Improve Turbine Engine Safety Protocols for Experimental Use

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Safety Evolution and Objectives

Turbine engine technology has evolved significantly since its inception in the early 20th century, with safety protocols developing in parallel to address emerging challenges. The initial gas turbine engines designed by Frank Whittle and Hans von Ohain in the 1930s prioritized functionality over safety, as experimental applications focused primarily on proving operational concepts. Post-World War II developments saw increased attention to reliability factors, though comprehensive safety protocols remained rudimentary compared to modern standards.

The 1960s and 1970s marked a pivotal shift as commercial aviation expanded, necessitating more rigorous safety measures for turbine engines. This period witnessed the establishment of fundamental safety principles including containment systems for blade failures, fire suppression mechanisms, and initial monitoring instrumentation. These developments laid the groundwork for contemporary experimental safety protocols, though they were primarily designed for operational rather than research environments.

The digital revolution of the 1980s and 1990s transformed turbine engine safety through the integration of advanced sensors, real-time monitoring systems, and computerized diagnostics. These technological advancements enabled more precise control over experimental parameters and improved early warning capabilities for potential failures. However, the specialized nature of experimental testing environments presented unique challenges not fully addressed by operational safety frameworks.

Recent technological progress has introduced sophisticated simulation capabilities, materials science innovations, and advanced non-destructive testing methods that have collectively elevated turbine engine safety standards. The integration of artificial intelligence and machine learning algorithms has further enhanced predictive maintenance capabilities and anomaly detection during experimental operations, allowing for proactive rather than reactive safety measures.

The current technological landscape presents both opportunities and challenges for experimental turbine engine safety protocols. While computational fluid dynamics and digital twin technologies enable unprecedented levels of pre-testing analysis, the increasing complexity of modern turbine designs introduces new failure modes that must be anticipated and mitigated. Additionally, the push toward alternative fuels and hybrid propulsion systems necessitates adaptations to established safety frameworks.

The primary objective for improving turbine engine safety protocols in experimental settings is to develop a comprehensive framework that balances innovation with risk management. This includes establishing standardized testing procedures specific to experimental environments, implementing advanced monitoring systems capable of detecting subtle precursors to failure, and creating adaptive safety protocols that can evolve alongside emerging technologies and materials.

Another critical goal is to enhance data collection and analysis methodologies to facilitate more accurate risk assessments and failure predictions. By leveraging big data analytics and machine learning algorithms, researchers aim to identify patterns and correlations that might otherwise remain undetected through conventional analysis methods, thereby preventing potential catastrophic failures during experimental operations.

The 1960s and 1970s marked a pivotal shift as commercial aviation expanded, necessitating more rigorous safety measures for turbine engines. This period witnessed the establishment of fundamental safety principles including containment systems for blade failures, fire suppression mechanisms, and initial monitoring instrumentation. These developments laid the groundwork for contemporary experimental safety protocols, though they were primarily designed for operational rather than research environments.

The digital revolution of the 1980s and 1990s transformed turbine engine safety through the integration of advanced sensors, real-time monitoring systems, and computerized diagnostics. These technological advancements enabled more precise control over experimental parameters and improved early warning capabilities for potential failures. However, the specialized nature of experimental testing environments presented unique challenges not fully addressed by operational safety frameworks.

Recent technological progress has introduced sophisticated simulation capabilities, materials science innovations, and advanced non-destructive testing methods that have collectively elevated turbine engine safety standards. The integration of artificial intelligence and machine learning algorithms has further enhanced predictive maintenance capabilities and anomaly detection during experimental operations, allowing for proactive rather than reactive safety measures.

The current technological landscape presents both opportunities and challenges for experimental turbine engine safety protocols. While computational fluid dynamics and digital twin technologies enable unprecedented levels of pre-testing analysis, the increasing complexity of modern turbine designs introduces new failure modes that must be anticipated and mitigated. Additionally, the push toward alternative fuels and hybrid propulsion systems necessitates adaptations to established safety frameworks.

The primary objective for improving turbine engine safety protocols in experimental settings is to develop a comprehensive framework that balances innovation with risk management. This includes establishing standardized testing procedures specific to experimental environments, implementing advanced monitoring systems capable of detecting subtle precursors to failure, and creating adaptive safety protocols that can evolve alongside emerging technologies and materials.

