Strategic Blade Geometry for Enhanced Turbine Engine Thrust

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Blade Geometry Evolution and Objectives

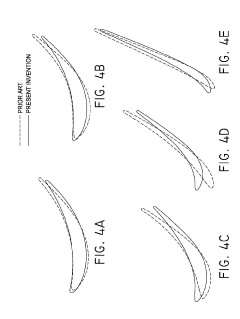

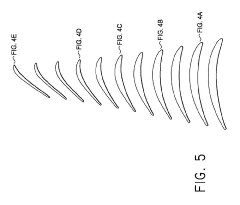

The evolution of turbine blade geometry has undergone significant transformations since the inception of jet engines in the 1940s. Initially, turbine blades featured simple, straight designs with minimal aerodynamic considerations. By the 1960s, engineers began implementing twisted blade profiles to accommodate varying gas flow velocities at different radial positions, marking the first major geometric innovation in turbine design.

The 1970s and 1980s witnessed the introduction of advanced cooling techniques, necessitating complex internal passages within blade structures. This period saw the emergence of film cooling holes and serpentine cooling channels, fundamentally altering blade geometry to balance thermal management with aerodynamic performance. The incorporation of these features represented a critical evolutionary step in maintaining blade integrity under increasingly extreme operating conditions.

The 1990s brought computational fluid dynamics (CFD) into mainstream design processes, enabling more sophisticated three-dimensional blade geometries. This computational revolution facilitated the development of swept and leaned blade configurations that could better manage secondary flows and shock wave interactions, directly enhancing engine thrust capabilities while reducing aerodynamic losses.

Material advancements in the early 2000s, particularly in single-crystal superalloys and ceramic matrix composites, allowed for thinner, more intricate blade geometries that could withstand higher temperatures. These material innovations permitted more aggressive aerodynamic profiles previously considered structurally unfeasible, resulting in measurable thrust improvements without increasing engine size or weight.

The current technological frontier focuses on adaptive and variable geometry concepts, where blade shapes can dynamically respond to changing flight conditions. Research into morphing blade technologies aims to optimize performance across diverse operating regimes, potentially revolutionizing the thrust-to-weight ratio paradigm in modern turbofan engines.

The primary objective of strategic blade geometry development is to maximize thrust while minimizing fuel consumption, achieved through optimized gas path management. Secondary objectives include extending component lifespan by reducing thermal stresses and improving off-design performance to maintain efficiency across varying flight envelopes. Engineers also aim to enhance manufacturability of complex geometries through advanced production techniques like additive manufacturing.

Looking forward, the industry trajectory points toward biomimetic blade designs that incorporate nature-inspired features such as tubercles or serrations to further improve aerodynamic efficiency. The ultimate goal remains achieving the theoretical maximum propulsive efficiency while maintaining structural integrity under increasingly demanding operating conditions.

The 1970s and 1980s witnessed the introduction of advanced cooling techniques, necessitating complex internal passages within blade structures. This period saw the emergence of film cooling holes and serpentine cooling channels, fundamentally altering blade geometry to balance thermal management with aerodynamic performance. The incorporation of these features represented a critical evolutionary step in maintaining blade integrity under increasingly extreme operating conditions.

The 1990s brought computational fluid dynamics (CFD) into mainstream design processes, enabling more sophisticated three-dimensional blade geometries. This computational revolution facilitated the development of swept and leaned blade configurations that could better manage secondary flows and shock wave interactions, directly enhancing engine thrust capabilities while reducing aerodynamic losses.

Material advancements in the early 2000s, particularly in single-crystal superalloys and ceramic matrix composites, allowed for thinner, more intricate blade geometries that could withstand higher temperatures. These material innovations permitted more aggressive aerodynamic profiles previously considered structurally unfeasible, resulting in measurable thrust improvements without increasing engine size or weight.

The current technological frontier focuses on adaptive and variable geometry concepts, where blade shapes can dynamically respond to changing flight conditions. Research into morphing blade technologies aims to optimize performance across diverse operating regimes, potentially revolutionizing the thrust-to-weight ratio paradigm in modern turbofan engines.

