Test Abiotic Stress Factors on Turbine Engine Metal Components

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Materials Evolution and Testing Objectives

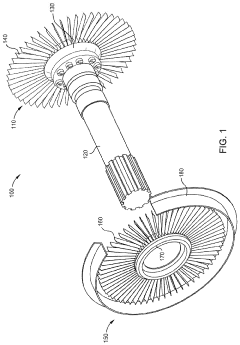

Turbine engines represent a critical component in various industries, from aviation to power generation, with their performance and durability directly impacting operational efficiency and safety. The evolution of turbine engine materials has been driven by the continuous pursuit of higher operating temperatures, improved efficiency, and extended component lifespans under increasingly demanding conditions.

The development of turbine engine materials began with simple steel alloys in the early 20th century, progressing through several generations of nickel-based superalloys that dramatically improved high-temperature performance. The 1940s saw the introduction of vacuum melting techniques, enabling better control of alloy composition. By the 1960s, directionally solidified casting methods emerged, followed by single-crystal superalloys in the 1970s that eliminated grain boundaries—a primary failure point under high-temperature stress.

Recent decades have witnessed the integration of thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) to protect base materials from extreme temperatures and corrosive environments. Ceramic matrix composites (CMCs) and intermetallic compounds have also gained prominence for their exceptional heat resistance and reduced weight characteristics.

The primary objective of testing abiotic stress factors on turbine engine metal components is to understand material behavior under extreme operational conditions that simulate real-world environments. These tests aim to identify failure mechanisms, establish performance limits, and validate theoretical models before components enter service.

Key testing objectives include evaluating high-temperature mechanical properties such as creep resistance, fatigue strength, and thermal stability. Oxidation and hot corrosion resistance testing is crucial for components exposed to combustion products and environmental contaminants. Thermal cycling tests assess material integrity during repeated heating and cooling cycles that induce thermal stresses.

Additionally, testing must evaluate the impact of manufacturing processes on material performance, as techniques like additive manufacturing introduce unique microstructural characteristics that can significantly affect component behavior. The interaction between different materials in composite systems, particularly at interfaces where dissimilar materials meet, represents another critical testing focus.

The ultimate goal of these testing regimes is to develop predictive models that accurately forecast component lifespan under various operational scenarios, enabling optimized maintenance schedules and improved safety margins. This approach supports the industry trend toward condition-based maintenance strategies rather than traditional time-based replacement protocols.

The development of turbine engine materials began with simple steel alloys in the early 20th century, progressing through several generations of nickel-based superalloys that dramatically improved high-temperature performance. The 1940s saw the introduction of vacuum melting techniques, enabling better control of alloy composition. By the 1960s, directionally solidified casting methods emerged, followed by single-crystal superalloys in the 1970s that eliminated grain boundaries—a primary failure point under high-temperature stress.

Recent decades have witnessed the integration of thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) to protect base materials from extreme temperatures and corrosive environments. Ceramic matrix composites (CMCs) and intermetallic compounds have also gained prominence for their exceptional heat resistance and reduced weight characteristics.

The primary objective of testing abiotic stress factors on turbine engine metal components is to understand material behavior under extreme operational conditions that simulate real-world environments. These tests aim to identify failure mechanisms, establish performance limits, and validate theoretical models before components enter service.

Key testing objectives include evaluating high-temperature mechanical properties such as creep resistance, fatigue strength, and thermal stability. Oxidation and hot corrosion resistance testing is crucial for components exposed to combustion products and environmental contaminants. Thermal cycling tests assess material integrity during repeated heating and cooling cycles that induce thermal stresses.

Additionally, testing must evaluate the impact of manufacturing processes on material performance, as techniques like additive manufacturing introduce unique microstructural characteristics that can significantly affect component behavior. The interaction between different materials in composite systems, particularly at interfaces where dissimilar materials meet, represents another critical testing focus.

The ultimate goal of these testing regimes is to develop predictive models that accurately forecast component lifespan under various operational scenarios, enabling optimized maintenance schedules and improved safety margins. This approach supports the industry trend toward condition-based maintenance strategies rather than traditional time-based replacement protocols.