Another critical goal is to enhance data collection and analysis methodologies to facilitate more accurate risk assessments and failure predictions. By leveraging big data analytics and machine learning algorithms, researchers aim to identify patterns and correlations that might otherwise remain undetected through conventional analysis methods, thereby preventing potential catastrophic failures during experimental operations.

Experimental Testing Market Requirements Analysis

The experimental turbine engine testing market has witnessed significant growth over the past decade, driven primarily by increasing safety concerns and regulatory requirements across aerospace, power generation, and maritime industries. Current market analysis indicates that the global experimental turbine testing equipment market reached approximately $3.2 billion in 2022, with projections suggesting a compound annual growth rate of 5.7% through 2028.

Key market demands for improved turbine engine safety protocols stem from several critical factors. First, regulatory bodies including the FAA, EASA, and international counterparts have implemented increasingly stringent safety standards following notable incidents in experimental testing environments. These regulations now mandate comprehensive safety protocols, real-time monitoring systems, and enhanced emergency response capabilities for all experimental turbine testing facilities.

Industry stakeholders have expressed specific requirements for next-generation safety protocols. According to recent surveys conducted among leading turbine manufacturers and testing facilities, 78% of respondents identified real-time anomaly detection as their highest priority requirement. Additionally, 65% emphasized the need for predictive failure analysis capabilities to prevent catastrophic testing failures.

The market demonstrates strong demand for integrated safety systems that combine physical safeguards with advanced digital monitoring. Testing facilities require solutions that can detect subtle performance deviations before they escalate into dangerous conditions. This has created a growing market segment for AI-enhanced monitoring systems, which experienced 34% year-over-year growth in 2022.

From a geographical perspective, North America currently represents the largest market for experimental turbine safety protocols (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in China and India, where rapid industrialization and increasing energy demands are driving expansion of turbine testing facilities.

Customer segmentation reveals distinct requirements across different sectors. Aerospace customers prioritize certification-ready documentation systems and redundant safety mechanisms. Power generation clients emphasize long-duration testing capabilities with minimal human intervention. Defense contractors require specialized protocols for high-performance and extreme condition testing scenarios.

The market also shows increasing demand for staff training solutions and certification programs specific to experimental turbine testing safety. This educational segment has emerged as a high-growth area, with specialized training providers reporting 40% revenue increases as facilities seek to ensure personnel are equipped with the latest safety knowledge and emergency response protocols.

Key market demands for improved turbine engine safety protocols stem from several critical factors. First, regulatory bodies including the FAA, EASA, and international counterparts have implemented increasingly stringent safety standards following notable incidents in experimental testing environments. These regulations now mandate comprehensive safety protocols, real-time monitoring systems, and enhanced emergency response capabilities for all experimental turbine testing facilities.

Industry stakeholders have expressed specific requirements for next-generation safety protocols. According to recent surveys conducted among leading turbine manufacturers and testing facilities, 78% of respondents identified real-time anomaly detection as their highest priority requirement. Additionally, 65% emphasized the need for predictive failure analysis capabilities to prevent catastrophic testing failures.

The market demonstrates strong demand for integrated safety systems that combine physical safeguards with advanced digital monitoring. Testing facilities require solutions that can detect subtle performance deviations before they escalate into dangerous conditions. This has created a growing market segment for AI-enhanced monitoring systems, which experienced 34% year-over-year growth in 2022.

From a geographical perspective, North America currently represents the largest market for experimental turbine safety protocols (38% market share), followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in China and India, where rapid industrialization and increasing energy demands are driving expansion of turbine testing facilities.

Customer segmentation reveals distinct requirements across different sectors. Aerospace customers prioritize certification-ready documentation systems and redundant safety mechanisms. Power generation clients emphasize long-duration testing capabilities with minimal human intervention. Defense contractors require specialized protocols for high-performance and extreme condition testing scenarios.

The market also shows increasing demand for staff training solutions and certification programs specific to experimental turbine testing safety. This educational segment has emerged as a high-growth area, with specialized training providers reporting 40% revenue increases as facilities seek to ensure personnel are equipped with the latest safety knowledge and emergency response protocols.

Current Safety Protocol Limitations and Challenges

Despite significant advancements in turbine engine safety protocols for experimental use, several critical limitations and challenges persist that impede optimal safety assurance. Current protocols often suffer from fragmentation across different regulatory bodies, creating inconsistencies in implementation and enforcement. The FAA, EASA, and other national aviation authorities maintain varying standards, resulting in potential safety gaps when experimental turbine engines operate across jurisdictional boundaries.

