significantly, with compliance deadlines shortening from 8-10 years to 5-6 years between announcement and enforcement. This acceleration has prompted fuel system designers to adopt more agile development methodologies and increased use of computational fluid dynamics (CFD) simulation to rapidly iterate designs before physical prototyping.

Looking forward, upcoming regulations targeting non-volatile particulate matter (nvPM) emissions will likely drive further refinements in atomization technology, with increased focus on droplet size distribution and mixing efficiency to minimize soot formation during combustion processes.

These increasingly stringent regulations have fundamentally altered the design philosophy of fuel injection systems. Traditional designs prioritized performance and reliability, whereas modern systems must balance these requirements with emissions reduction capabilities. This has led to the development of lean-burn combustion technologies, which operate at lower flame temperatures to reduce NOx formation but require more sophisticated fuel atomization and distribution.

The European Union's Clean Sky initiative and the FAA's Continuous Lower Energy, Emissions and Noise (CLEEN) program have further accelerated innovation by providing funding frameworks specifically targeting emissions reduction technologies. These programs have resulted in rapid advancement of staged injection systems that can optimize fuel delivery across different operating conditions.

Regional variations in emissions regulations have created additional design challenges. For instance, airport-specific emissions charges in Europe have prompted manufacturers to develop injection systems with specialized low-emission ground idle modes, while maintaining high-altitude cruise efficiency. This has driven the adoption of multi-point injection architectures capable of dynamically adjusting spray patterns based on flight phase.

Material selection for injector components has also evolved in response to regulatory pressures. Traditional nickel-based alloys are increasingly being replaced with advanced ceramics and ceramic matrix composites that can withstand higher temperatures while enabling more precise fuel metering and atomization. These materials support leaner combustion while maintaining durability requirements.

The timeline for implementing new emissions standards has compressed significantly, with compliance deadlines shortening from 8-10 years to 5-6 years between announcement and enforcement. This acceleration has prompted fuel system designers to adopt more agile development methodologies and increased use of computational fluid dynamics (CFD) simulation to rapidly iterate designs before physical prototyping.

Looking forward, upcoming regulations targeting non-volatile particulate matter (nvPM) emissions will likely drive further refinements in atomization technology, with increased focus on droplet size distribution and mixing efficiency to minimize soot formation during combustion processes.

Materials Science Advancements for Injection Components

The evolution of materials science has fundamentally transformed turbine engine fuel injection systems, with recent advancements focusing on enhancing durability, thermal resistance, and precision manufacturing capabilities. Traditional nickel-based superalloys are increasingly being supplemented or replaced by ceramic matrix composites (CMCs) and ceramic thermal barrier coatings, which offer superior heat resistance up to 1400°C while maintaining structural integrity under extreme operating conditions.

Additive manufacturing techniques have revolutionized the production of injection components, enabling the creation of complex geometries previously impossible with conventional manufacturing methods. These techniques allow for optimized fuel flow paths, reduced weight, and integrated cooling channels that significantly enhance injection efficiency while minimizing carbon deposits and coking issues.

Surface engineering innovations have yielded remarkable improvements in wear resistance and anti-fouling properties. Advanced coatings such as diamond-like carbon (DLC) films and nanostructured ceramic coatings provide exceptional hardness and low friction coefficients, extending component lifespan by up to 300% in high-temperature, high-pressure environments. These coatings also demonstrate superior resistance to fuel contaminants and combustion byproducts.

Smart materials represent the cutting edge of injection system development, with shape memory alloys (SMAs) and piezoelectric materials enabling adaptive injection behavior. These materials can respond to changing engine conditions in real-time, altering nozzle geometries and spray patterns to optimize combustion across different power settings and environmental conditions.

Nanomaterial integration has emerged as a promising frontier, with research showing that nanoparticle-reinforced metals exhibit enhanced mechanical properties and thermal stability. Carbon nanotubes and graphene-reinforced components demonstrate up to 40% improvement in thermal conductivity, facilitating more efficient heat management in critical injection components.

Corrosion-resistant alloys specifically engineered for alternative and sustainable aviation fuels are addressing compatibility challenges with biofuels and hydrogen. These specialized materials maintain structural integrity and performance when exposed to the unique chemical properties of next-generation fuels, which often present different corrosion mechanisms compared to conventional jet fuels.

The miniaturization trend in injection systems has driven development of micro-manufacturing techniques capable of producing precision components at increasingly smaller scales. Advanced electron beam machining and laser processing enable the fabrication of micro-orifices with tolerances measured in micrometers, critical for achieving the atomization quality required in modern high-efficiency combustion systems.

Additive manufacturing techniques have revolutionized the production of injection components, enabling the creation of complex geometries previously impossible with conventional manufacturing methods. These techniques allow for optimized fuel flow paths, reduced weight, and integrated cooling channels that significantly enhance injection efficiency while minimizing carbon deposits and coking issues.

Surface engineering innovations have yielded remarkable improvements in wear resistance and anti-fouling properties. Advanced coatings such as diamond-like carbon (DLC) films and nanostructured ceramic coatings provide exceptional hardness and low friction coefficients, extending component lifespan by up to 300% in high-temperature, high-pressure environments. These coatings also demonstrate superior resistance to fuel contaminants and combustion byproducts.

Smart materials represent the cutting edge of injection system development, with shape memory alloys (SMAs) and piezoelectric materials enabling adaptive injection behavior. These materials can respond to changing engine conditions in real-time, altering nozzle geometries and spray patterns to optimize combustion across different power settings and environmental conditions.

Nanomaterial integration has emerged as a promising frontier, with research showing that nanoparticle-reinforced metals exhibit enhanced mechanical properties and thermal stability. Carbon nanotubes and graphene-reinforced components demonstrate up to 40% improvement in thermal conductivity, facilitating more efficient heat management in critical injection components.

Corrosion-resistant alloys specifically engineered for alternative and sustainable aviation fuels are addressing compatibility challenges with biofuels and hydrogen. These specialized materials maintain structural integrity and performance when exposed to the unique chemical properties of next-generation fuels, which often present different corrosion mechanisms compared to conventional jet fuels.

The miniaturization trend in injection systems has driven development of micro-manufacturing techniques capable of producing precision components at increasingly smaller scales. Advanced electron beam machining and laser processing enable the fabrication of micro-orifices with tolerances measured in micrometers, critical for achieving the atomization quality required in modern high-efficiency combustion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!