Assess Effectiveness of Turbine Engine Heat Shields

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Heat Shield Technology Background and Objectives

Turbine engine heat shields have evolved significantly since their inception in the mid-20th century, transitioning from simple metallic barriers to sophisticated multi-layered thermal protection systems. The fundamental purpose of these shields remains consistent: to protect engine components from extreme temperatures that can reach up to 1600°C in modern high-performance turbines. This temperature management is critical for maintaining structural integrity, optimizing engine performance, and extending operational lifespan.

The technological evolution of heat shields has been driven by advancements in materials science, computational fluid dynamics, and manufacturing processes. Early heat shields primarily utilized nickel-based superalloys, which provided adequate protection for first-generation turbine engines. As engine performance demands increased, thermal barrier coatings (TBCs) emerged in the 1970s, introducing ceramic layers that significantly enhanced thermal insulation properties.

Current technological trends in turbine heat shield development focus on several key areas: nano-structured materials with superior thermal resistance, advanced manufacturing techniques including additive manufacturing for complex geometries, and active cooling systems that dynamically respond to thermal loads. The integration of sensor technologies for real-time temperature monitoring represents another significant advancement, enabling predictive maintenance and optimized thermal management.

The primary objectives of modern turbine heat shield technology encompass multiple dimensions. From a performance perspective, the goal is to enable higher operating temperatures that directly correlate with improved engine efficiency and power output. Durability objectives focus on extending component lifespan under extreme thermal cycling conditions, reducing maintenance frequency and associated costs.

Environmental considerations have become increasingly important, with objectives to reduce emissions through more efficient combustion enabled by better thermal management. Weight reduction represents another critical objective, particularly in aerospace applications where every gram impacts fuel efficiency and payload capacity.

The economic dimension cannot be overlooked, with objectives to reduce manufacturing costs while maintaining or improving performance characteristics. This includes developing materials and processes that are less resource-intensive and more amenable to mass production techniques.

Looking forward, the technological roadmap for turbine heat shield development aims to achieve operating temperatures exceeding 1800°C, with shield lifespans measured in tens of thousands of operational hours rather than thousands. These ambitious targets will require breakthrough innovations in materials science and manufacturing technologies, potentially including self-healing materials and biomimetic cooling structures inspired by natural thermal regulation systems.

The technological evolution of heat shields has been driven by advancements in materials science, computational fluid dynamics, and manufacturing processes. Early heat shields primarily utilized nickel-based superalloys, which provided adequate protection for first-generation turbine engines. As engine performance demands increased, thermal barrier coatings (TBCs) emerged in the 1970s, introducing ceramic layers that significantly enhanced thermal insulation properties.

Current technological trends in turbine heat shield development focus on several key areas: nano-structured materials with superior thermal resistance, advanced manufacturing techniques including additive manufacturing for complex geometries, and active cooling systems that dynamically respond to thermal loads. The integration of sensor technologies for real-time temperature monitoring represents another significant advancement, enabling predictive maintenance and optimized thermal management.

The primary objectives of modern turbine heat shield technology encompass multiple dimensions. From a performance perspective, the goal is to enable higher operating temperatures that directly correlate with improved engine efficiency and power output. Durability objectives focus on extending component lifespan under extreme thermal cycling conditions, reducing maintenance frequency and associated costs.

Environmental considerations have become increasingly important, with objectives to reduce emissions through more efficient combustion enabled by better thermal management. Weight reduction represents another critical objective, particularly in aerospace applications where every gram impacts fuel efficiency and payload capacity.

The economic dimension cannot be overlooked, with objectives to reduce manufacturing costs while maintaining or improving performance characteristics. This includes developing materials and processes that are less resource-intensive and more amenable to mass production techniques.

Looking forward, the technological roadmap for turbine heat shield development aims to achieve operating temperatures exceeding 1800°C, with shield lifespans measured in tens of thousands of operational hours rather than thousands. These ambitious targets will require breakthrough innovations in materials science and manufacturing technologies, potentially including self-healing materials and biomimetic cooling structures inspired by natural thermal regulation systems.

Market Analysis for Advanced Thermal Protection Systems

The global market for advanced thermal protection systems in turbine engines is experiencing robust growth, driven by increasing demands for fuel efficiency, environmental regulations, and the need for extended engine life cycles. Currently valued at approximately 3.2 billion USD, this market segment is projected to reach 5.7 billion USD by 2028, representing a compound annual growth rate of 7.8% during the forecast period.

