How to Improve Fuel Distribution in Turbine Engines

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Fuel Distribution Background and Objectives

Turbine engines have been the cornerstone of aviation propulsion since their introduction in the mid-20th century. The evolution of fuel distribution systems within these engines has undergone significant transformations, from early mechanical systems to today's sophisticated electronic control mechanisms. This technological progression has been driven by the continuous pursuit of higher efficiency, reduced emissions, and enhanced reliability in increasingly demanding operational environments.

The fundamental challenge in turbine engine fuel distribution lies in delivering precisely metered fuel across varying operational conditions—from idle to maximum thrust, and from sea level to high-altitude flight. Historical approaches focused primarily on mechanical solutions, with hydromechanical fuel controls dominating until the 1970s. The subsequent decades witnessed a gradual transition toward electronic control systems, culminating in today's Full Authority Digital Engine Control (FADEC) systems that optimize fuel distribution with unprecedented precision.

Current technological trends indicate a movement toward even more sophisticated distribution systems incorporating advanced sensors, predictive algorithms, and adaptive control mechanisms. These innovations aim to address the persistent challenges of combustion stability, thermal management, and emissions reduction that continue to constrain engine performance. The industry is increasingly exploring novel injection technologies, alternative fuel compatibility, and real-time combustion monitoring to further refine fuel distribution processes.

The global imperative for reduced environmental impact has accelerated research into fuel distribution systems that can minimize pollutant formation through more homogeneous combustion. Concurrently, military applications demand fuel systems capable of operating under extreme conditions while maintaining optimal performance characteristics. These divergent requirements are shaping the technological landscape of turbine engine development.

The primary objectives of improving fuel distribution in turbine engines encompass several interconnected goals: enhancing thermodynamic efficiency to reduce specific fuel consumption; minimizing emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons; extending component lifespan through more uniform temperature distributions; improving transient response characteristics; and ensuring reliable operation across an expanded flight envelope. Additionally, next-generation systems must accommodate alternative and sustainable aviation fuels without compromising performance or durability.

As we look toward future developments, the integration of computational fluid dynamics modeling, advanced materials science, and artificial intelligence promises to revolutionize how fuel is distributed within turbine engines. These technological frontiers represent the next evolutionary step in a field that continues to push the boundaries of engineering capability in pursuit of more efficient, cleaner, and more reliable propulsion systems.

The fundamental challenge in turbine engine fuel distribution lies in delivering precisely metered fuel across varying operational conditions—from idle to maximum thrust, and from sea level to high-altitude flight. Historical approaches focused primarily on mechanical solutions, with hydromechanical fuel controls dominating until the 1970s. The subsequent decades witnessed a gradual transition toward electronic control systems, culminating in today's Full Authority Digital Engine Control (FADEC) systems that optimize fuel distribution with unprecedented precision.

Current technological trends indicate a movement toward even more sophisticated distribution systems incorporating advanced sensors, predictive algorithms, and adaptive control mechanisms. These innovations aim to address the persistent challenges of combustion stability, thermal management, and emissions reduction that continue to constrain engine performance. The industry is increasingly exploring novel injection technologies, alternative fuel compatibility, and real-time combustion monitoring to further refine fuel distribution processes.

The global imperative for reduced environmental impact has accelerated research into fuel distribution systems that can minimize pollutant formation through more homogeneous combustion. Concurrently, military applications demand fuel systems capable of operating under extreme conditions while maintaining optimal performance characteristics. These divergent requirements are shaping the technological landscape of turbine engine development.

The primary objectives of improving fuel distribution in turbine engines encompass several interconnected goals: enhancing thermodynamic efficiency to reduce specific fuel consumption; minimizing emissions of nitrogen oxides, carbon monoxide, and unburned hydrocarbons; extending component lifespan through more uniform temperature distributions; improving transient response characteristics; and ensuring reliable operation across an expanded flight envelope. Additionally, next-generation systems must accommodate alternative and sustainable aviation fuels without compromising performance or durability.

As we look toward future developments, the integration of computational fluid dynamics modeling, advanced materials science, and artificial intelligence promises to revolutionize how fuel is distributed within turbine engines. These technological frontiers represent the next evolutionary step in a field that continues to push the boundaries of engineering capability in pursuit of more efficient, cleaner, and more reliable propulsion systems.