The primary objective of strategic blade geometry development is to maximize thrust while minimizing fuel consumption, achieved through optimized gas path management. Secondary objectives include extending component lifespan by reducing thermal stresses and improving off-design performance to maintain efficiency across varying flight envelopes. Engineers also aim to enhance manufacturability of complex geometries through advanced production techniques like additive manufacturing.

Looking forward, the industry trajectory points toward biomimetic blade designs that incorporate nature-inspired features such as tubercles or serrations to further improve aerodynamic efficiency. The ultimate goal remains achieving the theoretical maximum propulsive efficiency while maintaining structural integrity under increasingly demanding operating conditions.

Market Demand for High-Thrust Engine Technologies

The global market for high-thrust engine technologies has experienced substantial growth over the past decade, driven primarily by increasing demand in commercial aviation, military applications, and space exploration. According to industry reports, the commercial aircraft engine market alone was valued at approximately $68 billion in 2022, with projections indicating a compound annual growth rate of 7.1% through 2030.

The demand for enhanced thrust capabilities stems from several key market factors. Airlines are continuously seeking more fuel-efficient engines that can deliver higher thrust-to-weight ratios, reducing operational costs while meeting increasingly stringent environmental regulations. This has created a significant market pull for advanced blade geometry solutions that can optimize airflow and combustion efficiency.

Military aviation represents another substantial market segment, with defense departments worldwide investing heavily in next-generation fighter and transport aircraft. These applications require engines capable of delivering exceptional thrust performance under extreme operational conditions, creating demand for innovative blade designs that can withstand high temperatures and stresses while maximizing propulsive efficiency.

The emerging urban air mobility (UAM) sector presents a rapidly growing market opportunity, with projections suggesting a market size exceeding $15 billion by 2030. This sector demands compact, lightweight engines with optimized thrust characteristics for vertical takeoff and landing operations, creating new requirements for specialized blade geometries.

Space launch systems constitute a smaller but high-value market segment, with private space companies and government agencies seeking propulsion solutions that can deliver maximum thrust efficiency for orbital insertion and beyond. The commercial space industry has grown at an unprecedented rate, with launch service revenues reaching $9.9 billion in 2022, creating demand for advanced turbine technologies.

Regional analysis reveals that North America currently dominates the high-thrust engine technology market with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where domestic aviation markets are expanding rapidly and indigenous aerospace manufacturing capabilities are being developed.

Customer requirements across these markets consistently emphasize several key performance metrics: specific fuel consumption reduction, thrust-to-weight ratio improvement, operational reliability, and maintenance cost reduction. Strategic blade geometry innovations that can deliver measurable improvements in these areas face strong market demand, with potential customers willing to pay premium prices for solutions that offer competitive advantages.

The demand for enhanced thrust capabilities stems from several key market factors. Airlines are continuously seeking more fuel-efficient engines that can deliver higher thrust-to-weight ratios, reducing operational costs while meeting increasingly stringent environmental regulations. This has created a significant market pull for advanced blade geometry solutions that can optimize airflow and combustion efficiency.

Military aviation represents another substantial market segment, with defense departments worldwide investing heavily in next-generation fighter and transport aircraft. These applications require engines capable of delivering exceptional thrust performance under extreme operational conditions, creating demand for innovative blade designs that can withstand high temperatures and stresses while maximizing propulsive efficiency.

The emerging urban air mobility (UAM) sector presents a rapidly growing market opportunity, with projections suggesting a market size exceeding $15 billion by 2030. This sector demands compact, lightweight engines with optimized thrust characteristics for vertical takeoff and landing operations, creating new requirements for specialized blade geometries.

Space launch systems constitute a smaller but high-value market segment, with private space companies and government agencies seeking propulsion solutions that can deliver maximum thrust efficiency for orbital insertion and beyond. The commercial space industry has grown at an unprecedented rate, with launch service revenues reaching $9.9 billion in 2022, creating demand for advanced turbine technologies.

Regional analysis reveals that North America currently dominates the high-thrust engine technology market with approximately 38% market share, followed by Europe (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in the Asia-Pacific region, particularly in China and India, where domestic aviation markets are expanding rapidly and indigenous aerospace manufacturing capabilities are being developed.

