Blade Longevity Vs Weight: Impact on Turbine Engine Design

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Blade Technology Evolution and Objectives

Turbine blade technology has undergone significant evolution since the introduction of the first jet engines in the 1940s. Initially, these components were manufactured from stainless steel, offering modest temperature resistance but limited longevity. The 1950s marked a pivotal shift with the introduction of nickel-based superalloys, dramatically improving high-temperature performance while maintaining reasonable weight characteristics. This advancement enabled higher operating temperatures and consequently greater engine efficiency.

The 1960s and 1970s witnessed the development of directionally solidified (DS) casting techniques, creating blades with aligned grain boundaries that substantially enhanced creep resistance. This innovation represented a critical step in extending blade service life without significant weight penalties. By the 1980s, single-crystal blade technology emerged, eliminating grain boundaries entirely and further improving durability under extreme thermal conditions.

Thermal barrier coatings (TBCs) became prevalent in the 1990s, adding protective ceramic layers that insulated the metal substrate from peak temperatures. This development allowed engineers to push operating temperatures higher while preserving blade integrity. Concurrently, internal cooling channels evolved from simple passages to complex networks featuring turbulators and film cooling holes, creating protective air barriers between hot gases and blade surfaces.

The early 2000s saw the integration of advanced computational modeling techniques, enabling precise prediction of blade behavior under various operating conditions. This facilitated more aggressive designs that optimized the longevity-weight balance. Recent developments have focused on ceramic matrix composites (CMCs) and intermetallic compounds, offering superior temperature resistance with lower density compared to traditional superalloys.

The fundamental objective driving turbine blade technology development remains consistent: maximizing engine efficiency while ensuring component reliability. This translates to specific technical goals including increasing temperature capability beyond 1600°C, reducing blade weight by 20-30% without compromising structural integrity, extending service intervals to 30,000+ operating hours, and developing materials capable of withstanding increasingly severe thermal cycling conditions.

Additional objectives include reducing manufacturing costs through advanced production techniques like additive manufacturing, minimizing the use of strategic materials such as rhenium and ruthenium, and developing more environmentally sustainable production processes. The industry also aims to create predictive maintenance capabilities through integrated sensor technologies and improve aerodynamic efficiency through more sophisticated blade geometries that maintain performance despite inevitable in-service degradation.

The 1960s and 1970s witnessed the development of directionally solidified (DS) casting techniques, creating blades with aligned grain boundaries that substantially enhanced creep resistance. This innovation represented a critical step in extending blade service life without significant weight penalties. By the 1980s, single-crystal blade technology emerged, eliminating grain boundaries entirely and further improving durability under extreme thermal conditions.

Thermal barrier coatings (TBCs) became prevalent in the 1990s, adding protective ceramic layers that insulated the metal substrate from peak temperatures. This development allowed engineers to push operating temperatures higher while preserving blade integrity. Concurrently, internal cooling channels evolved from simple passages to complex networks featuring turbulators and film cooling holes, creating protective air barriers between hot gases and blade surfaces.

The early 2000s saw the integration of advanced computational modeling techniques, enabling precise prediction of blade behavior under various operating conditions. This facilitated more aggressive designs that optimized the longevity-weight balance. Recent developments have focused on ceramic matrix composites (CMCs) and intermetallic compounds, offering superior temperature resistance with lower density compared to traditional superalloys.

The fundamental objective driving turbine blade technology development remains consistent: maximizing engine efficiency while ensuring component reliability. This translates to specific technical goals including increasing temperature capability beyond 1600°C, reducing blade weight by 20-30% without compromising structural integrity, extending service intervals to 30,000+ operating hours, and developing materials capable of withstanding increasingly severe thermal cycling conditions.

Additional objectives include reducing manufacturing costs through advanced production techniques like additive manufacturing, minimizing the use of strategic materials such as rhenium and ruthenium, and developing more environmentally sustainable production processes. The industry also aims to create predictive maintenance capabilities through integrated sensor technologies and improve aerodynamic efficiency through more sophisticated blade geometries that maintain performance despite inevitable in-service degradation.

