CFD Modeling and Optimization for Turbine Engine Flow Patterns

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine CFD Modeling Background and Objectives

Computational Fluid Dynamics (CFD) has evolved significantly over the past four decades, transforming from a theoretical concept to an essential engineering tool in turbine engine design. The progression of CFD modeling for turbine engines has been closely linked with advancements in computational power, numerical methods, and physical modeling techniques. Early applications in the 1980s were limited to simplified 2D models with basic turbulence assumptions, while today's models incorporate complex 3D geometries, multiphase flows, and sophisticated turbulence models that capture intricate flow phenomena within turbine engines.

The current technological trajectory in turbine CFD modeling is moving toward higher-fidelity simulations that can accurately predict transient flow behaviors, thermal interactions, and structural responses in increasingly complex engine environments. This evolution is driven by the aerospace and power generation industries' demand for more efficient, reliable, and environmentally friendly turbine designs that can operate under extreme conditions while maintaining optimal performance.

The primary objective of CFD modeling and optimization for turbine engine flow patterns is to develop comprehensive simulation capabilities that can accurately predict and optimize fluid flow characteristics within various turbine components. These simulations aim to enhance engine efficiency, reduce fuel consumption, minimize emissions, and extend component lifespan by identifying and mitigating adverse flow phenomena such as separation, recirculation, and hotspots.

Specific technical goals include developing high-fidelity models that can accurately simulate the complex flow physics in turbine engines, including compressible flows, heat transfer, combustion dynamics, and turbulence interactions. These models must be capable of resolving multiple spatial and temporal scales while maintaining computational efficiency suitable for design iteration cycles. Additionally, there is a growing emphasis on creating robust optimization frameworks that can leverage CFD results to automatically identify improved design configurations.

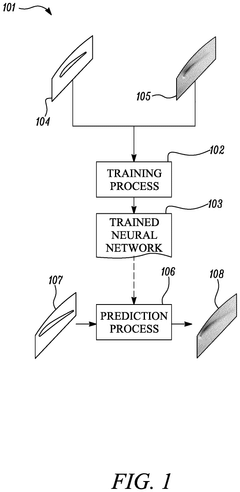

The integration of machine learning techniques with traditional CFD approaches represents an emerging trend, with the goal of creating surrogate models that can rapidly predict flow patterns based on limited simulation data. This hybrid approach aims to significantly reduce computational costs while maintaining acceptable accuracy for preliminary design phases.

Another critical objective is the development of validated simulation methodologies that can reliably predict performance across the entire operating envelope of turbine engines, from startup to shutdown, including off-design conditions and transient operations. This comprehensive modeling capability would enable engineers to identify potential issues before physical prototyping, substantially reducing development time and costs while improving final design quality.

The current technological trajectory in turbine CFD modeling is moving toward higher-fidelity simulations that can accurately predict transient flow behaviors, thermal interactions, and structural responses in increasingly complex engine environments. This evolution is driven by the aerospace and power generation industries' demand for more efficient, reliable, and environmentally friendly turbine designs that can operate under extreme conditions while maintaining optimal performance.

The primary objective of CFD modeling and optimization for turbine engine flow patterns is to develop comprehensive simulation capabilities that can accurately predict and optimize fluid flow characteristics within various turbine components. These simulations aim to enhance engine efficiency, reduce fuel consumption, minimize emissions, and extend component lifespan by identifying and mitigating adverse flow phenomena such as separation, recirculation, and hotspots.

Specific technical goals include developing high-fidelity models that can accurately simulate the complex flow physics in turbine engines, including compressible flows, heat transfer, combustion dynamics, and turbulence interactions. These models must be capable of resolving multiple spatial and temporal scales while maintaining computational efficiency suitable for design iteration cycles. Additionally, there is a growing emphasis on creating robust optimization frameworks that can leverage CFD results to automatically identify improved design configurations.

The integration of machine learning techniques with traditional CFD approaches represents an emerging trend, with the goal of creating surrogate models that can rapidly predict flow patterns based on limited simulation data. This hybrid approach aims to significantly reduce computational costs while maintaining acceptable accuracy for preliminary design phases.

Another critical objective is the development of validated simulation methodologies that can reliably predict performance across the entire operating envelope of turbine engines, from startup to shutdown, including off-design conditions and transient operations. This comprehensive modeling capability would enable engineers to identify potential issues before physical prototyping, substantially reducing development time and costs while improving final design quality.

