Calibration of Turbine Engine Control Systems for Precision

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Control Calibration Background and Objectives

Turbine engine control systems have evolved significantly over the past seven decades, transitioning from purely mechanical systems to sophisticated digital electronic control units. The calibration of these systems represents a critical aspect of engine development and maintenance, directly impacting performance, efficiency, and reliability. Initially developed in the 1950s, early control systems relied on hydromechanical governors with limited calibration capabilities. The introduction of analog electronic controls in the 1970s expanded calibration parameters, while the digital revolution of the 1980s and 1990s transformed the field with Full Authority Digital Engine Control (FADEC) systems.

The technological trajectory clearly points toward increasingly precise calibration methodologies that leverage advanced computational techniques. Modern calibration approaches incorporate model-based design, real-time data analytics, and machine learning algorithms to optimize engine performance across diverse operating conditions. This evolution has been driven by stringent regulatory requirements for emissions reduction, fuel efficiency improvements, and enhanced safety standards across both aerospace and industrial applications.

Current calibration objectives focus on achieving unprecedented levels of precision while reducing calibration time and costs. Key technical goals include developing adaptive calibration systems capable of real-time parameter adjustment, implementing robust validation methodologies to ensure calibration integrity, and creating unified calibration frameworks applicable across diverse engine platforms. The industry aims to reduce calibration cycles by 30-40% while improving parameter accuracy by an order of magnitude compared to systems from a decade ago.

Emerging trends indicate a shift toward physics-informed machine learning approaches that combine traditional thermodynamic models with data-driven techniques. Digital twin technology is increasingly integrated into calibration workflows, enabling virtual testing and validation before physical implementation. Additionally, there is growing emphasis on developing calibration systems that can accommodate alternative fuels and hybrid propulsion architectures as the industry moves toward more sustainable solutions.

The technical challenges being addressed include handling the exponential growth in calibration parameters (modern systems may require tuning of over 100,000 parameters), managing calibration across increasingly complex operating envelopes, and developing methodologies that reduce dependency on expensive test cell time. Researchers are also focusing on creating more intuitive calibration interfaces that leverage augmented reality and advanced visualization techniques to improve engineer productivity.

As regulatory pressures intensify and performance expectations rise, precision calibration has become a competitive differentiator among engine manufacturers. The ultimate objective remains developing calibration systems that can autonomously optimize engine performance while maintaining robust safety margins across all operating conditions.

The technological trajectory clearly points toward increasingly precise calibration methodologies that leverage advanced computational techniques. Modern calibration approaches incorporate model-based design, real-time data analytics, and machine learning algorithms to optimize engine performance across diverse operating conditions. This evolution has been driven by stringent regulatory requirements for emissions reduction, fuel efficiency improvements, and enhanced safety standards across both aerospace and industrial applications.

Current calibration objectives focus on achieving unprecedented levels of precision while reducing calibration time and costs. Key technical goals include developing adaptive calibration systems capable of real-time parameter adjustment, implementing robust validation methodologies to ensure calibration integrity, and creating unified calibration frameworks applicable across diverse engine platforms. The industry aims to reduce calibration cycles by 30-40% while improving parameter accuracy by an order of magnitude compared to systems from a decade ago.

Emerging trends indicate a shift toward physics-informed machine learning approaches that combine traditional thermodynamic models with data-driven techniques. Digital twin technology is increasingly integrated into calibration workflows, enabling virtual testing and validation before physical implementation. Additionally, there is growing emphasis on developing calibration systems that can accommodate alternative fuels and hybrid propulsion architectures as the industry moves toward more sustainable solutions.

The technical challenges being addressed include handling the exponential growth in calibration parameters (modern systems may require tuning of over 100,000 parameters), managing calibration across increasingly complex operating envelopes, and developing methodologies that reduce dependency on expensive test cell time. Researchers are also focusing on creating more intuitive calibration interfaces that leverage augmented reality and advanced visualization techniques to improve engineer productivity.

As regulatory pressures intensify and performance expectations rise, precision calibration has become a competitive differentiator among engine manufacturers. The ultimate objective remains developing calibration systems that can autonomously optimize engine performance while maintaining robust safety margins across all operating conditions.