Market Requirements for Advanced Turbine Engine Performance

The global aviation industry is witnessing unprecedented demands for advanced turbine engine performance, driven primarily by economic and environmental imperatives. Airlines and aircraft operators increasingly require engines that deliver substantial reductions in fuel consumption, with industry benchmarks now targeting 15-20% improvement over previous generation engines. This requirement stems from fuel costs representing approximately 30% of airline operating expenses, making fuel efficiency a critical competitive factor.

Environmental regulations have become equally significant market drivers, with the International Civil Aviation Organization (ICAO) establishing stringent emissions standards. Modern turbine engines must demonstrate at least 50% reduction in nitrogen oxide emissions compared to CAEP/6 standards, while meeting increasingly strict noise regulations that demand 75% smaller noise footprints than engines from two decades ago.

Reliability metrics have evolved substantially, with the market now demanding mean time between removals (MTBR) exceeding 20,000 flight hours for new engine designs. This represents a doubling of performance compared to engines from the early 2000s, directly impacting maintenance costs and operational availability.

Weight considerations have become paramount as manufacturers pursue performance improvements. The market increasingly values power-to-weight ratios exceeding 10:1, representing a significant advancement over previous generation engines that typically achieved 7:1 or 8:1 ratios. Each percentage point of weight reduction typically translates to 0.25-0.5% improvement in specific fuel consumption.

Blade technology sits at the critical intersection of these requirements. The market demands blade designs that simultaneously extend service life while reducing weight—traditionally opposing objectives. Advanced turbine engines now require blade lifespans exceeding 25,000 flight cycles while incorporating weight reductions of 15-20% compared to conventional designs.

Maintenance economics have become a defining market requirement, with operators demanding 25-30% reductions in maintenance costs per flight hour. This has driven significant innovation in blade design, materials, and manufacturing processes to extend component life while reducing overall engine weight.

Military applications present additional market requirements, emphasizing thrust-to-weight ratios exceeding 15:1 for next-generation fighter engines, alongside rapid throttle response capabilities and thermal management systems capable of handling extreme operating conditions. These specialized requirements often drive innovations that eventually transition to commercial applications.

Environmental regulations have become equally significant market drivers, with the International Civil Aviation Organization (ICAO) establishing stringent emissions standards. Modern turbine engines must demonstrate at least 50% reduction in nitrogen oxide emissions compared to CAEP/6 standards, while meeting increasingly strict noise regulations that demand 75% smaller noise footprints than engines from two decades ago.

Reliability metrics have evolved substantially, with the market now demanding mean time between removals (MTBR) exceeding 20,000 flight hours for new engine designs. This represents a doubling of performance compared to engines from the early 2000s, directly impacting maintenance costs and operational availability.

Weight considerations have become paramount as manufacturers pursue performance improvements. The market increasingly values power-to-weight ratios exceeding 10:1, representing a significant advancement over previous generation engines that typically achieved 7:1 or 8:1 ratios. Each percentage point of weight reduction typically translates to 0.25-0.5% improvement in specific fuel consumption.

Blade technology sits at the critical intersection of these requirements. The market demands blade designs that simultaneously extend service life while reducing weight—traditionally opposing objectives. Advanced turbine engines now require blade lifespans exceeding 25,000 flight cycles while incorporating weight reductions of 15-20% compared to conventional designs.

Maintenance economics have become a defining market requirement, with operators demanding 25-30% reductions in maintenance costs per flight hour. This has driven significant innovation in blade design, materials, and manufacturing processes to extend component life while reducing overall engine weight.

Military applications present additional market requirements, emphasizing thrust-to-weight ratios exceeding 15:1 for next-generation fighter engines, alongside rapid throttle response capabilities and thermal management systems capable of handling extreme operating conditions. These specialized requirements often drive innovations that eventually transition to commercial applications.

Current Challenges in Blade Design Trade-offs

The turbine blade design process faces significant challenges in balancing longevity against weight considerations. Engineers must navigate complex trade-offs between material durability and overall engine efficiency. Current blade designs struggle with the inherent contradiction between the need for lightweight components to improve fuel efficiency and the requirement for robust structures that can withstand extreme operating conditions.

Material selection represents one of the most critical challenges in this balance. Traditional nickel-based superalloys offer excellent heat resistance and durability but contribute substantially to engine weight. While newer materials like ceramic matrix composites (CMCs) and titanium aluminides promise weight reduction, they introduce concerns regarding long-term reliability, especially under variable load conditions and thermal cycling.