Customer requirements across these markets consistently emphasize several key performance metrics: specific fuel consumption reduction, thrust-to-weight ratio improvement, operational reliability, and maintenance cost reduction. Strategic blade geometry innovations that can deliver measurable improvements in these areas face strong market demand, with potential customers willing to pay premium prices for solutions that offer competitive advantages.

Current State and Challenges in Blade Geometry Design

The current state of blade geometry design in turbine engines represents a complex interplay between theoretical aerodynamics, materials science, and manufacturing capabilities. Traditional blade designs have predominantly focused on airfoil profiles derived from NACA series and similar standardized geometries, which have served the industry adequately but are increasingly recognized as suboptimal for modern performance demands. These conventional approaches typically prioritize manufacturability over aerodynamic efficiency, resulting in performance compromises that modern aviation can no longer afford.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have enabled more sophisticated blade geometry modeling, allowing engineers to simulate complex flow patterns and structural stresses with unprecedented accuracy. However, the implementation of these advanced designs faces significant challenges in translating theoretical optimizations into physically manufacturable components. The gap between simulation capabilities and manufacturing constraints remains a critical bottleneck in the industry.

Material limitations present another substantial challenge in blade geometry innovation. While computational models may suggest geometrically optimal designs, these must be balanced against material properties such as thermal resistance, fatigue strength, and creep behavior. Current superalloys and ceramic matrix composites have specific limitations that constrain the feasible design space for blade geometries, particularly at the extreme temperatures experienced in high-performance turbines.

Geographically, blade geometry research and development demonstrates distinct regional characteristics. North American and European entities tend to focus on evolutionary improvements to existing designs, emphasizing reliability and certification pathways. In contrast, emerging research centers in Asia, particularly in China and Singapore, are pursuing more revolutionary approaches, including biomimetic designs inspired by natural fluid dynamics. This geographical diversity in research approaches creates both competitive tension and collaborative opportunities in the global advancement of blade technology.

Manufacturing precision represents perhaps the most significant current challenge. Even with advanced techniques like additive manufacturing and five-axis CNC machining, achieving the micron-level tolerances required for optimal blade performance remains difficult at production scales. Surface finish quality, internal cooling channel geometry, and trailing edge thinness are particularly problematic aspects that often require compromises between theoretical performance and practical manufacturability.

The integration of active flow control mechanisms into blade geometry presents another frontier challenge. Concepts such as variable geometry trailing edges, boundary layer suction, and pulsed jets show promising performance improvements in laboratory settings but face substantial hurdles in reliability, weight, and system complexity when considered for real-world implementation.

Recent advancements in computational fluid dynamics (CFD) and finite element analysis (FEA) have enabled more sophisticated blade geometry modeling, allowing engineers to simulate complex flow patterns and structural stresses with unprecedented accuracy. However, the implementation of these advanced designs faces significant challenges in translating theoretical optimizations into physically manufacturable components. The gap between simulation capabilities and manufacturing constraints remains a critical bottleneck in the industry.

Material limitations present another substantial challenge in blade geometry innovation. While computational models may suggest geometrically optimal designs, these must be balanced against material properties such as thermal resistance, fatigue strength, and creep behavior. Current superalloys and ceramic matrix composites have specific limitations that constrain the feasible design space for blade geometries, particularly at the extreme temperatures experienced in high-performance turbines.

Geographically, blade geometry research and development demonstrates distinct regional characteristics. North American and European entities tend to focus on evolutionary improvements to existing designs, emphasizing reliability and certification pathways. In contrast, emerging research centers in Asia, particularly in China and Singapore, are pursuing more revolutionary approaches, including biomimetic designs inspired by natural fluid dynamics. This geographical diversity in research approaches creates both competitive tension and collaborative opportunities in the global advancement of blade technology.

Manufacturing precision represents perhaps the most significant current challenge. Even with advanced techniques like additive manufacturing and five-axis CNC machining, achieving the micron-level tolerances required for optimal blade performance remains difficult at production scales. Surface finish quality, internal cooling channel geometry, and trailing edge thinness are particularly problematic aspects that often require compromises between theoretical performance and practical manufacturability.