Market Demand Analysis for Enhanced Fuel Distribution Systems

The global market for enhanced fuel distribution systems in turbine engines is experiencing robust growth, driven primarily by the aviation and power generation sectors. Current market valuations indicate that the aerospace turbine engine market alone exceeds $45 billion annually, with fuel distribution systems representing approximately 8-10% of this value. Industry forecasts project a compound annual growth rate of 6.2% through 2030, significantly outpacing general industrial growth rates.

Customer demand for improved fuel distribution systems stems from several critical market pressures. First, stringent environmental regulations worldwide are forcing engine manufacturers to develop solutions that reduce emissions while maintaining or improving performance. The International Civil Aviation Organization (ICAO) has established increasingly strict standards for NOx and particulate emissions, creating immediate market pull for advanced fuel distribution technologies that can achieve more complete combustion.

Economic factors are equally compelling market drivers. Commercial airlines operate on thin profit margins, with fuel costs representing 20-30% of operating expenses. Even marginal improvements in fuel efficiency translate to substantial cost savings at scale. A 1% improvement in fuel efficiency can result in annual savings of $300,000-$600,000 per aircraft, creating strong financial incentives for adoption of enhanced distribution systems.

Military applications represent another significant market segment, where performance requirements often supersede cost considerations. Defense contractors seek fuel distribution systems that enable rapid throttle response, operation across extreme environmental conditions, and compatibility with alternative fuels. This segment values reliability and performance over initial acquisition costs.

The industrial gas turbine market presents additional opportunities, particularly as distributed power generation gains prominence. This sector demands fuel distribution systems that can accommodate variable fuel compositions while maintaining stable combustion characteristics across different load profiles.

Regional analysis reveals that North America and Europe currently dominate market demand, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.7% annually, driven by expanding aviation markets and power generation needs.

Customer requirements are evolving toward systems that offer multi-fuel capability, reduced maintenance intervals, and integrated digital monitoring. The ability to precisely control fuel-air mixtures across all operating conditions has become a key differentiator in the marketplace, with customers willing to pay premium prices for systems that deliver measurable efficiency improvements and emissions reductions.

Customer demand for improved fuel distribution systems stems from several critical market pressures. First, stringent environmental regulations worldwide are forcing engine manufacturers to develop solutions that reduce emissions while maintaining or improving performance. The International Civil Aviation Organization (ICAO) has established increasingly strict standards for NOx and particulate emissions, creating immediate market pull for advanced fuel distribution technologies that can achieve more complete combustion.

Economic factors are equally compelling market drivers. Commercial airlines operate on thin profit margins, with fuel costs representing 20-30% of operating expenses. Even marginal improvements in fuel efficiency translate to substantial cost savings at scale. A 1% improvement in fuel efficiency can result in annual savings of $300,000-$600,000 per aircraft, creating strong financial incentives for adoption of enhanced distribution systems.

Military applications represent another significant market segment, where performance requirements often supersede cost considerations. Defense contractors seek fuel distribution systems that enable rapid throttle response, operation across extreme environmental conditions, and compatibility with alternative fuels. This segment values reliability and performance over initial acquisition costs.

The industrial gas turbine market presents additional opportunities, particularly as distributed power generation gains prominence. This sector demands fuel distribution systems that can accommodate variable fuel compositions while maintaining stable combustion characteristics across different load profiles.

Regional analysis reveals that North America and Europe currently dominate market demand, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 8.7% annually, driven by expanding aviation markets and power generation needs.

Customer requirements are evolving toward systems that offer multi-fuel capability, reduced maintenance intervals, and integrated digital monitoring. The ability to precisely control fuel-air mixtures across all operating conditions has become a key differentiator in the marketplace, with customers willing to pay premium prices for systems that deliver measurable efficiency improvements and emissions reductions.

Current Challenges in Turbine Engine Fuel Distribution

Despite significant advancements in turbine engine technology, fuel distribution remains a critical challenge affecting performance, efficiency, and emissions. Current turbine engines face several persistent issues in achieving optimal fuel distribution across combustion chambers. The primary challenge lies in maintaining uniform fuel-air mixture ratios throughout the combustion zone, particularly during transient operations such as rapid acceleration or deceleration. This non-uniformity leads to localized hot spots, incomplete combustion, and increased emissions of nitrogen oxides (NOx) and carbon monoxide.