Cooling system integration presents another significant design challenge. More effective cooling systems extend blade life but typically require additional material mass and complex internal geometries. Engineers must determine optimal cooling channel configurations that maximize heat dissipation without compromising structural integrity or adding excessive weight. Current designs struggle to achieve uniform cooling across the entire blade surface, resulting in localized hot spots that accelerate degradation.

Manufacturing limitations further complicate the trade-off equation. Advanced manufacturing techniques like additive manufacturing offer potential solutions for creating optimized internal cooling structures, but face challenges in material consistency and quality control. Traditional casting methods provide more predictable results but limit design complexity. This manufacturing constraint often forces designers to compromise between ideal theoretical designs and practically producible components.

Operational profile considerations add another layer of complexity. Blades must withstand different stress patterns during startup, steady operation, and shutdown phases. Current designs typically optimize for one operational phase at the expense of others, resulting in compromised overall performance. The industry lacks comprehensive models that can accurately predict blade behavior across the entire operational envelope while accounting for both weight and longevity factors.

Economic pressures intensify these technical challenges. Maintenance intervals directly impact operational costs, creating tension between initial manufacturing costs and long-term operational expenses. Lighter blades may reduce fuel consumption but potentially increase maintenance frequency and associated costs. Current design methodologies struggle to quantify this economic trade-off effectively, often resulting in conservative approaches that prioritize proven reliability over potential efficiency gains from weight reduction.

Material selection represents one of the most critical challenges in this balance. Traditional nickel-based superalloys offer excellent heat resistance and durability but contribute substantially to engine weight. While newer materials like ceramic matrix composites (CMCs) and titanium aluminides promise weight reduction, they introduce concerns regarding long-term reliability, especially under variable load conditions and thermal cycling.

Cooling system integration presents another significant design challenge. More effective cooling systems extend blade life but typically require additional material mass and complex internal geometries. Engineers must determine optimal cooling channel configurations that maximize heat dissipation without compromising structural integrity or adding excessive weight. Current designs struggle to achieve uniform cooling across the entire blade surface, resulting in localized hot spots that accelerate degradation.

Manufacturing limitations further complicate the trade-off equation. Advanced manufacturing techniques like additive manufacturing offer potential solutions for creating optimized internal cooling structures, but face challenges in material consistency and quality control. Traditional casting methods provide more predictable results but limit design complexity. This manufacturing constraint often forces designers to compromise between ideal theoretical designs and practically producible components.

Operational profile considerations add another layer of complexity. Blades must withstand different stress patterns during startup, steady operation, and shutdown phases. Current designs typically optimize for one operational phase at the expense of others, resulting in compromised overall performance. The industry lacks comprehensive models that can accurately predict blade behavior across the entire operational envelope while accounting for both weight and longevity factors.

Economic pressures intensify these technical challenges. Maintenance intervals directly impact operational costs, creating tension between initial manufacturing costs and long-term operational expenses. Lighter blades may reduce fuel consumption but potentially increase maintenance frequency and associated costs. Current design methodologies struggle to quantify this economic trade-off effectively, often resulting in conservative approaches that prioritize proven reliability over potential efficiency gains from weight reduction.

Contemporary Blade Longevity-Weight Balance Solutions

01 Advanced materials for turbine blade weight reduction

Lightweight materials such as advanced composites, titanium alloys, and ceramic matrix composites are used in turbine engine blades to reduce overall weight while maintaining structural integrity. These materials offer high strength-to-weight ratios, allowing for thinner blade designs without compromising performance. The reduced weight decreases centrifugal forces during operation, which in turn reduces stress on other engine components and improves fuel efficiency.- Advanced materials for turbine blade weight reduction: Lightweight materials such as advanced composites, titanium alloys, and ceramic matrix composites are used in turbine engine blades to reduce overall weight while maintaining structural integrity. These materials offer high strength-to-weight ratios, allowing for thinner blade designs without compromising performance. The reduced weight decreases centrifugal forces during operation, which in turn reduces stress on other engine components and improves fuel efficiency.

- Cooling systems for extended blade longevity: Innovative cooling systems are integrated into turbine blades to manage high operating temperatures and extend service life. These systems include internal cooling channels, film cooling techniques, and thermal barrier coatings that protect the blade material from thermal degradation. By effectively managing heat distribution, these cooling technologies prevent premature failure due to thermal fatigue and creep, significantly increasing the operational lifespan of turbine blades.