Aviation industry demands constitute the largest market share, accounting for nearly 62% of the total market value. This dominance stems from stringent safety regulations and the critical need for reliable heat management in aircraft engines. The power generation sector follows with approximately 24% market share, while marine and defense applications collectively represent the remaining 14%.

Geographically, North America leads the market with 38% share, followed by Europe (31%), Asia-Pacific (23%), and the rest of the world (8%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, primarily due to expanding aviation markets in China and India, coupled with increasing investments in power generation infrastructure.

Key market drivers include the push for higher operating temperatures in turbine engines to improve thermodynamic efficiency, which necessitates more advanced thermal protection solutions. Additionally, environmental regulations mandating reduced emissions are compelling manufacturers to develop more efficient combustion systems that generate higher temperatures, further driving demand for sophisticated heat shields.

Customer requirements are evolving toward multi-functional thermal protection systems that not only provide heat resistance but also contribute to noise reduction, weight savings, and improved aerodynamics. This trend is creating new market opportunities for integrated thermal management solutions.

Market challenges include the high cost of advanced ceramic matrix composites and other specialized materials used in modern heat shields, which can represent up to 15% of total engine manufacturing costs. Supply chain vulnerabilities for rare earth elements and specialized materials also pose significant risks to market growth.

Emerging market segments include small-scale turbines for distributed power generation and urban air mobility applications, which require compact yet highly effective thermal protection systems. Additionally, the retrofitting market for existing turbine fleets represents a substantial opportunity, estimated at 820 million USD annually, as operators seek to extend equipment life and improve performance without full system replacement.

Aviation industry demands constitute the largest market share, accounting for nearly 62% of the total market value. This dominance stems from stringent safety regulations and the critical need for reliable heat management in aircraft engines. The power generation sector follows with approximately 24% market share, while marine and defense applications collectively represent the remaining 14%.

Geographically, North America leads the market with 38% share, followed by Europe (31%), Asia-Pacific (23%), and the rest of the world (8%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.3% annually, primarily due to expanding aviation markets in China and India, coupled with increasing investments in power generation infrastructure.

Key market drivers include the push for higher operating temperatures in turbine engines to improve thermodynamic efficiency, which necessitates more advanced thermal protection solutions. Additionally, environmental regulations mandating reduced emissions are compelling manufacturers to develop more efficient combustion systems that generate higher temperatures, further driving demand for sophisticated heat shields.

Customer requirements are evolving toward multi-functional thermal protection systems that not only provide heat resistance but also contribute to noise reduction, weight savings, and improved aerodynamics. This trend is creating new market opportunities for integrated thermal management solutions.

Market challenges include the high cost of advanced ceramic matrix composites and other specialized materials used in modern heat shields, which can represent up to 15% of total engine manufacturing costs. Supply chain vulnerabilities for rare earth elements and specialized materials also pose significant risks to market growth.

Emerging market segments include small-scale turbines for distributed power generation and urban air mobility applications, which require compact yet highly effective thermal protection systems. Additionally, the retrofitting market for existing turbine fleets represents a substantial opportunity, estimated at 820 million USD annually, as operators seek to extend equipment life and improve performance without full system replacement.

Current Heat Shield Technologies and Engineering Challenges

Heat shield technologies for turbine engines have evolved significantly over the past decades, with several distinct approaches currently dominating the market. Thermal Barrier Coatings (TBCs) represent the most widely adopted solution, typically consisting of yttria-stabilized zirconia (YSZ) ceramic layers applied over metallic bond coats. These systems provide effective thermal insulation while maintaining structural integrity under extreme thermal cycling conditions. Modern TBCs can reduce metal surface temperatures by 100-300°C, significantly extending component life and enabling higher operating temperatures.

Ceramic matrix composites (CMCs) have emerged as a revolutionary alternative to traditional metallic components in high-temperature sections. These materials combine ceramic reinforcements within ceramic matrices to achieve exceptional heat resistance while overcoming the inherent brittleness of monolithic ceramics. Leading aerospace manufacturers have reported 20-30% weight reduction and temperature capabilities exceeding 1300°C with CMC implementation.

