Comparing Turbine Engine Shroud Designs: Safety vs Performance

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Shroud Design Evolution and Objectives

Turbine engine shroud designs have undergone significant evolution since their inception in early jet engine development. Initially, shrouds were simple metallic structures designed primarily to contain blade failures and direct airflow. The 1950s marked the beginning of more sophisticated designs as engineers recognized the critical role shrouds play in both engine safety and performance optimization.

The evolution accelerated during the 1970s-1980s when advanced materials such as nickel-based superalloys and ceramic matrix composites (CMCs) enabled shrouds to withstand higher temperatures, allowing engines to operate more efficiently. This period saw the introduction of active clearance control systems that could adjust shroud-to-blade tip clearances during different flight phases, significantly improving fuel efficiency.

By the 1990s, abradable coatings became standard in shroud designs, allowing for controlled wear patterns that could establish optimal clearances without damaging blade tips. The early 2000s brought computational fluid dynamics (CFD) and finite element analysis (FEA) into the design process, enabling engineers to model complex thermal and mechanical interactions between shrouds and other engine components.

Recent developments have focused on advanced cooling techniques, including impingement cooling, film cooling, and transpiration cooling systems that maintain shroud structural integrity while allowing higher turbine inlet temperatures. Modern shrouds increasingly incorporate sensor technology for real-time monitoring of clearances, temperatures, and wear patterns, enabling predictive maintenance.

The primary objectives of contemporary turbine shroud design center around balancing competing priorities. Safety considerations demand robust containment capabilities to prevent catastrophic engine failures by containing blade fragments in case of failure. Thermal management objectives require designs that can withstand extreme temperature gradients while maintaining dimensional stability.

Performance objectives focus on minimizing blade tip clearances to reduce air leakage and improve thermodynamic efficiency, with each 1% reduction in tip clearance potentially yielding 1-2% improvement in specific fuel consumption. Durability objectives necessitate resistance to oxidation, erosion, and thermal fatigue to ensure the shroud maintains its dimensional integrity throughout thousands of flight cycles.

Weight reduction represents another critical objective, as lighter shroud designs directly contribute to overall engine weight savings, improving aircraft fuel efficiency. The industry continues to pursue innovative designs that can simultaneously address these often-conflicting objectives, with the ultimate goal of creating shrouds that enhance both safety margins and performance metrics without compromising either priority.

The evolution accelerated during the 1970s-1980s when advanced materials such as nickel-based superalloys and ceramic matrix composites (CMCs) enabled shrouds to withstand higher temperatures, allowing engines to operate more efficiently. This period saw the introduction of active clearance control systems that could adjust shroud-to-blade tip clearances during different flight phases, significantly improving fuel efficiency.

By the 1990s, abradable coatings became standard in shroud designs, allowing for controlled wear patterns that could establish optimal clearances without damaging blade tips. The early 2000s brought computational fluid dynamics (CFD) and finite element analysis (FEA) into the design process, enabling engineers to model complex thermal and mechanical interactions between shrouds and other engine components.

Recent developments have focused on advanced cooling techniques, including impingement cooling, film cooling, and transpiration cooling systems that maintain shroud structural integrity while allowing higher turbine inlet temperatures. Modern shrouds increasingly incorporate sensor technology for real-time monitoring of clearances, temperatures, and wear patterns, enabling predictive maintenance.

The primary objectives of contemporary turbine shroud design center around balancing competing priorities. Safety considerations demand robust containment capabilities to prevent catastrophic engine failures by containing blade fragments in case of failure. Thermal management objectives require designs that can withstand extreme temperature gradients while maintaining dimensional stability.

Performance objectives focus on minimizing blade tip clearances to reduce air leakage and improve thermodynamic efficiency, with each 1% reduction in tip clearance potentially yielding 1-2% improvement in specific fuel consumption. Durability objectives necessitate resistance to oxidation, erosion, and thermal fatigue to ensure the shroud maintains its dimensional integrity throughout thousands of flight cycles.

Weight reduction represents another critical objective, as lighter shroud designs directly contribute to overall engine weight savings, improving aircraft fuel efficiency. The industry continues to pursue innovative designs that can simultaneously address these often-conflicting objectives, with the ultimate goal of creating shrouds that enhance both safety margins and performance metrics without compromising either priority.