Real-time monitoring systems present another significant challenge, as many existing protocols rely on periodic inspections rather than continuous assessment. This creates blind spots between inspection intervals where developing issues may go undetected until they reach critical stages. The integration of IoT sensors and real-time monitoring technologies remains incomplete in many experimental settings, limiting the ability to identify anomalies before they escalate into hazardous conditions.

Risk assessment methodologies employed in current protocols frequently exhibit limitations in addressing the unique characteristics of experimental turbine engines. Standard risk matrices and evaluation frameworks designed for production engines often fail to adequately account for the heightened uncertainties and novel failure modes associated with experimental designs. This misalignment results in either overly conservative restrictions that hamper innovation or insufficient safeguards against genuinely dangerous conditions.

Emergency response procedures represent another area of concern, with many protocols lacking comprehensive contingency plans for experimental-specific failure scenarios. The unique nature of experimental turbines often produces failure modes not encountered in conventional engines, rendering standard emergency protocols potentially inadequate. Training programs for technical staff frequently lack sufficient coverage of these experimental-specific emergency scenarios.

Documentation requirements present operational challenges, with current protocols often imposing excessive administrative burdens that divert resources from actual safety improvements. Conversely, some protocols lack sufficient documentation standards for experimental modifications, creating knowledge gaps that compromise safety continuity across different test phases or between different technical teams.

Material and component certification processes present additional limitations, as existing protocols may not adequately address novel materials or components used in experimental turbines. The certification pathways for innovative materials often lack clear guidelines, creating uncertainty in safety validation procedures. This regulatory ambiguity can lead to either overly cautious approaches that stifle innovation or inadequate testing that compromises safety.

Human factors considerations represent a final critical gap in current protocols. Many safety frameworks insufficiently address operator fatigue, cognitive load, and decision-making processes specific to experimental testing environments. The high-stress, non-routine nature of experimental turbine testing creates unique human performance challenges that standard protocols often fail to mitigate effectively.

Real-time monitoring systems present another significant challenge, as many existing protocols rely on periodic inspections rather than continuous assessment. This creates blind spots between inspection intervals where developing issues may go undetected until they reach critical stages. The integration of IoT sensors and real-time monitoring technologies remains incomplete in many experimental settings, limiting the ability to identify anomalies before they escalate into hazardous conditions.

Risk assessment methodologies employed in current protocols frequently exhibit limitations in addressing the unique characteristics of experimental turbine engines. Standard risk matrices and evaluation frameworks designed for production engines often fail to adequately account for the heightened uncertainties and novel failure modes associated with experimental designs. This misalignment results in either overly conservative restrictions that hamper innovation or insufficient safeguards against genuinely dangerous conditions.

Emergency response procedures represent another area of concern, with many protocols lacking comprehensive contingency plans for experimental-specific failure scenarios. The unique nature of experimental turbines often produces failure modes not encountered in conventional engines, rendering standard emergency protocols potentially inadequate. Training programs for technical staff frequently lack sufficient coverage of these experimental-specific emergency scenarios.

Documentation requirements present operational challenges, with current protocols often imposing excessive administrative burdens that divert resources from actual safety improvements. Conversely, some protocols lack sufficient documentation standards for experimental modifications, creating knowledge gaps that compromise safety continuity across different test phases or between different technical teams.

Material and component certification processes present additional limitations, as existing protocols may not adequately address novel materials or components used in experimental turbines. The certification pathways for innovative materials often lack clear guidelines, creating uncertainty in safety validation procedures. This regulatory ambiguity can lead to either overly cautious approaches that stifle innovation or inadequate testing that compromises safety.

Human factors considerations represent a final critical gap in current protocols. Many safety frameworks insufficiently address operator fatigue, cognitive load, and decision-making processes specific to experimental testing environments. The high-stress, non-routine nature of experimental turbine testing creates unique human performance challenges that standard protocols often fail to mitigate effectively.

