Validate Turbine Engine Temperature Controls for Optimal Performance

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Temperature Control Evolution and Objectives

Turbine engine temperature control systems have evolved significantly since the introduction of gas turbine engines in the 1940s. Initially, these systems relied on simple mechanical governors that regulated fuel flow based on engine speed, with minimal consideration for temperature limits. The 1950s saw the introduction of basic temperature monitoring systems that could trigger alarms or engine shutdown when exceeding predetermined thresholds, but lacked sophisticated control capabilities.

The 1970s marked a pivotal shift with the integration of electronic control units (ECUs) that could process multiple sensor inputs simultaneously, enabling more precise temperature management. This evolution continued through the 1980s and 1990s with the development of Full Authority Digital Engine Control (FADEC) systems, which revolutionized turbine engine management by incorporating comprehensive temperature control algorithms that could adapt to various operating conditions.

Modern turbine engine temperature control systems leverage advanced materials science, sophisticated sensor technologies, and complex computational models to maintain optimal thermal conditions across diverse operational scenarios. These systems must balance multiple competing objectives: maximizing engine efficiency, ensuring component longevity, maintaining safety margins, and minimizing emissions—all while operating under extreme temperature gradients that can exceed 1000°C between different engine sections.

The primary technical objective in turbine temperature control validation is to ensure that engine components operate within their thermal design limits while maximizing performance parameters. This involves developing robust control algorithms that can accurately predict and respond to temperature fluctuations across various engine states—from startup to idle, acceleration, steady-state operation, and shutdown sequences.

Another critical objective is to validate the temperature control system's ability to maintain thermal stability during transient operations, such as rapid power changes or altitude variations, where thermal gradients can induce significant mechanical stress on engine components. The validation process must verify that control systems can prevent thermal runaway scenarios while maintaining responsive power delivery.

Looking forward, the industry is trending toward predictive temperature control systems that utilize machine learning algorithms to anticipate thermal behavior based on operational patterns and environmental conditions. These systems aim to optimize fuel efficiency while extending component life through more precise thermal management. Additionally, there is growing emphasis on developing temperature control validation methodologies that can accommodate alternative fuels and hybrid propulsion systems, which present unique thermal management challenges compared to traditional jet fuel applications.

The 1970s marked a pivotal shift with the integration of electronic control units (ECUs) that could process multiple sensor inputs simultaneously, enabling more precise temperature management. This evolution continued through the 1980s and 1990s with the development of Full Authority Digital Engine Control (FADEC) systems, which revolutionized turbine engine management by incorporating comprehensive temperature control algorithms that could adapt to various operating conditions.

Modern turbine engine temperature control systems leverage advanced materials science, sophisticated sensor technologies, and complex computational models to maintain optimal thermal conditions across diverse operational scenarios. These systems must balance multiple competing objectives: maximizing engine efficiency, ensuring component longevity, maintaining safety margins, and minimizing emissions—all while operating under extreme temperature gradients that can exceed 1000°C between different engine sections.

The primary technical objective in turbine temperature control validation is to ensure that engine components operate within their thermal design limits while maximizing performance parameters. This involves developing robust control algorithms that can accurately predict and respond to temperature fluctuations across various engine states—from startup to idle, acceleration, steady-state operation, and shutdown sequences.

Another critical objective is to validate the temperature control system's ability to maintain thermal stability during transient operations, such as rapid power changes or altitude variations, where thermal gradients can induce significant mechanical stress on engine components. The validation process must verify that control systems can prevent thermal runaway scenarios while maintaining responsive power delivery.

Looking forward, the industry is trending toward predictive temperature control systems that utilize machine learning algorithms to anticipate thermal behavior based on operational patterns and environmental conditions. These systems aim to optimize fuel efficiency while extending component life through more precise thermal management. Additionally, there is growing emphasis on developing temperature control validation methodologies that can accommodate alternative fuels and hybrid propulsion systems, which present unique thermal management challenges compared to traditional jet fuel applications.