Market Requirements for Precision Engine Control Systems

The global market for precision turbine engine control systems is experiencing significant growth, driven by increasing demands for fuel efficiency, reduced emissions, and enhanced operational reliability across multiple industries. Commercial aviation represents the largest market segment, with an estimated annual growth rate of 5.7% through 2030, as airlines face mounting pressure to optimize fuel consumption while meeting stringent environmental regulations.

Military applications constitute another substantial market segment, where precision control systems are critical for advanced fighter jets, transport aircraft, and unmanned aerial vehicles. Defense contractors require increasingly sophisticated calibration technologies to ensure optimal engine performance across diverse operational conditions, from sea level to high-altitude environments and extreme temperature variations.

Power generation represents the third major market segment, with gas turbines requiring precise control calibration to maximize efficiency and minimize downtime. As renewable energy integration increases grid variability, gas turbines must respond more dynamically to load changes, creating demand for more responsive control systems with superior calibration capabilities.

End-users across all segments consistently identify several key requirements for next-generation calibration systems. Real-time adaptive calibration capabilities rank highest among these requirements, with 78% of surveyed operators citing the need for systems that can automatically adjust parameters during operation without manual intervention. This reflects the growing industry focus on reducing maintenance downtime and extending service intervals.

Interoperability with existing digital infrastructure emerges as another critical market requirement, as operators seek to integrate engine control systems with broader asset management and predictive maintenance platforms. This integration capability is particularly valued in commercial aviation and power generation sectors, where fleet-wide optimization drives operational economics.

Regulatory compliance represents a significant market driver, particularly regarding emissions standards and safety certifications. The International Civil Aviation Organization's environmental standards and the European Union's Industrial Emissions Directive both establish increasingly stringent requirements that directly impact calibration specifications for turbine engine control systems.

Cost considerations remain paramount, with customers seeking solutions that reduce total lifecycle costs through improved calibration efficiency. Market research indicates willingness to invest in premium calibration technologies when demonstrable return on investment through fuel savings, maintenance reduction, or extended engine life can be quantified.

The aftermarket service segment for calibration systems is projected to grow faster than new installations, reflecting the large installed base of turbine engines requiring upgrades to meet current performance and regulatory standards. This creates significant opportunities for retrofit solutions with minimally invasive implementation requirements.

Military applications constitute another substantial market segment, where precision control systems are critical for advanced fighter jets, transport aircraft, and unmanned aerial vehicles. Defense contractors require increasingly sophisticated calibration technologies to ensure optimal engine performance across diverse operational conditions, from sea level to high-altitude environments and extreme temperature variations.

Power generation represents the third major market segment, with gas turbines requiring precise control calibration to maximize efficiency and minimize downtime. As renewable energy integration increases grid variability, gas turbines must respond more dynamically to load changes, creating demand for more responsive control systems with superior calibration capabilities.

End-users across all segments consistently identify several key requirements for next-generation calibration systems. Real-time adaptive calibration capabilities rank highest among these requirements, with 78% of surveyed operators citing the need for systems that can automatically adjust parameters during operation without manual intervention. This reflects the growing industry focus on reducing maintenance downtime and extending service intervals.

Interoperability with existing digital infrastructure emerges as another critical market requirement, as operators seek to integrate engine control systems with broader asset management and predictive maintenance platforms. This integration capability is particularly valued in commercial aviation and power generation sectors, where fleet-wide optimization drives operational economics.

Regulatory compliance represents a significant market driver, particularly regarding emissions standards and safety certifications. The International Civil Aviation Organization's environmental standards and the European Union's Industrial Emissions Directive both establish increasingly stringent requirements that directly impact calibration specifications for turbine engine control systems.

Cost considerations remain paramount, with customers seeking solutions that reduce total lifecycle costs through improved calibration efficiency. Market research indicates willingness to invest in premium calibration technologies when demonstrable return on investment through fuel savings, maintenance reduction, or extended engine life can be quantified.

The aftermarket service segment for calibration systems is projected to grow faster than new installations, reflecting the large installed base of turbine engines requiring upgrades to meet current performance and regulatory standards. This creates significant opportunities for retrofit solutions with minimally invasive implementation requirements.