The integration of active flow control mechanisms into blade geometry presents another frontier challenge. Concepts such as variable geometry trailing edges, boundary layer suction, and pulsed jets show promising performance improvements in laboratory settings but face substantial hurdles in reliability, weight, and system complexity when considered for real-world implementation.

Contemporary Blade Geometry Optimization Approaches

01 Blade geometry optimization for thrust enhancement

Specific blade geometries can be designed to optimize thrust production in turbines. These designs focus on the shape, curvature, and profile of the blade to maximize airflow efficiency and thrust generation. Advanced computational methods are used to model and predict how different geometric configurations affect thrust performance under various operating conditions.- Blade geometry optimization for thrust enhancement: Specific blade geometries can be designed to optimize thrust production in turbines. These designs focus on the shape, curvature, and profile of the blade to maximize airflow efficiency and thrust generation. Advanced computational methods are used to model and analyze how different geometric configurations affect thrust performance under various operating conditions.

- Variable pitch blade systems for thrust control: Variable pitch blade systems allow for dynamic adjustment of blade angles to optimize thrust based on operating conditions. These systems incorporate mechanisms that can alter the blade pitch during operation, enabling better control over thrust production and efficiency. The ability to adjust blade geometry in real-time helps maintain optimal performance across different operational states and load requirements.

- Blade tip geometry modifications: Modifications to blade tip geometry can significantly impact thrust performance and efficiency. Specialized tip designs such as winglets, swept tips, or other aerodynamic features help reduce tip vortices and losses while improving thrust generation. These modifications can be particularly effective in reducing drag and improving overall turbine performance without requiring complete blade redesign.

- Composite blade structures for improved thrust performance: Advanced composite materials and construction techniques enable the creation of blade geometries that would be difficult or impossible with traditional materials. These composite structures allow for more precise aerodynamic profiles and can be engineered with varying stiffness properties along the blade length. The resulting blades can maintain optimal geometry under load, leading to improved thrust performance and efficiency.

- Computational fluid dynamics for thrust optimization: Computational fluid dynamics (CFD) techniques are employed to analyze and optimize turbine blade geometries for maximum thrust. These advanced simulation methods allow engineers to predict how different blade designs will perform under various operating conditions before physical prototyping. The analysis helps identify optimal blade profiles, angles, and other geometric parameters that maximize thrust while minimizing losses and maintaining structural integrity.

02 Variable pitch and twist configurations

Turbine blades with variable pitch and twist configurations allow for dynamic adjustment of blade geometry to optimize thrust across different operating conditions. These systems enable the blade angle to change relative to the airflow, maximizing efficiency and thrust production. The ability to adjust blade pitch and twist in response to changing conditions results in improved overall performance and thrust control.Expand Specific Solutions03 Aerodynamic surface features for thrust improvement

Specialized surface features on turbine blades can significantly improve thrust performance. These features include winglets, vortex generators, and specific surface textures that control boundary layer behavior and reduce drag. By manipulating airflow patterns around the blade, these geometric modifications enhance lift-to-drag ratios and increase the overall thrust efficiency of the turbine system.Expand Specific Solutions04 Composite blade structures with optimized geometry

Advanced composite materials enable the creation of complex blade geometries that would be difficult to achieve with traditional materials. These composite structures can be precisely engineered with varying thickness, stiffness, and aerodynamic properties along the blade span. The resulting optimized geometries provide improved thrust performance while maintaining structural integrity under high loads.Expand Specific Solutions05 Blade tip geometry modifications

Specialized modifications to turbine blade tip geometry can significantly impact thrust performance. These designs focus on reducing tip vortices and associated energy losses that diminish thrust. Techniques include swept tips, tip fences, and other end geometry optimizations that improve aerodynamic efficiency at the blade extremities, resulting in enhanced overall thrust production and reduced noise.Expand Specific Solutions