Fuel atomization quality presents another significant hurdle, as inadequate atomization results in larger droplets that burn inefficiently and create carbon deposits on fuel nozzles. These deposits progressively alter spray patterns and exacerbate distribution problems over time. Modern high-bypass ratio engines with their more compact combustors further complicate this issue by providing less space for proper fuel-air mixing before ignition occurs.

Altitude and environmental variations introduce additional complexities, as changing air densities and temperatures significantly impact fuel atomization and vaporization characteristics. Current fuel injection systems struggle to maintain optimal spray patterns across the wide operational envelope of modern aircraft, from sea level to high-altitude cruise conditions.

Fuel system response time remains problematic during rapid power changes, where momentary rich or lean conditions can occur before the system achieves steady-state operation. This lag contributes to combustion instabilities, potential flame-outs during critical flight phases, and increased maintenance requirements due to thermal cycling of components.

The integration of alternative and sustainable aviation fuels presents emerging challenges, as these fuels often exhibit different viscosity, energy density, and atomization properties compared to conventional jet fuels. Current distribution systems designed for traditional fuels may require significant modifications to accommodate these newer fuel formulations effectively.

Advanced computational fluid dynamics (CFD) modeling has revealed complex flow interactions within combustion chambers that were previously not well understood. These include recirculation zones, vortex formations, and boundary layer effects that significantly influence fuel distribution patterns but are difficult to control with conventional injection technologies.

Manufacturing tolerances and component wear over operational lifecycles further compound distribution challenges, as minute variations in injector geometry can produce substantial differences in spray patterns. The industry currently lacks cost-effective methods for real-time monitoring of fuel distribution quality during engine operation, making it difficult to implement adaptive control strategies.

Fuel atomization quality presents another significant hurdle, as inadequate atomization results in larger droplets that burn inefficiently and create carbon deposits on fuel nozzles. These deposits progressively alter spray patterns and exacerbate distribution problems over time. Modern high-bypass ratio engines with their more compact combustors further complicate this issue by providing less space for proper fuel-air mixing before ignition occurs.

Altitude and environmental variations introduce additional complexities, as changing air densities and temperatures significantly impact fuel atomization and vaporization characteristics. Current fuel injection systems struggle to maintain optimal spray patterns across the wide operational envelope of modern aircraft, from sea level to high-altitude cruise conditions.

Fuel system response time remains problematic during rapid power changes, where momentary rich or lean conditions can occur before the system achieves steady-state operation. This lag contributes to combustion instabilities, potential flame-outs during critical flight phases, and increased maintenance requirements due to thermal cycling of components.

The integration of alternative and sustainable aviation fuels presents emerging challenges, as these fuels often exhibit different viscosity, energy density, and atomization properties compared to conventional jet fuels. Current distribution systems designed for traditional fuels may require significant modifications to accommodate these newer fuel formulations effectively.

Advanced computational fluid dynamics (CFD) modeling has revealed complex flow interactions within combustion chambers that were previously not well understood. These include recirculation zones, vortex formations, and boundary layer effects that significantly influence fuel distribution patterns but are difficult to control with conventional injection technologies.

Manufacturing tolerances and component wear over operational lifecycles further compound distribution challenges, as minute variations in injector geometry can produce substantial differences in spray patterns. The industry currently lacks cost-effective methods for real-time monitoring of fuel distribution quality during engine operation, making it difficult to implement adaptive control strategies.