Market Requirements for Turbine Engine Shrouds

The turbine engine shroud market is experiencing significant growth driven by the expanding aerospace and power generation industries. Current market analysis indicates a strong demand for advanced shroud designs that can withstand higher operating temperatures and pressures while maintaining structural integrity. This demand stems from the aviation industry's push for more fuel-efficient engines with higher thrust-to-weight ratios and the power generation sector's need for more efficient gas turbines.

Primary market requirements for turbine engine shrouds center around thermal resistance, with operating temperatures in modern engines reaching up to 1600°C. Material selection has become critical, with customers demanding shrouds that can maintain dimensional stability under extreme thermal cycling conditions. Ceramic matrix composites and advanced metallic alloys with specialized thermal barrier coatings are increasingly specified in procurement requirements.

Durability requirements have intensified, with end-users expecting shroud lifespans of 20,000+ operating hours before replacement. This represents a significant increase from previous generation requirements of 10,000-15,000 hours, reflecting the industry's focus on reducing maintenance costs and increasing time between overhauls.

Weight reduction remains a paramount concern, particularly in the aerospace sector where every kilogram saved translates to substantial fuel savings over an aircraft's operational life. The market is demanding shroud designs that are 15-30% lighter than previous generations while maintaining or improving performance characteristics.

Clearance control has emerged as a critical market requirement, with tighter tolerances between blade tips and shrouds directly impacting engine efficiency. Advanced abradable coatings that can maintain optimal clearance throughout thermal cycling are increasingly specified by engine manufacturers.

Cost considerations continue to drive market requirements, with customers seeking solutions that balance initial acquisition costs with lifecycle expenses. The total cost of ownership model has become the standard evaluation metric, with particular emphasis on maintenance intervals and replacement costs.

Regulatory compliance forms another key market requirement, with certification standards becoming more stringent regarding emissions, noise, and safety. Shroud designs must now demonstrate compliance with these evolving standards, particularly regarding containment capabilities in blade-off scenarios.

Customization capabilities are increasingly valued, with engine manufacturers seeking shroud suppliers who can rapidly adapt designs to specific engine architectures and operating conditions. This trend is driving the development of modular shroud systems that can be configured for different applications while maintaining core performance characteristics.

Primary market requirements for turbine engine shrouds center around thermal resistance, with operating temperatures in modern engines reaching up to 1600°C. Material selection has become critical, with customers demanding shrouds that can maintain dimensional stability under extreme thermal cycling conditions. Ceramic matrix composites and advanced metallic alloys with specialized thermal barrier coatings are increasingly specified in procurement requirements.

Durability requirements have intensified, with end-users expecting shroud lifespans of 20,000+ operating hours before replacement. This represents a significant increase from previous generation requirements of 10,000-15,000 hours, reflecting the industry's focus on reducing maintenance costs and increasing time between overhauls.

Weight reduction remains a paramount concern, particularly in the aerospace sector where every kilogram saved translates to substantial fuel savings over an aircraft's operational life. The market is demanding shroud designs that are 15-30% lighter than previous generations while maintaining or improving performance characteristics.

Clearance control has emerged as a critical market requirement, with tighter tolerances between blade tips and shrouds directly impacting engine efficiency. Advanced abradable coatings that can maintain optimal clearance throughout thermal cycling are increasingly specified by engine manufacturers.

Cost considerations continue to drive market requirements, with customers seeking solutions that balance initial acquisition costs with lifecycle expenses. The total cost of ownership model has become the standard evaluation metric, with particular emphasis on maintenance intervals and replacement costs.

Regulatory compliance forms another key market requirement, with certification standards becoming more stringent regarding emissions, noise, and safety. Shroud designs must now demonstrate compliance with these evolving standards, particularly regarding containment capabilities in blade-off scenarios.

Customization capabilities are increasingly valued, with engine manufacturers seeking shroud suppliers who can rapidly adapt designs to specific engine architectures and operating conditions. This trend is driving the development of modular shroud systems that can be configured for different applications while maintaining core performance characteristics.

Current Shroud Technologies and Engineering Challenges

Turbine engine shroud designs have evolved significantly over the past decades, with current technologies focusing on balancing safety and performance requirements. Modern shroud designs typically fall into three main categories: metallic shrouds, ceramic matrix composites (CMCs), and hybrid systems. Each presents distinct advantages and challenges in implementation.