- Aerodynamic design optimization for efficiency and durability: Advanced aerodynamic designs for turbine blades focus on optimizing airflow patterns to reduce drag and improve efficiency while enhancing structural durability. These designs incorporate sophisticated 3D geometries, including swept and leaned configurations, that distribute mechanical loads more evenly across the blade. Computer modeling and simulation techniques are used to predict stress concentrations and optimize blade profiles for both performance and longevity.

- Protective coatings and surface treatments: Specialized coatings and surface treatments are applied to turbine blades to protect against environmental degradation factors such as oxidation, corrosion, and erosion. These include thermal barrier coatings, metallic overlays, and diffusion coatings that create protective layers on the blade surface. Additionally, surface hardening treatments improve wear resistance while maintaining the lightweight characteristics of the base material, extending blade life in harsh operating environments.

- Manufacturing techniques for optimized blade structure: Advanced manufacturing methods such as single crystal casting, directional solidification, additive manufacturing, and precision machining enable the production of turbine blades with optimized internal structures. These techniques allow for the creation of complex internal cooling passages, variable wall thicknesses, and integrated features that would be impossible with conventional manufacturing. The resulting blades achieve an optimal balance between weight reduction and structural integrity, with precisely controlled grain structures that enhance creep resistance and fatigue life.

02 Cooling systems for extended blade life

Advanced cooling systems are integrated into turbine blades to manage high operating temperatures and extend service life. These systems include internal cooling channels, film cooling holes, and thermal barrier coatings that work together to maintain blade temperatures within acceptable limits. Effective cooling prevents thermal fatigue, creep, and oxidation, which are primary factors in blade deterioration. By controlling temperature distribution across the blade, these cooling technologies significantly enhance blade longevity in high-temperature environments.Expand Specific Solutions03 Protective coatings and surface treatments

Specialized coatings and surface treatments are applied to turbine blades to protect against environmental degradation factors such as oxidation, corrosion, and erosion. These include thermal barrier coatings (TBCs), metallic overlay coatings, diffusion coatings, and various surface hardening treatments. The protective layers act as sacrificial barriers that preserve the underlying blade material, extending operational life while allowing for lighter base materials to be used without compromising durability.Expand Specific Solutions04 Optimized blade geometry and design

Advanced computational modeling and design techniques are used to optimize turbine blade geometry for both weight reduction and longevity. These designs incorporate aerodynamic profiles that maximize efficiency while minimizing stress concentrations. Features such as hollow cores, variable thickness profiles, and integrated damping mechanisms reduce weight while maintaining structural integrity. The optimized designs also consider vibration characteristics to prevent resonance issues that could lead to premature failure.Expand Specific Solutions05 Manufacturing techniques for improved blade properties

Innovative manufacturing processes such as single crystal casting, directional solidification, additive manufacturing, and precision machining are employed to create turbine blades with superior mechanical properties. These techniques allow for more precise control over material microstructure, resulting in blades with enhanced creep resistance, fatigue strength, and overall durability. Advanced joining methods and repair techniques also contribute to extended service life by allowing for cost-effective maintenance rather than complete replacement.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The blade longevity versus weight trade-off in turbine engine design represents a mature technological challenge in an expanding market. The global turbine industry is in a growth phase, with an estimated market size exceeding $200 billion annually, driven by energy transition demands. Leading companies demonstrate varying technological maturity levels: Siemens Energy, GE, and Rolls-Royce have established advanced blade materials and designs for power generation turbines, while aerospace specialists like Safran Aircraft Engines, Pratt & Whitney, and MTU Aero Engines focus on lightweight, high-temperature resistant solutions. Vestas and Siemens Gamesa lead in wind turbine blade technology, emphasizing durability in harsh environments. Research institutions like Fraunhofer-Gesellschaft and Northwestern Polytechnical University are developing next-generation composite materials to further optimize the longevity-weight balance.