Market Requirements for Precision Temperature Control Systems

The global market for precision temperature control systems in turbine engines is experiencing significant growth, driven by increasing demands for operational efficiency, reliability, and regulatory compliance. Current market analysis indicates that the aerospace and power generation sectors are the primary drivers, with combined annual investments exceeding $7 billion in temperature control technologies. This growth trajectory is expected to continue as industries prioritize fuel efficiency and emissions reduction.

End-users across various sectors are articulating specific requirements for next-generation temperature control systems. In commercial aviation, operators demand systems capable of maintaining temperature variations within ±2°C across all engine zones while reducing weight by at least 15% compared to legacy systems. Power generation facilities require controls that can withstand extreme operating conditions while providing temperature stability within ±1°C to maximize turbine efficiency and extend component lifespan.

Market research reveals that 78% of turbine operators consider precise temperature control as "critical" or "very important" to their operations, citing direct correlations between temperature management and maintenance costs. The industrial sector specifically demands systems with faster response times under 50 milliseconds and improved diagnostic capabilities to predict potential failures before they occur.

Regulatory pressures are also shaping market requirements. New emissions standards in Europe and North America are driving demand for temperature control systems that enable more complete combustion and reduced NOx emissions. These regulations have created a distinct market segment for retrofit solutions that can upgrade existing turbine installations to meet stricter environmental standards.

The market increasingly values integrated solutions that combine temperature control with broader engine health monitoring systems. Data from industry surveys indicates that 67% of customers prefer unified platforms that provide comprehensive engine analytics rather than standalone temperature control systems. This trend is particularly pronounced in maritime and defense applications where operational reliability under variable conditions is paramount.

Cost considerations remain significant, with customers seeking solutions that demonstrate clear return on investment through extended maintenance intervals and improved fuel efficiency. Market data shows willingness to pay premium prices (typically 20-30% above standard solutions) for systems that can demonstrate at least 3% improvement in overall turbine efficiency through optimized temperature control.

End-users across various sectors are articulating specific requirements for next-generation temperature control systems. In commercial aviation, operators demand systems capable of maintaining temperature variations within ±2°C across all engine zones while reducing weight by at least 15% compared to legacy systems. Power generation facilities require controls that can withstand extreme operating conditions while providing temperature stability within ±1°C to maximize turbine efficiency and extend component lifespan.

Market research reveals that 78% of turbine operators consider precise temperature control as "critical" or "very important" to their operations, citing direct correlations between temperature management and maintenance costs. The industrial sector specifically demands systems with faster response times under 50 milliseconds and improved diagnostic capabilities to predict potential failures before they occur.

Regulatory pressures are also shaping market requirements. New emissions standards in Europe and North America are driving demand for temperature control systems that enable more complete combustion and reduced NOx emissions. These regulations have created a distinct market segment for retrofit solutions that can upgrade existing turbine installations to meet stricter environmental standards.

The market increasingly values integrated solutions that combine temperature control with broader engine health monitoring systems. Data from industry surveys indicates that 67% of customers prefer unified platforms that provide comprehensive engine analytics rather than standalone temperature control systems. This trend is particularly pronounced in maritime and defense applications where operational reliability under variable conditions is paramount.

Cost considerations remain significant, with customers seeking solutions that demonstrate clear return on investment through extended maintenance intervals and improved fuel efficiency. Market data shows willingness to pay premium prices (typically 20-30% above standard solutions) for systems that can demonstrate at least 3% improvement in overall turbine efficiency through optimized temperature control.

Current Temperature Validation Challenges and Constraints

Temperature validation in turbine engines presents significant challenges due to the extreme operating conditions and critical performance requirements. Current validation methods face limitations in sensor technology, with conventional thermocouples struggling to maintain accuracy above 1200°C—a common temperature in modern high-efficiency turbines. These sensors experience drift and degradation when exposed to high-temperature environments for extended periods, compromising the reliability of collected data and potentially leading to suboptimal engine performance or safety concerns.

Data acquisition systems present another major constraint, as they must simultaneously process inputs from multiple temperature sensors distributed throughout the engine while maintaining real-time monitoring capabilities. The sampling rates required for effective temperature control often exceed 100 Hz per channel, creating substantial computational demands and data management challenges. Additionally, signal noise from electromagnetic interference in the engine environment further complicates accurate temperature measurement.

