Environmental Impact of Turbine Engine Exhaust on Atmosphere

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Emissions Background and Objectives

Turbine engines have been a cornerstone of modern aviation and power generation since their development in the mid-20th century. Initially designed for military applications during World War II, these engines rapidly evolved to become the standard propulsion system for commercial aircraft and a critical component in power generation facilities worldwide. The environmental impact of turbine engine exhaust has become increasingly significant as global air traffic has grown exponentially, with commercial flights increasing from approximately 9 million in 1970 to over 38 million in 2019 before the COVID-19 pandemic.

The primary emissions from turbine engines include carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), unburned hydrocarbons (UHC), carbon monoxide (CO), particulate matter (PM), and water vapor. These emissions contribute to various environmental challenges, including climate change, air quality degradation, and potential health impacts on populations living near airports and power plants. The aviation sector alone contributes approximately 2.5% of global CO2 emissions, with this percentage projected to increase significantly by 2050 without technological intervention.

The evolution of environmental concerns regarding turbine engine emissions has paralleled the development of increasingly stringent international regulations. The International Civil Aviation Organization (ICAO) established its Committee on Aviation Environmental Protection (CAEP) in 1983, which has progressively tightened emission standards through successive iterations (CAEP/1 through CAEP/11). Similarly, power generation turbines face regulations from entities such as the Environmental Protection Agency (EPA) in the United States and equivalent bodies globally.

Technological advancements in turbine engine design have consistently aimed to improve fuel efficiency and reduce emissions. The bypass ratio of turbofan engines has increased from approximately 1:1 in early designs to over 12:1 in modern engines, significantly improving fuel efficiency. Combustor technology has evolved from conventional designs to lean-burn and rich-quench-lean configurations that reduce NOx formation. Materials science advancements have enabled higher operating temperatures, further improving efficiency and reducing emissions per unit of power generated.

The primary objective of current research in this field is to develop turbine engine technologies that can meet the aviation industry's commitment to carbon-neutral growth from 2020 and a 50% reduction in net aviation CO2 emissions by 2050 compared to 2005 levels. For power generation turbines, objectives include facilitating the integration of renewable energy sources through improved operational flexibility and developing hydrogen-compatible turbines to enable zero-carbon power generation.

Additional technical goals include reducing non-CO2 climate impacts, particularly those associated with contrail formation and NOx emissions at cruise altitudes, which may have climate impacts several times greater than CO2 alone. Understanding these complex atmospheric interactions and developing mitigation strategies represents a significant scientific and engineering challenge that requires interdisciplinary collaboration across atmospheric science, combustion chemistry, and engine design.

The primary emissions from turbine engines include carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), unburned hydrocarbons (UHC), carbon monoxide (CO), particulate matter (PM), and water vapor. These emissions contribute to various environmental challenges, including climate change, air quality degradation, and potential health impacts on populations living near airports and power plants. The aviation sector alone contributes approximately 2.5% of global CO2 emissions, with this percentage projected to increase significantly by 2050 without technological intervention.

The evolution of environmental concerns regarding turbine engine emissions has paralleled the development of increasingly stringent international regulations. The International Civil Aviation Organization (ICAO) established its Committee on Aviation Environmental Protection (CAEP) in 1983, which has progressively tightened emission standards through successive iterations (CAEP/1 through CAEP/11). Similarly, power generation turbines face regulations from entities such as the Environmental Protection Agency (EPA) in the United States and equivalent bodies globally.

Technological advancements in turbine engine design have consistently aimed to improve fuel efficiency and reduce emissions. The bypass ratio of turbofan engines has increased from approximately 1:1 in early designs to over 12:1 in modern engines, significantly improving fuel efficiency. Combustor technology has evolved from conventional designs to lean-burn and rich-quench-lean configurations that reduce NOx formation. Materials science advancements have enabled higher operating temperatures, further improving efficiency and reducing emissions per unit of power generated.

The primary objective of current research in this field is to develop turbine engine technologies that can meet the aviation industry's commitment to carbon-neutral growth from 2020 and a 50% reduction in net aviation CO2 emissions by 2050 compared to 2005 levels. For power generation turbines, objectives include facilitating the integration of renewable energy sources through improved operational flexibility and developing hydrogen-compatible turbines to enable zero-carbon power generation.