Leading Companies in Turbine Engine Manufacturing

The strategic blade geometry for enhanced turbine engine thrust market is currently in a growth phase, characterized by increasing demand for more efficient and powerful engines across aerospace and power generation sectors. The market size is expanding steadily, driven by aviation industry recovery and energy transition initiatives. Technologically, the field shows varying maturity levels among key players. Industry leaders like Rolls-Royce, GE Aviation, Pratt & Whitney, and Safran Aircraft Engines demonstrate advanced capabilities in computational fluid dynamics and materials science for blade optimization. MTU Aero Engines, Siemens Energy, and Mitsubishi Power are making significant progress in specialized applications, while emerging competitors from China such as AECC Commercial Aircraft Engine Co. are rapidly closing technological gaps through strategic investments and research partnerships.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed their "Advanced Aero Series" blade geometry that incorporates three-dimensional aerodynamic design principles to optimize pressure distribution and minimize secondary flow losses. Their blade designs feature variable stacking axes that create controlled lean and sweep profiles, reducing shock wave formation and improving flow characteristics at transonic speeds. The company employs a proprietary "Thermal Barrier System" that combines advanced cooling channels with specialized ceramic coatings to protect blades in high-temperature environments. Their manufacturing process utilizes directionally solidified and single-crystal casting techniques to enhance creep resistance and thermal fatigue properties. Pratt & Whitney's latest innovation includes adaptive tip geometries that minimize tip leakage flows while maintaining clearance tolerances across the operational envelope, significantly improving overall turbine efficiency and thrust output.

Strengths: Excellent balance between performance and manufacturability; superior durability in harsh operating environments; good serviceability and maintenance characteristics. Weaknesses: Somewhat conservative design approach compared to competitors; higher weight profiles in some applications; moderate production costs that impact economic feasibility for smaller engines.

MTU Aero Engines AG

Technical Solution: MTU Aero Engines has developed their "High-Efficiency Blade System" (HEBS) that incorporates advanced aerodynamic profiles with optimized three-dimensional geometries. Their blade designs feature controlled diffusion airfoils with precisely calculated thickness distributions to manage pressure gradients and prevent flow separation. MTU utilizes a proprietary cooling architecture that combines impingement cooling, film cooling, and internal convection passages to maintain optimal blade temperatures while minimizing cooling air requirements. Their manufacturing process employs advanced directional solidification techniques and protective coating systems that enhance blade durability in high-temperature environments. MTU's latest innovation includes active clearance control systems that maintain optimal blade tip clearances throughout the flight envelope, significantly reducing tip leakage losses and improving overall turbine efficiency and thrust output.

Strengths: Excellent balance of performance and reliability; superior fuel efficiency across operating range; good manufacturability compared to more exotic designs. Weaknesses: Moderate temperature limitations compared to ceramic composite alternatives; higher weight profiles than some competitors; relatively high development costs for smaller engine applications.

Critical Patents in Strategic Blade Design

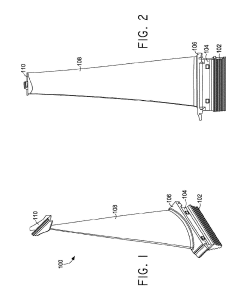

Turbine blade having improved flutter capability and increased turbine stage output

PatentActiveUS20190136696A1

Innovation

- A turbine blade design featuring a modified airfoil profile with a specific Cartesian coordinate shape, including a neck, platform, and shroud, which improves spanwise stiffness distribution, reduces bending stress, and enhances flutter resistance by balancing hot gas and centrifugal loading, while a MCrAlY bond coating provides improved oxidation resistance.