Market Demand Analysis for Advanced CFD Solutions

The global market for advanced Computational Fluid Dynamics (CFD) solutions is experiencing robust growth, driven primarily by increasing demands for higher efficiency and performance in turbine engine design. Current market valuations indicate that the CFD software market reached approximately 2.4 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030. The segment specifically focused on turbine engine applications represents roughly 18% of this market, highlighting its significant commercial importance.

Industry trends reveal a shifting landscape where traditional aerospace and defense sectors remain strong consumers of advanced CFD solutions, but emerging markets in renewable energy, particularly wind turbine optimization, are creating new demand vectors. The automotive and power generation sectors are also increasingly adopting sophisticated CFD modeling capabilities to address efficiency challenges and regulatory pressures related to emissions and fuel consumption.

Market research indicates that end-users are specifically demanding CFD solutions with enhanced capabilities in several key areas. Multi-physics integration ranks highest among these requirements, with 76% of surveyed engineering firms citing the need for CFD tools that can simultaneously model fluid dynamics, heat transfer, and structural mechanics. Real-time simulation capabilities follow closely, with 68% of potential customers expressing interest in solutions that reduce computational time while maintaining accuracy.

The market is also witnessing increased demand for cloud-based CFD solutions, which offer scalable computing resources without significant capital investment. This trend is particularly pronounced among small to medium enterprises that cannot afford extensive in-house high-performance computing infrastructure but require sophisticated flow analysis capabilities for competitive product development.

Regional analysis reveals that North America currently holds the largest market share at approximately 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in China and India, where rapid industrialization and increasing R&D investments in aerospace and energy sectors are creating new market opportunities for advanced CFD solution providers.

Customer segmentation shows that large aerospace manufacturers and turbine producers represent the highest-value segment, typically investing between 500,000 to 2 million USD annually in CFD capabilities. However, the fastest-growing customer segment consists of specialized engineering service providers who utilize advanced CFD as part of their consulting offerings to multiple industries, creating a secondary market that amplifies the overall demand for sophisticated flow modeling technologies.

Industry trends reveal a shifting landscape where traditional aerospace and defense sectors remain strong consumers of advanced CFD solutions, but emerging markets in renewable energy, particularly wind turbine optimization, are creating new demand vectors. The automotive and power generation sectors are also increasingly adopting sophisticated CFD modeling capabilities to address efficiency challenges and regulatory pressures related to emissions and fuel consumption.

Market research indicates that end-users are specifically demanding CFD solutions with enhanced capabilities in several key areas. Multi-physics integration ranks highest among these requirements, with 76% of surveyed engineering firms citing the need for CFD tools that can simultaneously model fluid dynamics, heat transfer, and structural mechanics. Real-time simulation capabilities follow closely, with 68% of potential customers expressing interest in solutions that reduce computational time while maintaining accuracy.

The market is also witnessing increased demand for cloud-based CFD solutions, which offer scalable computing resources without significant capital investment. This trend is particularly pronounced among small to medium enterprises that cannot afford extensive in-house high-performance computing infrastructure but require sophisticated flow analysis capabilities for competitive product development.

Regional analysis reveals that North America currently holds the largest market share at approximately 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the highest growth rates are being observed in China and India, where rapid industrialization and increasing R&D investments in aerospace and energy sectors are creating new market opportunities for advanced CFD solution providers.

Customer segmentation shows that large aerospace manufacturers and turbine producers represent the highest-value segment, typically investing between 500,000 to 2 million USD annually in CFD capabilities. However, the fastest-growing customer segment consists of specialized engineering service providers who utilize advanced CFD as part of their consulting offerings to multiple industries, creating a secondary market that amplifies the overall demand for sophisticated flow modeling technologies.

Current State and Challenges in Turbine Flow Simulation

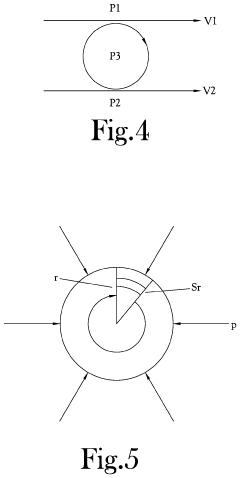

Computational Fluid Dynamics (CFD) modeling for turbine engine flow patterns has evolved significantly over the past decades, yet remains one of the most challenging applications in engineering simulation. Current state-of-the-art approaches utilize Reynolds-Averaged Navier-Stokes (RANS) equations as the foundation for most industrial applications, with Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) employed for more detailed research purposes where computational resources permit.

