Noise Reduction Strategies for Turbine Engines

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Noise Reduction Background and Objectives

Turbine engine noise has been a persistent challenge in aviation and power generation since the advent of jet engines in the 1940s. The evolution of noise reduction technologies has closely followed the development of turbine engines themselves, with significant advancements occurring during the transition from first-generation turbojet engines to modern high-bypass turbofan designs. Early research focused primarily on operational performance rather than environmental impacts, but this paradigm shifted dramatically with the introduction of noise regulations in the 1960s and 1970s.

The technical trajectory of noise reduction strategies has progressed from rudimentary acoustic liners to sophisticated multi-dimensional approaches incorporating aerodynamic, material science, and computational fluid dynamics innovations. Historical data indicates that commercial aircraft noise levels have decreased by approximately 20 decibels over the past five decades, representing a 75% reduction in perceived noise. However, with increasing air traffic and power generation demands, absolute noise pollution continues to present significant challenges.

Current technical objectives in turbine engine noise reduction are multifaceted, addressing both aviation and industrial applications. Primary goals include achieving compliance with increasingly stringent regulatory frameworks such as ICAO Chapter 14 standards and European Union Directive 2002/49/EC, while maintaining or improving operational efficiency. Specific technical targets involve reducing fan noise, combustion noise, and jet noise components through innovative design modifications and material applications.

The emergence of computational aeroacoustics (CAA) has revolutionized the approach to noise prediction and mitigation, enabling more precise identification of noise sources and more effective targeted interventions. Advanced simulation capabilities now allow engineers to model complex noise generation mechanisms and evaluate potential solutions before physical prototyping, significantly accelerating the development cycle.

Looking forward, the industry aims to achieve an additional 10 dB noise reduction by 2030, which represents a significant technical challenge given the diminishing returns of conventional approaches. This ambitious target necessitates fundamental innovations in engine architecture, materials science, and active noise control systems. The ultimate objective extends beyond mere regulatory compliance to creating truly "neighbor-friendly" engines that minimize community impact while maximizing energy efficiency.

The convergence of environmental concerns, regulatory pressures, and technological capabilities has created a fertile environment for innovation in this field. As urban air mobility concepts and distributed energy systems gain traction, the importance of noise reduction strategies will only increase, driving further research and development investment across the aerospace and energy sectors.

The technical trajectory of noise reduction strategies has progressed from rudimentary acoustic liners to sophisticated multi-dimensional approaches incorporating aerodynamic, material science, and computational fluid dynamics innovations. Historical data indicates that commercial aircraft noise levels have decreased by approximately 20 decibels over the past five decades, representing a 75% reduction in perceived noise. However, with increasing air traffic and power generation demands, absolute noise pollution continues to present significant challenges.

Current technical objectives in turbine engine noise reduction are multifaceted, addressing both aviation and industrial applications. Primary goals include achieving compliance with increasingly stringent regulatory frameworks such as ICAO Chapter 14 standards and European Union Directive 2002/49/EC, while maintaining or improving operational efficiency. Specific technical targets involve reducing fan noise, combustion noise, and jet noise components through innovative design modifications and material applications.

The emergence of computational aeroacoustics (CAA) has revolutionized the approach to noise prediction and mitigation, enabling more precise identification of noise sources and more effective targeted interventions. Advanced simulation capabilities now allow engineers to model complex noise generation mechanisms and evaluate potential solutions before physical prototyping, significantly accelerating the development cycle.

Looking forward, the industry aims to achieve an additional 10 dB noise reduction by 2030, which represents a significant technical challenge given the diminishing returns of conventional approaches. This ambitious target necessitates fundamental innovations in engine architecture, materials science, and active noise control systems. The ultimate objective extends beyond mere regulatory compliance to creating truly "neighbor-friendly" engines that minimize community impact while maximizing energy efficiency.