Advanced cooling systems work in conjunction with heat shields, employing sophisticated internal cooling channels, film cooling, and transpiration cooling techniques. These systems create protective air barriers between hot gases and component surfaces, enhancing overall thermal management effectiveness. Recent innovations include shaped cooling holes and double-wall cooling architectures that improve cooling efficiency by 15-25%.

Despite these advancements, significant engineering challenges persist. Durability under thermal cycling remains problematic, with thermal expansion mismatches between coating layers causing progressive degradation. Field data indicates that typical TBC systems experience spallation failures after 1,000-3,000 thermal cycles, necessitating regular inspection and replacement.

Manufacturing complexity presents another major hurdle, particularly for CMCs and advanced cooling geometries. Current production methods involve labor-intensive processes with high rejection rates, driving up costs and limiting widespread adoption. Industry reports suggest that CMC components can cost 5-10 times more than their metallic counterparts.

Environmental degradation mechanisms, including calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure, pose increasing concerns for modern heat shields. These contaminants can penetrate protective coatings, causing accelerated deterioration and catastrophic failure. Research indicates that even minor CMAS contamination can reduce heat shield effectiveness by up to 40%.

Performance prediction and testing methodologies represent another significant challenge. Current simulation models struggle to accurately predict real-world behavior under the complex, multi-physics conditions experienced in operational engines. This gap between predicted and actual performance necessitates extensive testing, adding considerable time and expense to development cycles.

Ceramic matrix composites (CMCs) have emerged as a revolutionary alternative to traditional metallic components in high-temperature sections. These materials combine ceramic reinforcements within ceramic matrices to achieve exceptional heat resistance while overcoming the inherent brittleness of monolithic ceramics. Leading aerospace manufacturers have reported 20-30% weight reduction and temperature capabilities exceeding 1300°C with CMC implementation.

Advanced cooling systems work in conjunction with heat shields, employing sophisticated internal cooling channels, film cooling, and transpiration cooling techniques. These systems create protective air barriers between hot gases and component surfaces, enhancing overall thermal management effectiveness. Recent innovations include shaped cooling holes and double-wall cooling architectures that improve cooling efficiency by 15-25%.

Despite these advancements, significant engineering challenges persist. Durability under thermal cycling remains problematic, with thermal expansion mismatches between coating layers causing progressive degradation. Field data indicates that typical TBC systems experience spallation failures after 1,000-3,000 thermal cycles, necessitating regular inspection and replacement.

Manufacturing complexity presents another major hurdle, particularly for CMCs and advanced cooling geometries. Current production methods involve labor-intensive processes with high rejection rates, driving up costs and limiting widespread adoption. Industry reports suggest that CMC components can cost 5-10 times more than their metallic counterparts.

Environmental degradation mechanisms, including calcium-magnesium-alumino-silicate (CMAS) infiltration and volcanic ash exposure, pose increasing concerns for modern heat shields. These contaminants can penetrate protective coatings, causing accelerated deterioration and catastrophic failure. Research indicates that even minor CMAS contamination can reduce heat shield effectiveness by up to 40%.

Performance prediction and testing methodologies represent another significant challenge. Current simulation models struggle to accurately predict real-world behavior under the complex, multi-physics conditions experienced in operational engines. This gap between predicted and actual performance necessitates extensive testing, adding considerable time and expense to development cycles.

Existing Assessment Methods for Heat Shield Effectiveness

01 Advanced materials for heat shield construction

The effectiveness of turbine engine heat shields is significantly enhanced through the use of advanced materials. These materials include ceramic matrix composites, thermal barrier coatings, and high-temperature alloys that can withstand extreme thermal conditions. These advanced materials provide superior thermal insulation properties, reducing heat transfer to critical engine components and improving overall engine efficiency and durability under high-temperature operating conditions.- Advanced materials for heat shield construction: Heat shields in turbine engines can be constructed using advanced materials that offer superior thermal resistance and durability. These materials include ceramic matrix composites, thermal barrier coatings, and high-temperature alloys that can withstand extreme operating conditions. The effectiveness of these materials lies in their ability to maintain structural integrity while providing thermal insulation, thereby protecting critical engine components from excessive heat exposure and extending the operational life of the turbine.

- Cooling systems integration with heat shields: The effectiveness of turbine engine heat shields can be significantly enhanced by integrating them with active cooling systems. These integrated designs incorporate cooling channels, impingement cooling, film cooling, or transpiration cooling techniques that work in conjunction with the physical barrier provided by the heat shield. This approach creates a more comprehensive thermal management solution that not only blocks heat but actively removes it from critical areas, allowing engines to operate at higher temperatures for improved efficiency while maintaining component integrity.