Metallic shrouds, predominantly manufactured from nickel-based superalloys, remain the industry standard due to their proven reliability and mechanical robustness. These designs incorporate sophisticated cooling systems, including impingement cooling, film cooling, and transpiration cooling techniques. However, they face significant limitations in thermal efficiency and weight considerations, particularly as engine operating temperatures continue to rise in pursuit of improved performance.

Ceramic matrix composites have emerged as promising alternatives, offering superior temperature resistance (up to 1400°C compared to approximately 1100°C for advanced metallic systems) and reduced weight profiles. Silicon carbide (SiC) and alumina-based CMCs lead current implementations, providing up to 30% weight reduction compared to metallic counterparts. Despite these advantages, CMCs present substantial manufacturing challenges, including inconsistent material properties, complex joining techniques, and higher production costs.

Hybrid shroud systems, combining metallic substrates with ceramic thermal barrier coatings (TBCs), represent a compromise solution gaining traction in modern engine designs. These systems utilize yttria-stabilized zirconia (YSZ) coatings of 100-500μm thickness to enhance temperature capabilities while maintaining structural integrity. However, coating delamination and thermal cycling fatigue remain persistent engineering challenges.

Clearance control presents another critical challenge across all shroud technologies. Active clearance control systems (ACCS) have become increasingly sophisticated, employing thermal management techniques to maintain optimal tip clearances throughout flight envelopes. These systems must balance the risk of blade tip rubs against efficiency losses from excessive clearances, with each millimeter of excess clearance typically resulting in 0.5-1% efficiency reduction.

Environmental durability poses additional challenges, particularly in addressing erosion from particulate ingestion and chemical degradation from contaminants. Current solutions include sacrificial abradable linings and environmental barrier coatings, though these add complexity and maintenance requirements.

Manufacturing precision represents a persistent challenge, with dimensional tolerances typically required at ±0.05mm or better to ensure proper sealing and clearance control. Advanced manufacturing techniques, including additive manufacturing and precision machining, are being deployed to address these requirements, though scalability and cost concerns remain significant barriers to widespread implementation.

Metallic shrouds, predominantly manufactured from nickel-based superalloys, remain the industry standard due to their proven reliability and mechanical robustness. These designs incorporate sophisticated cooling systems, including impingement cooling, film cooling, and transpiration cooling techniques. However, they face significant limitations in thermal efficiency and weight considerations, particularly as engine operating temperatures continue to rise in pursuit of improved performance.

Ceramic matrix composites have emerged as promising alternatives, offering superior temperature resistance (up to 1400°C compared to approximately 1100°C for advanced metallic systems) and reduced weight profiles. Silicon carbide (SiC) and alumina-based CMCs lead current implementations, providing up to 30% weight reduction compared to metallic counterparts. Despite these advantages, CMCs present substantial manufacturing challenges, including inconsistent material properties, complex joining techniques, and higher production costs.

Hybrid shroud systems, combining metallic substrates with ceramic thermal barrier coatings (TBCs), represent a compromise solution gaining traction in modern engine designs. These systems utilize yttria-stabilized zirconia (YSZ) coatings of 100-500μm thickness to enhance temperature capabilities while maintaining structural integrity. However, coating delamination and thermal cycling fatigue remain persistent engineering challenges.

Clearance control presents another critical challenge across all shroud technologies. Active clearance control systems (ACCS) have become increasingly sophisticated, employing thermal management techniques to maintain optimal tip clearances throughout flight envelopes. These systems must balance the risk of blade tip rubs against efficiency losses from excessive clearances, with each millimeter of excess clearance typically resulting in 0.5-1% efficiency reduction.

Environmental durability poses additional challenges, particularly in addressing erosion from particulate ingestion and chemical degradation from contaminants. Current solutions include sacrificial abradable linings and environmental barrier coatings, though these add complexity and maintenance requirements.

Manufacturing precision represents a persistent challenge, with dimensional tolerances typically required at ±0.05mm or better to ensure proper sealing and clearance control. Advanced manufacturing techniques, including additive manufacturing and precision machining, are being deployed to address these requirements, though scalability and cost concerns remain significant barriers to widespread implementation.