The convergence of environmental concerns, regulatory pressures, and technological capabilities has created a fertile environment for innovation in this field. As urban air mobility concepts and distributed energy systems gain traction, the importance of noise reduction strategies will only increase, driving further research and development investment across the aerospace and energy sectors.

Market Demand Analysis for Quieter Turbine Technologies

The global market for quieter turbine technologies has experienced significant growth over the past decade, driven primarily by stringent noise regulations and increasing environmental awareness. According to industry reports, the market for noise reduction solutions in turbine engines reached approximately $3.2 billion in 2022, with a projected compound annual growth rate of 6.8% through 2030. This growth trajectory reflects the escalating demand for noise mitigation technologies across various sectors including aviation, power generation, and industrial applications.

Commercial aviation represents the largest market segment, accounting for nearly 45% of the total demand. Airlines face mounting pressure from both regulatory bodies and communities surrounding airports to reduce noise pollution. The International Civil Aviation Organization (ICAO) has progressively tightened noise certification standards through its Chapter 14 requirements, compelling aircraft and engine manufacturers to invest heavily in quieter turbine technologies.

Power generation constitutes the second-largest market segment, with particular emphasis on gas turbines used in urban and suburban settings. Utility companies increasingly prioritize noise reduction as a key parameter when commissioning new power plants or retrofitting existing facilities. This trend is especially pronounced in densely populated regions where noise complaints can lead to operational restrictions and financial penalties.

Market research indicates that end-users are willing to pay a premium of 15-20% for significantly quieter turbine technologies, particularly when these solutions also deliver secondary benefits such as improved fuel efficiency or reduced maintenance requirements. This price elasticity has created substantial opportunities for technology providers who can deliver integrated solutions addressing both noise reduction and operational performance.

Regional analysis reveals that North America and Europe currently dominate the market for quieter turbine technologies, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, expanding aviation sectors, and increasingly stringent environmental regulations in countries like China, Japan, and South Korea.

Customer surveys consistently highlight three primary drivers of market demand: regulatory compliance, corporate social responsibility initiatives, and operational benefits. While regulatory compliance remains the foremost driver, particularly in mature markets, the growing emphasis on environmental, social, and governance (ESG) factors has elevated noise reduction to a strategic priority for many organizations seeking to enhance their sustainability credentials.

The market landscape is further shaped by emerging trends such as urbanization, which brings residential areas closer to industrial and transportation hubs, thereby intensifying noise-related conflicts. This demographic shift has accelerated demand for retrofit solutions that can be applied to existing turbine installations, creating a substantial aftermarket opportunity estimated at $1.1 billion annually.

Commercial aviation represents the largest market segment, accounting for nearly 45% of the total demand. Airlines face mounting pressure from both regulatory bodies and communities surrounding airports to reduce noise pollution. The International Civil Aviation Organization (ICAO) has progressively tightened noise certification standards through its Chapter 14 requirements, compelling aircraft and engine manufacturers to invest heavily in quieter turbine technologies.

Power generation constitutes the second-largest market segment, with particular emphasis on gas turbines used in urban and suburban settings. Utility companies increasingly prioritize noise reduction as a key parameter when commissioning new power plants or retrofitting existing facilities. This trend is especially pronounced in densely populated regions where noise complaints can lead to operational restrictions and financial penalties.

Market research indicates that end-users are willing to pay a premium of 15-20% for significantly quieter turbine technologies, particularly when these solutions also deliver secondary benefits such as improved fuel efficiency or reduced maintenance requirements. This price elasticity has created substantial opportunities for technology providers who can deliver integrated solutions addressing both noise reduction and operational performance.

Regional analysis reveals that North America and Europe currently dominate the market for quieter turbine technologies, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization, expanding aviation sectors, and increasingly stringent environmental regulations in countries like China, Japan, and South Korea.