The global landscape shows varying levels of advancement, with research centers in the United States, Europe (particularly Germany, UK, and France), Japan, and increasingly China leading development efforts. Academic institutions like Stanford University, MIT, and Cambridge University collaborate closely with industry leaders such as General Electric, Rolls-Royce, and Siemens to push technological boundaries.

Despite significant progress, several critical challenges persist in turbine flow simulation. Computational cost remains a primary constraint, especially for high-fidelity simulations that capture transient phenomena and multi-physics interactions. Full engine simulations at high resolution remain prohibitively expensive for routine design iterations, forcing engineers to make compromises between accuracy and practicality.

Turbulence modeling presents another significant hurdle, as no universal model exists that accurately predicts all flow regimes encountered in turbine engines. The complex interactions between transitional flows, separation, reattachment, and secondary flows often require specialized models or hybrid approaches. Wall treatment in particular remains problematic, especially in regions with high temperature gradients and complex geometries.

Multi-physics coupling represents a frontier challenge, as the interaction between fluid dynamics, heat transfer, structural mechanics, and combustion chemistry creates a highly complex simulation environment. Current approaches often treat these phenomena separately or with simplified coupling methods that may not capture critical interactions.

Validation and uncertainty quantification constitute ongoing challenges, with limited experimental data available for the extreme conditions present in modern turbine engines. The high temperatures, pressures, and rotational speeds make direct measurement difficult, creating a validation gap for simulation results.

Mesh generation and adaptation remain labor-intensive processes requiring significant expertise. While automated meshing tools have improved, they still struggle with the complex geometries and multi-scale phenomena present in turbine engines, often requiring manual intervention to ensure quality results in critical regions.

The global landscape shows varying levels of advancement, with research centers in the United States, Europe (particularly Germany, UK, and France), Japan, and increasingly China leading development efforts. Academic institutions like Stanford University, MIT, and Cambridge University collaborate closely with industry leaders such as General Electric, Rolls-Royce, and Siemens to push technological boundaries.

Despite significant progress, several critical challenges persist in turbine flow simulation. Computational cost remains a primary constraint, especially for high-fidelity simulations that capture transient phenomena and multi-physics interactions. Full engine simulations at high resolution remain prohibitively expensive for routine design iterations, forcing engineers to make compromises between accuracy and practicality.

Turbulence modeling presents another significant hurdle, as no universal model exists that accurately predicts all flow regimes encountered in turbine engines. The complex interactions between transitional flows, separation, reattachment, and secondary flows often require specialized models or hybrid approaches. Wall treatment in particular remains problematic, especially in regions with high temperature gradients and complex geometries.

Multi-physics coupling represents a frontier challenge, as the interaction between fluid dynamics, heat transfer, structural mechanics, and combustion chemistry creates a highly complex simulation environment. Current approaches often treat these phenomena separately or with simplified coupling methods that may not capture critical interactions.

Validation and uncertainty quantification constitute ongoing challenges, with limited experimental data available for the extreme conditions present in modern turbine engines. The high temperatures, pressures, and rotational speeds make direct measurement difficult, creating a validation gap for simulation results.

Mesh generation and adaptation remain labor-intensive processes requiring significant expertise. While automated meshing tools have improved, they still struggle with the complex geometries and multi-scale phenomena present in turbine engines, often requiring manual intervention to ensure quality results in critical regions.