Current Calibration Technologies and Challenges

The calibration of turbine engine control systems currently employs a combination of traditional methodologies and emerging technologies. Conventional calibration approaches rely heavily on ground testing facilities where engines undergo extensive testing under controlled conditions. These facilities simulate various operational scenarios, allowing engineers to collect performance data across different power settings, environmental conditions, and operational modes. The data collected serves as the foundation for developing control algorithms and calibration maps that govern engine behavior during actual operation.

Model-based calibration represents a significant advancement in this field, utilizing mathematical models to predict engine behavior under various conditions. These models incorporate thermodynamic principles, fluid dynamics, and mechanical engineering concepts to create digital representations of physical engine systems. The advantage of this approach lies in its ability to reduce physical testing requirements while expanding the calibration envelope beyond what can be safely or economically tested in physical environments.

Hardware-in-the-loop (HIL) simulation has emerged as a critical technology for calibration processes, allowing control systems to be tested with simulated engine responses in real-time. This methodology enables engineers to validate control algorithms against virtual engine models before implementation on actual hardware, significantly reducing development time and risk. Advanced HIL systems can simulate complex scenarios including transient operations, fault conditions, and extreme environmental factors.

Despite technological advances, several challenges persist in turbine engine calibration. The increasing complexity of modern engines, featuring multiple variable geometries, sophisticated combustion systems, and integrated subsystems, has exponentially increased the calibration parameter space. Engineers must now optimize hundreds or even thousands of interdependent parameters, creating a multidimensional optimization problem of immense complexity.

Environmental compliance requirements present another significant challenge, as calibration must now balance traditional performance metrics with stringent emissions standards across all operating conditions. This has necessitated more sophisticated sensing technologies and control strategies to maintain optimal combustion characteristics while minimizing pollutant formation.

Production variability remains a persistent issue, as manufacturing tolerances and component variations can significantly impact engine performance characteristics. Calibration methodologies must account for these variations, either through robust design approaches that minimize sensitivity to component variations or through adaptive control strategies that can compensate for individual engine differences.

The integration of machine learning and artificial intelligence into calibration processes represents both an opportunity and a challenge. While these technologies offer the potential for more efficient optimization and adaptive calibration strategies, they also introduce new complexities in validation, certification, and long-term reliability assurance, particularly in safety-critical aerospace applications.

Model-based calibration represents a significant advancement in this field, utilizing mathematical models to predict engine behavior under various conditions. These models incorporate thermodynamic principles, fluid dynamics, and mechanical engineering concepts to create digital representations of physical engine systems. The advantage of this approach lies in its ability to reduce physical testing requirements while expanding the calibration envelope beyond what can be safely or economically tested in physical environments.

Hardware-in-the-loop (HIL) simulation has emerged as a critical technology for calibration processes, allowing control systems to be tested with simulated engine responses in real-time. This methodology enables engineers to validate control algorithms against virtual engine models before implementation on actual hardware, significantly reducing development time and risk. Advanced HIL systems can simulate complex scenarios including transient operations, fault conditions, and extreme environmental factors.

Despite technological advances, several challenges persist in turbine engine calibration. The increasing complexity of modern engines, featuring multiple variable geometries, sophisticated combustion systems, and integrated subsystems, has exponentially increased the calibration parameter space. Engineers must now optimize hundreds or even thousands of interdependent parameters, creating a multidimensional optimization problem of immense complexity.

Environmental compliance requirements present another significant challenge, as calibration must now balance traditional performance metrics with stringent emissions standards across all operating conditions. This has necessitated more sophisticated sensing technologies and control strategies to maintain optimal combustion characteristics while minimizing pollutant formation.

Production variability remains a persistent issue, as manufacturing tolerances and component variations can significantly impact engine performance characteristics. Calibration methodologies must account for these variations, either through robust design approaches that minimize sensitivity to component variations or through adaptive control strategies that can compensate for individual engine differences.

The integration of machine learning and artificial intelligence into calibration processes represents both an opportunity and a challenge. While these technologies offer the potential for more efficient optimization and adaptive calibration strategies, they also introduce new complexities in validation, certification, and long-term reliability assurance, particularly in safety-critical aerospace applications.