- Geometric design optimization for heat shields: The geometric configuration of heat shields plays a crucial role in their effectiveness. Optimized designs include features such as double-wall constructions, segmented shields, overlapping panels, and aerodynamic profiles that minimize hot gas ingestion. These geometric optimizations help to create dead air spaces for insulation, accommodate thermal expansion, reduce thermal stresses, and improve overall heat shield performance while minimizing weight and maximizing durability in the harsh environment of turbine engines.

- Attachment and sealing mechanisms for heat shields: The effectiveness of turbine engine heat shields is heavily dependent on their attachment and sealing mechanisms. Advanced fastening systems that accommodate thermal expansion while maintaining secure positioning are essential for heat shield performance. These include floating mounts, flexible attachments, and specialized sealing systems that prevent hot gas ingress between shield segments. Proper attachment ensures that the heat shields remain in place during operation while allowing for thermal growth, vibration damping, and ease of maintenance or replacement.

- Monitoring and predictive maintenance of heat shields: Advanced monitoring systems and predictive maintenance approaches significantly enhance the long-term effectiveness of turbine engine heat shields. These technologies include embedded sensors, thermal imaging, acoustic monitoring, and computational models that can detect early signs of heat shield degradation or failure. By implementing condition-based monitoring and predictive maintenance strategies, operators can optimize heat shield replacement schedules, prevent catastrophic failures, and ensure consistent thermal protection throughout the operational life of the engine.

02 Innovative heat shield designs and configurations

Various innovative designs and configurations have been developed to enhance heat shield effectiveness in turbine engines. These include segmented shield designs that accommodate thermal expansion, multi-layer shield structures that provide improved insulation, and aerodynamically optimized shapes that reduce drag while maintaining thermal protection. These design innovations help to distribute thermal loads more evenly, prevent hot spots, and extend the operational life of both the shields and protected components.Expand Specific Solutions03 Cooling systems integration with heat shields

The integration of cooling systems with heat shields significantly improves their effectiveness in turbine engines. These integrated systems may include film cooling techniques, impingement cooling, transpiration cooling, or internal cooling channels. By actively managing heat through these cooling mechanisms, the temperature gradient across the shield is reduced, allowing for operation in higher temperature environments while maintaining structural integrity and protecting surrounding components.Expand Specific Solutions04 Attachment methods and sealing technologies

Advanced attachment methods and sealing technologies play a crucial role in heat shield effectiveness. These include flexible mounting systems that accommodate thermal expansion, advanced fastening techniques that maintain shield integrity under vibration, and sophisticated sealing systems that prevent hot gas ingestion. These technologies ensure that heat shields remain properly positioned and sealed during all operating conditions, preventing thermal leakage and maintaining the protective barrier between hot gases and critical engine components.Expand Specific Solutions05 Monitoring and predictive maintenance systems

The implementation of monitoring and predictive maintenance systems enhances the long-term effectiveness of turbine engine heat shields. These systems utilize sensors to monitor shield temperatures, detect degradation, and predict potential failures before they occur. By continuously assessing heat shield performance and condition, maintenance can be scheduled proactively, ensuring optimal thermal protection throughout the operational life of the engine and preventing catastrophic failures due to heat shield degradation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Heat Shield Industry

The turbine engine heat shield market is currently in a growth phase, with increasing demand driven by aerospace and power generation sectors. Major players include established aerospace giants like RTX Corp. (formerly United Technologies), Pratt & Whitney, and Rolls-Royce, who leverage extensive R&D capabilities to develop advanced thermal protection solutions. The market is characterized by technological competition between traditional materials and emerging composites, with companies like General Electric, Siemens Energy, and Honeywell advancing heat shield technology through proprietary designs. Asian manufacturers including IHI Corp. and AVIC are rapidly gaining market share by focusing on cost-effective solutions. The technology maturity varies significantly across applications, with aerospace implementations being more advanced than industrial applications, creating opportunities for specialized players like Woodward and BorgWarner to develop niche solutions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a multi-faceted approach to turbine engine heat shield assessment that combines advanced materials science with digital monitoring technologies. Their methodology utilizes proprietary thermal barrier coatings with embedded temperature-sensitive phosphors that enable precise temperature mapping across heat shield surfaces. Honeywell's assessment platform incorporates non-destructive testing techniques including ultrasonic inspection and eddy current analysis to detect subsurface defects without removing components. Their digital twin technology creates virtual models of heat shield components that evolve based on operational data, allowing for predictive performance analysis under various conditions. Honeywell employs specialized thermal cycling test rigs that can rapidly alternate between extreme temperature conditions to evaluate thermal fatigue resistance. Their assessment process includes chemical composition analysis using energy-dispersive X-ray spectroscopy to track material degradation at the molecular level over operational lifetimes.