General Electric Technology GmbH

Technical Solution: GE has revolutionized turbine blade technology through their CMC (Ceramic Matrix Composites) program, which has produced blades that operate at temperatures 200°C higher than traditional nickel alloys while being approximately one-third the weight. Their proprietary silicon carbide fiber and silicon carbide matrix composites maintain strength at high temperatures while significantly reducing cooling air requirements. GE's TiAl (Titanium Aluminide) low-pressure turbine blades, implemented in the GEnx and LEAP engines, offer a 50% weight reduction compared to conventional nickel-based alloys while maintaining adequate durability. The company has also pioneered 3D aerodynamic designs with optimized airfoil shapes that reduce aerodynamic losses by up to 15% while extending blade life through reduced stress concentrations. GE's advanced manufacturing techniques include direct metal laser melting (DMLM) that enables complex internal cooling passages impossible to create with conventional manufacturing.

Strengths: Industry-leading CMC technology that dramatically improves the weight-to-longevity ratio; extensive experience with titanium aluminide applications; advanced computational fluid dynamics capabilities for optimized aerodynamic designs. Weaknesses: High manufacturing costs for CMC components; complex production processes requiring specialized equipment; longer development cycles for implementing new materials across product lines.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed innovative blade technologies through their LEAP engine program in partnership with GE. Their 3D woven RTM (Resin Transfer Molding) carbon fiber composite fan blades reduce weight by approximately 40% compared to traditional titanium blades while maintaining exceptional durability. For high-pressure turbine blades, Safran employs advanced directionally solidified and single crystal superalloys with proprietary compositions optimized for both creep resistance and fatigue life. Their blades incorporate sophisticated multi-layer coating systems including MCrAlY bond coats and ceramic thermal barrier coatings that extend blade life by up to 25% in high-temperature environments. Safran has pioneered near-surface cooling technologies that maintain lower metal temperatures with reduced cooling air requirements, allowing for thinner blade profiles without compromising structural integrity. Their manufacturing processes include precision investment casting with integrated cooling channels and advanced non-destructive testing protocols to ensure consistent quality.

Strengths: Leading expertise in composite fan blade technology; advanced coating systems that significantly extend blade life; sophisticated cooling designs that optimize the weight-durability balance. Weaknesses: Complex manufacturing processes requiring specialized equipment; higher production costs compared to conventional technologies; challenges in scaling innovations across different engine platforms.

Critical Patents and Innovations in Blade Technology

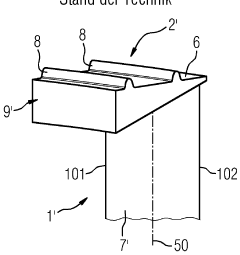

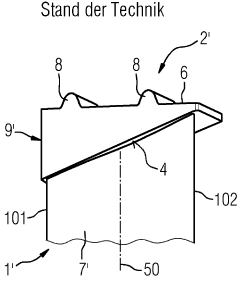

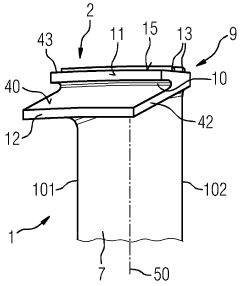

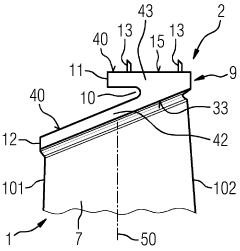

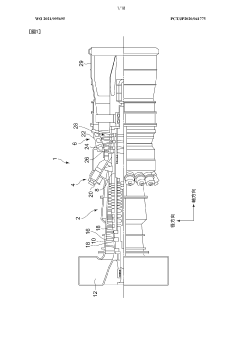

Turbine blade and method for producing a turbine blade

PatentWO2023134983A1

Innovation

- A turbine blade design featuring a V-shaped blade tip with an acute inner surface and wedge-shaped sealing fins, which can be manufactured using existing materials and processes, including casting, forging, and machining, to reduce weight without compromising mechanical strength.