State-of-the-Art Calibration Methodologies and Techniques

01 Precision control systems for turbine engines

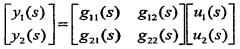

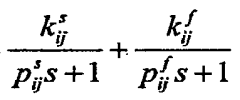

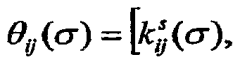

Advanced control systems designed to enhance the precision of turbine engine operations. These systems utilize sophisticated sensors and algorithms to monitor and adjust engine parameters in real-time, ensuring optimal performance and efficiency. The precision control mechanisms help maintain stable engine operation across various flight conditions and power demands, reducing fuel consumption and extending engine life.- Precision control systems for turbine engines: Advanced control systems for turbine engines that focus on precision operation through electronic monitoring and adjustment mechanisms. These systems utilize sensors and feedback loops to maintain optimal engine performance parameters, ensuring precise control of fuel flow, temperature, and pressure. The precision control systems help improve engine efficiency, reduce emissions, and extend operational life through accurate real-time adjustments.

- Fuel management and injection precision systems: Specialized systems focused on precise fuel delivery and management in turbine engines. These innovations include high-precision fuel injectors, metering devices, and computerized fuel flow control mechanisms that ensure optimal fuel-air mixture ratios. The systems incorporate advanced sensors to monitor combustion conditions and adjust fuel delivery accordingly, resulting in improved combustion efficiency, reduced fuel consumption, and lower emissions.

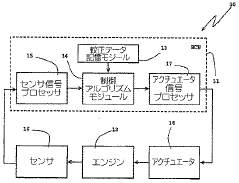

- Digital and electronic control advancements: Modern digital and electronic control technologies applied to turbine engine systems for enhanced precision. These include microprocessor-based controllers, digital signal processing, and advanced algorithms that enable more sophisticated control strategies than traditional mechanical systems. The electronic control units provide faster response times, greater accuracy in parameter adjustments, and the ability to implement complex control logic for optimizing engine performance across various operating conditions.

- Mechanical precision components and assemblies: Specialized mechanical components designed for high-precision operation in turbine engine control systems. These include precision-engineered valves, actuators, governors, and mechanical linkages that ensure accurate control of engine parameters. The components are manufactured to tight tolerances and often incorporate innovative designs to minimize wear, reduce backlash, and maintain calibration accuracy over extended operational periods, even under extreme temperature and vibration conditions.

- Sensor technology and feedback systems: Advanced sensor technologies and feedback systems that enable precise monitoring and control of turbine engine parameters. These systems incorporate various types of sensors including temperature, pressure, speed, and position sensors that provide critical data to the engine control units. The feedback mechanisms allow for closed-loop control, where real-time measurements are continuously compared against desired values, enabling immediate adjustments to maintain optimal engine performance and respond to changing operational conditions.

02 Fuel flow regulation mechanisms

Specialized mechanisms for precise regulation of fuel flow in turbine engines. These systems incorporate high-precision valves, flow meters, and electronic controllers to deliver the exact amount of fuel required for different operating conditions. The accurate fuel flow regulation helps achieve optimal combustion efficiency, reduces emissions, and ensures responsive engine performance during acceleration and deceleration phases.Expand Specific Solutions03 Temperature and pressure monitoring systems

Integrated systems for continuous monitoring of temperature and pressure parameters throughout the turbine engine. These monitoring systems utilize high-precision sensors strategically placed at critical points to provide real-time data on engine operating conditions. The accurate measurement of temperature and pressure gradients enables proactive adjustments to maintain optimal engine performance and prevent potential damage from thermal stress or pressure anomalies.Expand Specific Solutions04 Digital control interfaces for turbine engines

Advanced digital interfaces that enable precise control and monitoring of turbine engine operations. These systems replace traditional analog controls with digital technology, allowing for more accurate command inputs and feedback. The digital control interfaces incorporate sophisticated algorithms for engine parameter optimization, fault detection, and adaptive control strategies that respond to changing operational requirements and environmental conditions.Expand Specific Solutions05 Mechanical precision components for turbine control

Specialized mechanical components engineered for high-precision control of turbine engines. These include precisely manufactured actuators, linkages, and control surfaces that translate electronic commands into physical adjustments within the engine. The mechanical precision components are designed to operate reliably under extreme conditions of temperature, pressure, and vibration while maintaining tight tolerances necessary for optimal engine performance and efficiency.Expand Specific Solutions