Market Demand Analysis for Stress-Resistant Turbine Components

The global market for stress-resistant turbine components has experienced significant growth in recent years, driven by increasing demands for higher efficiency, longer service life, and reduced maintenance costs in power generation, aerospace, and industrial applications. The market value for specialized turbine components reached $32.7 billion in 2022, with a projected compound annual growth rate of 5.8% through 2030, according to industry analyses.

Energy sector transformation represents a primary driver for this market. As power generation shifts toward renewable sources and high-efficiency combined cycle plants, turbines face more frequent cycling operations and higher operating temperatures. This operational pattern subjects metal components to increased thermal fatigue, oxidation, and creep, creating demand for advanced materials and testing methodologies that can predict component behavior under these stress conditions.

The aerospace industry constitutes another significant market segment, valued at approximately $8.4 billion in 2022. Commercial and military aircraft manufacturers require turbine components capable of withstanding extreme temperature fluctuations, high-velocity particulate impacts, and corrosive environments. Testing protocols that accurately simulate these abiotic stress factors have become essential for certification and reliability assurance.

Industrial applications, particularly in oil and gas, chemical processing, and marine propulsion, represent a growing market segment with specific requirements for corrosion resistance and performance under variable load conditions. These sectors increasingly demand components tested under simulated real-world stress conditions rather than standardized laboratory environments.

Geographically, North America and Europe currently dominate the market for stress-resistant turbine components, accounting for approximately 58% of global demand. However, the Asia-Pacific region, particularly China and India, shows the fastest growth rate at 7.3% annually, driven by rapid industrialization and power infrastructure development.

Customer requirements are evolving toward more sophisticated testing protocols that can simultaneously evaluate multiple stress factors. End-users increasingly demand components validated under combined thermal cycling, mechanical loading, and corrosive environment testing rather than isolated stress evaluations. This shift reflects operational realities where components rarely experience single stress factors in isolation.

The economic value proposition for advanced stress-resistant components is compelling. While premium materials and extensive testing increase initial component costs by 15-30%, the extended service life and reduced maintenance requirements typically deliver 2-3 times return on investment over the component lifecycle. This favorable economics continues to drive market expansion despite higher upfront costs.

Energy sector transformation represents a primary driver for this market. As power generation shifts toward renewable sources and high-efficiency combined cycle plants, turbines face more frequent cycling operations and higher operating temperatures. This operational pattern subjects metal components to increased thermal fatigue, oxidation, and creep, creating demand for advanced materials and testing methodologies that can predict component behavior under these stress conditions.

The aerospace industry constitutes another significant market segment, valued at approximately $8.4 billion in 2022. Commercial and military aircraft manufacturers require turbine components capable of withstanding extreme temperature fluctuations, high-velocity particulate impacts, and corrosive environments. Testing protocols that accurately simulate these abiotic stress factors have become essential for certification and reliability assurance.

Industrial applications, particularly in oil and gas, chemical processing, and marine propulsion, represent a growing market segment with specific requirements for corrosion resistance and performance under variable load conditions. These sectors increasingly demand components tested under simulated real-world stress conditions rather than standardized laboratory environments.

Geographically, North America and Europe currently dominate the market for stress-resistant turbine components, accounting for approximately 58% of global demand. However, the Asia-Pacific region, particularly China and India, shows the fastest growth rate at 7.3% annually, driven by rapid industrialization and power infrastructure development.

Customer requirements are evolving toward more sophisticated testing protocols that can simultaneously evaluate multiple stress factors. End-users increasingly demand components validated under combined thermal cycling, mechanical loading, and corrosive environment testing rather than isolated stress evaluations. This shift reflects operational realities where components rarely experience single stress factors in isolation.

The economic value proposition for advanced stress-resistant components is compelling. While premium materials and extensive testing increase initial component costs by 15-30%, the extended service life and reduced maintenance requirements typically deliver 2-3 times return on investment over the component lifecycle. This favorable economics continues to drive market expansion despite higher upfront costs.

Current Abiotic Stress Testing Methodologies and Challenges

The testing of abiotic stress factors on turbine engine metal components has evolved significantly over the past decades, with methodologies becoming increasingly sophisticated to match the demanding operational environments these components face. Current testing approaches can be broadly categorized into laboratory-based simulations, accelerated life testing, and in-situ monitoring systems, each with their own strengths and limitations.