Customer surveys consistently highlight three primary drivers of market demand: regulatory compliance, corporate social responsibility initiatives, and operational benefits. While regulatory compliance remains the foremost driver, particularly in mature markets, the growing emphasis on environmental, social, and governance (ESG) factors has elevated noise reduction to a strategic priority for many organizations seeking to enhance their sustainability credentials.

The market landscape is further shaped by emerging trends such as urbanization, which brings residential areas closer to industrial and transportation hubs, thereby intensifying noise-related conflicts. This demographic shift has accelerated demand for retrofit solutions that can be applied to existing turbine installations, creating a substantial aftermarket opportunity estimated at $1.1 billion annually.

Current Noise Reduction Technologies and Challenges

Current noise reduction technologies for turbine engines encompass a range of approaches targeting different noise sources. Acoustic liners remain the most widely implemented solution, featuring honeycomb structures with perforated facesheets that effectively absorb sound waves across specific frequency ranges. Advanced liner designs now incorporate variable-depth chambers and multi-degree-of-freedom configurations to address broader frequency spectra, particularly effective for fan and compressor noise attenuation.

Chevron nozzles represent another significant advancement, featuring serrated trailing edges that modify the shear layer between the exhaust jet and ambient air. These modifications reduce the turbulent mixing noise by creating smaller, less energetic vortices. Major engine manufacturers have reported noise reductions of 2-3 dB with minimal thrust penalties through optimized chevron designs.

Active noise control systems have progressed substantially, employing sensors, controllers, and actuators to generate anti-phase sound waves that cancel unwanted noise. While demonstrating promising results in laboratory settings with reductions of up to 6 dB in specific frequency bands, these systems face implementation challenges related to weight, complexity, and reliability in harsh operating environments.

Aerodynamic refinements to blade and vane designs have yielded notable improvements. Swept and leaned stator vanes reduce rotor-stator interaction noise by minimizing wake interactions. Similarly, optimized blade counts and spacing between rotors and stators have proven effective in minimizing tonal noise components.

Despite these advancements, significant challenges persist. High-temperature environments limit material selection for acoustic treatments in hot sections of engines. Weight constraints remain critical, as noise reduction technologies must not compromise fuel efficiency or payload capacity. Integration complexity presents another obstacle, as solutions must function within existing engine architectures without disrupting aerodynamic performance.

Regulatory pressures continue to intensify, with ICAO Chapter 14 standards requiring substantial noise reductions compared to previous requirements. Meeting these standards while simultaneously addressing emissions targets creates competing design priorities. Additionally, the industry faces a knowledge gap in understanding broadband noise generation mechanisms, particularly those associated with turbulence in high-speed flows.

Cost considerations further complicate implementation, as noise reduction technologies must demonstrate favorable cost-benefit ratios to gain industry adoption. The balance between noise reduction performance and economic viability remains a persistent challenge for engine manufacturers and operators alike.

Chevron nozzles represent another significant advancement, featuring serrated trailing edges that modify the shear layer between the exhaust jet and ambient air. These modifications reduce the turbulent mixing noise by creating smaller, less energetic vortices. Major engine manufacturers have reported noise reductions of 2-3 dB with minimal thrust penalties through optimized chevron designs.

Active noise control systems have progressed substantially, employing sensors, controllers, and actuators to generate anti-phase sound waves that cancel unwanted noise. While demonstrating promising results in laboratory settings with reductions of up to 6 dB in specific frequency bands, these systems face implementation challenges related to weight, complexity, and reliability in harsh operating environments.

Aerodynamic refinements to blade and vane designs have yielded notable improvements. Swept and leaned stator vanes reduce rotor-stator interaction noise by minimizing wake interactions. Similarly, optimized blade counts and spacing between rotors and stators have proven effective in minimizing tonal noise components.

Despite these advancements, significant challenges persist. High-temperature environments limit material selection for acoustic treatments in hot sections of engines. Weight constraints remain critical, as noise reduction technologies must not compromise fuel efficiency or payload capacity. Integration complexity presents another obstacle, as solutions must function within existing engine architectures without disrupting aerodynamic performance.