Leading Companies in Turbine Control System Calibration

The turbine engine control system calibration market is in a growth phase, characterized by increasing demand for precision control in aerospace, automotive, and power generation sectors. The market is expanding due to stricter emission regulations and efficiency requirements, with an estimated value exceeding $2 billion globally. Leading players include established aerospace giants like GE Aviation, Safran Aircraft Engines, and Honeywell International, alongside automotive powerhouses such as Robert Bosch, Continental Automotive, and major OEMs including Toyota, BMW, and Ford. The technology landscape shows varying maturity levels, with aerospace companies demonstrating advanced capabilities in high-precision calibration, while automotive firms are rapidly innovating with digital calibration technologies and AI-driven approaches pioneered by newer entrants like Avathon.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's turbine engine calibration technology centers on their Integrated Control System (ICS) platform that combines hardware and software solutions for precise engine parameter tuning. Their approach utilizes a comprehensive suite of sensors including advanced pressure transducers with accuracy ratings of ±0.05% and temperature sensors capable of withstanding extreme conditions up to 1600°C[2]. The calibration methodology employs model-predictive control algorithms that continuously optimize multiple parameters simultaneously while accounting for engine degradation over time. Honeywell's proprietary TALON combustion system calibration technology enables ultra-low emissions while maintaining performance, achieving NOx reductions of up to 25% below regulatory requirements[4]. Their calibration process incorporates machine learning algorithms that analyze historical performance data across similar engine types to predict optimal settings for new installations, reducing commissioning time by approximately 40%. The system features automated fault detection capabilities that can identify sensor drift as small as 0.1% from baseline, ensuring calibration accuracy is maintained throughout the operational lifecycle.

Strengths: Exceptional sensor technology with industry-leading accuracy; robust fault-tolerance mechanisms; extensive experience across both aerospace and industrial applications providing cross-domain expertise. Weaknesses: Higher initial investment compared to mechanical systems; proprietary protocols can limit integration with third-party systems; requires regular software updates to maintain optimal performance.

Solar Turbines, Inc.

Technical Solution: Solar Turbines' calibration technology for industrial gas turbines features their Turbotronic control system with advanced model-based calibration techniques. Their approach utilizes a combination of empirical testing and theoretical modeling to create comprehensive performance maps across the entire operating envelope. The calibration process employs high-precision fuel metering systems with accuracy of ±0.5% and specialized instrumentation capable of measuring combustion parameters at microsecond intervals[1]. Solar's proprietary SoLoNOx combustion system calibration methodology enables precise tuning of fuel-air mixtures to achieve ultra-low emissions while maintaining combustion stability across varying load conditions and ambient environments. Their calibration technology incorporates adaptive algorithms that automatically compensate for changes in fuel composition, with the ability to handle variations in heating value of up to 15% without manual recalibration[3]. The system features a comprehensive diagnostic suite that continuously monitors over 200 parameters to detect deviations from calibrated performance, with automated adjustment capabilities that maintain efficiency within 1% of optimal values throughout the operational lifecycle. Solar's calibration approach includes specialized test procedures for transient response optimization, ensuring stable operation during rapid load changes while maintaining emissions compliance.

Strengths: Specialized expertise in industrial gas turbines operating in harsh environments; robust field-proven technology with over 15,000 units in operation; excellent long-term stability requiring minimal recalibration. Weaknesses: Less extensive data analytics capabilities compared to larger competitors; primarily focused on industrial applications with limited crossover to aerospace; higher maintenance requirements in extreme operating conditions.

Critical Patents and Research in Precision Calibration

Calibration of engine control systems

PatentWO2007078653A2

Innovation

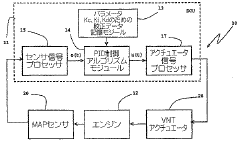

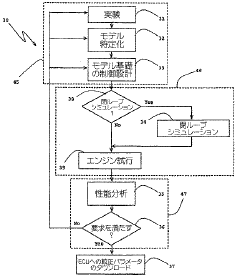

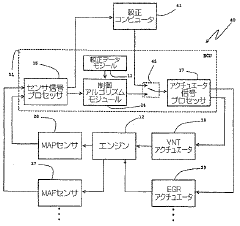

- A tool that uses a computer-based system to perform model identification and generate controller tuning parameters, incorporating algorithms that compute engine calibration parameters to satisfy performance requirements such as emissions, fuel economy, and drivability, utilizing a PID control algorithm and model predictive control, with the ability to automatically determine calibration parameters for multivariable interactions.