Additional technical goals include reducing non-CO2 climate impacts, particularly those associated with contrail formation and NOx emissions at cruise altitudes, which may have climate impacts several times greater than CO2 alone. Understanding these complex atmospheric interactions and developing mitigation strategies represents a significant scientific and engineering challenge that requires interdisciplinary collaboration across atmospheric science, combustion chemistry, and engine design.

Market Analysis of Low-Emission Turbine Technologies

The global market for low-emission turbine technologies has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing awareness of climate change impacts. The market size for these technologies reached approximately $25 billion in 2022, with projections indicating growth to $45 billion by 2030, representing a compound annual growth rate of 7.8%. This growth trajectory is particularly pronounced in regions with strict emission control policies, such as the European Union, North America, and increasingly in parts of Asia.

Aviation and power generation sectors constitute the largest market segments for low-emission turbine technologies. The commercial aviation industry, facing pressure to reduce its carbon footprint, has increased investment in cleaner turbine engines by 34% over the past five years. Similarly, the power generation sector has seen a 28% increase in adoption of low-emission gas turbines as utilities transition away from coal-fired plants toward cleaner energy sources.

Market demand is being shaped by several key factors. Regulatory frameworks, such as the International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and various national clean air policies, are creating compliance requirements that drive technology adoption. Additionally, corporate sustainability commitments are influencing procurement decisions, with 67% of Fortune 500 companies now including emissions reduction targets in their strategic planning.

Consumer preferences are also shifting market dynamics, particularly in commercial aviation where "flight shaming" movements have increased passenger awareness of environmental impacts. This has prompted airlines to prominently feature fuel efficiency and emissions reductions in their marketing campaigns, creating downstream pressure on aircraft and engine manufacturers.

From a geographical perspective, Europe leads in market adoption of low-emission turbine technologies, accounting for 38% of global market share, followed by North America at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies, particularly China and India, where rapid industrialization is being balanced against growing environmental concerns and international climate commitments.

The market landscape is characterized by significant price premiums for low-emission technologies, with customers typically paying 15-20% more compared to conventional alternatives. However, this premium is increasingly offset by operational cost savings through improved fuel efficiency and reduced regulatory compliance costs. Market analysis indicates that the return on investment period for these technologies has decreased from 8-10 years a decade ago to 4-6 years currently, significantly improving their commercial viability.

Aviation and power generation sectors constitute the largest market segments for low-emission turbine technologies. The commercial aviation industry, facing pressure to reduce its carbon footprint, has increased investment in cleaner turbine engines by 34% over the past five years. Similarly, the power generation sector has seen a 28% increase in adoption of low-emission gas turbines as utilities transition away from coal-fired plants toward cleaner energy sources.

Market demand is being shaped by several key factors. Regulatory frameworks, such as the International Civil Aviation Organization's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) and various national clean air policies, are creating compliance requirements that drive technology adoption. Additionally, corporate sustainability commitments are influencing procurement decisions, with 67% of Fortune 500 companies now including emissions reduction targets in their strategic planning.

Consumer preferences are also shifting market dynamics, particularly in commercial aviation where "flight shaming" movements have increased passenger awareness of environmental impacts. This has prompted airlines to prominently feature fuel efficiency and emissions reductions in their marketing campaigns, creating downstream pressure on aircraft and engine manufacturers.

From a geographical perspective, Europe leads in market adoption of low-emission turbine technologies, accounting for 38% of global market share, followed by North America at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in emerging economies, particularly China and India, where rapid industrialization is being balanced against growing environmental concerns and international climate commitments.

The market landscape is characterized by significant price premiums for low-emission technologies, with customers typically paying 15-20% more compared to conventional alternatives. However, this premium is increasingly offset by operational cost savings through improved fuel efficiency and reduced regulatory compliance costs. Market analysis indicates that the return on investment period for these technologies has decreased from 8-10 years a decade ago to 4-6 years currently, significantly improving their commercial viability.