Regulatory pressures continue to intensify, with ICAO Chapter 14 standards requiring substantial noise reductions compared to previous requirements. Meeting these standards while simultaneously addressing emissions targets creates competing design priorities. Additionally, the industry faces a knowledge gap in understanding broadband noise generation mechanisms, particularly those associated with turbulence in high-speed flows.

Cost considerations further complicate implementation, as noise reduction technologies must demonstrate favorable cost-benefit ratios to gain industry adoption. The balance between noise reduction performance and economic viability remains a persistent challenge for engine manufacturers and operators alike.

State-of-the-Art Noise Suppression Methodologies

01 Acoustic liners and sound absorption materials

Acoustic liners and sound absorption materials are used in turbine engines to reduce noise emissions. These materials are strategically placed in the engine nacelle, exhaust system, and other components to absorb sound waves generated during engine operation. The liners typically consist of honeycomb structures, porous materials, or resonant chambers that convert acoustic energy into heat through viscous and thermal losses. Advanced acoustic liners can be tuned to target specific frequency ranges that are most problematic in turbine engine noise.- Acoustic liners and sound absorption materials: Acoustic liners and sound absorption materials are used in turbine engines to reduce noise emissions. These materials are strategically placed in the engine nacelle, exhaust system, and other components to absorb sound waves generated during engine operation. The liners typically consist of honeycomb structures, porous materials, or resonant chambers that convert acoustic energy into heat through viscous and thermal losses. Advanced acoustic liners can be tuned to target specific frequency ranges that are most problematic in turbine engine noise.

- Exhaust system modifications for noise reduction: Modifications to the exhaust system of turbine engines can significantly reduce noise emissions. These modifications include the use of multi-lobe mixers, serrated nozzle edges, and chevron designs that enhance mixing between the hot exhaust gases and the surrounding air. By promoting more gradual mixing, these designs reduce the shear forces that generate noise. Additionally, variable geometry exhaust systems can be implemented to optimize noise reduction across different operating conditions while maintaining engine performance.

- Active noise control systems: Active noise control systems use electronic sensors, processors, and actuators to reduce turbine engine noise. These systems detect sound waves generated by the engine, process the signal, and generate anti-phase sound waves that cancel out the original noise. The technology can be applied to various components of the engine, including the intake, combustion chamber, and exhaust. Advanced systems incorporate adaptive algorithms that continuously adjust to changing engine conditions and noise characteristics for optimal noise cancellation.

- Aerodynamic design improvements: Aerodynamic design improvements focus on reducing noise generation at the source by optimizing the flow of air through the turbine engine. These improvements include redesigned fan blades with swept or leaned profiles, increased blade spacing, optimized stator vanes, and improved blade tip clearance control. By reducing flow separation, vortex formation, and turbulence, these design changes minimize the aerodynamic sources of noise while often simultaneously improving engine efficiency and performance.

- Combustion noise reduction techniques: Combustion noise reduction techniques address the noise generated by the fuel burning process in turbine engines. These techniques include staged combustion systems, fuel injection optimization, and combustion chamber redesigns that promote more uniform and stable burning. By controlling the combustion process to reduce pressure fluctuations and temperature gradients, these approaches minimize the acoustic energy generated during combustion. Advanced fuel nozzles and swirlers that improve fuel atomization and mixing also contribute to quieter combustion.