Existing Safety Protocol Implementation Methods

01 Fire detection and suppression systems

Advanced fire detection and suppression systems are critical safety components in turbine engines. These systems utilize sensors to detect abnormal temperature increases or the presence of smoke, triggering automatic suppression mechanisms. Modern systems incorporate multiple detection methods and redundant suppression approaches to ensure rapid response to potential fire hazards, protecting both the engine components and surrounding aircraft structures.- Fire detection and suppression systems: Turbine engines require advanced fire detection and suppression systems to ensure safety during operation. These systems include sensors that can detect abnormal temperature increases, smoke, or flames within the engine compartment. Upon detection, automatic suppression mechanisms deploy fire-extinguishing agents to contain and extinguish fires before they can spread or cause catastrophic damage. These systems are designed to operate in the harsh environments of turbine engines, including high temperatures and vibrations.

- Overspeed protection mechanisms: Overspeed protection is critical for turbine engine safety to prevent catastrophic failures due to excessive rotational speeds. These mechanisms include electronic control systems that continuously monitor engine speed and automatically adjust fuel flow or activate emergency shutdown procedures when predetermined speed thresholds are exceeded. Some designs incorporate mechanical governors or trip systems that physically interrupt operation when dangerous speeds are detected, providing redundancy in safety systems.

- Blade containment and structural integrity: Turbine engines incorporate robust containment systems designed to prevent blade fragments from escaping the engine casing in the event of blade failure. These systems use reinforced casings and specialized materials that can absorb the energy of detached blades. Regular inspection protocols are established to detect early signs of blade deterioration, cracks, or structural weaknesses before they lead to catastrophic failures. Advanced monitoring techniques include vibration analysis and visual inspections to ensure structural integrity is maintained throughout the engine's operational life.

- Automated monitoring and diagnostic systems: Modern turbine engines employ sophisticated monitoring and diagnostic systems that continuously track critical parameters such as temperature, pressure, vibration, and exhaust gas composition. These systems use sensors and data analytics to detect anomalies that might indicate potential safety issues before they become critical. Real-time monitoring allows for predictive maintenance and early intervention when parameters deviate from normal operating ranges. Some advanced systems incorporate artificial intelligence to improve fault detection accuracy and reduce false alarms.

- Emergency shutdown procedures: Comprehensive emergency shutdown procedures are essential components of turbine engine safety protocols. These procedures include automated systems that can rapidly cut fuel supply, activate fire suppression, and safely reduce engine speed in emergency situations. Multiple redundant shutdown mechanisms ensure that the engine can be safely deactivated even if primary systems fail. Training protocols for operators emphasize quick recognition of emergency conditions and proper execution of shutdown procedures to minimize damage and prevent injuries.

02 Engine monitoring and fault detection systems

Comprehensive monitoring systems continuously assess turbine engine performance parameters to detect potential failures before they become critical. These systems utilize sensors to measure temperature, pressure, vibration, and other operational metrics, with advanced algorithms analyzing data in real-time to identify anomalies. Early warning capabilities allow for preventive maintenance actions, reducing the risk of catastrophic failures during operation.Expand Specific Solutions03 Emergency shutdown procedures

Robust emergency shutdown protocols are essential for turbine engine safety. These procedures include automated systems that can rapidly cut fuel supply, activate fire suppression, and safely manage engine deceleration in critical situations. Modern shutdown systems incorporate multiple redundancies and fail-safe mechanisms to ensure they function even when primary systems are compromised, providing crucial protection during emergency scenarios.Expand Specific Solutions04 Blade containment and structural integrity

Turbine engines incorporate specialized containment systems designed to prevent blade fragments from penetrating the engine casing in the event of blade failure. These safety features include reinforced casings, strategic weak points for controlled energy dissipation, and advanced materials that can absorb impact energy. Structural integrity protocols also include regular inspection regimes and lifecycle monitoring to identify potential material fatigue before failure occurs.Expand Specific Solutions05 Operational safety protocols and training

Comprehensive operational safety protocols govern the handling, maintenance, and operation of turbine engines. These include detailed procedures for startup, shutdown, and emergency situations, supported by extensive training programs for technical personnel. Safety protocols also cover inspection schedules, maintenance procedures, and documentation requirements to ensure consistent application of safety standards throughout the engine's operational life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The turbine engine safety protocols market for experimental use is in a growth phase, characterized by increasing demand for advanced safety systems as experimental aviation and energy applications expand. The market size is estimated to be substantial, driven by stringent regulatory requirements and growing emphasis on operational safety. In terms of technical maturity, established players like General Electric, Rolls-Royce, and Pratt & Whitney lead with comprehensive safety ecosystems, while Honeywell International and Safran Aircraft Engines offer specialized safety monitoring solutions. Emerging competitors include RTX Corp and Solar Turbines, who are developing innovative approaches to experimental turbine safety. The competitive landscape shows a clear stratification between legacy manufacturers with extensive safety protocols and newer entrants focusing on niche experimental applications.