Laboratory-based testing methodologies typically involve specialized equipment designed to replicate specific environmental stressors. These include high-temperature furnaces capable of reaching 1600°C for thermal stress testing, corrosion chambers that simulate salt spray and acidic environments, and mechanical testing apparatus for fatigue and creep evaluation. While these controlled environments offer excellent repeatability, they often struggle to accurately replicate the complex, multi-factor stress conditions experienced in actual turbine operation.

Accelerated life testing has become a standard approach for evaluating long-term material performance within reasonable timeframes. This methodology applies stressors at intensities exceeding normal operating conditions to induce failure mechanisms more rapidly. Techniques such as thermal cycling, where components are rapidly shifted between temperature extremes, and thermo-mechanical fatigue testing, which combines mechanical loading with thermal variations, are commonly employed. However, the acceleration factors used can sometimes trigger failure modes that would not occur under normal operating conditions, leading to potentially misleading results.

Digital twin technology and computational modeling represent the cutting edge of current methodologies. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations allow engineers to predict material responses to complex stress combinations without physical testing. These approaches are increasingly incorporating machine learning algorithms to improve predictive accuracy based on historical test data. Despite their sophistication, these models still require validation against physical test results and struggle with accurately modeling certain microstructural changes over time.

A significant challenge in current testing methodologies is the difficulty in simultaneously applying multiple stress factors in proportions that accurately reflect real-world conditions. For instance, while a component may experience simultaneous high temperature, vibration, and corrosive atmosphere in operation, laboratory tests often isolate these factors or combine only two at a time due to equipment limitations.

Another persistent challenge is the time-scale disparity between accelerated testing and actual service life. Modern turbine components are designed for operational lifespans of 20,000+ hours, yet testing programs typically run for weeks or months. This necessitates extrapolation of results, introducing uncertainty, particularly for novel materials or designs without extensive service history.

Laboratory-based testing methodologies typically involve specialized equipment designed to replicate specific environmental stressors. These include high-temperature furnaces capable of reaching 1600°C for thermal stress testing, corrosion chambers that simulate salt spray and acidic environments, and mechanical testing apparatus for fatigue and creep evaluation. While these controlled environments offer excellent repeatability, they often struggle to accurately replicate the complex, multi-factor stress conditions experienced in actual turbine operation.

Accelerated life testing has become a standard approach for evaluating long-term material performance within reasonable timeframes. This methodology applies stressors at intensities exceeding normal operating conditions to induce failure mechanisms more rapidly. Techniques such as thermal cycling, where components are rapidly shifted between temperature extremes, and thermo-mechanical fatigue testing, which combines mechanical loading with thermal variations, are commonly employed. However, the acceleration factors used can sometimes trigger failure modes that would not occur under normal operating conditions, leading to potentially misleading results.

Digital twin technology and computational modeling represent the cutting edge of current methodologies. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations allow engineers to predict material responses to complex stress combinations without physical testing. These approaches are increasingly incorporating machine learning algorithms to improve predictive accuracy based on historical test data. Despite their sophistication, these models still require validation against physical test results and struggle with accurately modeling certain microstructural changes over time.

A significant challenge in current testing methodologies is the difficulty in simultaneously applying multiple stress factors in proportions that accurately reflect real-world conditions. For instance, while a component may experience simultaneous high temperature, vibration, and corrosive atmosphere in operation, laboratory tests often isolate these factors or combine only two at a time due to equipment limitations.

Another persistent challenge is the time-scale disparity between accelerated testing and actual service life. Modern turbine components are designed for operational lifespans of 20,000+ hours, yet testing programs typically run for weeks or months. This necessitates extrapolation of results, introducing uncertainty, particularly for novel materials or designs without extensive service history.

Contemporary Approaches to Abiotic Stress Factor Simulation

01 Thermal stress resistance in turbine engine components

Turbine engine metal components are subjected to extreme thermal stress during operation. Various methods and materials have been developed to enhance thermal stress resistance, including specialized coatings, thermal barrier systems, and advanced alloy compositions. These innovations help components withstand rapid temperature changes and thermal cycling, thereby extending component lifespan and improving engine efficiency under high-temperature operating conditions.- Thermal stress resistance in turbine components: Turbine engine metal components are subjected to extreme thermal stress during operation. Various technologies have been developed to enhance thermal stress resistance, including specialized coatings, thermal barrier systems, and advanced alloy compositions. These innovations help components withstand rapid temperature changes and thermal cycling, which are significant abiotic stress factors affecting turbine engine performance and longevity.