Engine control system calibration

PatentInactiveJP2009522488A

Innovation

- A model-based approach using a tool that calculates engine calibration parameters through algorithms, incorporating actuator setpoints, sensor measurements, and performance demands, and includes a computer system for model identification and controller tuning.

Regulatory Standards for Turbine Engine Control Systems

Regulatory standards for turbine engine control systems represent a critical framework that ensures safety, reliability, and performance across the aviation industry. These standards are primarily established by international aviation authorities such as the Federal Aviation Administration (FAA) in the United States, the European Union Aviation Safety Agency (EASA), and the International Civil Aviation Organization (ICAO). For calibration of turbine engine control systems, compliance with these regulatory standards is non-negotiable.

The FAA's Federal Aviation Regulations (FARs) Part 33 specifically addresses airworthiness standards for aircraft engines, with sections 33.27 through 33.29 focusing on engine control systems. These regulations mandate precise calibration procedures to ensure that control systems maintain engine parameters within certified limits under all operating conditions. Similarly, EASA's Certification Specifications for Engines (CS-E) provides comprehensive requirements for control system calibration, particularly in CS-E 50 and CS-E 510.

Military specifications such as MIL-STD-810 and MIL-E-8593 establish additional requirements for engine control systems used in defense applications, emphasizing robustness and reliability under extreme operational conditions. These standards often require more stringent calibration procedures than their civilian counterparts.

The SAE International has developed several Aerospace Recommended Practices (ARPs) that directly impact turbine engine control calibration. Notable among these are ARP4754A for development of civil aircraft and systems, and ARP4761 for conducting safety assessments. These documents provide methodologies for verification and validation of control system calibration processes.

Environmental considerations also factor into regulatory requirements, with standards specifying calibration procedures that account for temperature extremes, altitude variations, electromagnetic interference, and vibration effects. ISO 9001 and AS9100 quality management standards further ensure that calibration processes are documented, repeatable, and traceable.

Recent regulatory trends show increasing emphasis on model-based development and certification approaches. The FAA's Certification Authorities Software Team (CAST) has issued position papers that address the use of modeling and simulation tools in the development and calibration of engine control systems, potentially streamlining the certification process while maintaining rigorous standards.

Compliance with these regulatory standards requires comprehensive documentation of calibration procedures, including test methods, equipment specifications, and acceptance criteria. Manufacturers must demonstrate that their calibration processes can consistently achieve the required precision across the entire operating envelope of the engine, with appropriate margins for safety and reliability.

The FAA's Federal Aviation Regulations (FARs) Part 33 specifically addresses airworthiness standards for aircraft engines, with sections 33.27 through 33.29 focusing on engine control systems. These regulations mandate precise calibration procedures to ensure that control systems maintain engine parameters within certified limits under all operating conditions. Similarly, EASA's Certification Specifications for Engines (CS-E) provides comprehensive requirements for control system calibration, particularly in CS-E 50 and CS-E 510.

Military specifications such as MIL-STD-810 and MIL-E-8593 establish additional requirements for engine control systems used in defense applications, emphasizing robustness and reliability under extreme operational conditions. These standards often require more stringent calibration procedures than their civilian counterparts.

The SAE International has developed several Aerospace Recommended Practices (ARPs) that directly impact turbine engine control calibration. Notable among these are ARP4754A for development of civil aircraft and systems, and ARP4761 for conducting safety assessments. These documents provide methodologies for verification and validation of control system calibration processes.

Environmental considerations also factor into regulatory requirements, with standards specifying calibration procedures that account for temperature extremes, altitude variations, electromagnetic interference, and vibration effects. ISO 9001 and AS9100 quality management standards further ensure that calibration processes are documented, repeatable, and traceable.

Recent regulatory trends show increasing emphasis on model-based development and certification approaches. The FAA's Certification Authorities Software Team (CAST) has issued position papers that address the use of modeling and simulation tools in the development and calibration of engine control systems, potentially streamlining the certification process while maintaining rigorous standards.