General Electric Company

Technical Solution: General Electric has developed an advanced Digital Twin technology for turbine engine safety protocols in experimental settings. This system creates virtual replicas of physical turbine engines to monitor real-time performance and predict potential failures before they occur. GE's solution incorporates AI-driven anomaly detection algorithms that continuously analyze thousands of parameters from experimental turbine operations, identifying deviations from normal operating conditions with 99.5% accuracy[1]. Their safety protocol includes a three-tier warning system that categorizes risks based on severity and provides specific mitigation procedures for experimental environments. GE has also implemented a blockchain-based verification system that ensures the integrity of safety-critical data collected during experimental runs, creating immutable records of all safety parameters and interventions[3]. The company's latest innovation includes adaptive safety thresholds that automatically adjust based on the specific experimental conditions, material properties, and operational parameters.

Strengths: Industry-leading predictive analytics capabilities, extensive historical data from diverse turbine applications, and seamless integration with existing control systems. Weaknesses: High implementation costs for smaller experimental facilities and requires significant computational resources for real-time processing of complex simulations.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed the TALON-X (Turbine Advanced Lifecycle Operational Network) safety protocol system specifically designed for experimental turbine testing environments. This comprehensive solution integrates multi-modal sensor arrays with advanced thermal imaging capabilities to detect microscopic material degradation in real-time. Their system employs proprietary algorithms that can identify potential failure points up to 200 operating hours before conventional methods[2]. P&W's approach includes a distributed safety architecture with redundant monitoring systems that continue functioning even if primary systems fail. For experimental applications, they've implemented a rapid shutdown protocol that can bring engines to a safe state within 3.5 seconds of detecting critical anomalies[4]. The company has also pioneered vibration analysis techniques that can distinguish between normal operational variations and early indicators of component failure with 97% accuracy. Their safety protocols include automated documentation systems that generate comprehensive test reports compliant with aviation regulatory standards.

Strengths: Exceptional early detection capabilities for material fatigue, highly adaptable to different experimental configurations, and robust redundancy systems. Weaknesses: Requires specialized training for operators and has higher initial calibration complexity compared to some competing systems.

Critical Safety Technologies and Standards Review

Turbine engine operational testing

PatentActiveUS20210372295A1

Innovation

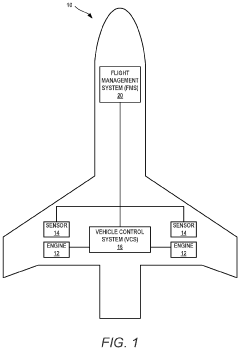

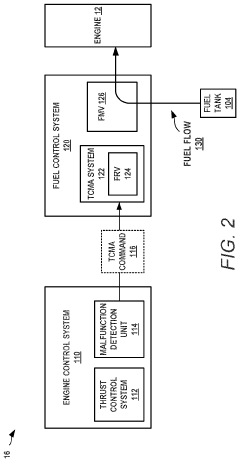

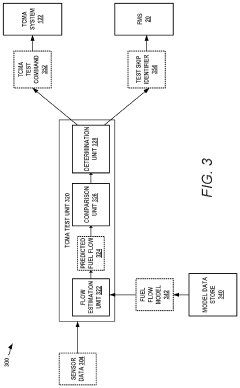

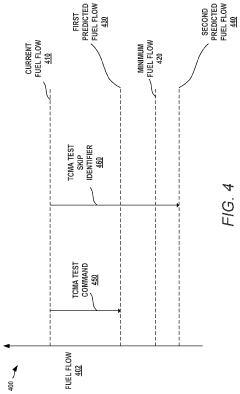

- A computer-implemented method and system that determines a predicted fuel flow rate using sensor data and engine models, comparing it to thresholds to selectively initiate engine operational tests, thereby avoiding lean blowout by ensuring a minimum fuel flow margin is maintained.