Strengths: Industry-leading materials science expertise; integrated approach combining physical inspection with digital modeling. Weaknesses: Assessment methodology requires specialized equipment not widely available in maintenance facilities; significant data processing requirements.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed a comprehensive heat shield effectiveness assessment methodology specifically optimized for industrial gas turbines. Their approach utilizes advanced thermal imaging systems with resolution capabilities down to 0.05°C to detect hotspots and thermal anomalies during operation. Siemens employs a network of thermocouples strategically positioned throughout the turbine hot gas path to create detailed temperature profiles under various operating conditions. Their proprietary "HeatMap" software platform integrates operational data with computational fluid dynamics models to predict heat shield performance degradation over time. Siemens has pioneered the use of laser-induced breakdown spectroscopy for in-situ material composition analysis, allowing for real-time assessment of coating degradation. Their methodology incorporates accelerated life testing in specialized test rigs that can simulate up to 30,000 hours of operational conditions in compressed timeframes, enabling accurate lifetime predictions for heat shield components.

Strengths: Extensive experience with large-scale industrial turbines; sophisticated data analytics platform for performance trending. Weaknesses: Assessment methodology primarily optimized for land-based power generation applications; less applicable to aerospace applications with more extreme thermal cycling.

Critical Patents and Research in Thermal Barrier Coatings

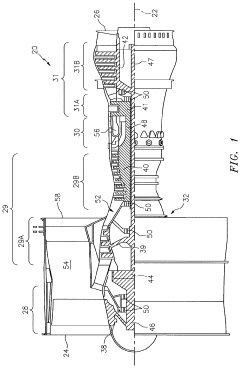

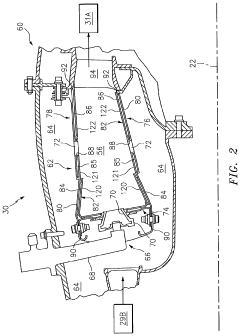

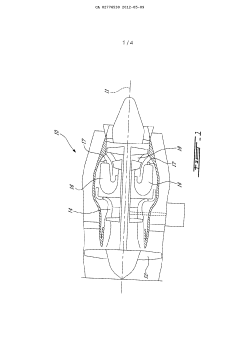

Stepped heat shield for a turbine engine combustor

PatentActiveUS10794595B2

Innovation

- The design incorporates a combustor wall with a shell and heat shield, featuring a cavity with directed air flow through impingement and effusion apertures, and a stepped heat shield configuration with a riser portion to direct air towards quench apertures, creating an air blanket for film cooling and convective cooling, thereby managing thermal stresses.

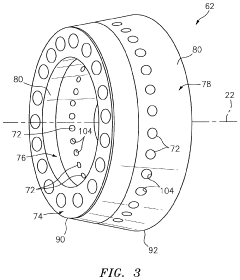

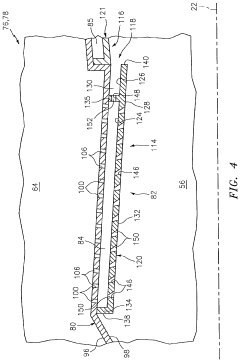

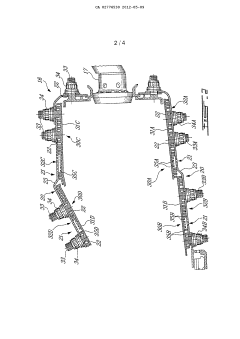

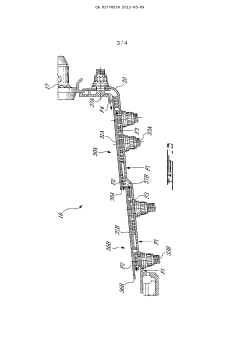

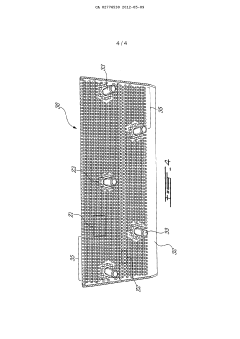

Pin FIN arrangement for heat shield of gas turbine engine

PatentActiveCA2776530C

Innovation

- A heat shield unit with pin fins arranged in arrays of different densities, where the upstream portion has a lower density than the downstream portion, and connectors align with fluid-coolant injection apertures to optimize coolant distribution and flow, reducing flow restrictions and enhancing cooling efficiency.