- Oxidation and corrosion resistance technologies: Oxidation and corrosion represent major abiotic stress factors for turbine engine metal components operating in harsh environments. Advanced surface treatments, protective coatings, and corrosion-resistant alloys have been developed to mitigate these stresses. These technologies extend component life by creating protective barriers against oxidative environments and corrosive agents encountered during turbine operation.

- Mechanical stress and fatigue management: Turbine engine components face significant mechanical stresses including vibration, centrifugal forces, and cyclic loading. Innovations in this area focus on structural design optimization, fatigue-resistant materials, and stress distribution techniques. These approaches help manage mechanical abiotic stress factors by enhancing component durability and preventing premature failure under high-stress operating conditions.

- Environmental degradation resistance: Turbine engine components are exposed to various environmental abiotic stressors including particulate erosion, foreign object damage, and extreme weather conditions. Technologies addressing these challenges include erosion-resistant coatings, particle deflection systems, and environmentally adaptive materials. These innovations help maintain component integrity and performance despite exposure to harsh and variable environmental conditions.

- Advanced materials and manufacturing techniques: Novel materials and manufacturing processes have been developed specifically to address multiple abiotic stress factors simultaneously. These include single-crystal superalloys, directionally solidified components, additive manufacturing techniques, and composite materials. These advanced approaches provide comprehensive protection against thermal, mechanical, and chemical stresses while optimizing weight, strength, and durability of turbine engine metal components.

02 Corrosion and oxidation protection systems

Metal components in turbine engines face severe corrosion and oxidation challenges due to exposure to combustion gases, moisture, and environmental contaminants. Protective coating systems, including aluminide coatings, MCrAlY overlays, and ceramic-based environmental barrier coatings, have been developed to mitigate these abiotic stress factors. These systems create protective oxide scales that prevent further degradation of the base metal, particularly in hot sections of the engine where oxidation rates accelerate.Expand Specific Solutions03 Mechanical stress and fatigue resistance improvements

Turbine engine components experience significant mechanical stresses including vibration, centrifugal forces, and cyclic loading. Advanced manufacturing techniques such as directional solidification, single crystal growth, and precision machining have been developed to enhance fatigue resistance. Additionally, surface treatments like shot peening, laser shock peening, and deep cold working introduce compressive residual stresses that improve fatigue life and crack resistance under the extreme mechanical loads experienced during engine operation.Expand Specific Solutions04 Advanced materials and alloy compositions

Specialized superalloys and composite materials have been developed specifically to withstand the combined abiotic stresses in turbine engines. These materials incorporate precise combinations of elements such as nickel, cobalt, chromium, aluminum, titanium, and various rare earth elements to optimize high-temperature strength, creep resistance, and environmental stability. Some innovations include oxide dispersion strengthened alloys, intermetallic compounds, and metal matrix composites that maintain structural integrity under extreme operating conditions.Expand Specific Solutions05 Monitoring and predictive maintenance systems

Advanced sensor systems and analytical methods have been developed to monitor and predict the effects of abiotic stress factors on turbine engine components. These technologies include real-time monitoring of component temperatures, vibration patterns, and material degradation. Predictive maintenance algorithms use this data to forecast potential failures before they occur, allowing for scheduled maintenance and component replacement before critical damage develops, thereby enhancing safety and reducing operational costs.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Turbine Technology

The testing of abiotic stress factors on turbine engine metal components is currently in a mature development phase, with a global market valued at approximately $5-7 billion annually and growing steadily. Major aerospace and power generation players dominate this competitive landscape, with Rolls-Royce, GE, RTX (formerly Raytheon), and Safran Aircraft Engines leading technological innovation. These companies have established sophisticated testing methodologies for thermal cycling, oxidation resistance, and mechanical stress evaluation. Emerging players like AECC South Industry and Toshiba Energy Systems are rapidly advancing their capabilities, while research institutions such as Zhejiang University and AVIC Shenyang Engine Research Institute contribute significant academic advancements. The industry is trending toward integrated digital twin simulations complementing physical testing protocols to enhance component durability in extreme operating environments.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has established a sophisticated testing framework for evaluating abiotic stress on turbine components that combines physical testing with digital twin technology. Their approach centers on "Integrated Component Testing" where multiple stress factors—thermal cycling, mechanical loading, and environmental exposure—are applied simultaneously rather than sequentially. This methodology more accurately replicates real-world operating conditions. Rolls-Royce's testing facilities include specialized environmental chambers capable of reproducing diverse atmospheric conditions from arctic cold to desert heat, with precise control of humidity, salt content, and particulate matter concentration. Their proprietary VORSYS (Vibration-Oxidation-Reaction System) allows for the evaluation of vibrational stress combined with chemical attack, particularly relevant for components in the hot section of turbines. The company has also developed non-destructive evaluation techniques using acoustic emission and thermographic imaging to monitor material degradation in real-time during stress testing, allowing for the collection of time-series data on failure progression.