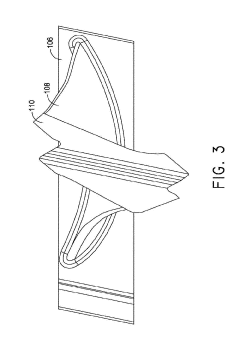

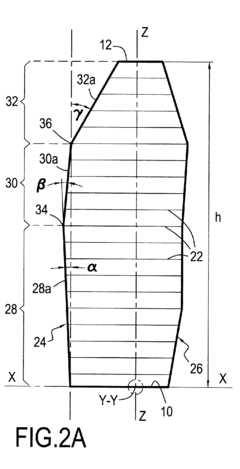

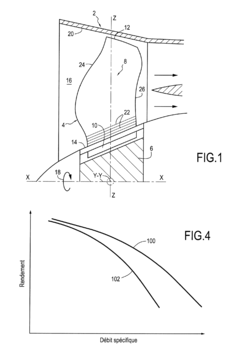

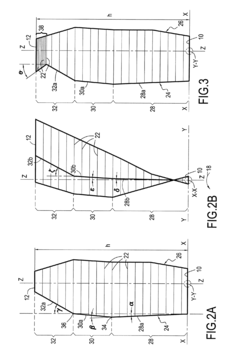

Turbomachine arrow blade

PatentActiveEP1921324A1

Innovation

- A turbine engine blade geometry with stacked sections along a radial axis, featuring specific longitudinal and tangential inclinations of leading edges and centers of gravity, resulting in a low 'belly' at 30-40% of the total height and pronounced rearward sweep, enhancing aerodynamic performance and acoustic characteristics, and allowing for mechanical balancing and manufacturability in composite materials.

Materials Science Advancements for Blade Manufacturing

The evolution of turbine blade materials has been fundamental to achieving enhanced thrust performance in modern engines. Traditional nickel-based superalloys have dominated the industry for decades, but recent advancements in materials science have opened new frontiers for blade manufacturing. Single-crystal superalloys represent a significant breakthrough, eliminating grain boundaries that typically serve as weak points under high-temperature stress conditions. These materials demonstrate superior creep resistance and thermal stability, enabling operation at temperatures approaching 1100°C.

Ceramic matrix composites (CMCs) have emerged as revolutionary materials for turbine blade applications, offering weight reduction of up to 30% compared to metallic alternatives while maintaining structural integrity at elevated temperatures. Silicon carbide-based CMCs particularly excel in harsh operating environments, with their self-healing microstructural properties providing enhanced durability during thermal cycling.

Advanced coating technologies have become integral to blade material systems. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia can reduce the effective temperature experienced by the blade substrate by 100-150°C, significantly extending component lifespan. Environmental barrier coatings have similarly evolved to protect against oxidation and hot corrosion, with new-generation platinum aluminide systems demonstrating exceptional resistance to sulfidation attack.

Additive manufacturing has transformed blade production capabilities, enabling the creation of complex cooling geometries previously impossible with conventional manufacturing methods. Direct metal laser sintering (DMLS) and electron beam melting (EBM) processes allow for precise control of microstructural properties, resulting in blades with optimized grain structures specifically tailored for directional stress loading.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now assist in identifying novel alloy compositions with superior high-temperature properties, reducing experimental iterations required for qualification. These digital tools have enabled the development of fourth-generation superalloys containing rhenium and ruthenium, which exhibit exceptional phase stability during prolonged high-temperature exposure.

Nanostructured materials represent the cutting edge of blade manufacturing science, with research demonstrating that controlled oxide dispersion strengthening can dramatically improve creep resistance. Carbon nanotube and graphene reinforcements are being explored as potential additions to metallic matrices, potentially offering unprecedented strength-to-weight ratios while maintaining thermal conductivity necessary for effective cooling.

Ceramic matrix composites (CMCs) have emerged as revolutionary materials for turbine blade applications, offering weight reduction of up to 30% compared to metallic alternatives while maintaining structural integrity at elevated temperatures. Silicon carbide-based CMCs particularly excel in harsh operating environments, with their self-healing microstructural properties providing enhanced durability during thermal cycling.

Advanced coating technologies have become integral to blade material systems. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia can reduce the effective temperature experienced by the blade substrate by 100-150°C, significantly extending component lifespan. Environmental barrier coatings have similarly evolved to protect against oxidation and hot corrosion, with new-generation platinum aluminide systems demonstrating exceptional resistance to sulfidation attack.

Additive manufacturing has transformed blade production capabilities, enabling the creation of complex cooling geometries previously impossible with conventional manufacturing methods. Direct metal laser sintering (DMLS) and electron beam melting (EBM) processes allow for precise control of microstructural properties, resulting in blades with optimized grain structures specifically tailored for directional stress loading.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under extreme conditions. Machine learning algorithms now assist in identifying novel alloy compositions with superior high-temperature properties, reducing experimental iterations required for qualification. These digital tools have enabled the development of fourth-generation superalloys containing rhenium and ruthenium, which exhibit exceptional phase stability during prolonged high-temperature exposure.