Environmental Impact and Sustainability of Heat Shield Technologies

The environmental impact of turbine engine heat shield technologies extends beyond their primary function of thermal protection. Traditional heat shields often utilize materials with significant ecological footprints, including rare earth elements and metals requiring energy-intensive extraction processes. The manufacturing of ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs), while offering superior heat resistance, typically involves high-temperature processing that consumes substantial energy and generates considerable greenhouse gas emissions.

Recent sustainability assessments reveal that the lifecycle environmental impact of heat shields varies dramatically based on material selection and manufacturing techniques. Advanced nickel-based superalloys, while effective for heat resistance, require approximately 40% more energy to produce than conventional steel alternatives, contributing to higher carbon emissions during the manufacturing phase.

The durability factor presents a critical sustainability consideration. Longer-lasting heat shields reduce replacement frequency, thereby decreasing material consumption and associated environmental impacts over the turbine engine's operational lifespan. Research indicates that next-generation ceramic heat shields can extend service intervals by up to 30% compared to conventional metallic shields, significantly reducing waste generation and resource depletion.

Water consumption represents another environmental concern, particularly in manufacturing processes for advanced heat shield materials. Production of high-performance ceramics typically requires 2-3 times more water than conventional metal processing, creating potential sustainability challenges in water-stressed regions where manufacturing facilities operate.

Recycling capabilities vary substantially across heat shield technologies. While metallic heat shields offer recycling rates approaching 70-80%, advanced ceramic composites present significant end-of-life challenges with current recycling rates below 25%. This disparity creates important considerations for circular economy principles in turbine engine component design.

Emerging bio-inspired heat shield materials show promising environmental profiles. Biomimetic designs based on natural heat-regulation systems demonstrate potential for reducing both manufacturing energy requirements and operational environmental impacts. These innovations could potentially decrease the carbon footprint of heat shield production by 15-20% compared to conventional approaches.

The environmental trade-offs between manufacturing impacts and operational benefits require careful assessment. While producing advanced heat shields may generate higher initial environmental costs, their contribution to improved engine efficiency and reduced fuel consumption during operation often yields net positive environmental outcomes over the full product lifecycle.

Recent sustainability assessments reveal that the lifecycle environmental impact of heat shields varies dramatically based on material selection and manufacturing techniques. Advanced nickel-based superalloys, while effective for heat resistance, require approximately 40% more energy to produce than conventional steel alternatives, contributing to higher carbon emissions during the manufacturing phase.

The durability factor presents a critical sustainability consideration. Longer-lasting heat shields reduce replacement frequency, thereby decreasing material consumption and associated environmental impacts over the turbine engine's operational lifespan. Research indicates that next-generation ceramic heat shields can extend service intervals by up to 30% compared to conventional metallic shields, significantly reducing waste generation and resource depletion.

Water consumption represents another environmental concern, particularly in manufacturing processes for advanced heat shield materials. Production of high-performance ceramics typically requires 2-3 times more water than conventional metal processing, creating potential sustainability challenges in water-stressed regions where manufacturing facilities operate.

Recycling capabilities vary substantially across heat shield technologies. While metallic heat shields offer recycling rates approaching 70-80%, advanced ceramic composites present significant end-of-life challenges with current recycling rates below 25%. This disparity creates important considerations for circular economy principles in turbine engine component design.

Emerging bio-inspired heat shield materials show promising environmental profiles. Biomimetic designs based on natural heat-regulation systems demonstrate potential for reducing both manufacturing energy requirements and operational environmental impacts. These innovations could potentially decrease the carbon footprint of heat shield production by 15-20% compared to conventional approaches.

The environmental trade-offs between manufacturing impacts and operational benefits require careful assessment. While producing advanced heat shields may generate higher initial environmental costs, their contribution to improved engine efficiency and reduced fuel consumption during operation often yields net positive environmental outcomes over the full product lifecycle.