Current Fuel Distribution Solutions and Methodologies

01 Fuel distribution systems for gas turbine engines

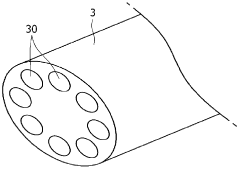

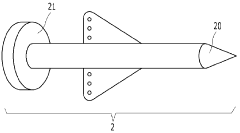

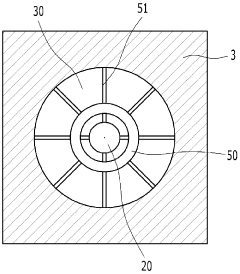

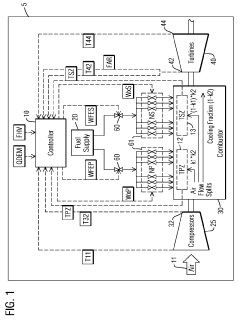

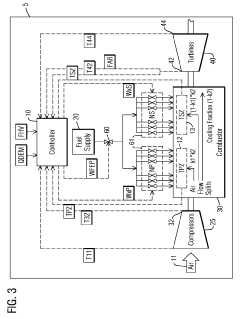

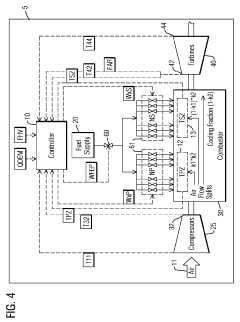

Specialized systems designed to distribute fuel efficiently throughout gas turbine engines. These systems typically include manifolds, valves, and control mechanisms that ensure proper fuel flow to combustion chambers. Advanced distribution systems can adjust fuel delivery based on engine operating conditions, optimizing performance and efficiency while maintaining stable combustion across various power settings.- Fuel distribution systems for gas turbine engines: Fuel distribution systems in gas turbine engines are designed to deliver fuel efficiently to combustion chambers. These systems typically include fuel manifolds, distribution valves, and injection nozzles that ensure proper atomization and distribution of fuel across multiple combustion zones. Advanced systems incorporate sensors and control mechanisms to optimize fuel-air ratios and combustion efficiency under varying operating conditions.

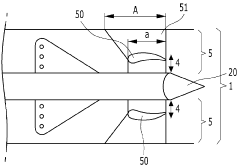

- Staged fuel injection techniques: Staged fuel injection involves delivering fuel to different zones of the combustion chamber at varying rates or timings. This approach allows for better control of the combustion process, reduced emissions, and improved engine performance across different power settings. Modern turbine engines employ multiple fuel stages that can be independently controlled to optimize combustion stability, efficiency, and emissions characteristics throughout the flight envelope.

- Fuel atomization and mixing improvements: Enhanced fuel atomization and mixing technologies focus on breaking fuel into finer droplets and ensuring thorough mixing with air before combustion. These technologies include advanced nozzle designs, swirlers, and pre-mixing chambers that promote homogeneous fuel-air mixtures. Better atomization and mixing lead to more complete combustion, reduced fuel consumption, lower emissions, and extended component life due to more uniform temperature distribution.

- Electronic fuel control systems: Electronic fuel control systems utilize digital technology to precisely manage fuel flow rates based on multiple engine parameters. These systems incorporate sensors, electronic control units, and actuators to dynamically adjust fuel distribution according to thrust demands, ambient conditions, and engine health. Advanced control algorithms enable features such as automatic power recovery, transient response optimization, and fault detection, significantly improving engine reliability and performance.

- Fuel distribution for alternative fuels: Specialized fuel distribution systems are being developed to accommodate alternative fuels such as hydrogen, biofuels, and synthetic fuels in turbine engines. These systems address the unique properties of alternative fuels, including different energy densities, viscosities, and combustion characteristics. Modifications to fuel delivery components, sealing materials, and control parameters ensure efficient operation while maintaining engine performance and durability when using non-conventional fuel sources.

02 Fuel injection and atomization techniques

Methods and devices for injecting and atomizing fuel in turbine engines to improve combustion efficiency. These techniques focus on creating optimal fuel droplet size and distribution patterns within the combustion chamber. Enhanced atomization leads to more complete combustion, reduced emissions, and improved engine performance across various operating conditions.Expand Specific Solutions03 Fuel flow control and regulation mechanisms

Systems that precisely control and regulate fuel flow to turbine engines based on operational requirements. These mechanisms include electronic control units, flow regulators, and metering devices that adjust fuel delivery in response to changing power demands, environmental conditions, and engine parameters. Advanced control systems can optimize fuel-air ratios for different operating modes, enhancing efficiency and reducing emissions.Expand Specific Solutions04 Multi-stage combustion and fuel staging

Techniques for distributing fuel across multiple combustion stages or zones within turbine engines. These approaches involve strategic fuel delivery to different areas of the combustion chamber to optimize the combustion process. Fuel staging can help manage temperature profiles, reduce emissions, and improve combustion stability across various operating conditions, particularly during startup, idle, and power transitions.Expand Specific Solutions05 Alternative fuel compatibility and dual-fuel systems