02 Exhaust system modifications

Modifications to the exhaust system of turbine engines can significantly reduce noise emissions. These modifications include the use of multi-lobed mixers, serrated nozzle edges, and chevron designs that enhance mixing between the hot exhaust gases and the surrounding air. By promoting more gradual mixing, these designs reduce the shear forces that generate noise. Additionally, variable geometry exhaust systems can be employed to optimize noise reduction across different operating conditions while maintaining engine performance.Expand Specific Solutions03 Active noise control systems

Active noise control systems use electronic sensors, processors, and actuators to reduce turbine engine noise. These systems detect sound waves generated by the engine, process this information, and generate anti-phase sound waves that cancel out the original noise. The technology can be applied to various components of the engine, including the intake, combustion chamber, and exhaust. Advanced systems incorporate adaptive algorithms that continuously adjust to changing engine conditions and noise characteristics for optimal noise reduction.Expand Specific Solutions04 Aerodynamic design improvements

Aerodynamic design improvements focus on reducing noise generation at the source by optimizing the flow of air through the turbine engine. These improvements include redesigned fan blades with swept or leaned profiles, increased blade-vane spacing, and optimized blade counts to reduce wake interactions. Advanced computational fluid dynamics is used to identify and mitigate noise-generating flow structures. By reducing turbulence and improving flow characteristics, these design enhancements minimize the aerodynamic noise produced during engine operation.Expand Specific Solutions05 Combustion noise reduction techniques

Combustion noise reduction techniques address the noise generated in the combustion chamber of turbine engines. These techniques include fuel staging, where fuel is introduced in multiple zones to control the combustion process, and the use of advanced fuel injectors that promote more uniform mixing of fuel and air. Acoustic dampers and resonators can be incorporated into the combustion chamber design to attenuate pressure oscillations. Additionally, lean-burn combustion technologies not only reduce emissions but also help minimize combustion-generated noise by creating more stable and controlled burning.Expand Specific Solutions

Leading Companies and Research Institutions in Engine Acoustics

The turbine engine noise reduction market is in a growth phase, characterized by increasing regulatory pressure and environmental concerns. The market size is expanding as aviation and power generation sectors prioritize quieter operations, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels across different applications. Industry leaders like Rolls-Royce, GE, Pratt & Whitney (RTX), and Safran Aircraft Engines are driving innovation through advanced acoustic liners, active noise control systems, and aerodynamic improvements. Airbus, Boeing, and MTU Aero Engines are also making substantial contributions, particularly in nacelle design and material science. The competitive landscape shows collaboration between OEMs and specialized technology providers, with increasing focus on integrated noise reduction solutions that maintain performance efficiency.

General Electric Company

Technical Solution: General Electric has developed advanced noise reduction strategies for turbine engines through their comprehensive acoustic treatment systems. Their technology incorporates multi-degree-of-freedom acoustic liners with optimized perforation patterns and cavity depths to target specific frequency ranges[1]. GE's latest turbofan engines feature chevron nozzles that create controlled mixing of exhaust gases, reducing jet noise by up to 4dB[2]. They've also pioneered active noise control systems that use sound waves to cancel out engine noise through phase opposition. GE's proprietary 3D-printed acoustic panels allow for complex geometries impossible with traditional manufacturing, enabling better sound absorption across broader frequency ranges[3]. Their integrated approach combines computational aeroacoustics modeling with experimental validation to identify and mitigate noise sources throughout the engine, from fan blades to combustion chambers and turbine sections.

Strengths: Industry-leading computational modeling capabilities allow for precise noise prediction and mitigation strategies. Their extensive testing facilities enable rapid prototyping and validation. Weaknesses: Higher implementation costs compared to traditional solutions, and some technologies add weight which can impact fuel efficiency.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a comprehensive noise reduction strategy for turbine engines centered around their "Silent Power" initiative. Their approach integrates advanced acoustic liners with variable geometry to adapt to different flight conditions and noise profiles. The company has pioneered swept and leaned fan blade designs that significantly reduce fan noise, one of the primary noise sources in modern turbofans[1]. Their proprietary low-noise combustor technology minimizes combustion noise through optimized fuel injection patterns and acoustic damping. Rolls-Royce has implemented serrated trailing edges on turbine blades, reducing turbulence-generated noise by up to 5dB without efficiency penalties[2]. Their engines feature advanced exhaust systems with mixer-ejector nozzles that enhance mixing of hot core and bypass flows, substantially reducing jet noise. The company also utilizes active noise control systems in nacelle designs, employing microphones and speakers to generate anti-noise signals that cancel out specific tonal components[3].