Current Challenges in Turbine Exhaust Emission Control

The control of turbine engine exhaust emissions presents significant technical challenges across multiple sectors, including aviation, power generation, and marine applications. Current emission control technologies struggle to simultaneously address the complex mixture of pollutants including nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), particulate matter (PM), and sulfur oxides (SOx). These emissions contribute substantially to atmospheric pollution, climate change, and public health concerns.

A primary challenge lies in the trade-off between NOx reduction and fuel efficiency. Low-temperature combustion techniques effectively reduce NOx formation but often lead to incomplete combustion, increasing CO and UHC emissions. Conversely, high-temperature combustion improves fuel efficiency but significantly increases NOx production, creating a persistent engineering dilemma.

Material limitations present another substantial obstacle. Emission control systems must withstand extreme operating conditions, including temperatures exceeding 1500°C in aviation turbines and rapid thermal cycling. Current catalyst materials for selective catalytic reduction (SCR) systems demonstrate reduced efficiency at the high temperatures characteristic of turbine operations, limiting their practical application in aerospace environments.

Weight and space constraints are particularly critical in aviation applications. Adding comprehensive emission control systems increases aircraft weight, directly impacting fuel consumption and operational range. The aviation industry faces the difficult task of balancing emission reduction goals with performance requirements while maintaining safety standards and economic viability.

Regulatory compliance across diverse global standards creates additional complexity. Different regions have established varying emission control requirements, forcing manufacturers to develop adaptable systems or region-specific solutions. The International Civil Aviation Organization (ICAO) standards for aircraft emissions continue to become more stringent, while power generation facilities face increasingly strict regulations from the Environmental Protection Agency (EPA) and equivalent international bodies.

Emerging challenges include the detection and mitigation of ultrafine particulate matter (PM2.5 and smaller), which recent research has linked to significant health impacts. Current filtration technologies struggle to efficiently capture these microscopic particles without creating prohibitive pressure drops in exhaust systems.

Economic factors further complicate implementation efforts. Advanced emission control technologies significantly increase both initial capital expenditure and ongoing maintenance costs. The return on investment for these technologies often depends on regulatory requirements rather than direct operational benefits, creating market hesitancy in voluntary adoption.

The development of effective monitoring systems represents another technical hurdle. Real-time, accurate measurement of emissions under varying operational conditions remains difficult, particularly for aircraft in flight, limiting the ability to optimize control systems and verify compliance with regulatory standards.

A primary challenge lies in the trade-off between NOx reduction and fuel efficiency. Low-temperature combustion techniques effectively reduce NOx formation but often lead to incomplete combustion, increasing CO and UHC emissions. Conversely, high-temperature combustion improves fuel efficiency but significantly increases NOx production, creating a persistent engineering dilemma.

Material limitations present another substantial obstacle. Emission control systems must withstand extreme operating conditions, including temperatures exceeding 1500°C in aviation turbines and rapid thermal cycling. Current catalyst materials for selective catalytic reduction (SCR) systems demonstrate reduced efficiency at the high temperatures characteristic of turbine operations, limiting their practical application in aerospace environments.

Weight and space constraints are particularly critical in aviation applications. Adding comprehensive emission control systems increases aircraft weight, directly impacting fuel consumption and operational range. The aviation industry faces the difficult task of balancing emission reduction goals with performance requirements while maintaining safety standards and economic viability.

Regulatory compliance across diverse global standards creates additional complexity. Different regions have established varying emission control requirements, forcing manufacturers to develop adaptable systems or region-specific solutions. The International Civil Aviation Organization (ICAO) standards for aircraft emissions continue to become more stringent, while power generation facilities face increasingly strict regulations from the Environmental Protection Agency (EPA) and equivalent international bodies.

Emerging challenges include the detection and mitigation of ultrafine particulate matter (PM2.5 and smaller), which recent research has linked to significant health impacts. Current filtration technologies struggle to efficiently capture these microscopic particles without creating prohibitive pressure drops in exhaust systems.

Economic factors further complicate implementation efforts. Advanced emission control technologies significantly increase both initial capital expenditure and ongoing maintenance costs. The return on investment for these technologies often depends on regulatory requirements rather than direct operational benefits, creating market hesitancy in voluntary adoption.