Performance Metrics and Testing Standards for Heat Shields

Evaluating the effectiveness of turbine engine heat shields requires standardized performance metrics and rigorous testing protocols. The aerospace and power generation industries have established comprehensive frameworks for assessing heat shield capabilities under extreme thermal and mechanical conditions.

Temperature resistance serves as the primary performance metric, with heat shields typically required to withstand temperatures ranging from 1000°C to 1600°C in modern turbine applications. This resistance is quantified through thermal cycling tests that measure material degradation after repeated exposure to temperature extremes. The ASTM E2584 standard provides guidelines for evaluating the thermal performance of these protective systems under cyclic conditions.

Thermal conductivity represents another critical metric, typically measured in W/m·K, with lower values indicating superior insulation properties. Industry standards require heat shields to maintain conductivity below 0.5 W/m·K at operating temperatures to ensure efficient thermal management. The ASTM C177 and C518 standards outline the guarded hot plate and heat flow meter methods for precise conductivity measurements.

Erosion resistance constitutes an essential performance parameter, particularly for components exposed to high-velocity gas flows containing particulate matter. The ASTM G76 standard test method quantifies material loss under particle impingement, with acceptable erosion rates typically below 0.05 mm/year for long-term applications.

Mechanical integrity under thermal stress is evaluated through thermal shock resistance tests, where specimens undergo rapid temperature changes from ambient to operating conditions. The ASTM C1525 standard provides a methodology for determining thermal shock parameters, with R-values (thermal shock resistance) serving as comparative metrics between different shield materials.

Durability testing involves accelerated aging protocols that simulate thousands of operational hours within compressed timeframes. These tests incorporate thermal cycling, vibration exposure, and chemical environment simulation to predict service life. The ISO 13123 standard establishes procedures for evaluating thermal barrier coating durability under combined thermal and mechanical loading.

Acoustic performance has emerged as an increasingly important metric, particularly for aerospace applications where noise reduction requirements are stringent. Heat shields must demonstrate specific sound transmission loss values across relevant frequency ranges, typically measured according to SAE ARP1587 standards.

Emissions compliance testing ensures that heat shield materials do not release harmful substances during operation. The EPA Method 202 and similar standards establish protocols for measuring particulate emissions from materials at elevated temperatures, with strict limits on allowable release rates.

Temperature resistance serves as the primary performance metric, with heat shields typically required to withstand temperatures ranging from 1000°C to 1600°C in modern turbine applications. This resistance is quantified through thermal cycling tests that measure material degradation after repeated exposure to temperature extremes. The ASTM E2584 standard provides guidelines for evaluating the thermal performance of these protective systems under cyclic conditions.

Thermal conductivity represents another critical metric, typically measured in W/m·K, with lower values indicating superior insulation properties. Industry standards require heat shields to maintain conductivity below 0.5 W/m·K at operating temperatures to ensure efficient thermal management. The ASTM C177 and C518 standards outline the guarded hot plate and heat flow meter methods for precise conductivity measurements.

Erosion resistance constitutes an essential performance parameter, particularly for components exposed to high-velocity gas flows containing particulate matter. The ASTM G76 standard test method quantifies material loss under particle impingement, with acceptable erosion rates typically below 0.05 mm/year for long-term applications.

Mechanical integrity under thermal stress is evaluated through thermal shock resistance tests, where specimens undergo rapid temperature changes from ambient to operating conditions. The ASTM C1525 standard provides a methodology for determining thermal shock parameters, with R-values (thermal shock resistance) serving as comparative metrics between different shield materials.

Durability testing involves accelerated aging protocols that simulate thousands of operational hours within compressed timeframes. These tests incorporate thermal cycling, vibration exposure, and chemical environment simulation to predict service life. The ISO 13123 standard establishes procedures for evaluating thermal barrier coating durability under combined thermal and mechanical loading.

Acoustic performance has emerged as an increasingly important metric, particularly for aerospace applications where noise reduction requirements are stringent. Heat shields must demonstrate specific sound transmission loss values across relevant frequency ranges, typically measured according to SAE ARP1587 standards.

Emissions compliance testing ensures that heat shield materials do not release harmful substances during operation. The EPA Method 202 and similar standards establish protocols for measuring particulate emissions from materials at elevated temperatures, with strict limits on allowable release rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!