Strengths: Industry-leading integration of digital twin technology with physical testing; exceptional capability to replicate complex operational environments with multiple stress factors. Weaknesses: Testing protocols are highly specialized for aviation applications and may require significant modification for other turbine applications; high operational costs for maintaining sophisticated test equipment.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed an integrated approach to testing abiotic stress factors on turbine components through their Advanced Materials Resilience Assessment Protocol (AMRAP). This system combines physical testing with multi-physics simulation to evaluate material performance under extreme conditions. Their methodology focuses particularly on the synergistic effects of multiple stress factors, recognizing that the combined impact of thermal cycling, mechanical loading, and environmental exposure often exceeds the sum of individual stressors. Safran's testing facilities include specialized equipment for evaluating sulfidation and hot corrosion resistance, with capabilities to simulate various fuel contaminant scenarios. Their proprietary high-velocity particle impingement testing system can reproduce erosion conditions experienced in desert or volcanic ash environments while simultaneously applying thermal gradients. Safran has also pioneered techniques for evaluating material performance under transient conditions, such as rapid thermal cycling that occurs during engine start-up and shutdown, which can induce particularly damaging thermal-mechanical fatigue.

Strengths: Exceptional capabilities for evaluating synergistic effects of multiple stress factors; specialized expertise in transient condition testing that accurately replicates operational cycles. Weaknesses: Testing methodologies are heavily optimized for aerospace applications; relatively limited experience with certain industrial turbine environments compared to some competitors.

Critical Patents and Research in Turbine Material Testing

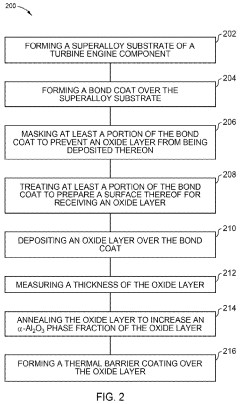

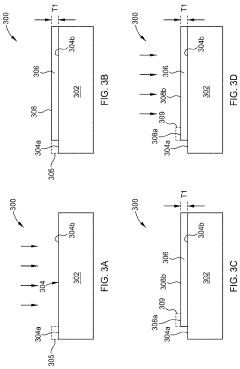

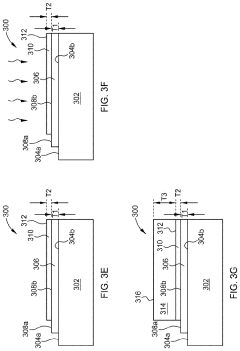

Oxide layer compositions for turbine engine components

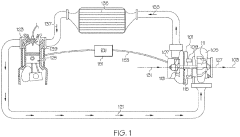

PatentInactiveUS20210381386A1

Innovation

- A turbine engine component with a superalloy substrate, a bond coat, an oxide layer containing aluminum oxide and a metal dopant, and a thermal barrier coating, where the oxide layer is deposited using methods like CVD, PVD, or ALD to slow TGO growth and improve adhesion, thereby extending TBC lifespan and preventing spalling.