Nanostructured materials represent the cutting edge of blade manufacturing science, with research demonstrating that controlled oxide dispersion strengthening can dramatically improve creep resistance. Carbon nanotube and graphene reinforcements are being explored as potential additions to metallic matrices, potentially offering unprecedented strength-to-weight ratios while maintaining thermal conductivity necessary for effective cooling.

Environmental Impact of Enhanced Thrust Technologies

The environmental implications of enhanced thrust technologies through strategic blade geometry optimization extend beyond performance metrics to significant ecological considerations. Advanced turbine blade designs that increase thrust efficiency typically result in reduced fuel consumption per unit of power output. This translates directly to lower carbon emissions, with modern optimized blade geometries potentially reducing CO2 emissions by 8-15% compared to conventional designs. The environmental benefit compounds when considering the lifecycle of aircraft or power generation systems, where even marginal efficiency improvements yield substantial cumulative emission reductions.

Noise pollution represents another critical environmental dimension affected by blade geometry. Strategic blade designs incorporating swept tips, serrated trailing edges, and optimized pitch angles have demonstrated noise reduction capabilities of 3-7 decibels in operational settings. This reduction is particularly significant in urban environments where noise regulations are becoming increasingly stringent, and in wildlife habitats where acoustic disturbances can disrupt ecological patterns.

Material consumption patterns also shift with advanced blade geometries. While high-performance blade designs often require specialized alloys and composites that may have higher environmental production costs, their extended operational lifespan and improved efficiency create a favorable environmental balance over time. Modern computational fluid dynamics modeling suggests that optimized blade geometries can extend component life by 15-30%, reducing the environmental impact associated with manufacturing replacement parts.

The water footprint of enhanced thrust technologies deserves consideration as well. Cooling systems for high-performance turbines typically require substantial water resources, but strategic blade geometries that improve thermal efficiency can reduce cooling requirements by up to 12%. This water conservation aspect becomes increasingly important in regions facing water scarcity challenges.

Local air quality benefits significantly from advanced blade designs that enable more complete combustion processes. Particulate matter emissions can decrease by 20-35% with optimized blade geometries that create more efficient air-fuel mixing patterns. This improvement has direct implications for human health in communities surrounding airports, power plants, and industrial facilities utilizing turbine technologies.

Finally, the environmental impact assessment must consider the full lifecycle, including manufacturing processes and end-of-life disposal. While enhanced thrust technologies may require more energy-intensive manufacturing initially, their operational efficiency gains typically offset this impact within 1-3 years of deployment, creating a net positive environmental effect over the system's operational lifetime.

Noise pollution represents another critical environmental dimension affected by blade geometry. Strategic blade designs incorporating swept tips, serrated trailing edges, and optimized pitch angles have demonstrated noise reduction capabilities of 3-7 decibels in operational settings. This reduction is particularly significant in urban environments where noise regulations are becoming increasingly stringent, and in wildlife habitats where acoustic disturbances can disrupt ecological patterns.

Material consumption patterns also shift with advanced blade geometries. While high-performance blade designs often require specialized alloys and composites that may have higher environmental production costs, their extended operational lifespan and improved efficiency create a favorable environmental balance over time. Modern computational fluid dynamics modeling suggests that optimized blade geometries can extend component life by 15-30%, reducing the environmental impact associated with manufacturing replacement parts.

The water footprint of enhanced thrust technologies deserves consideration as well. Cooling systems for high-performance turbines typically require substantial water resources, but strategic blade geometries that improve thermal efficiency can reduce cooling requirements by up to 12%. This water conservation aspect becomes increasingly important in regions facing water scarcity challenges.

Local air quality benefits significantly from advanced blade designs that enable more complete combustion processes. Particulate matter emissions can decrease by 20-35% with optimized blade geometries that create more efficient air-fuel mixing patterns. This improvement has direct implications for human health in communities surrounding airports, power plants, and industrial facilities utilizing turbine technologies.

Finally, the environmental impact assessment must consider the full lifecycle, including manufacturing processes and end-of-life disposal. While enhanced thrust technologies may require more energy-intensive manufacturing initially, their operational efficiency gains typically offset this impact within 1-3 years of deployment, creating a net positive environmental effect over the system's operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!