Strengths: Holistic approach addressing multiple noise sources simultaneously; strong integration with airframe manufacturers allowing for system-level optimization. Weaknesses: Some solutions add complexity to maintenance procedures; higher initial costs compared to conventional designs; potential weight penalties affecting overall aircraft efficiency.

Critical Patents and Research in Turbine Noise Attenuation

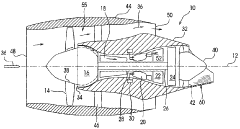

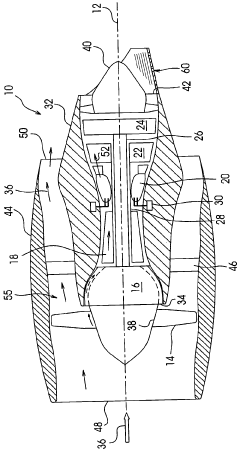

Exhaust flow guide for jet noise reduction

PatentInactiveCA2449469C

Innovation

- An exhaust flow guide made of curved sheet metal is attached to the engine exhaust end, forming a partial nozzle that asymmetrically guides the exhaust flow to change noise directivity and reduce jet noise power levels, applicable to both short and long cowl nacelle engines, enhancing mixing of exhaust gases with surrounding fluid flow.

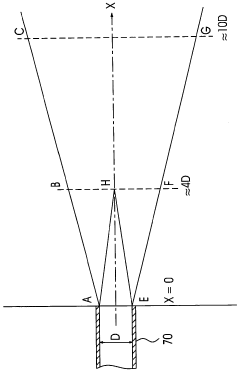

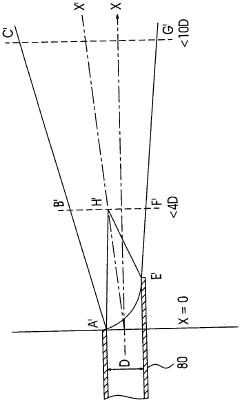

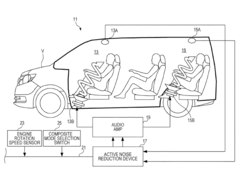

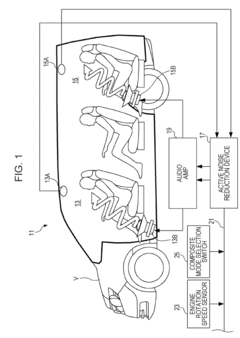

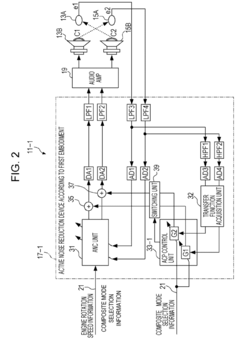

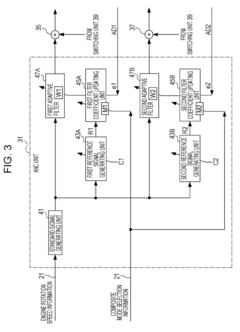

Active noise reduction system, and vehicular active noise reduction system

PatentActiveUS9595253B2

Innovation

- An active noise reduction system with dual sound collecting and output units, along with an active noise reduction device that generates composite audio signals to cancel noise, while using transfer function acquisition and correction units to stabilize control operations and prevent howling by setting appropriate gain coefficients and filter coefficients.

Environmental Regulations and Noise Compliance Standards

The global regulatory landscape for aircraft noise has evolved significantly over the past decades, with increasingly stringent standards being implemented to address growing environmental concerns. The International Civil Aviation Organization (ICAO) has established comprehensive noise certification standards through Annex 16, which defines specific noise limits for different aircraft categories. These standards, known as Chapters, have progressively tightened requirements, with the current Chapter 14 representing the most demanding noise reduction targets for new aircraft designs.