Fuel distribution systems designed to accommodate alternative fuels or operate with multiple fuel types in turbine engines. These systems include specialized components and control strategies that allow engines to run on different fuels, either individually or in combination. Dual-fuel capabilities provide operational flexibility, potential cost savings, and environmental benefits through the use of cleaner or more readily available fuel sources.Expand Specific Solutions

Key Industry Players in Turbine Engine Fuel Technology

The fuel distribution technology in turbine engines is currently in a mature development stage, with a global market size estimated at $15 billion and growing steadily at 4-5% annually. Key industry players demonstrate varying levels of technical maturity: Rolls-Royce, GE, and Pratt & Whitney (RTX) lead with advanced fuel atomization and distribution systems, while Siemens Energy and Solar Turbines have made significant progress in combustion efficiency innovations. Emerging competitors like Safran and Mitsubishi Heavy Industries are rapidly advancing their capabilities through strategic R&D investments. The competitive landscape is characterized by increasing focus on sustainable fuels integration and digital control systems, with established aerospace players extending their technological advantages into adjacent industrial turbine applications.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced fuel distribution systems for turbine engines featuring their patented Fuel Spray Nozzle technology with enhanced atomization capabilities. Their system incorporates a staged combustion approach where fuel is introduced through multiple injection points that activate based on power requirements. This allows for precise fuel-air mixture control across various operating conditions. The company has implemented advanced computational fluid dynamics (CFD) modeling to optimize fuel spray patterns and combustion chamber design, resulting in more uniform temperature distribution and reduced hot spots. Their latest systems include adaptive fuel distribution that continuously adjusts based on real-time engine parameters and environmental conditions, utilizing sophisticated electronic control units (ECUs) that can make microsecond adjustments to fuel flow rates. Rolls-Royce has also pioneered the integration of additive manufacturing techniques to create complex fuel injector geometries that would be impossible with traditional manufacturing methods.

Strengths: Superior atomization technology leads to more complete combustion and lower emissions. Their adaptive systems provide optimal performance across diverse operating conditions. Weaknesses: The complex systems require sophisticated maintenance procedures and specialized training for service personnel. Higher initial manufacturing costs compared to conventional systems.

General Electric Company

Technical Solution: GE's approach to improving fuel distribution in turbine engines centers on their Advanced Fuel Injection (AFI) technology. Their system utilizes a dual-annular counter-rotating swirler design that creates an optimal air-fuel mixture through enhanced turbulence and improved atomization. GE has implemented precision fuel metering through digitally controlled valves that can adjust fuel flow with millisecond response times. Their TAPS (Twin Annular Premixing Swirler) combustion system features multiple fuel injection points arranged in concentric rings, allowing for staged combustion that optimizes performance across different power settings. The company has also developed integrated sensor networks that provide real-time feedback on combustion conditions, enabling dynamic adjustments to fuel distribution patterns. GE's latest innovations include 3D-printed fuel nozzles with intricate internal geometries that promote more efficient mixing and combustion, resulting in up to 15% improvement in fuel efficiency compared to conventional designs while significantly reducing NOx emissions.

Strengths: Industry-leading fuel efficiency gains and emissions reduction. Robust digital control systems allow for precise optimization across the entire flight envelope. Weaknesses: Higher complexity increases potential failure points. The advanced systems require more sophisticated diagnostic equipment and maintenance procedures.

Critical Patents and Innovations in Fuel Distribution

Gas turbine provided with a device for improved fuel flow distribution.

PatentActiveKR1020170003050A

Innovation

- A device with improved fuel flow distribution is implemented, featuring a vane with an airfoil or straight cross-section and a main ring, positioned in the gap between the fuel supply nozzle and case, to evenly distribute the fuel and air mixture, reducing recirculation zones and protecting the nozzle tips.

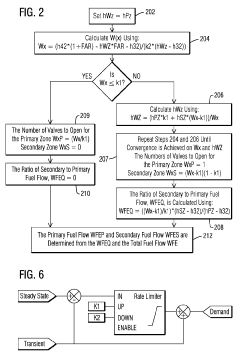

Method for controlling fuel distribution in a gas turbine engine with multiple combustion zones

PatentActiveUS20190234315A1

Innovation

- A method for distributing fuel in gas turbine engines by determining the ratio of air flow burnt to total air flow through combustion zones using weighted enthalpy sums and transient fractions, calculated by a controller to achieve predetermined flame temperatures, which decouples steady state and transient methods for efficient and responsive fuel control.