The development of effective monitoring systems represents another technical hurdle. Real-time, accurate measurement of emissions under varying operational conditions remains difficult, particularly for aircraft in flight, limiting the ability to optimize control systems and verify compliance with regulatory standards.

State-of-the-Art Emission Reduction Technologies

01 Emission reduction technologies in turbine engines

Various technologies have been developed to reduce harmful emissions from turbine engine exhaust. These include advanced combustion systems, catalytic converters, and exhaust treatment systems that minimize pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. These technologies help turbine engines meet increasingly stringent environmental regulations while maintaining performance efficiency.- Emission reduction technologies in turbine engines: Various technologies have been developed to reduce harmful emissions from turbine engine exhaust. These include advanced combustion systems, catalytic converters, and exhaust gas treatment systems that minimize the release of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. These technologies help turbine engines meet increasingly stringent environmental regulations while maintaining performance efficiency.

- Noise reduction solutions for turbine exhaust: Turbine engine noise is a significant environmental concern, particularly for aircraft and power generation facilities near populated areas. Innovations in this area include acoustic liners, exhaust mufflers, and specialized nozzle designs that modify the flow characteristics of exhaust gases. These solutions help reduce noise pollution while maintaining the aerodynamic efficiency of the engine system.

- Heat recovery and energy efficiency improvements: Systems that capture and utilize waste heat from turbine exhaust can significantly improve overall energy efficiency and reduce environmental impact. These include heat exchangers, regenerative cycles, and combined cycle systems that convert otherwise wasted thermal energy into useful power. By maximizing energy extraction from fuel, these technologies reduce the carbon footprint per unit of power generated.

- Monitoring and control systems for environmental compliance: Advanced monitoring and control systems help manage turbine engine emissions in real-time. These include sensors that measure exhaust gas composition, temperature, and flow rates, coupled with control algorithms that optimize engine operation to minimize environmental impact. Such systems enable operators to maintain compliance with regulations while adapting to changing operational conditions.

- Alternative fuels and hydrogen integration: The use of alternative fuels, including hydrogen, biofuels, and synthetic fuels, can significantly reduce the environmental impact of turbine engine exhaust. These fuels often produce fewer pollutants and greenhouse gases compared to conventional fossil fuels. Modifications to fuel delivery systems and combustion chambers allow turbine engines to operate efficiently with these cleaner fuel sources.

02 Noise reduction solutions for turbine exhaust

Noise pollution from turbine engine exhaust represents a significant environmental concern, particularly around airports and power generation facilities. Innovations in this area include acoustic liners, specialized exhaust nozzles, and sound-dampening materials that reduce the acoustic footprint of turbine operations. These solutions help mitigate community noise impacts while maintaining engine performance parameters.Expand Specific Solutions03 Heat management and energy recovery systems

Turbine exhaust contains significant thermal energy that can be recovered and repurposed. Advanced heat exchangers, waste heat recovery systems, and thermal management technologies capture this otherwise wasted energy to improve overall system efficiency. These systems reduce the environmental impact by decreasing the heat signature of exhaust gases and converting thermal energy into useful power, thereby reducing the overall carbon footprint.Expand Specific Solutions04 Monitoring and control systems for exhaust emissions

Sophisticated monitoring and control systems have been developed to continuously assess and manage turbine engine exhaust emissions. These include sensors, data analytics platforms, and adaptive control algorithms that optimize engine operation to minimize environmental impact. Real-time monitoring enables operators to maintain compliance with environmental regulations while identifying opportunities for performance improvements and emission reductions.Expand Specific Solutions05 Alternative fuels and combustion improvements

Research into alternative fuels and improved combustion processes aims to reduce the environmental impact of turbine engine exhaust at the source. Innovations include hydrogen fuel systems, biofuel compatibility, and advanced combustion chamber designs that promote more complete fuel burning. These approaches significantly reduce carbon dioxide emissions and other pollutants while maintaining or enhancing engine performance characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The environmental impact of turbine engine exhaust on the atmosphere represents a mature technological challenge within the aerospace and power generation sectors. The market is characterized by established players like General Electric, Rolls-Royce, and Siemens Energy dominating traditional solutions, while emerging companies such as ZeroAvia are pioneering hydrogen-electric alternatives. The industry is in a transitional phase, with increasing regulatory pressure driving innovation toward lower-emission technologies. Research institutions like Southwest Research Institute collaborate with major manufacturers to develop emission reduction technologies. The global market for cleaner turbine technologies is expanding rapidly, estimated at over $30 billion annually, as aviation and power generation sectors seek to meet stringent environmental targets while maintaining performance standards.