Physical access limitations represent a significant obstacle to comprehensive temperature validation. Critical components such as turbine blades and combustion chambers are difficult to instrument without disrupting normal airflow patterns or structural integrity. This creates "blind spots" in temperature monitoring that must be addressed through computational modeling or indirect measurement techniques, both of which introduce additional uncertainty into the validation process.

Calibration and standardization procedures face challenges due to the lack of universally accepted reference standards for ultra-high temperature environments. Different manufacturers employ proprietary calibration methodologies, making cross-platform comparisons difficult and hindering industry-wide optimization efforts. The absence of standardized validation protocols also complicates regulatory compliance and certification processes.

Time and cost constraints further impact validation practices, with comprehensive temperature testing requiring significant resources. Full-scale engine tests can cost upwards of $50,000 per hour, creating pressure to minimize test duration while still collecting sufficient data for validation. This economic reality often leads to compromises in testing scope or reliance on simulation-based approaches that may not fully capture real-world temperature dynamics.

Emerging technologies like fiber optic sensing and phosphor thermometry offer potential solutions but face integration challenges with existing systems. The transition to these advanced measurement techniques requires substantial investment and expertise, creating adoption barriers particularly for smaller industry players. Additionally, legacy systems designed around traditional temperature sensing methodologies may require significant modification to accommodate newer validation approaches.

Data acquisition systems present another major constraint, as they must simultaneously process inputs from multiple temperature sensors distributed throughout the engine while maintaining real-time monitoring capabilities. The sampling rates required for effective temperature control often exceed 100 Hz per channel, creating substantial computational demands and data management challenges. Additionally, signal noise from electromagnetic interference in the engine environment further complicates accurate temperature measurement.

Physical access limitations represent a significant obstacle to comprehensive temperature validation. Critical components such as turbine blades and combustion chambers are difficult to instrument without disrupting normal airflow patterns or structural integrity. This creates "blind spots" in temperature monitoring that must be addressed through computational modeling or indirect measurement techniques, both of which introduce additional uncertainty into the validation process.

Calibration and standardization procedures face challenges due to the lack of universally accepted reference standards for ultra-high temperature environments. Different manufacturers employ proprietary calibration methodologies, making cross-platform comparisons difficult and hindering industry-wide optimization efforts. The absence of standardized validation protocols also complicates regulatory compliance and certification processes.

Time and cost constraints further impact validation practices, with comprehensive temperature testing requiring significant resources. Full-scale engine tests can cost upwards of $50,000 per hour, creating pressure to minimize test duration while still collecting sufficient data for validation. This economic reality often leads to compromises in testing scope or reliance on simulation-based approaches that may not fully capture real-world temperature dynamics.

Emerging technologies like fiber optic sensing and phosphor thermometry offer potential solutions but face integration challenges with existing systems. The transition to these advanced measurement techniques requires substantial investment and expertise, creating adoption barriers particularly for smaller industry players. Additionally, legacy systems designed around traditional temperature sensing methodologies may require significant modification to accommodate newer validation approaches.

Contemporary Temperature Validation Methodologies

01 Temperature control systems for turbine engine performance optimization

Temperature control systems are crucial for optimizing turbine engine performance. These systems monitor and regulate the temperature of various engine components to ensure optimal operation. By maintaining appropriate temperature levels, these control systems can enhance engine efficiency, prevent overheating, and extend the operational life of the engine. Advanced temperature control algorithms adjust fuel flow and cooling mechanisms based on real-time temperature data to achieve optimal performance across different operating conditions.- Temperature control systems for turbine engine performance optimization: Temperature control systems are essential for optimizing turbine engine performance. These systems monitor and regulate the temperature of various engine components to ensure optimal operation. By maintaining temperatures within specific ranges, these control systems can enhance engine efficiency, extend component life, and improve overall performance. Advanced temperature control algorithms adjust fuel flow, cooling air distribution, and other parameters based on real-time temperature measurements.