In the United States, the Federal Aviation Administration (FAA) has adopted these international standards through Federal Aviation Regulations (FAR) Part 36, which mandates specific noise certification requirements for all aircraft operating in U.S. airspace. Similarly, the European Union Aviation Safety Agency (EASA) enforces comparable regulations through CS-36, often implementing even more stringent requirements than their international counterparts.

Airport-specific noise regulations present additional compliance challenges for turbine engine manufacturers. Many major airports worldwide have implemented noise quotas, curfews, and surcharges for noisier aircraft, creating economic incentives for quieter engine technologies. Notable examples include London Heathrow's Quota Count system and Frankfurt Airport's night flight restrictions, which directly impact airline fleet decisions and consequently engine selection criteria.

The regulatory framework is further complicated by community noise exposure metrics such as Day-Night Average Sound Level (DNL) and Effective Perceived Noise Level (EPNL), which quantify human perception of aircraft noise rather than simple decibel measurements. These metrics drive noise abatement procedures and land use planning around airports, indirectly influencing engine design requirements.

Future regulatory trends indicate a continued tightening of noise standards. The ICAO's Committee on Aviation Environmental Protection (CAEP) is currently developing potential Chapter 15 standards, which may reduce permissible noise levels by an additional 3-5 dB compared to Chapter 14. This represents a significant technical challenge for engine manufacturers, as each 3 dB reduction effectively requires halving the perceived noise output.

Compliance with these evolving standards necessitates comprehensive noise reduction strategies throughout the engine design process. Manufacturers must now consider noise as a primary design parameter alongside traditional metrics like thrust, fuel efficiency, and emissions. This regulatory pressure has accelerated innovation in noise reduction technologies, including advanced acoustic liners, chevron nozzles, and variable cycle engines that can optimize performance for both noise and efficiency requirements.

In the United States, the Federal Aviation Administration (FAA) has adopted these international standards through Federal Aviation Regulations (FAR) Part 36, which mandates specific noise certification requirements for all aircraft operating in U.S. airspace. Similarly, the European Union Aviation Safety Agency (EASA) enforces comparable regulations through CS-36, often implementing even more stringent requirements than their international counterparts.

Airport-specific noise regulations present additional compliance challenges for turbine engine manufacturers. Many major airports worldwide have implemented noise quotas, curfews, and surcharges for noisier aircraft, creating economic incentives for quieter engine technologies. Notable examples include London Heathrow's Quota Count system and Frankfurt Airport's night flight restrictions, which directly impact airline fleet decisions and consequently engine selection criteria.

The regulatory framework is further complicated by community noise exposure metrics such as Day-Night Average Sound Level (DNL) and Effective Perceived Noise Level (EPNL), which quantify human perception of aircraft noise rather than simple decibel measurements. These metrics drive noise abatement procedures and land use planning around airports, indirectly influencing engine design requirements.

Future regulatory trends indicate a continued tightening of noise standards. The ICAO's Committee on Aviation Environmental Protection (CAEP) is currently developing potential Chapter 15 standards, which may reduce permissible noise levels by an additional 3-5 dB compared to Chapter 14. This represents a significant technical challenge for engine manufacturers, as each 3 dB reduction effectively requires halving the perceived noise output.

Compliance with these evolving standards necessitates comprehensive noise reduction strategies throughout the engine design process. Manufacturers must now consider noise as a primary design parameter alongside traditional metrics like thrust, fuel efficiency, and emissions. This regulatory pressure has accelerated innovation in noise reduction technologies, including advanced acoustic liners, chevron nozzles, and variable cycle engines that can optimize performance for both noise and efficiency requirements.