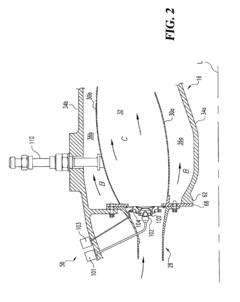

General Electric Company

Technical Solution: General Electric has developed advanced TAPS (Twin Annular Premixing Swirler) combustion systems that significantly reduce NOx emissions from aircraft engines. Their latest LEAP engine technology incorporates advanced materials and aerodynamic designs to improve fuel efficiency by 15% while reducing CO2 emissions proportionally. GE's emissions reduction strategy focuses on lean-burn combustion technology that minimizes the formation of nitrogen oxides by operating at lower flame temperatures. Additionally, their additive manufacturing techniques allow for complex geometries in fuel nozzles that optimize fuel-air mixing, resulting in more complete combustion and fewer particulate emissions. GE has also pioneered water injection technology for turbines that can reduce NOx emissions by up to 80% in certain applications.

Strengths: Industry-leading NOx reduction technology; comprehensive research capabilities across multiple turbine applications; strong integration of digital monitoring for emissions optimization. Weaknesses: Technologies often require significant capital investment; some solutions increase system complexity and maintenance requirements; water injection systems add operational complexity in water-scarce regions.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed the UltraFan® engine architecture with advanced lean-burn combustion technology that reduces NOx emissions by over 20% compared to previous generation engines. Their ALECSys (Advanced Low Emissions Combustion System) technology pre-mixes fuel and air before combustion to achieve significantly lower flame temperatures and NOx formation. Rolls-Royce has also pioneered sustainable aviation fuel (SAF) compatibility across their turbine portfolio, with engines capable of operating on 100% SAF blends that can reduce lifecycle carbon emissions by up to 80%. Their environmental strategy includes innovative air quality monitoring systems that provide real-time emissions data during engine operation, allowing for adaptive control systems that optimize combustion parameters based on atmospheric conditions and operational requirements.

Strengths: Holistic approach combining combustion technology with sustainable fuels; strong focus on lifecycle emissions rather than just point-of-use; extensive testing infrastructure for emissions validation. Weaknesses: High R&D costs reflected in product pricing; some technologies still in demonstration phase rather than full commercial deployment; complex integration requirements with aircraft systems.

Key Patents and Research in Exhaust Treatment

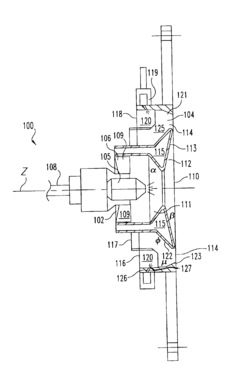

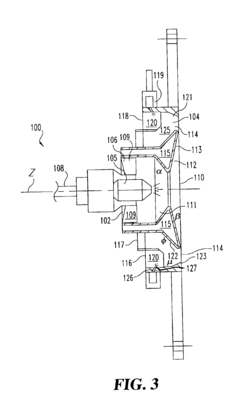

Fuel premixing module for gas turbine engine combustor

PatentInactiveUS6968692B2

Innovation

- A novel premixing module design featuring a pilot premixer surrounded by a main premixer, with axial inflow swirlers and strategically positioned fluid inlets, allows for efficient fuel and air mixing, controlling reaction temperatures and minimizing NOx formation by limiting the mixing length and optimizing fuel/air ratios.

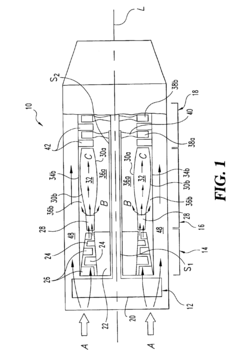

Dry low combustion system with means for eliminating combustion noise

PatentInactiveEP1488086A1

Innovation

- The system incorporates a radial inflow swirler and tubular premixers within a combustion chamber, with a contoured dome to minimize flow separation and enhance mixing, along with twist mixers to prevent pre-ignition, creating a stable swirling flow that reduces noise and emissions.