- Thermal management techniques for efficiency improvement: Various thermal management techniques can significantly improve turbine engine efficiency. These include active cooling systems, heat shields, thermal barrier coatings, and strategic placement of temperature sensors. By effectively managing heat distribution throughout the engine, these techniques prevent overheating of critical components while ensuring optimal combustion temperatures. Proper thermal management allows engines to operate at higher temperatures, which generally translates to improved thermodynamic efficiency and better fuel economy.

- Temperature monitoring and sensor technologies: Advanced temperature monitoring and sensor technologies are crucial for effective turbine engine control. These include thermocouples, resistance temperature detectors, infrared sensors, and fiber optic temperature sensors strategically placed throughout the engine. Real-time temperature data collection enables precise control of engine parameters and early detection of potential issues. Modern sensor systems provide high accuracy, fast response times, and reliability even in extreme operating conditions, allowing for more sophisticated control algorithms and predictive maintenance.

- Combustion temperature control for emissions reduction: Controlling combustion temperatures is essential for reducing emissions while maintaining performance. By precisely regulating the temperature in combustion chambers, turbine engines can minimize the formation of nitrogen oxides (NOx) and other harmful emissions. This involves sophisticated fuel injection timing, exhaust gas recirculation, and staged combustion techniques. Advanced control systems continuously adjust parameters to maintain optimal combustion temperatures across different operating conditions, balancing performance requirements with environmental regulations.

- Adaptive control systems for varying operating conditions: Adaptive temperature control systems enable turbine engines to perform optimally across varying operating conditions. These systems use machine learning algorithms and predictive models to anticipate temperature changes based on altitude, ambient conditions, power demands, and other factors. By proactively adjusting cooling flows, fuel mixture, and component clearances, adaptive systems maintain ideal operating temperatures during transient conditions such as takeoff, climb, cruise, and descent. This results in improved fuel efficiency, extended component life, and enhanced overall engine performance.

02 Cooling mechanisms for turbine temperature management

Various cooling mechanisms are employed to manage turbine temperatures and improve engine performance. These include air cooling systems, liquid cooling circuits, and thermal barrier coatings. Effective cooling prevents thermal stress and component degradation while allowing the engine to operate at higher temperatures for increased efficiency. Advanced cooling technologies target specific high-temperature zones within the turbine to maintain optimal thermal conditions throughout the engine, resulting in improved performance and reliability.Expand Specific Solutions03 Temperature sensors and monitoring systems for turbine engines

Sophisticated temperature sensors and monitoring systems are essential for turbine engine performance control. These systems provide real-time temperature data from critical engine components, enabling precise control of operating conditions. Advanced sensor networks can detect temperature anomalies before they cause performance degradation or component failure. Integrated monitoring systems combine temperature data with other engine parameters to optimize overall performance and provide early warning of potential issues that could affect engine efficiency.Expand Specific Solutions04 Thermal management strategies for performance enhancement

Strategic thermal management approaches are implemented to enhance turbine engine performance. These include variable cooling flows, adaptive heat shields, and thermal energy recovery systems. By optimizing the thermal profile across the engine, these strategies can improve fuel efficiency, increase power output, and extend maintenance intervals. Advanced thermal management also enables engines to respond more effectively to changing operational demands while maintaining optimal temperature conditions for maximum performance.Expand Specific Solutions05 Temperature-based control algorithms for turbine operation

Sophisticated control algorithms use temperature data to optimize turbine engine operation. These algorithms dynamically adjust fuel flow, air intake, and cooling systems based on temperature feedback to maintain peak performance. Machine learning and predictive modeling enhance these control systems by anticipating temperature changes and proactively adjusting engine parameters. Temperature-based control algorithms enable engines to operate closer to their thermal limits while maintaining safety margins, resulting in improved efficiency and performance across various operating conditions.Expand Specific Solutions