Current CFD Methodologies for Turbine Flow Optimization

01 CFD modeling for fluid flow simulation in various applications

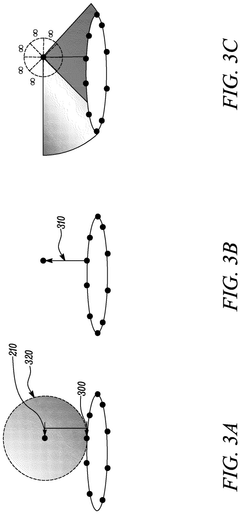

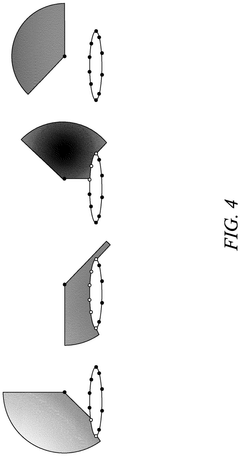

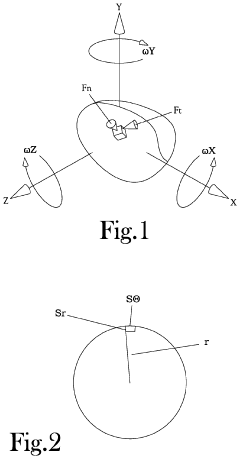

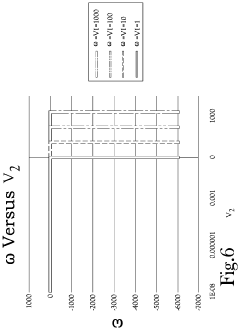

Computational Fluid Dynamics (CFD) is used to simulate and analyze fluid flow patterns across different industrial applications. These simulations help in understanding complex flow behaviors, optimizing designs, and predicting performance under various conditions. The modeling techniques incorporate mathematical equations that govern fluid dynamics to create accurate representations of real-world flow scenarios.- CFD modeling for fluid flow simulation in various applications: Computational Fluid Dynamics (CFD) is used to simulate and analyze fluid flow patterns across different industrial applications. These simulations help in understanding complex flow behaviors, optimizing designs, and predicting performance under various conditions. The modeling techniques incorporate mathematical equations that govern fluid dynamics to create accurate representations of real-world flow scenarios.

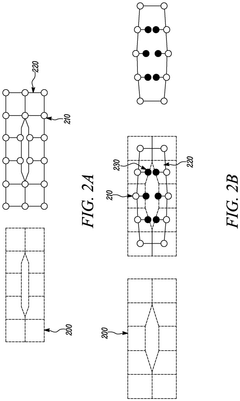

- Advanced algorithms and numerical methods for flow pattern analysis: Advanced computational algorithms and numerical methods are essential for accurate CFD modeling of flow patterns. These include finite element methods, finite volume approaches, and turbulence models that enhance simulation accuracy. The algorithms help in solving complex differential equations that govern fluid flow, enabling detailed analysis of velocity fields, pressure distributions, and other flow characteristics.

- CFD modeling for optimization of equipment and system designs: CFD modeling is utilized to optimize the design of various equipment and systems by analyzing flow patterns. This approach allows engineers to test multiple design iterations virtually before physical prototyping, reducing development time and costs. The simulations provide insights into how geometric modifications affect flow characteristics, helping to improve efficiency, reduce pressure drops, and enhance overall performance.

- Integration of CFD with other simulation technologies: Modern CFD modeling approaches integrate with other simulation technologies such as heat transfer analysis, structural mechanics, and multiphysics simulations. This integration enables comprehensive analysis of complex systems where fluid flow interacts with other physical phenomena. Combined simulation approaches provide more realistic predictions of system behavior under operational conditions.

- Real-time and data-driven CFD modeling techniques: Emerging CFD modeling techniques incorporate real-time simulation capabilities and data-driven approaches. These methods leverage machine learning algorithms and high-performance computing to enhance simulation speed and accuracy. Real-time CFD enables dynamic analysis of changing flow conditions, while data-driven approaches use experimental data to improve model predictions and reduce computational requirements.

02 Advanced numerical methods for flow pattern prediction

Advanced numerical algorithms and computational methods are employed to predict and visualize flow patterns with high accuracy. These methods include finite element analysis, finite volume methods, and turbulence modeling techniques that solve the Navier-Stokes equations. The approaches enable engineers to capture complex phenomena such as turbulence, boundary layer effects, and transient flow behaviors in their simulations.Expand Specific Solutions03 CFD applications in medical and biological flow analysis

CFD modeling is increasingly applied to medical and biological flow analysis, including blood flow in vessels, airflow in respiratory systems, and fluid dynamics in medical devices. These simulations help in understanding physiological processes, diagnosing conditions, designing medical devices, and planning surgical interventions. The models incorporate patient-specific anatomical data to create personalized flow simulations.Expand Specific Solutions04 Multi-phase and multi-physics CFD modeling