Climate Policy Implications for Turbine Industry

The evolving climate policy landscape presents significant implications for the turbine industry, requiring manufacturers and operators to adapt to increasingly stringent emissions regulations. International agreements such as the Paris Climate Accord have established frameworks for reducing greenhouse gas emissions, with many nations implementing specific targets that directly impact turbine operations in power generation, aviation, and marine applications.

Regulatory bodies worldwide are implementing progressively stricter emission standards for nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The European Union's Industrial Emissions Directive and the United States Environmental Protection Agency's Clean Air Act amendments represent cornerstone policies that mandate substantial reductions in turbine exhaust pollutants. These regulations are driving rapid technological adaptation across the industry.

Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are becoming more prevalent globally. These economic instruments create direct financial incentives for turbine manufacturers and operators to minimize carbon emissions. The increasing price of carbon emissions is fundamentally altering the cost-benefit analysis of different turbine technologies, favoring lower-emission alternatives despite potentially higher initial capital investments.

Industry stakeholders face mounting pressure to incorporate sustainability metrics into corporate governance structures. Environmental, Social, and Governance (ESG) reporting requirements are becoming standard practice, with investors increasingly considering climate impact in their decision-making processes. This shift is compelling turbine manufacturers to prioritize environmental performance alongside traditional metrics like efficiency and reliability.

The transition toward renewable energy sources is accelerating, supported by policy incentives and subsidies that favor cleaner technologies. Hybrid systems that combine traditional turbines with renewable energy sources are gaining policy support, creating new market opportunities for innovative turbine designs that can operate flexibly within integrated energy systems.

Research and development tax credits and grants specifically targeting low-emission turbine technologies are expanding across developed economies. These financial incentives are reshaping investment priorities within the industry, directing capital toward next-generation turbine designs with minimal environmental footprint. Companies that successfully leverage these incentives gain competitive advantages in an increasingly environmentally conscious marketplace.

Looking forward, policy trends indicate a continued tightening of emissions standards with potential expansion to previously unregulated pollutants. The industry must prepare for comprehensive lifecycle emissions accounting requirements that consider not only operational emissions but also manufacturing and end-of-life environmental impacts of turbine systems.

Regulatory bodies worldwide are implementing progressively stricter emission standards for nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. The European Union's Industrial Emissions Directive and the United States Environmental Protection Agency's Clean Air Act amendments represent cornerstone policies that mandate substantial reductions in turbine exhaust pollutants. These regulations are driving rapid technological adaptation across the industry.

Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are becoming more prevalent globally. These economic instruments create direct financial incentives for turbine manufacturers and operators to minimize carbon emissions. The increasing price of carbon emissions is fundamentally altering the cost-benefit analysis of different turbine technologies, favoring lower-emission alternatives despite potentially higher initial capital investments.

Industry stakeholders face mounting pressure to incorporate sustainability metrics into corporate governance structures. Environmental, Social, and Governance (ESG) reporting requirements are becoming standard practice, with investors increasingly considering climate impact in their decision-making processes. This shift is compelling turbine manufacturers to prioritize environmental performance alongside traditional metrics like efficiency and reliability.

The transition toward renewable energy sources is accelerating, supported by policy incentives and subsidies that favor cleaner technologies. Hybrid systems that combine traditional turbines with renewable energy sources are gaining policy support, creating new market opportunities for innovative turbine designs that can operate flexibly within integrated energy systems.

Research and development tax credits and grants specifically targeting low-emission turbine technologies are expanding across developed economies. These financial incentives are reshaping investment priorities within the industry, directing capital toward next-generation turbine designs with minimal environmental footprint. Companies that successfully leverage these incentives gain competitive advantages in an increasingly environmentally conscious marketplace.

Looking forward, policy trends indicate a continued tightening of emissions standards with potential expansion to previously unregulated pollutants. The industry must prepare for comprehensive lifecycle emissions accounting requirements that consider not only operational emissions but also manufacturing and end-of-life environmental impacts of turbine systems.