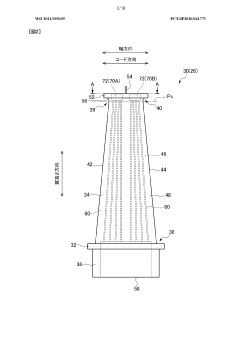

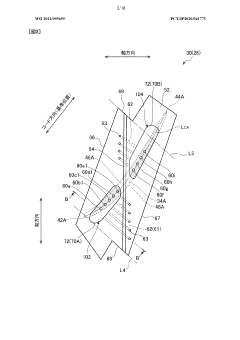

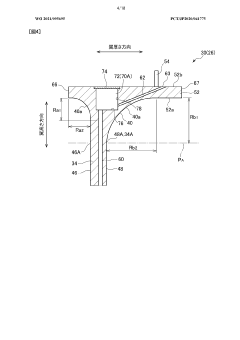

Turbine blade, and gas turbine

PatentWO2021095695A1

Innovation

- The design incorporates a turbine blade with a cooling cavity that extends to overlap the fillet portion in the blade height direction, featuring first and second cooling holes and cavities that reduce the weight and stress concentration at the blade tip, thereby adjusting the center of gravity and minimizing centrifugal loads.

Environmental Impact and Sustainability Considerations

The environmental footprint of turbine engine design has become increasingly significant in today's sustainability-focused world. The relationship between blade longevity and weight directly impacts environmental considerations through multiple pathways. Longer-lasting blades reduce the frequency of replacements, thereby decreasing the environmental burden associated with manufacturing new components, which typically involves energy-intensive processes and rare earth materials.

Weight optimization in turbine blades yields substantial environmental benefits through improved fuel efficiency. Studies indicate that a 1% reduction in turbine weight can result in approximately 0.75-1.2% decrease in fuel consumption, translating to significant reductions in greenhouse gas emissions over an engine's operational lifetime. For commercial aviation alone, this could represent thousands of tons of CO2 emissions avoided per aircraft.

Material selection for turbine blades presents important sustainability trade-offs. While lightweight materials may improve operational efficiency, their production often involves more energy-intensive processes. For instance, advanced titanium alloys and composite materials offer weight advantages but typically have higher embodied carbon footprints compared to traditional nickel-based superalloys. Life cycle assessment (LCA) studies suggest that the environmental benefits during operation generally outweigh manufacturing impacts within 2-3 years of service.

End-of-life considerations are increasingly important in turbine design. The recyclability of blade materials varies significantly, with some advanced composites presenting challenges for material recovery. Designing for disassembly and incorporating recyclable materials can reduce waste and resource depletion. Recent innovations in blade design have improved recyclability rates from approximately 60% to over 85% for certain components.

Regulatory frameworks worldwide are evolving to address environmental impacts of aerospace and power generation industries. The International Civil Aviation Organization (ICAO) has established increasingly stringent emissions standards, while power generation faces carbon pricing mechanisms in many jurisdictions. These regulatory pressures are accelerating research into sustainable blade technologies that optimize the longevity-weight relationship.

Emerging technologies such as additive manufacturing offer promising pathways to reduce environmental impacts by enabling more precise material placement, reducing waste, and potentially extending blade life through improved designs. Additionally, bio-inspired design approaches are yielding structures that optimize strength-to-weight ratios while minimizing material use, further enhancing sustainability profiles of modern turbine engines.

Weight optimization in turbine blades yields substantial environmental benefits through improved fuel efficiency. Studies indicate that a 1% reduction in turbine weight can result in approximately 0.75-1.2% decrease in fuel consumption, translating to significant reductions in greenhouse gas emissions over an engine's operational lifetime. For commercial aviation alone, this could represent thousands of tons of CO2 emissions avoided per aircraft.

Material selection for turbine blades presents important sustainability trade-offs. While lightweight materials may improve operational efficiency, their production often involves more energy-intensive processes. For instance, advanced titanium alloys and composite materials offer weight advantages but typically have higher embodied carbon footprints compared to traditional nickel-based superalloys. Life cycle assessment (LCA) studies suggest that the environmental benefits during operation generally outweigh manufacturing impacts within 2-3 years of service.

End-of-life considerations are increasingly important in turbine design. The recyclability of blade materials varies significantly, with some advanced composites presenting challenges for material recovery. Designing for disassembly and incorporating recyclable materials can reduce waste and resource depletion. Recent innovations in blade design have improved recyclability rates from approximately 60% to over 85% for certain components.

Regulatory frameworks worldwide are evolving to address environmental impacts of aerospace and power generation industries. The International Civil Aviation Organization (ICAO) has established increasingly stringent emissions standards, while power generation faces carbon pricing mechanisms in many jurisdictions. These regulatory pressures are accelerating research into sustainable blade technologies that optimize the longevity-weight relationship.