Environmental Impact and Emission Reduction Opportunities

Improving fuel distribution in turbine engines has significant environmental implications that extend beyond operational efficiency. The combustion process in turbine engines produces various pollutants including nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter. These emissions contribute to air pollution, smog formation, and climate change through greenhouse gas effects.

Enhanced fuel distribution systems directly correlate with reduced emissions profiles. When fuel is distributed more uniformly across combustion chambers, it creates more complete combustion conditions, significantly decreasing the formation of partial combustion products like CO and UHC. Studies indicate that optimized fuel-air mixing can reduce NOx emissions by 20-30% compared to conventional systems.

Advanced fuel distribution technologies also enable leaner combustion regimes, where excess air reduces peak flame temperatures and consequently suppresses thermal NOx formation. Staged combustion approaches, facilitated by precise fuel distribution control, can maintain performance while operating in these environmentally advantageous conditions.

The aviation sector, a major user of turbine engines, faces increasing regulatory pressure to reduce its environmental footprint. ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) and the EU's emissions trading system exemplify the growing global focus on aviation emissions reduction. Improved fuel distribution represents a critical pathway to compliance with these evolving standards.

Beyond regulatory compliance, emission reduction through better fuel distribution offers economic benefits. Carbon taxation schemes and emissions trading systems increasingly monetize environmental impacts, creating direct financial incentives for cleaner combustion technologies. Additionally, reduced fuel consumption translates to lower carbon dioxide emissions, addressing climate change concerns.

Emerging technologies such as low-emission combustors leverage advanced fuel distribution methods to achieve substantial environmental improvements. These include variable geometry fuel injectors, micro-mixing fuel preparation systems, and electronically controlled distribution networks that adapt to changing operational conditions. Such innovations can reduce lifecycle carbon emissions by 15-25% compared to previous generation systems.

The environmental benefits extend to noise reduction as well. More uniform combustion processes tend to produce more stable flame characteristics, reducing combustion-induced pressure oscillations that contribute to engine noise. This addresses another significant environmental concern, particularly for communities near airports and industrial facilities utilizing turbine engines.

Enhanced fuel distribution systems directly correlate with reduced emissions profiles. When fuel is distributed more uniformly across combustion chambers, it creates more complete combustion conditions, significantly decreasing the formation of partial combustion products like CO and UHC. Studies indicate that optimized fuel-air mixing can reduce NOx emissions by 20-30% compared to conventional systems.

Advanced fuel distribution technologies also enable leaner combustion regimes, where excess air reduces peak flame temperatures and consequently suppresses thermal NOx formation. Staged combustion approaches, facilitated by precise fuel distribution control, can maintain performance while operating in these environmentally advantageous conditions.

The aviation sector, a major user of turbine engines, faces increasing regulatory pressure to reduce its environmental footprint. ICAO's CORSIA (Carbon Offsetting and Reduction Scheme for International Aviation) and the EU's emissions trading system exemplify the growing global focus on aviation emissions reduction. Improved fuel distribution represents a critical pathway to compliance with these evolving standards.

Beyond regulatory compliance, emission reduction through better fuel distribution offers economic benefits. Carbon taxation schemes and emissions trading systems increasingly monetize environmental impacts, creating direct financial incentives for cleaner combustion technologies. Additionally, reduced fuel consumption translates to lower carbon dioxide emissions, addressing climate change concerns.

Emerging technologies such as low-emission combustors leverage advanced fuel distribution methods to achieve substantial environmental improvements. These include variable geometry fuel injectors, micro-mixing fuel preparation systems, and electronically controlled distribution networks that adapt to changing operational conditions. Such innovations can reduce lifecycle carbon emissions by 15-25% compared to previous generation systems.

The environmental benefits extend to noise reduction as well. More uniform combustion processes tend to produce more stable flame characteristics, reducing combustion-induced pressure oscillations that contribute to engine noise. This addresses another significant environmental concern, particularly for communities near airports and industrial facilities utilizing turbine engines.