Stainless steel alloys, turbocharger components formed from the stainless steel alloys, and methods for manufacturing the same

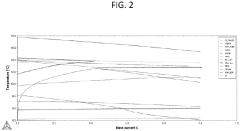

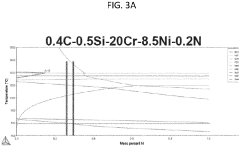

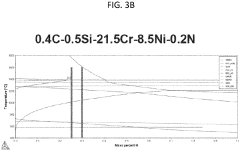

PatentActiveEP3816315A1

Innovation

- Development of an austenitic stainless steel alloy with a chromium content of 20.0% to 21.5%, nickel content of 8.5% to 10.0%, manganese content of 4.0% to 5.0%, silicon content of 0.5% to 2.0%, carbon content of 0.4% to 0.5%, and nitrogen content of 0.2% to 0.3%, excluding niobium, tungsten, and molybdenum beyond impurity levels, to achieve cost reduction and improved machinability while maintaining oxidation resistance.

Environmental Impact Assessment of Turbine Materials Testing

The environmental impact of turbine materials testing procedures represents a critical consideration in the development and validation of engine components. Testing abiotic stress factors on turbine engine metal components involves various processes that can generate significant environmental footprints if not properly managed. These testing procedures often utilize hazardous chemicals, consume substantial energy, and produce waste materials that require specialized disposal methods.

Primary environmental concerns include the release of heavy metals and specialized alloy particles during mechanical testing, which may contaminate soil and water systems if improperly contained. Thermal cycling tests, essential for evaluating material performance under extreme temperature conditions, typically require considerable energy inputs, contributing to carbon emissions when non-renewable energy sources are utilized. Additionally, corrosion testing frequently employs aggressive chemical solutions that present disposal challenges and potential environmental hazards.

Water consumption represents another significant environmental factor, particularly in cooling systems and certain stress tests. Modern testing facilities have implemented closed-loop water systems to minimize consumption, though these systems themselves require energy for operation and maintenance. Air quality impacts also emerge from testing operations, especially when evaluating components under combustion conditions or when using certain surface preparation techniques that release volatile organic compounds.

The lifecycle assessment of testing equipment reveals additional environmental considerations. Many specialized testing apparatuses contain rare earth elements and sophisticated electronics with limited recycling pathways. The manufacturing and eventual decommissioning of this equipment contributes to the overall environmental footprint of turbine materials testing operations.

Recent advancements have focused on developing more environmentally sustainable testing methodologies. Digital simulation and modeling approaches can reduce the number of physical tests required, thereby decreasing material waste and energy consumption. When physical testing remains necessary, miniaturized test specimens have gained popularity, requiring less material and energy while still providing statistically significant results.

Regulatory frameworks increasingly mandate environmental impact assessments for industrial testing facilities. Organizations like the International Organization for Standardization (ISO) have developed specific standards addressing environmental management in testing operations. Compliance with these standards not only ensures regulatory adherence but often yields operational efficiencies through improved resource management.

Forward-looking testing facilities have begun implementing comprehensive environmental management systems that track and minimize impacts across all testing operations. These systems typically incorporate energy efficiency measures, waste reduction protocols, and chemical management practices designed to mitigate environmental impacts while maintaining testing integrity and reliability.

Primary environmental concerns include the release of heavy metals and specialized alloy particles during mechanical testing, which may contaminate soil and water systems if improperly contained. Thermal cycling tests, essential for evaluating material performance under extreme temperature conditions, typically require considerable energy inputs, contributing to carbon emissions when non-renewable energy sources are utilized. Additionally, corrosion testing frequently employs aggressive chemical solutions that present disposal challenges and potential environmental hazards.

Water consumption represents another significant environmental factor, particularly in cooling systems and certain stress tests. Modern testing facilities have implemented closed-loop water systems to minimize consumption, though these systems themselves require energy for operation and maintenance. Air quality impacts also emerge from testing operations, especially when evaluating components under combustion conditions or when using certain surface preparation techniques that release volatile organic compounds.

The lifecycle assessment of testing equipment reveals additional environmental considerations. Many specialized testing apparatuses contain rare earth elements and sophisticated electronics with limited recycling pathways. The manufacturing and eventual decommissioning of this equipment contributes to the overall environmental footprint of turbine materials testing operations.

Recent advancements have focused on developing more environmentally sustainable testing methodologies. Digital simulation and modeling approaches can reduce the number of physical tests required, thereby decreasing material waste and energy consumption. When physical testing remains necessary, miniaturized test specimens have gained popularity, requiring less material and energy while still providing statistically significant results.

Regulatory frameworks increasingly mandate environmental impact assessments for industrial testing facilities. Organizations like the International Organization for Standardization (ISO) have developed specific standards addressing environmental management in testing operations. Compliance with these standards not only ensures regulatory adherence but often yields operational efficiencies through improved resource management.