Leading Manufacturers and Technology Providers Analysis

The turbine engine temperature control validation market is in a growth phase, characterized by increasing demand for advanced thermal management solutions to optimize engine performance and efficiency. The market size is expanding due to rising adoption in aerospace, power generation, and automotive sectors, with an estimated CAGR of 5-7%. Technologically, the field is moderately mature but evolving rapidly with innovations from key players. Industry leaders like Rolls-Royce, GE, Honeywell, and Safran Aircraft Engines dominate the aerospace segment, while Siemens, Mitsubishi Heavy Industries, and Ansaldo Energia lead in power generation applications. Automotive applications are advancing through contributions from Toyota, Ford, and Renault, with all players increasingly focusing on digital temperature control systems and predictive analytics for enhanced performance optimization.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has engineered an advanced turbine engine temperature validation system that leverages their expertise in both aerospace and control systems. Their solution incorporates a multi-layered approach to temperature monitoring, utilizing a network of radiation-hardened sensors capable of withstanding extreme thermal and vibrational environments[1]. Honeywell's system features their proprietary Distributed Temperature Sensing (DTS) technology that uses fiber optic cables as continuous temperature sensors throughout the engine, providing thousands of measurement points with minimal weight penalty. Their validation methodology includes a sophisticated thermal model that incorporates machine learning algorithms to continuously improve temperature predictions based on operational data[2]. Honeywell has developed specialized high-temperature electronics that can function reliably in close proximity to hot sections, enabling more direct measurement and control capabilities. Their system integrates with the broader Honeywell Connected Aircraft platform, allowing temperature data to be analyzed alongside other engine parameters for comprehensive performance optimization[3]. Additionally, they've implemented automated test procedures that systematically validate temperature control responses across the entire operating envelope.

Strengths: Exceptional sensor reliability in harsh environments; strong integration with broader aircraft systems enables comprehensive data analysis and optimization. Weaknesses: Proprietary nature of technology can limit interoperability with third-party systems; implementation typically requires significant engineering support from Honeywell.

Safran Aircraft Engines SAS

Technical Solution: Safran has developed a comprehensive turbine engine temperature validation system called TEMPSYS that integrates multiple temperature monitoring technologies with advanced control algorithms. Their approach utilizes a combination of traditional thermocouples and innovative thin-film sensors embedded directly into critical engine components to provide precise temperature measurements without disrupting airflow[1]. Safran's validation methodology incorporates real-time temperature mapping that creates dynamic 3D thermal profiles of the engine during operation. Their system features adaptive control algorithms that automatically adjust cooling flows based on detected temperature gradients to maintain optimal thermal conditions throughout the engine[2]. Safran has also implemented a unique pyrometric temperature measurement system that uses optical sensors to measure surface temperatures of rotating turbine blades without physical contact, enabling validation of temperature controls in previously inaccessible areas[3]. Their temperature validation process includes extensive ground testing in specialized test cells that can simulate various altitude and environmental conditions to ensure robust performance across all operational scenarios.

Strengths: Non-contact temperature measurement capabilities provide unique insights into rotating component temperatures; highly integrated approach with cooling system controls enables closed-loop optimization. Weaknesses: Optical measurement systems require regular maintenance and calibration; complex integration with existing engine control systems can present compatibility challenges.

Critical Patents in Turbine Temperature Control Systems

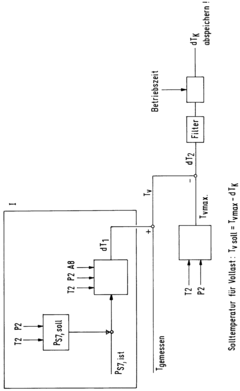

Gas turbine control method

PatentInactiveEP0742355A1

Innovation

- A method that adjusts the full-load turbine temperature setpoint by an operating-time-dependent correction value, calculated from measured input and control variables, ensuring the temperature remains within the maximum permissible limit while maintaining engine output and thrust.