Materials Science Advancements for Fuel System Components

Recent advancements in materials science have revolutionized the development of fuel system components in turbine engines, directly impacting fuel distribution efficiency. High-temperature resistant alloys, including nickel-based superalloys and titanium aluminides, have emerged as critical materials for fuel nozzles and injectors, maintaining structural integrity under extreme thermal conditions while preventing premature fuel vaporization.

Ceramic matrix composites (CMCs) represent a significant breakthrough, offering exceptional thermal resistance with substantially reduced weight compared to traditional metal components. These materials enable the design of more intricate fuel distribution channels that maintain precise geometries even under thermal cycling, resulting in more consistent spray patterns and improved atomization characteristics.

Surface engineering technologies have similarly transformed fuel system performance through the application of specialized coatings. Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia provide critical insulation for metallic substrates, while anti-coking coatings utilizing chromium-aluminum compounds significantly reduce carbon deposit formation in fuel passages—a common cause of flow restriction and distribution imbalance.

Advanced polymer composites with enhanced chemical resistance properties are increasingly utilized in low-temperature sections of fuel systems. These materials offer superior compatibility with modern aviation fuels containing various additives, preventing degradation issues that could compromise fuel delivery precision. Fluoropolymer linings, in particular, demonstrate exceptional resistance to chemical attack while maintaining dimensional stability.

Additive manufacturing techniques have enabled the production of previously impossible geometries in fuel system components. Direct metal laser sintering (DMLS) and electron beam melting (EBM) processes allow for the creation of complex internal cooling passages and optimized fuel flow paths that would be unachievable through conventional manufacturing methods. These techniques facilitate the integration of variable cross-section channels that dynamically respond to different operating conditions.

Nanomaterial integration represents the cutting edge of fuel system component development. Carbon nanotube reinforced metals exhibit extraordinary strength-to-weight ratios and thermal conductivity properties, enabling more responsive thermal management within fuel delivery systems. Meanwhile, nanostructured catalytic surfaces incorporated into fuel passages promote more complete fuel atomization and can potentially reduce emissions through enhanced combustion efficiency.

Self-healing material systems are emerging as a promising solution for maintaining long-term fuel distribution performance. These innovative materials incorporate microcapsules containing repair agents that automatically release when microscopic cracks form, preventing the progressive deterioration of critical flow geometries and maintaining consistent fuel spray patterns throughout the operational lifecycle of engine components.

Ceramic matrix composites (CMCs) represent a significant breakthrough, offering exceptional thermal resistance with substantially reduced weight compared to traditional metal components. These materials enable the design of more intricate fuel distribution channels that maintain precise geometries even under thermal cycling, resulting in more consistent spray patterns and improved atomization characteristics.

Surface engineering technologies have similarly transformed fuel system performance through the application of specialized coatings. Thermal barrier coatings (TBCs) based on yttria-stabilized zirconia provide critical insulation for metallic substrates, while anti-coking coatings utilizing chromium-aluminum compounds significantly reduce carbon deposit formation in fuel passages—a common cause of flow restriction and distribution imbalance.

Advanced polymer composites with enhanced chemical resistance properties are increasingly utilized in low-temperature sections of fuel systems. These materials offer superior compatibility with modern aviation fuels containing various additives, preventing degradation issues that could compromise fuel delivery precision. Fluoropolymer linings, in particular, demonstrate exceptional resistance to chemical attack while maintaining dimensional stability.

Additive manufacturing techniques have enabled the production of previously impossible geometries in fuel system components. Direct metal laser sintering (DMLS) and electron beam melting (EBM) processes allow for the creation of complex internal cooling passages and optimized fuel flow paths that would be unachievable through conventional manufacturing methods. These techniques facilitate the integration of variable cross-section channels that dynamically respond to different operating conditions.

Nanomaterial integration represents the cutting edge of fuel system component development. Carbon nanotube reinforced metals exhibit extraordinary strength-to-weight ratios and thermal conductivity properties, enabling more responsive thermal management within fuel delivery systems. Meanwhile, nanostructured catalytic surfaces incorporated into fuel passages promote more complete fuel atomization and can potentially reduce emissions through enhanced combustion efficiency.

Self-healing material systems are emerging as a promising solution for maintaining long-term fuel distribution performance. These innovative materials incorporate microcapsules containing repair agents that automatically release when microscopic cracks form, preventing the progressive deterioration of critical flow geometries and maintaining consistent fuel spray patterns throughout the operational lifecycle of engine components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!