Multi-phase and multi-physics CFD modeling techniques are used to simulate complex interactions between different fluids or between fluids and structures. These approaches account for phenomena such as heat transfer, chemical reactions, particle transport, and fluid-structure interactions. The integrated modeling approach provides comprehensive insights into complex systems where multiple physical processes occur simultaneously.Expand Specific Solutions05 Optimization and validation of CFD flow models

Methods for optimizing and validating CFD flow models ensure accuracy and reliability of simulation results. These include mesh refinement techniques, sensitivity analysis, experimental validation, and uncertainty quantification. The optimization processes improve computational efficiency while maintaining solution accuracy, and validation procedures compare simulation results with experimental data to verify model fidelity.Expand Specific Solutions

Leading Companies and Research Institutions in CFD

The CFD modeling and optimization for turbine engine flow patterns market is currently in a growth phase, with increasing adoption across aerospace, power generation, and automotive sectors. The global market size is estimated at $2.5 billion, expanding at 8-10% annually as industries seek efficiency improvements and emission reductions. Technologically, the field shows varying maturity levels, with established players like Rolls-Royce, General Electric, and Siemens leading with sophisticated proprietary systems. Academic institutions including Harbin Institute of Technology and Northwestern Polytechnical University contribute significant research advancements. Mid-tier competitors such as Weichai Power and Mazda are rapidly developing capabilities, while specialized firms like Vorcat offer niche solutions. The competitive landscape reflects a blend of traditional engineering expertise and emerging computational innovations.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced CFD modeling techniques for turbine engine flow optimization that incorporate high-fidelity simulation capabilities. Their approach utilizes multi-scale modeling that simultaneously addresses both large flow structures and micro-level turbulence effects. The company employs proprietary HYDRA CFD code which implements unstructured mesh technology to accurately capture complex geometries within turbine passages. Their recent innovations include coupling aerodynamic and thermal models to predict hot spots and flow separation in turbine stages, significantly improving engine efficiency. Rolls-Royce has implemented machine learning algorithms to accelerate CFD convergence, reducing simulation time by approximately 40% while maintaining accuracy. Their digital twin technology integrates real-time operational data with CFD models to continuously optimize engine performance throughout the lifecycle, enabling predictive maintenance and performance optimization.

Strengths: Industry-leading expertise in turbomachinery CFD with proprietary simulation tools specifically optimized for aircraft engines. Their integrated approach combining aerodynamics, thermodynamics, and structural analysis provides comprehensive solutions. Weaknesses: Highly specialized computational resources required for full-engine simulations limit deployment flexibility, and their proprietary nature restricts broader academic collaboration.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has developed specialized CFD modeling techniques for turbine engine flow optimization that address the unique challenges of advanced propulsion systems. Their approach incorporates high-order numerical schemes that minimize numerical dissipation, crucial for accurately capturing vortex structures and boundary layer phenomena in turbine passages. The institute has implemented advanced turbulence modeling with scale-adaptive simulation (SAS) capabilities that bridge the gap between RANS and LES approaches, providing improved prediction of unsteady flow features while maintaining computational efficiency. Their technology includes specialized transition models calibrated specifically for the high-pressure, high-temperature environments found in modern turbine engines. AVIC has developed coupled aerothermal simulation capabilities that simultaneously address flow dynamics and heat transfer, enabling comprehensive analysis of cooling effectiveness in turbine blades. Their methodology incorporates uncertainty quantification techniques that assess the impact of manufacturing tolerances and operational variations on engine performance, enhancing design robustness.

Strengths: Deep specialization in military and commercial aviation propulsion systems with extensive validation against proprietary test data. Their models are specifically optimized for the extreme operating conditions encountered in advanced aerospace applications. Weaknesses: More limited computational resources compared to Western counterparts, potentially constraining the scale and resolution of full-engine simulations, and less integration with broader enterprise systems.

Key Algorithms and Models for Turbulent Flow Prediction

Fluid flow simulation

PatentPendingEP4510034A1

Innovation

- The use of neural networks, specifically trained with pre-computed CFD outputs, to simulate fluid flow and predict aerodynamic performance of technical objects, allowing for faster optimization of design parameters and reduced need for physical prototypes.

Methods for constructing surfaces for optimizing fluid flow

PatentActiveUS10698980B2

Innovation

- A method is introduced where fluid flow is modeled by representing flow elements as resistors and resistor arrays, with resistance values corresponding to flow characteristics, allowing for the tracking of both linear and rotational positions over time, and adjusting these resistors to reflect changes in flow velocity, thereby optimizing vortexes in the fluid flow.