Contemporary Shroud Design Solutions

01 Abradable shroud coatings for improved clearance control

Abradable coatings applied to turbine engine shrouds allow for controlled wear during blade tip contact, optimizing clearance while maintaining safety. These specialized materials create a sacrificial surface that wears preferentially when contacted by rotating blade tips, preventing catastrophic damage while establishing minimal operational clearances. This technology improves engine efficiency by reducing gas path leakage while enhancing safety through controlled interaction between rotating and stationary components.- Abradable shroud designs for improved clearance control: Abradable shroud designs incorporate materials that can be worn away by blade tips during operation, creating an optimal clearance between the blade tips and the shroud. This controlled wear process improves engine efficiency by minimizing gas leakage while preventing catastrophic damage from blade-shroud contact. These designs often use composite materials with specific abradability characteristics that maintain structural integrity while allowing for controlled wear patterns, ultimately enhancing both safety and performance of the turbine engine.

- Thermal management systems for shroud assemblies: Advanced thermal management systems for turbine shrouds help maintain dimensional stability during extreme temperature variations experienced in engine operation. These systems incorporate cooling channels, thermal barrier coatings, and innovative material combinations to control thermal expansion and contraction. By managing heat distribution and preventing warping or cracking of shroud components, these designs extend component lifespan, maintain optimal clearances, and prevent catastrophic failures, significantly improving both safety and performance metrics of the engine.

- Segmented shroud designs for stress distribution: Segmented shroud designs divide the shroud into multiple interconnected sections rather than using a single continuous ring. This configuration allows for better distribution of thermal and mechanical stresses, accommodates differential expansion during operation, and simplifies maintenance and replacement of damaged sections. The segmented approach enhances safety by preventing catastrophic failure of the entire shroud assembly and improves performance by maintaining optimal clearances throughout varying operating conditions.

- Advanced sealing mechanisms for shroud interfaces: Innovative sealing mechanisms at shroud interfaces prevent hot gas leakage between shroud segments and at the junction with other engine components. These designs incorporate labyrinth seals, brush seals, and advanced elastomeric compounds that maintain their integrity under extreme temperatures and pressures. By minimizing leakage paths, these sealing systems improve engine efficiency, reduce fuel consumption, and prevent hot gas ingestion into sensitive areas, enhancing both the performance capabilities and operational safety of the turbine engine.

- Composite and ceramic materials for high-temperature shroud applications: Advanced composite and ceramic materials are increasingly used in turbine shroud designs to withstand extreme operating temperatures while maintaining structural integrity. These materials offer superior thermal resistance, reduced weight, and enhanced durability compared to traditional metal alloys. Ceramic matrix composites (CMCs) and thermal barrier coatings provide exceptional heat resistance while allowing for thinner, lighter shroud designs that improve engine efficiency. These material innovations significantly enhance both the safety margins and performance capabilities of modern turbine engines.

02 Cooling systems for shroud assemblies

Advanced cooling systems for turbine shrouds manage thermal loads and prevent component failure. These designs incorporate cooling channels, impingement cooling, and film cooling techniques to maintain shroud structural integrity during high-temperature operation. Effective thermal management prevents distortion and cracking while allowing tighter clearances between blade tips and shrouds. This improves engine efficiency and extends component life while maintaining safe operating parameters under extreme thermal conditions.Expand Specific Solutions03 Segmented shroud designs for thermal expansion management

Segmented shroud designs accommodate differential thermal expansion in turbine engines, enhancing both safety and performance. By dividing the shroud into discrete segments with appropriate gaps and attachment mechanisms, these designs allow controlled thermal growth while maintaining overall structural integrity. This approach prevents warping and cracking during thermal cycling while enabling precise clearance control throughout the operational envelope, resulting in improved efficiency and reduced risk of catastrophic failure.Expand Specific Solutions04 Advanced materials for high-temperature shroud applications

Specialized materials for turbine shrouds withstand extreme temperatures while maintaining dimensional stability. These include ceramic matrix composites, thermal barrier coatings, and advanced metal alloys specifically engineered for high-temperature environments. The materials offer superior thermal resistance, oxidation protection, and mechanical strength, allowing shrouds to maintain integrity during thermal cycling and extreme operating conditions. This technology enables tighter clearances, improved efficiency, and enhanced safety margins in modern turbine engines.Expand Specific Solutions05 Active clearance control systems for shrouds