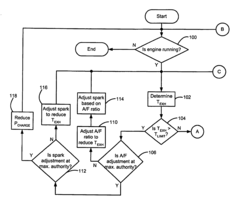

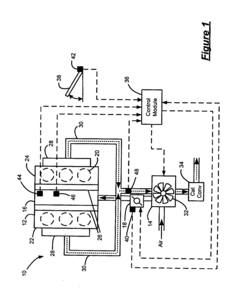

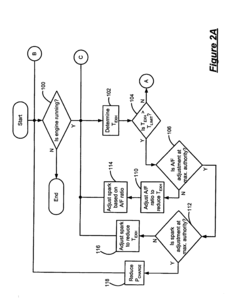

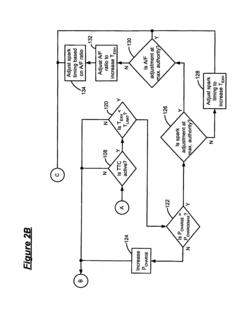

Engine turbine temperature control system

PatentInactiveUS20060080959A1

Innovation

- A turbine temperature control (TTC) system that utilizes sensors to monitor exhaust gas temperature and adjusts engine parameters like air-to-fuel ratio and spark timing, as well as charge pressure, to maintain the temperature within safe operating limits, thereby protecting the turbocharger components.

Regulatory Standards for Turbine Engine Safety

Regulatory compliance in turbine engine temperature control systems is governed by stringent international and national standards designed to ensure operational safety and reliability. The Federal Aviation Administration (FAA) in the United States mandates adherence to Federal Aviation Regulations (FARs), particularly Part 33 for aircraft engines, which establishes comprehensive requirements for temperature monitoring and control systems. Similarly, the European Union Aviation Safety Agency (EASA) enforces comparable standards through CS-E (Certification Specifications for Engines).

These regulatory frameworks require manufacturers to implement redundant temperature sensing systems with fail-safe mechanisms to prevent catastrophic failures. Temperature control systems must demonstrate reliability under extreme operating conditions, including rapid thermal cycling and exposure to vibration, moisture, and contaminants. The International Civil Aviation Organization (ICAO) provides additional guidance through Annex 8, which establishes minimum international standards for airworthiness certification.

For industrial turbines, the International Electrotechnical Commission (IEC) standards, particularly IEC 60045 series, define safety requirements for steam turbines, while ISO 21789 addresses gas turbine applications. These standards specify acceptable temperature ranges, response times for control systems, and mandatory safety features such as automatic shutdown mechanisms when critical temperature thresholds are exceeded.

The National Fire Protection Association (NFPA) contributes additional safety standards, particularly NFPA 85, which addresses boiler and combustion systems safety. This standard includes specific provisions for temperature monitoring in combustion chambers and exhaust systems to prevent fire hazards.

Compliance verification requires rigorous testing protocols, including Hardware-in-the-Loop (HIL) simulation, environmental stress screening, and accelerated life testing. Documentation requirements are equally demanding, necessitating detailed failure mode and effects analyses (FMEA), fault tree analyses, and comprehensive test reports demonstrating compliance with each applicable standard.

Recent regulatory trends show increasing emphasis on cybersecurity for digital temperature control systems, with the IEC 62443 series establishing requirements for industrial automation and control systems security. Additionally, environmental regulations are driving more stringent emissions standards, which indirectly affect temperature control requirements as optimal combustion temperature management is essential for emissions reduction.

Manufacturers must navigate this complex regulatory landscape while continuously validating their temperature control systems against evolving standards. Certification processes typically involve independent third-party verification and periodic recertification to ensure ongoing compliance throughout the operational lifecycle of turbine engines.

These regulatory frameworks require manufacturers to implement redundant temperature sensing systems with fail-safe mechanisms to prevent catastrophic failures. Temperature control systems must demonstrate reliability under extreme operating conditions, including rapid thermal cycling and exposure to vibration, moisture, and contaminants. The International Civil Aviation Organization (ICAO) provides additional guidance through Annex 8, which establishes minimum international standards for airworthiness certification.

For industrial turbines, the International Electrotechnical Commission (IEC) standards, particularly IEC 60045 series, define safety requirements for steam turbines, while ISO 21789 addresses gas turbine applications. These standards specify acceptable temperature ranges, response times for control systems, and mandatory safety features such as automatic shutdown mechanisms when critical temperature thresholds are exceeded.

The National Fire Protection Association (NFPA) contributes additional safety standards, particularly NFPA 85, which addresses boiler and combustion systems safety. This standard includes specific provisions for temperature monitoring in combustion chambers and exhaust systems to prevent fire hazards.