Sustainable Aviation Fuel Integration Strategies

Sustainable Aviation Fuel (SAF) integration represents a critical pathway for reducing the environmental impact of turbine engine exhaust on the atmosphere. Current aviation operations rely heavily on conventional jet fuels that produce significant carbon dioxide, nitrogen oxides, and particulate matter emissions. SAF offers a promising alternative with potential lifecycle carbon emission reductions of up to 80% compared to conventional jet fuel.

Integration strategies for SAF must address several key challenges simultaneously. The "drop-in" capability of SAF formulations remains essential, allowing these fuels to be used in existing aircraft and infrastructure without modification. ASTM International certification standards (D7566) provide the framework for ensuring SAF meets all safety and performance requirements while maintaining compatibility with conventional fuels.

Supply chain development represents another crucial integration component. Current SAF production capacity meets less than 0.1% of global jet fuel demand, necessitating strategic scaling approaches. Airport fuel infrastructure modifications, though minimal compared to other alternative energy solutions, still require careful planning and investment to accommodate increasing SAF volumes.

Financial mechanisms play a vital role in SAF integration. The price premium of SAF (typically 2-5 times conventional jet fuel) creates adoption barriers that can be addressed through policy instruments like blending mandates, tax incentives, and carbon pricing schemes. The European Union's ReFuelEU Aviation initiative exemplifies this approach by establishing progressive SAF blending requirements starting at 2% in 2025 and reaching 63% by 2050.

Airline procurement strategies have evolved to support SAF integration. Book-and-claim systems allow airlines to purchase SAF benefits without physically taking delivery of the fuel, enabling wider participation across route networks. Forward purchasing agreements provide producers with revenue certainty while helping airlines manage price volatility and demonstrate environmental commitment.

Technical integration considerations include fuel handling procedures, quality assurance protocols, and emissions monitoring systems. While current SAF blends are limited to 50% maximum concentration with conventional jet fuel, research continues toward developing 100% SAF capabilities that would maximize environmental benefits.

Cross-sector collaboration frameworks connecting fuel producers, airlines, airports, and regulators have proven essential for successful SAF integration. These partnerships facilitate knowledge sharing, risk distribution, and coordinated infrastructure development that individual stakeholders could not achieve independently.

Integration strategies for SAF must address several key challenges simultaneously. The "drop-in" capability of SAF formulations remains essential, allowing these fuels to be used in existing aircraft and infrastructure without modification. ASTM International certification standards (D7566) provide the framework for ensuring SAF meets all safety and performance requirements while maintaining compatibility with conventional fuels.

Supply chain development represents another crucial integration component. Current SAF production capacity meets less than 0.1% of global jet fuel demand, necessitating strategic scaling approaches. Airport fuel infrastructure modifications, though minimal compared to other alternative energy solutions, still require careful planning and investment to accommodate increasing SAF volumes.

Financial mechanisms play a vital role in SAF integration. The price premium of SAF (typically 2-5 times conventional jet fuel) creates adoption barriers that can be addressed through policy instruments like blending mandates, tax incentives, and carbon pricing schemes. The European Union's ReFuelEU Aviation initiative exemplifies this approach by establishing progressive SAF blending requirements starting at 2% in 2025 and reaching 63% by 2050.

Airline procurement strategies have evolved to support SAF integration. Book-and-claim systems allow airlines to purchase SAF benefits without physically taking delivery of the fuel, enabling wider participation across route networks. Forward purchasing agreements provide producers with revenue certainty while helping airlines manage price volatility and demonstrate environmental commitment.

Technical integration considerations include fuel handling procedures, quality assurance protocols, and emissions monitoring systems. While current SAF blends are limited to 50% maximum concentration with conventional jet fuel, research continues toward developing 100% SAF capabilities that would maximize environmental benefits.

Cross-sector collaboration frameworks connecting fuel producers, airlines, airports, and regulators have proven essential for successful SAF integration. These partnerships facilitate knowledge sharing, risk distribution, and coordinated infrastructure development that individual stakeholders could not achieve independently.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!