Forward-looking testing facilities have begun implementing comprehensive environmental management systems that track and minimize impacts across all testing operations. These systems typically incorporate energy efficiency measures, waste reduction protocols, and chemical management practices designed to mitigate environmental impacts while maintaining testing integrity and reliability.

Standardization and Certification Requirements for Turbine Components

The standardization and certification landscape for turbine engine components subjected to abiotic stress testing is governed by a complex framework of international, regional, and industry-specific requirements. Organizations such as the International Organization for Standardization (ISO), ASTM International, and the Society of Automotive Engineers (SAE) have established comprehensive standards that define testing methodologies, acceptance criteria, and certification processes.

Key certification standards include ISO 21789 for gas turbine applications, which outlines specific requirements for testing metal components under various environmental stressors. Similarly, ASTM E606 provides standardized methods for strain-controlled fatigue testing, particularly relevant when evaluating how turbine components respond to thermal cycling and mechanical stress.

The aerospace sector imposes particularly stringent certification requirements through standards like AS9100 and RTCA DO-160, which mandate rigorous environmental stress testing protocols. These standards specify precise parameters for simulating altitude, temperature variation, humidity, salt spray, and vibration—all critical abiotic factors affecting turbine component performance and longevity.

Certification processes typically require documented evidence of component testing across multiple stress dimensions. This includes thermal shock resistance (per ASTM B553), corrosion resistance (ASTM B117), and mechanical fatigue under combined stress conditions. Test data must demonstrate that components maintain structural integrity and functional performance within specified tolerances when subjected to these environmental challenges.

Regulatory bodies like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification frameworks that incorporate these standards into airworthiness directives. For power generation applications, standards from the International Electrotechnical Commission (IEC) and IEEE provide additional certification requirements specific to turbine components in energy production environments.

Emerging trends in standardization include the development of more sophisticated test protocols that better simulate real-world combined stress scenarios. These advanced standards increasingly incorporate computational modeling validation requirements alongside physical testing, creating a more comprehensive certification approach. Additionally, there is growing emphasis on standardizing accelerated life testing methodologies to predict long-term component performance under various abiotic stress conditions.

Manufacturers seeking certification must navigate this complex landscape by implementing robust quality management systems that ensure consistent compliance with relevant standards throughout the design, testing, and production processes. Documentation requirements have become increasingly stringent, with detailed test reports, material certifications, and process validations forming essential components of the certification package.

Key certification standards include ISO 21789 for gas turbine applications, which outlines specific requirements for testing metal components under various environmental stressors. Similarly, ASTM E606 provides standardized methods for strain-controlled fatigue testing, particularly relevant when evaluating how turbine components respond to thermal cycling and mechanical stress.

The aerospace sector imposes particularly stringent certification requirements through standards like AS9100 and RTCA DO-160, which mandate rigorous environmental stress testing protocols. These standards specify precise parameters for simulating altitude, temperature variation, humidity, salt spray, and vibration—all critical abiotic factors affecting turbine component performance and longevity.

Certification processes typically require documented evidence of component testing across multiple stress dimensions. This includes thermal shock resistance (per ASTM B553), corrosion resistance (ASTM B117), and mechanical fatigue under combined stress conditions. Test data must demonstrate that components maintain structural integrity and functional performance within specified tolerances when subjected to these environmental challenges.

Regulatory bodies like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification frameworks that incorporate these standards into airworthiness directives. For power generation applications, standards from the International Electrotechnical Commission (IEC) and IEEE provide additional certification requirements specific to turbine components in energy production environments.

Emerging trends in standardization include the development of more sophisticated test protocols that better simulate real-world combined stress scenarios. These advanced standards increasingly incorporate computational modeling validation requirements alongside physical testing, creating a more comprehensive certification approach. Additionally, there is growing emphasis on standardizing accelerated life testing methodologies to predict long-term component performance under various abiotic stress conditions.

Manufacturers seeking certification must navigate this complex landscape by implementing robust quality management systems that ensure consistent compliance with relevant standards throughout the design, testing, and production processes. Documentation requirements have become increasingly stringent, with detailed test reports, material certifications, and process validations forming essential components of the certification package.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!