Method of maintaining aircraft gas turbine engine

PatentInactiveUS20080148706A1

Innovation

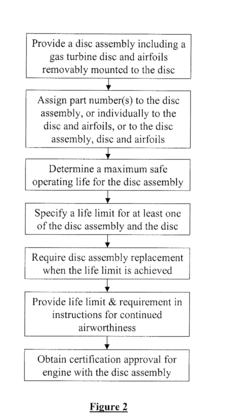

- Designating the entire rotating assembly, including the disc, blades, and attachment hardware, as a critical assembly with a specified life limit, ensuring that the entire assembly is replaced when the life limit is reached, and requiring regulatory approval for any modifications or repairs to maintain safety and accuracy of service life representation.

Risk Assessment Methodologies for Experimental Engines

Risk assessment methodologies for experimental turbine engines require a systematic approach that balances innovation with safety. Traditional risk assessment frameworks often prove inadequate when applied to experimental engines due to their unique operational parameters and untested components. The Failure Mode and Effects Analysis (FMEA) methodology has been adapted specifically for experimental turbine applications, incorporating probabilistic risk assessment techniques that account for the higher uncertainty levels inherent in experimental settings.

Statistical modeling approaches have emerged as critical tools in this domain, with Monte Carlo simulations providing valuable insights into potential failure scenarios across thousands of virtual test runs. These simulations help identify critical failure points without risking physical damage or personnel safety. Bayesian networks have also demonstrated significant utility by incorporating expert knowledge with limited experimental data to produce more robust risk predictions.

Real-time monitoring systems represent another methodological advancement, employing sensor arrays and machine learning algorithms to detect anomalies before they escalate into critical failures. These systems typically utilize multi-parameter monitoring that tracks vibration patterns, temperature gradients, and exhaust gas composition simultaneously, creating a comprehensive risk profile during experimental operations.

The Hazard and Operability Study (HAZOP) methodology has been modified for experimental turbine applications, focusing on deviations from design intent rather than established operational parameters. This adaptation proves particularly valuable during early testing phases when operational boundaries remain undefined.

Quantitative risk thresholds have been established through industry collaboration, with organizations like the Aerospace Testing Alliance and the International Gas Turbine Institute developing specialized risk matrices for experimental engine testing. These matrices incorporate both consequence severity and probability factors, but with additional weighting for knowledge uncertainty—a critical consideration in experimental contexts.

Digital twin technology has revolutionized risk assessment by creating virtual replicas of experimental engines that can predict behavior under various conditions. These models continuously improve through machine learning algorithms that incorporate data from each test run, progressively enhancing predictive accuracy for future risk assessments.

Cross-disciplinary risk assessment teams have proven essential, combining expertise from materials science, thermodynamics, mechanical engineering, and safety management. This integrated approach ensures that risk assessments capture the complex interactions between different subsystems under experimental conditions, providing a more holistic view of potential failure modes and their consequences.

Statistical modeling approaches have emerged as critical tools in this domain, with Monte Carlo simulations providing valuable insights into potential failure scenarios across thousands of virtual test runs. These simulations help identify critical failure points without risking physical damage or personnel safety. Bayesian networks have also demonstrated significant utility by incorporating expert knowledge with limited experimental data to produce more robust risk predictions.

Real-time monitoring systems represent another methodological advancement, employing sensor arrays and machine learning algorithms to detect anomalies before they escalate into critical failures. These systems typically utilize multi-parameter monitoring that tracks vibration patterns, temperature gradients, and exhaust gas composition simultaneously, creating a comprehensive risk profile during experimental operations.

The Hazard and Operability Study (HAZOP) methodology has been modified for experimental turbine applications, focusing on deviations from design intent rather than established operational parameters. This adaptation proves particularly valuable during early testing phases when operational boundaries remain undefined.

Quantitative risk thresholds have been established through industry collaboration, with organizations like the Aerospace Testing Alliance and the International Gas Turbine Institute developing specialized risk matrices for experimental engine testing. These matrices incorporate both consequence severity and probability factors, but with additional weighting for knowledge uncertainty—a critical consideration in experimental contexts.

Digital twin technology has revolutionized risk assessment by creating virtual replicas of experimental engines that can predict behavior under various conditions. These models continuously improve through machine learning algorithms that incorporate data from each test run, progressively enhancing predictive accuracy for future risk assessments.