Computational Resource Requirements and HPC Integration

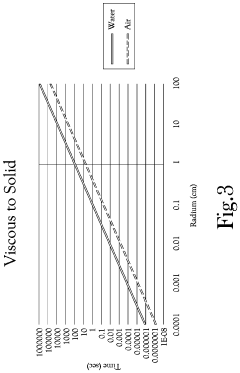

Computational Fluid Dynamics (CFD) modeling for turbine engine flow patterns demands substantial computational resources due to the complex nature of fluid dynamics simulations. Modern CFD simulations typically require processing power measured in teraFLOPS, with memory requirements often exceeding hundreds of gigabytes for high-fidelity models. The computational intensity increases exponentially with mesh resolution, particularly when modeling intricate turbine blade geometries and multi-physics phenomena such as heat transfer and combustion dynamics.

High-Performance Computing (HPC) infrastructure has become indispensable for effective CFD analysis in turbine engineering. Industry benchmarks indicate that a detailed full-engine simulation can require 10,000-100,000 CPU hours on standard computing clusters. Organizations implementing CFD workflows must consider scalable computing architectures that support parallel processing across hundreds or thousands of cores simultaneously.

Cloud-based HPC solutions have emerged as viable alternatives to on-premises infrastructure, offering flexible scaling options that align with project demands. Major providers like AWS, Google Cloud, and Microsoft Azure now offer specialized HPC instances optimized for CFD workloads, with interconnect technologies that minimize latency in parallel computations. Cost analyses suggest that hybrid approaches—maintaining baseline capacity on-premises while bursting to cloud resources during peak demand—often provide the optimal balance between performance and expenditure.

Storage requirements present another significant consideration, as CFD simulations generate massive datasets. A typical transient simulation can produce terabytes of output data that must be efficiently stored, transferred, and processed. Implementing hierarchical storage management systems with tiered access patterns has proven effective in managing these data volumes while maintaining reasonable access times for post-processing activities.

Software optimization plays a crucial role in resource utilization efficiency. Modern CFD codes increasingly leverage GPU acceleration, with performance improvements of 3-10x compared to CPU-only implementations for certain solver types. However, this requires specialized programming approaches and hardware configurations. The adoption of adaptive mesh refinement techniques has demonstrated computational savings of up to 40% while maintaining solution accuracy in critical flow regions.

Looking forward, quantum computing presents a potential paradigm shift for certain CFD algorithms, particularly those involving matrix operations and optimization problems. While still in early research stages, quantum-classical hybrid approaches show promise for addressing computational bottlenecks in specific turbine flow modeling scenarios.

High-Performance Computing (HPC) infrastructure has become indispensable for effective CFD analysis in turbine engineering. Industry benchmarks indicate that a detailed full-engine simulation can require 10,000-100,000 CPU hours on standard computing clusters. Organizations implementing CFD workflows must consider scalable computing architectures that support parallel processing across hundreds or thousands of cores simultaneously.

Cloud-based HPC solutions have emerged as viable alternatives to on-premises infrastructure, offering flexible scaling options that align with project demands. Major providers like AWS, Google Cloud, and Microsoft Azure now offer specialized HPC instances optimized for CFD workloads, with interconnect technologies that minimize latency in parallel computations. Cost analyses suggest that hybrid approaches—maintaining baseline capacity on-premises while bursting to cloud resources during peak demand—often provide the optimal balance between performance and expenditure.

Storage requirements present another significant consideration, as CFD simulations generate massive datasets. A typical transient simulation can produce terabytes of output data that must be efficiently stored, transferred, and processed. Implementing hierarchical storage management systems with tiered access patterns has proven effective in managing these data volumes while maintaining reasonable access times for post-processing activities.

Software optimization plays a crucial role in resource utilization efficiency. Modern CFD codes increasingly leverage GPU acceleration, with performance improvements of 3-10x compared to CPU-only implementations for certain solver types. However, this requires specialized programming approaches and hardware configurations. The adoption of adaptive mesh refinement techniques has demonstrated computational savings of up to 40% while maintaining solution accuracy in critical flow regions.

Looking forward, quantum computing presents a potential paradigm shift for certain CFD algorithms, particularly those involving matrix operations and optimization problems. While still in early research stages, quantum-classical hybrid approaches show promise for addressing computational bottlenecks in specific turbine flow modeling scenarios.