Active clearance control systems dynamically adjust shroud positioning during different engine operating conditions. These systems use thermal, mechanical, or pneumatic mechanisms to modify the shroud-to-blade tip clearance in real-time, optimizing performance across the operational envelope. By maintaining minimal clearances during cruise while providing additional clearance during transient operations, these systems maximize efficiency without compromising safety. This technology represents a significant advancement in turbine engine performance while ensuring adequate safety margins during all flight phases.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The turbine engine shroud design market is currently in a growth phase, with increasing demand for more efficient and safer engine designs. The market is dominated by established aerospace giants like GE, Rolls-Royce, and Mitsubishi Heavy Industries, who possess advanced technological capabilities and extensive R&D resources. These companies are actively balancing safety requirements with performance optimization in their shroud designs. Emerging players from China, including AECC Commercial Aircraft Engine Co. and AVIC research institutes, are rapidly developing capabilities to compete globally. The technology maturity varies significantly, with Western companies generally leading in innovation while Asian manufacturers are closing the gap through strategic investments and research partnerships. The market is expected to expand as aircraft fleet modernization continues worldwide, driving demand for more efficient engine components.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed sophisticated turbine shroud technologies that balance safety considerations with performance enhancement. Their J-series gas turbines feature advanced shroud designs incorporating enhanced cooling technologies and thermal barrier coatings that enable operation at temperatures exceeding 1600°C. MHI's shroud design philosophy emphasizes a systems approach, where shroud segments are designed as integral components of the overall turbine thermal management system. Their proprietary "Air Riding Seal" technology creates a dynamic seal between shroud segments that adjusts during thermal expansion, maintaining optimal clearances throughout the operational envelope. MHI has pioneered the use of directionally solidified superalloys in shroud applications, providing enhanced creep resistance at elevated temperatures. Their shroud cooling systems incorporate both convection and impingement cooling methods, with precisely positioned cooling holes that create protective film cooling along the hot gas path surfaces while minimizing aerodynamic losses.

Strengths: Exceptional high-temperature capability enabling higher turbine inlet temperatures and improved cycle efficiency; innovative sealing technologies that maintain tight clearances throughout the operational range. Weaknesses: Higher manufacturing complexity requiring specialized production techniques; cooling designs require precise control of cooling air distribution which can be challenging to maintain over the service life.

General Electric Company

Technical Solution: General Electric has pioneered advanced turbine engine shroud designs focusing on the balance between safety and performance. Their latest CMC (Ceramic Matrix Composite) shroud technology represents a significant advancement in turbine design, offering temperature capabilities up to 2400°F (1315°C), far exceeding traditional metal alloys. GE's shroud designs incorporate active clearance control systems that dynamically adjust the shroud-to-blade tip clearance during different flight phases, optimizing performance while maintaining safety margins. Their TAPS (Twin Annular Premixing Swirler) combustor design works in conjunction with advanced shroud configurations to reduce emissions while maintaining thermal efficiency. GE has also developed abradable coating systems for shrouds that allow for controlled wear during initial engine break-in, creating optimal clearances that enhance performance without compromising structural integrity. Their integrated cooling systems within shroud segments utilize sophisticated serpentine passages that maximize cooling effectiveness while minimizing the amount of cooling air diverted from the core flow.

Strengths: Superior thermal management capabilities allowing operation at higher temperatures, resulting in improved engine efficiency; advanced materials technology with proprietary CMC formulations providing exceptional durability. Weaknesses: Higher manufacturing costs compared to conventional shroud designs; complex cooling systems require precise manufacturing tolerances that can be challenging to maintain consistently in production.

Critical Patents and Technical Innovations

Turbine and turbine rotor blade

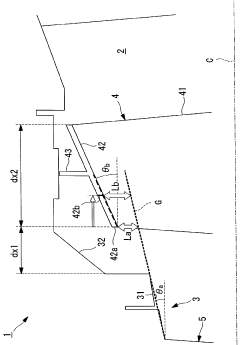

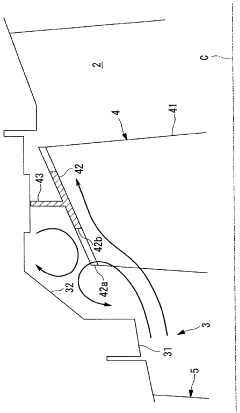

PatentWO2011070636A1

Innovation

- A turbine design with a tip shroud that has a larger inclination angle than the average casing angle, combined with a shorter length along the rotation axis and specific distance relationships, reduces collisions between the mainstream flow and the tip shroud, enhancing performance by minimizing turbulence and centrifugal loads.