Emerging technologies such as additive manufacturing offer promising pathways to reduce environmental impacts by enabling more precise material placement, reducing waste, and potentially extending blade life through improved designs. Additionally, bio-inspired design approaches are yielding structures that optimize strength-to-weight ratios while minimizing material use, further enhancing sustainability profiles of modern turbine engines.

Economic Analysis of Blade Lifecycle Costs

The economic analysis of blade lifecycle costs in turbine engine design reveals a complex interplay between initial investment and long-term operational expenses. When evaluating the trade-off between blade longevity and weight, manufacturers must consider the total cost of ownership rather than focusing solely on acquisition costs.

Material selection represents a significant portion of blade lifecycle economics. Advanced alloys and composites that offer extended service life typically command premium prices, increasing upfront costs by 30-45% compared to conventional materials. However, these materials can extend replacement intervals by 1.5-2.5 times, potentially yielding substantial maintenance savings over the engine's operational lifespan.

Maintenance economics present another critical consideration. Heavier, more durable blades generally require less frequent replacement, reducing scheduled maintenance events and associated labor costs. Industry data indicates that extending blade life by 20% can reduce maintenance labor hours by approximately 15-18% per maintenance cycle, translating to significant cost savings for operators.

Fuel efficiency implications cannot be overlooked in lifecycle cost calculations. Each additional kilogram of blade weight increases fuel consumption by approximately 0.05-0.1% in typical commercial applications. For a mid-sized commercial aircraft, this translates to $50,000-100,000 in additional fuel costs annually. The economic equilibrium point varies based on fuel prices, with higher fuel costs favoring lighter designs despite potentially shorter service intervals.

Operational reliability factors significantly impact the economic equation. Unscheduled maintenance due to premature blade failure can cost operators 3-5 times more than planned maintenance events. More durable blades, despite their weight penalty, may reduce these costly disruptions by 25-40%, improving overall fleet availability and revenue generation potential.

Market analysis reveals varying preferences across different segments. Commercial aviation operators typically prioritize fuel efficiency and reliability metrics, while military applications often emphasize performance and durability over weight considerations. Industrial power generation applications demonstrate greater tolerance for weight increases if they deliver substantial improvements in service intervals.

The economic optimization model must therefore balance multiple variables: initial acquisition costs, maintenance intervals, fuel consumption penalties, reliability improvements, and operational context. Advanced lifecycle cost modeling suggests that the optimal blade design varies significantly based on the specific application profile and operational parameters.

Material selection represents a significant portion of blade lifecycle economics. Advanced alloys and composites that offer extended service life typically command premium prices, increasing upfront costs by 30-45% compared to conventional materials. However, these materials can extend replacement intervals by 1.5-2.5 times, potentially yielding substantial maintenance savings over the engine's operational lifespan.

Maintenance economics present another critical consideration. Heavier, more durable blades generally require less frequent replacement, reducing scheduled maintenance events and associated labor costs. Industry data indicates that extending blade life by 20% can reduce maintenance labor hours by approximately 15-18% per maintenance cycle, translating to significant cost savings for operators.

Fuel efficiency implications cannot be overlooked in lifecycle cost calculations. Each additional kilogram of blade weight increases fuel consumption by approximately 0.05-0.1% in typical commercial applications. For a mid-sized commercial aircraft, this translates to $50,000-100,000 in additional fuel costs annually. The economic equilibrium point varies based on fuel prices, with higher fuel costs favoring lighter designs despite potentially shorter service intervals.

Operational reliability factors significantly impact the economic equation. Unscheduled maintenance due to premature blade failure can cost operators 3-5 times more than planned maintenance events. More durable blades, despite their weight penalty, may reduce these costly disruptions by 25-40%, improving overall fleet availability and revenue generation potential.

Market analysis reveals varying preferences across different segments. Commercial aviation operators typically prioritize fuel efficiency and reliability metrics, while military applications often emphasize performance and durability over weight considerations. Industrial power generation applications demonstrate greater tolerance for weight increases if they deliver substantial improvements in service intervals.

The economic optimization model must therefore balance multiple variables: initial acquisition costs, maintenance intervals, fuel consumption penalties, reliability improvements, and operational context. Advanced lifecycle cost modeling suggests that the optimal blade design varies significantly based on the specific application profile and operational parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!