Material Science Advancements for Acoustic Applications

Recent advancements in material science have revolutionized acoustic applications for turbine engine noise reduction. Innovative composite materials with enhanced sound absorption properties have emerged as frontrunners in this field. These materials, often combining multiple layers of varying densities and porosities, can effectively attenuate sound across broader frequency ranges than traditional solutions.

Metamaterials represent a significant breakthrough, engineered with precise microstructures that can manipulate, redirect, and absorb sound waves in ways previously impossible. These acoustic metamaterials can create frequency-specific sound barriers that target the particular noise signatures of turbine engines while maintaining structural integrity under extreme operating conditions.

Ceramic matrix composites (CMCs) have demonstrated exceptional potential for acoustic linings in high-temperature environments. Their ability to withstand thermal cycling while maintaining acoustic performance makes them ideal for turbine applications. Recent developments have improved their manufacturability and reduced production costs, making them increasingly viable for commercial implementation.

Nano-engineered materials offer unprecedented control over acoustic properties. By manipulating material structure at the nanoscale, researchers have developed materials with tailored acoustic impedance and absorption coefficients. Carbon nanotube-reinforced polymers, for example, provide exceptional sound damping while adding minimal weight to engine components.

Smart materials that adapt their acoustic properties in response to changing engine conditions represent the cutting edge of this field. Piezoelectric materials and shape memory alloys can dynamically alter their stiffness and damping characteristics to optimize noise reduction across various operating regimes. These active acoustic materials can be integrated into engine nacelles and exhaust systems for real-time noise management.

Biomimetic approaches have yielded promising results by emulating natural sound-absorbing structures. Materials inspired by owl feathers and other biological sound-dampening mechanisms have demonstrated remarkable noise reduction capabilities while maintaining aerodynamic efficiency. These bio-inspired designs often feature hierarchical structures that work across multiple scales to dissipate acoustic energy.

Advances in manufacturing techniques, particularly additive manufacturing, have enabled the production of complex acoustic structures previously impossible to fabricate. 3D-printed acoustic liners with precisely controlled geometries can be optimized for specific noise frequencies and tailored to exact engine specifications, offering customized solutions for different turbine designs.

Metamaterials represent a significant breakthrough, engineered with precise microstructures that can manipulate, redirect, and absorb sound waves in ways previously impossible. These acoustic metamaterials can create frequency-specific sound barriers that target the particular noise signatures of turbine engines while maintaining structural integrity under extreme operating conditions.

Ceramic matrix composites (CMCs) have demonstrated exceptional potential for acoustic linings in high-temperature environments. Their ability to withstand thermal cycling while maintaining acoustic performance makes them ideal for turbine applications. Recent developments have improved their manufacturability and reduced production costs, making them increasingly viable for commercial implementation.

Nano-engineered materials offer unprecedented control over acoustic properties. By manipulating material structure at the nanoscale, researchers have developed materials with tailored acoustic impedance and absorption coefficients. Carbon nanotube-reinforced polymers, for example, provide exceptional sound damping while adding minimal weight to engine components.

Smart materials that adapt their acoustic properties in response to changing engine conditions represent the cutting edge of this field. Piezoelectric materials and shape memory alloys can dynamically alter their stiffness and damping characteristics to optimize noise reduction across various operating regimes. These active acoustic materials can be integrated into engine nacelles and exhaust systems for real-time noise management.

Biomimetic approaches have yielded promising results by emulating natural sound-absorbing structures. Materials inspired by owl feathers and other biological sound-dampening mechanisms have demonstrated remarkable noise reduction capabilities while maintaining aerodynamic efficiency. These bio-inspired designs often feature hierarchical structures that work across multiple scales to dissipate acoustic energy.

Advances in manufacturing techniques, particularly additive manufacturing, have enabled the production of complex acoustic structures previously impossible to fabricate. 3D-printed acoustic liners with precisely controlled geometries can be optimized for specific noise frequencies and tailored to exact engine specifications, offering customized solutions for different turbine designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!