Tip shroud for a turbine engine

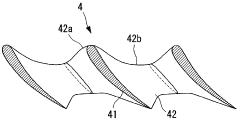

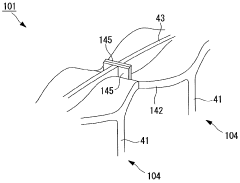

PatentActiveUS20210079795A1

Innovation

- Aerodynamically designed tip shroud with a fillet line and scalloped portions that form specific angles and rounded corners, reducing weight while maintaining aerodynamic efficiency by minimizing mixing losses and secondary losses, achieved through shaping methods that include forming fillet lines and connecting them with rounded corners to define scalloped portions.

Safety Certification Standards for Turbine Shrouds

Turbine engine shroud designs must adhere to rigorous safety certification standards established by international aviation authorities. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have developed comprehensive frameworks specifically addressing turbine shroud integrity. These standards primarily focus on structural durability, thermal resistance, and containment capabilities during catastrophic failures.

The certification process typically requires manufacturers to demonstrate compliance through extensive testing regimes. For turbine shrouds, this includes cyclic fatigue testing under simulated operational conditions, with requirements to withstand at least 150% of maximum anticipated operational stresses. Thermal shock resistance testing is particularly critical, as shrouds must maintain structural integrity during rapid temperature fluctuations ranging from ambient to over 1,200°C in modern high-performance engines.

Material certification standards have evolved significantly over the past decade, with increasing emphasis on advanced ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs). These materials must meet stringent specifications regarding oxidation resistance, thermal stability, and mechanical properties. The Aerospace Material Specification (AMS) provides detailed requirements for each material class, with specialized standards for nickel-based superalloys commonly used in conventional shroud designs.

Containment certification represents perhaps the most demanding aspect of shroud safety standards. Regulations require that shroud systems demonstrate the ability to contain high-energy debris in the event of blade failure, preventing catastrophic damage to critical aircraft systems. This typically involves ballistic impact testing where shroud assemblies must contain simulated blade fragments at operational rotational speeds.

Recent updates to certification standards have incorporated risk-based approaches, allowing manufacturers to demonstrate equivalent safety through alternative means. This has enabled innovation in shroud design while maintaining rigorous safety margins. The SAE International's Aerospace Standards (AS) now includes specific provisions for advanced shroud technologies, including active clearance control systems and hybrid material configurations.

Certification documentation requirements have also expanded, with manufacturers now required to provide comprehensive failure mode and effects analyses (FMEA) specific to shroud components. This includes detailed modeling of thermal gradients, mechanical stresses, and potential interaction effects with adjacent engine components throughout the operational envelope.

The certification process typically requires manufacturers to demonstrate compliance through extensive testing regimes. For turbine shrouds, this includes cyclic fatigue testing under simulated operational conditions, with requirements to withstand at least 150% of maximum anticipated operational stresses. Thermal shock resistance testing is particularly critical, as shrouds must maintain structural integrity during rapid temperature fluctuations ranging from ambient to over 1,200°C in modern high-performance engines.

Material certification standards have evolved significantly over the past decade, with increasing emphasis on advanced ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs). These materials must meet stringent specifications regarding oxidation resistance, thermal stability, and mechanical properties. The Aerospace Material Specification (AMS) provides detailed requirements for each material class, with specialized standards for nickel-based superalloys commonly used in conventional shroud designs.

Containment certification represents perhaps the most demanding aspect of shroud safety standards. Regulations require that shroud systems demonstrate the ability to contain high-energy debris in the event of blade failure, preventing catastrophic damage to critical aircraft systems. This typically involves ballistic impact testing where shroud assemblies must contain simulated blade fragments at operational rotational speeds.

Recent updates to certification standards have incorporated risk-based approaches, allowing manufacturers to demonstrate equivalent safety through alternative means. This has enabled innovation in shroud design while maintaining rigorous safety margins. The SAE International's Aerospace Standards (AS) now includes specific provisions for advanced shroud technologies, including active clearance control systems and hybrid material configurations.