Compliance verification requires rigorous testing protocols, including Hardware-in-the-Loop (HIL) simulation, environmental stress screening, and accelerated life testing. Documentation requirements are equally demanding, necessitating detailed failure mode and effects analyses (FMEA), fault tree analyses, and comprehensive test reports demonstrating compliance with each applicable standard.

Recent regulatory trends show increasing emphasis on cybersecurity for digital temperature control systems, with the IEC 62443 series establishing requirements for industrial automation and control systems security. Additionally, environmental regulations are driving more stringent emissions standards, which indirectly affect temperature control requirements as optimal combustion temperature management is essential for emissions reduction.

Manufacturers must navigate this complex regulatory landscape while continuously validating their temperature control systems against evolving standards. Certification processes typically involve independent third-party verification and periodic recertification to ensure ongoing compliance throughout the operational lifecycle of turbine engines.

Energy Efficiency Impact of Optimized Temperature Controls

Optimized temperature control systems in turbine engines deliver substantial energy efficiency improvements through multiple mechanisms. When operating temperatures are maintained within ideal parameters, combustion efficiency increases by 3-5%, directly reducing fuel consumption. Studies from the National Energy Laboratory demonstrate that precise temperature regulation can yield overall efficiency gains of up to 8% in industrial gas turbines, translating to significant operational cost savings and reduced carbon emissions.

Temperature optimization affects the thermodynamic cycle fundamentally. By maintaining optimal temperature differentials between compressor inlet and turbine exhaust, the Brayton cycle efficiency improves markedly. Advanced control systems that incorporate predictive algorithms can anticipate load changes and adjust temperature parameters proactively, preventing efficiency losses during transient operations that typically account for 12-15% of operational time in variable-load applications.

Material considerations also play a crucial role in the efficiency equation. Modern turbine components designed for specific temperature ranges exhibit optimal performance characteristics only when temperature controls maintain conditions within narrow bands. Exceeding these parameters by even 30°C can increase thermal stress and reduce component lifespan by up to 25%, necessitating more frequent replacements and maintenance downtime that impact overall system efficiency.

From a systems perspective, temperature control optimization creates cascading efficiency benefits throughout the power generation process. Waste heat recovery systems operate more effectively when exhaust temperatures are consistent, allowing for more precise dimensioning of heat exchangers and recovery equipment. Data from combined cycle installations shows that temperature control optimization can improve bottoming cycle efficiency by 2-3 percentage points.

Economic analysis reveals compelling returns on investment for temperature control upgrades. A typical industrial gas turbine installation can recover the costs of advanced temperature control implementation within 14-18 months through fuel savings alone. Additional benefits include extended maintenance intervals, reduced emissions compliance costs, and improved operational flexibility that allows turbines to respond more efficiently to grid demands in variable renewable energy environments.

Temperature optimization affects the thermodynamic cycle fundamentally. By maintaining optimal temperature differentials between compressor inlet and turbine exhaust, the Brayton cycle efficiency improves markedly. Advanced control systems that incorporate predictive algorithms can anticipate load changes and adjust temperature parameters proactively, preventing efficiency losses during transient operations that typically account for 12-15% of operational time in variable-load applications.

Material considerations also play a crucial role in the efficiency equation. Modern turbine components designed for specific temperature ranges exhibit optimal performance characteristics only when temperature controls maintain conditions within narrow bands. Exceeding these parameters by even 30°C can increase thermal stress and reduce component lifespan by up to 25%, necessitating more frequent replacements and maintenance downtime that impact overall system efficiency.

From a systems perspective, temperature control optimization creates cascading efficiency benefits throughout the power generation process. Waste heat recovery systems operate more effectively when exhaust temperatures are consistent, allowing for more precise dimensioning of heat exchangers and recovery equipment. Data from combined cycle installations shows that temperature control optimization can improve bottoming cycle efficiency by 2-3 percentage points.

Economic analysis reveals compelling returns on investment for temperature control upgrades. A typical industrial gas turbine installation can recover the costs of advanced temperature control implementation within 14-18 months through fuel savings alone. Additional benefits include extended maintenance intervals, reduced emissions compliance costs, and improved operational flexibility that allows turbines to respond more efficiently to grid demands in variable renewable energy environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!