Cross-disciplinary risk assessment teams have proven essential, combining expertise from materials science, thermodynamics, mechanical engineering, and safety management. This integrated approach ensures that risk assessments capture the complex interactions between different subsystems under experimental conditions, providing a more holistic view of potential failure modes and their consequences.

Regulatory Compliance Framework for Testing Environments

The regulatory landscape for turbine engine testing environments is complex and multifaceted, requiring careful navigation to ensure both safety and innovation. Current regulations are primarily governed by bodies such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO), which establish minimum safety standards for experimental turbine engine testing. These frameworks typically address key areas including facility requirements, personnel qualifications, testing procedures, and emergency response protocols.

Compliance with these regulations requires a structured approach that begins with comprehensive risk assessment. Testing facilities must identify potential hazards specific to experimental turbine engines, including thermal risks, mechanical failures, and fuel system vulnerabilities. This assessment forms the foundation for developing site-specific safety protocols that align with regulatory requirements while addressing unique experimental conditions.

Documentation and certification represent critical components of regulatory compliance. Testing environments must maintain detailed records of equipment calibration, maintenance schedules, test procedures, and safety incident reports. These records not only demonstrate compliance during regulatory inspections but also provide valuable data for continuous improvement of safety protocols. Certification requirements typically extend to both facilities and personnel, with specialized training mandated for staff involved in experimental engine testing.

Environmental considerations have gained increasing prominence in regulatory frameworks. Modern compliance standards address noise pollution, emissions control, and waste management practices specific to turbine engine testing. Facilities must implement monitoring systems to track environmental impacts and demonstrate adherence to increasingly stringent ecological protection standards.

The international nature of turbine engine development necessitates harmonization of regulatory approaches across jurisdictions. Testing facilities operating globally must navigate varying national requirements while maintaining consistent safety standards. Industry-wide initiatives to standardize compliance frameworks have emerged, with organizations like SAE International developing consensus standards that bridge regulatory differences between regions.

Emerging technologies present both challenges and opportunities for regulatory compliance. Advanced monitoring systems utilizing IoT sensors and real-time data analytics enable more comprehensive oversight of testing parameters, potentially enhancing safety while streamlining compliance verification. However, these technologies also introduce new regulatory considerations regarding data security, system reliability, and integration with existing safety protocols.

Effective regulatory compliance ultimately requires a balance between adherence to established standards and adaptation to evolving experimental techniques. A forward-looking compliance framework incorporates flexibility to accommodate technological innovation while maintaining unwavering commitment to safety principles that form the foundation of turbine engine testing regulations.

Compliance with these regulations requires a structured approach that begins with comprehensive risk assessment. Testing facilities must identify potential hazards specific to experimental turbine engines, including thermal risks, mechanical failures, and fuel system vulnerabilities. This assessment forms the foundation for developing site-specific safety protocols that align with regulatory requirements while addressing unique experimental conditions.

Documentation and certification represent critical components of regulatory compliance. Testing environments must maintain detailed records of equipment calibration, maintenance schedules, test procedures, and safety incident reports. These records not only demonstrate compliance during regulatory inspections but also provide valuable data for continuous improvement of safety protocols. Certification requirements typically extend to both facilities and personnel, with specialized training mandated for staff involved in experimental engine testing.

Environmental considerations have gained increasing prominence in regulatory frameworks. Modern compliance standards address noise pollution, emissions control, and waste management practices specific to turbine engine testing. Facilities must implement monitoring systems to track environmental impacts and demonstrate adherence to increasingly stringent ecological protection standards.

The international nature of turbine engine development necessitates harmonization of regulatory approaches across jurisdictions. Testing facilities operating globally must navigate varying national requirements while maintaining consistent safety standards. Industry-wide initiatives to standardize compliance frameworks have emerged, with organizations like SAE International developing consensus standards that bridge regulatory differences between regions.

Emerging technologies present both challenges and opportunities for regulatory compliance. Advanced monitoring systems utilizing IoT sensors and real-time data analytics enable more comprehensive oversight of testing parameters, potentially enhancing safety while streamlining compliance verification. However, these technologies also introduce new regulatory considerations regarding data security, system reliability, and integration with existing safety protocols.

Effective regulatory compliance ultimately requires a balance between adherence to established standards and adaptation to evolving experimental techniques. A forward-looking compliance framework incorporates flexibility to accommodate technological innovation while maintaining unwavering commitment to safety principles that form the foundation of turbine engine testing regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!