Certification documentation requirements have also expanded, with manufacturers now required to provide comprehensive failure mode and effects analyses (FMEA) specific to shroud components. This includes detailed modeling of thermal gradients, mechanical stresses, and potential interaction effects with adjacent engine components throughout the operational envelope.

Material Science Advancements for Shroud Applications

Material science has undergone significant evolution in turbine engine shroud applications, with researchers focusing on developing materials that can withstand extreme temperatures while maintaining structural integrity. Traditional nickel-based superalloys have been the industry standard for decades, but their performance limitations at temperatures exceeding 1000°C have driven innovation toward ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs).

Recent advancements in CMCs have yielded materials with exceptional temperature resistance up to 1400°C while offering weight reductions of 30-40% compared to metallic alternatives. Silicon carbide (SiC) fiber-reinforced SiC matrix composites demonstrate particularly promising results, with laboratory tests showing improved thermal shock resistance and reduced susceptibility to oxidation damage under cyclic loading conditions.

Thermal barrier coating systems have similarly evolved, with yttria-stabilized zirconia (YSZ) coatings now incorporating sophisticated multilayer architectures. These advanced TBCs can reduce the operating temperature of underlying metal components by 100-150°C, significantly extending component lifespan while allowing higher combustion temperatures for improved engine efficiency.

Environmental barrier coatings (EBCs) represent another critical advancement, specifically designed to protect CMCs from water vapor and other combustion byproducts. Recent developments in rare earth silicates and hafnium-based compounds have demonstrated superior resistance to chemical degradation in high-temperature steam environments, addressing a key failure mode in advanced shroud designs.

Additive manufacturing has revolutionized shroud material development by enabling complex cooling channel geometries previously impossible with conventional manufacturing techniques. These intricate designs allow for more efficient thermal management while maintaining structural integrity, with recent studies demonstrating temperature reductions of up to 80°C in critical regions.

Hybrid material systems combining metallic substrates with ceramic outer layers represent the cutting edge of shroud material science. These systems leverage the ductility and damage tolerance of metals with the thermal resistance of ceramics, creating components that offer both safety and performance advantages. Testing has shown these hybrid systems can withstand thermal cycling better than homogeneous materials, with failure rates reduced by approximately 40% under simulated engine conditions.

Nanomaterial incorporation into shroud coatings has emerged as a promising research direction, with nanostructured coatings demonstrating self-healing properties and improved erosion resistance. These materials can potentially extend maintenance intervals by 20-30%, significantly reducing lifecycle costs while maintaining safety margins.

Recent advancements in CMCs have yielded materials with exceptional temperature resistance up to 1400°C while offering weight reductions of 30-40% compared to metallic alternatives. Silicon carbide (SiC) fiber-reinforced SiC matrix composites demonstrate particularly promising results, with laboratory tests showing improved thermal shock resistance and reduced susceptibility to oxidation damage under cyclic loading conditions.

Thermal barrier coating systems have similarly evolved, with yttria-stabilized zirconia (YSZ) coatings now incorporating sophisticated multilayer architectures. These advanced TBCs can reduce the operating temperature of underlying metal components by 100-150°C, significantly extending component lifespan while allowing higher combustion temperatures for improved engine efficiency.

Environmental barrier coatings (EBCs) represent another critical advancement, specifically designed to protect CMCs from water vapor and other combustion byproducts. Recent developments in rare earth silicates and hafnium-based compounds have demonstrated superior resistance to chemical degradation in high-temperature steam environments, addressing a key failure mode in advanced shroud designs.

Additive manufacturing has revolutionized shroud material development by enabling complex cooling channel geometries previously impossible with conventional manufacturing techniques. These intricate designs allow for more efficient thermal management while maintaining structural integrity, with recent studies demonstrating temperature reductions of up to 80°C in critical regions.

Hybrid material systems combining metallic substrates with ceramic outer layers represent the cutting edge of shroud material science. These systems leverage the ductility and damage tolerance of metals with the thermal resistance of ceramics, creating components that offer both safety and performance advantages. Testing has shown these hybrid systems can withstand thermal cycling better than homogeneous materials, with failure rates reduced by approximately 40% under simulated engine conditions.

Nanomaterial incorporation into shroud coatings has emerged as a promising research direction, with nanostructured coatings demonstrating self-healing properties and improved erosion resistance. These materials can potentially extend maintenance intervals by 20-30%, significantly reducing lifecycle costs while maintaining safety margins.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!