Validation Techniques for CFD Turbine Models

Validation of Computational Fluid Dynamics (CFD) models for turbine engines requires rigorous methodologies to ensure simulation accuracy and reliability. The validation process typically begins with experimental data collection from physical turbine models, including pressure measurements, temperature distributions, and flow visualization techniques. These experimental benchmarks serve as the foundation for assessing CFD model performance.

Wind tunnel testing represents a critical validation approach, allowing controlled environment testing of scaled turbine components. Advanced measurement techniques such as Particle Image Velocimetry (PIV) and Laser Doppler Velocimetry (LDV) provide detailed flow field data that can be directly compared with CFD predictions. These optical methods capture instantaneous velocity fields and turbulence characteristics without disrupting the flow.

Statistical validation metrics play an essential role in quantifying the agreement between CFD predictions and experimental data. Grid convergence studies following the Grid Convergence Index (GCI) methodology help establish numerical uncertainty bounds. Validation metrics commonly include normalized root mean square error (NRMSE), correlation coefficients, and validation uncertainty quantification through comprehensive uncertainty propagation analysis.

Multi-fidelity validation approaches have emerged as particularly valuable for turbine applications. These methods incorporate data from varying fidelity levels, from simplified analytical models to high-fidelity simulations and experimental results. Bayesian calibration techniques enable systematic parameter tuning while accounting for uncertainties in both experimental measurements and numerical models.

For rotating machinery specific to turbine engines, specialized validation techniques address unique challenges like rotating reference frames and unsteady flow phenomena. Phase-locked measurements synchronized with blade positions allow for detailed comparison of time-dependent flow features. Hot-wire anemometry and pressure-sensitive paint techniques provide additional validation data for boundary layer behavior and surface pressure distributions.

Industry standards and best practices for CFD validation have been established by organizations such as ASME, AIAA, and ERCOFTAC. These guidelines recommend systematic validation hierarchies, from component-level validation to full system assessment. Round-robin testing, where multiple organizations simulate identical test cases, helps establish confidence in simulation methodologies across the turbine engineering community.

Recent advancements in validation techniques include machine learning approaches for uncertainty quantification and automated calibration processes. Digital twin frameworks integrate real-time operational data with simulation models, enabling continuous validation throughout the turbine lifecycle and improving predictive maintenance capabilities.

Wind tunnel testing represents a critical validation approach, allowing controlled environment testing of scaled turbine components. Advanced measurement techniques such as Particle Image Velocimetry (PIV) and Laser Doppler Velocimetry (LDV) provide detailed flow field data that can be directly compared with CFD predictions. These optical methods capture instantaneous velocity fields and turbulence characteristics without disrupting the flow.

Statistical validation metrics play an essential role in quantifying the agreement between CFD predictions and experimental data. Grid convergence studies following the Grid Convergence Index (GCI) methodology help establish numerical uncertainty bounds. Validation metrics commonly include normalized root mean square error (NRMSE), correlation coefficients, and validation uncertainty quantification through comprehensive uncertainty propagation analysis.

Multi-fidelity validation approaches have emerged as particularly valuable for turbine applications. These methods incorporate data from varying fidelity levels, from simplified analytical models to high-fidelity simulations and experimental results. Bayesian calibration techniques enable systematic parameter tuning while accounting for uncertainties in both experimental measurements and numerical models.

For rotating machinery specific to turbine engines, specialized validation techniques address unique challenges like rotating reference frames and unsteady flow phenomena. Phase-locked measurements synchronized with blade positions allow for detailed comparison of time-dependent flow features. Hot-wire anemometry and pressure-sensitive paint techniques provide additional validation data for boundary layer behavior and surface pressure distributions.

Industry standards and best practices for CFD validation have been established by organizations such as ASME, AIAA, and ERCOFTAC. These guidelines recommend systematic validation hierarchies, from component-level validation to full system assessment. Round-robin testing, where multiple organizations simulate identical test cases, helps establish confidence in simulation methodologies across the turbine engineering community.

Recent advancements in validation techniques include machine learning approaches for uncertainty quantification and automated calibration processes. Digital twin frameworks integrate real-time operational data with simulation models, enabling continuous validation throughout the turbine lifecycle and improving predictive maintenance capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!