Compliance with these regulatory standards requires comprehensive documentation of calibration procedures, including test methods, equipment specifications, and acceptance criteria. Manufacturers must demonstrate that their calibration processes can consistently achieve the required precision across the entire operating envelope of the engine, with appropriate margins for safety and reliability.

Environmental Impact and Sustainability Considerations

The calibration of turbine engine control systems has significant environmental implications that must be considered in the context of global sustainability goals. Precise calibration directly impacts fuel efficiency, with optimally calibrated systems consuming less fuel while maintaining performance parameters. Research indicates that even minor calibration improvements of 1-2% can translate to substantial fuel savings across a fleet, reducing carbon emissions by thousands of tons annually for commercial airlines and power generation facilities.

Emissions control represents another critical environmental dimension of turbine calibration. Modern regulatory frameworks such as the International Civil Aviation Organization's (ICAO) standards and the EPA's stationary source emissions guidelines impose increasingly stringent limits on NOx, CO, and particulate matter. Advanced calibration techniques that incorporate real-time emissions monitoring can reduce pollutant formation by optimizing combustion parameters across varying operational conditions.

The lifecycle environmental impact of calibration technologies deserves careful consideration. Traditional calibration methods often require extensive ground testing with engines running at various power settings, consuming significant fuel and generating emissions solely for calibration purposes. Newer model-based calibration approaches and digital twin technologies can reduce this environmental burden by shifting more calibration work to virtual environments, potentially reducing calibration-related emissions by up to 60% according to recent industry studies.

Resource efficiency in calibration processes extends beyond fuel considerations to include materials and energy used in calibration equipment. The transition toward more sustainable calibration practices includes the development of energy-efficient test cells, renewable power sources for calibration facilities, and reduced reliance on environmentally problematic calibration fluids and chemicals.

Climate resilience must also factor into calibration strategies as changing environmental conditions affect engine performance. Calibration systems must account for wider temperature ranges, changing air densities, and more frequent extreme weather events. Adaptive calibration algorithms that can compensate for these variations will be essential for maintaining efficiency and emissions compliance in a changing climate.

The circular economy presents opportunities for sustainability improvements in calibration systems. Modular design approaches for calibration hardware enable easier upgrades and repairs, extending useful life and reducing electronic waste. Cloud-based calibration data management systems can optimize calibration intervals based on actual performance data rather than fixed schedules, minimizing unnecessary maintenance activities and associated environmental impacts.

Emissions control represents another critical environmental dimension of turbine calibration. Modern regulatory frameworks such as the International Civil Aviation Organization's (ICAO) standards and the EPA's stationary source emissions guidelines impose increasingly stringent limits on NOx, CO, and particulate matter. Advanced calibration techniques that incorporate real-time emissions monitoring can reduce pollutant formation by optimizing combustion parameters across varying operational conditions.

The lifecycle environmental impact of calibration technologies deserves careful consideration. Traditional calibration methods often require extensive ground testing with engines running at various power settings, consuming significant fuel and generating emissions solely for calibration purposes. Newer model-based calibration approaches and digital twin technologies can reduce this environmental burden by shifting more calibration work to virtual environments, potentially reducing calibration-related emissions by up to 60% according to recent industry studies.

Resource efficiency in calibration processes extends beyond fuel considerations to include materials and energy used in calibration equipment. The transition toward more sustainable calibration practices includes the development of energy-efficient test cells, renewable power sources for calibration facilities, and reduced reliance on environmentally problematic calibration fluids and chemicals.

Climate resilience must also factor into calibration strategies as changing environmental conditions affect engine performance. Calibration systems must account for wider temperature ranges, changing air densities, and more frequent extreme weather events. Adaptive calibration algorithms that can compensate for these variations will be essential for maintaining efficiency and emissions compliance in a changing climate.

The circular economy presents opportunities for sustainability improvements in calibration systems. Modular design approaches for calibration hardware enable easier upgrades and repairs, extending useful life and reducing electronic waste. Cloud-based calibration data management systems can optimize calibration intervals based on actual performance data rather than fixed schedules, minimizing unnecessary maintenance activities and associated environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!