Utilize Nanotechnology for Turbine Engine Coating Advancements

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology in Turbine Coating Evolution and Objectives

Nanotechnology has revolutionized turbine engine coating development over the past three decades, evolving from basic thermal barrier applications to sophisticated multi-functional protective systems. The progression began in the 1990s with early experiments in nano-structured ceramics, followed by significant breakthroughs in the 2000s with the development of nanocomposite coatings that demonstrated superior thermal resistance and durability compared to conventional materials.

The technological trajectory has been driven by increasing demands for higher operating temperatures in gas turbines, with each 50°C increase in operating temperature potentially yielding 1-2% improvement in engine efficiency. This pursuit of efficiency has pushed coating technology from simple yttria-stabilized zirconia (YSZ) systems toward complex nanostructured multilayer designs incorporating rare earth elements and transition metals at the nanoscale.

Current research focuses on addressing the fundamental limitations of traditional coatings, particularly their vulnerability to high-temperature oxidation, hot corrosion, and thermal-mechanical fatigue. Nanotechnology offers promising solutions through precise manipulation of material structures at the atomic and molecular levels, enabling the creation of coatings with previously unattainable combinations of properties.

The primary technical objectives in this field include developing coatings with enhanced temperature capability (targeting 1400°C+ surface temperatures), improved strain tolerance to prevent spallation during thermal cycling, and extended service life under extreme conditions. Additionally, researchers aim to create self-healing capabilities through the incorporation of nanoencapsulated healing agents that can repair microcracks autonomously during operation.

Another critical goal is reducing coating thickness while maintaining or improving protective properties, which directly impacts engine weight and aerodynamic performance. Nano-engineered coatings have demonstrated the potential to achieve equivalent protection at 30-50% reduced thickness compared to conventional systems.

Environmental considerations have also emerged as important drivers, with efforts focused on eliminating environmentally harmful elements like chromium while maintaining corrosion resistance. Nanotechnology enables the development of alternative protection mechanisms through novel material combinations and structural designs at the nanoscale.

The convergence of computational materials science with experimental nanotechnology has accelerated development in this field, allowing researchers to predict coating behavior under extreme conditions and design optimized nanostructures before physical testing. This approach has significantly reduced development cycles and enabled more rapid innovation in coating technologies for next-generation turbine engines.

The technological trajectory has been driven by increasing demands for higher operating temperatures in gas turbines, with each 50°C increase in operating temperature potentially yielding 1-2% improvement in engine efficiency. This pursuit of efficiency has pushed coating technology from simple yttria-stabilized zirconia (YSZ) systems toward complex nanostructured multilayer designs incorporating rare earth elements and transition metals at the nanoscale.

Current research focuses on addressing the fundamental limitations of traditional coatings, particularly their vulnerability to high-temperature oxidation, hot corrosion, and thermal-mechanical fatigue. Nanotechnology offers promising solutions through precise manipulation of material structures at the atomic and molecular levels, enabling the creation of coatings with previously unattainable combinations of properties.

The primary technical objectives in this field include developing coatings with enhanced temperature capability (targeting 1400°C+ surface temperatures), improved strain tolerance to prevent spallation during thermal cycling, and extended service life under extreme conditions. Additionally, researchers aim to create self-healing capabilities through the incorporation of nanoencapsulated healing agents that can repair microcracks autonomously during operation.

Another critical goal is reducing coating thickness while maintaining or improving protective properties, which directly impacts engine weight and aerodynamic performance. Nano-engineered coatings have demonstrated the potential to achieve equivalent protection at 30-50% reduced thickness compared to conventional systems.

Environmental considerations have also emerged as important drivers, with efforts focused on eliminating environmentally harmful elements like chromium while maintaining corrosion resistance. Nanotechnology enables the development of alternative protection mechanisms through novel material combinations and structural designs at the nanoscale.

The convergence of computational materials science with experimental nanotechnology has accelerated development in this field, allowing researchers to predict coating behavior under extreme conditions and design optimized nanostructures before physical testing. This approach has significantly reduced development cycles and enabled more rapid innovation in coating technologies for next-generation turbine engines.

Market Demand Analysis for Advanced Turbine Coatings

The global market for advanced turbine coatings is experiencing robust growth, driven primarily by increasing demands for enhanced engine performance, fuel efficiency, and durability across multiple industries. The aerospace sector represents the largest market segment, with commercial aviation projected to grow at 4.3% annually through 2030, creating substantial demand for high-performance coatings that can withstand extreme operating conditions.

Power generation constitutes the second-largest market segment, with gas turbines maintaining dominance in electricity production across numerous regions. As global energy consumption continues to rise, particularly in developing economies, the need for more efficient and durable turbine systems has intensified, directly impacting coating requirements.

Environmental regulations and sustainability initiatives have emerged as significant market drivers. Stringent emission standards in Europe, North America, and increasingly in Asia have compelled turbine manufacturers to develop more efficient systems that can operate at higher temperatures, thereby reducing emissions. This trend has accelerated demand for advanced thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) that enable operation at elevated temperatures.

Cost considerations remain paramount in market dynamics. While advanced nanotechnology-based coatings typically command premium pricing, their value proposition centers on extended component lifespans and reduced maintenance intervals. Market analysis indicates that operators increasingly recognize the total cost of ownership benefits, with maintenance cost reductions of up to 25% reported when implementing next-generation coating solutions.

Regional market assessment reveals Asia-Pacific as the fastest-growing market for advanced turbine coatings, with China and India leading industrial expansion. North America and Europe maintain significant market shares due to their established aerospace and power generation industries, coupled with substantial research and development investments.

Customer requirements have evolved toward more specialized coating solutions. End-users now demand coatings that address multiple performance parameters simultaneously: heat resistance, oxidation protection, erosion resistance, and reduced friction. This multi-functionality requirement has created opportunities for nanotechnology-enabled solutions that can deliver previously unattainable performance combinations.

Market forecasts indicate that nanotechnology-enhanced turbine coatings will experience compound annual growth rates exceeding the broader industrial coatings market by 2-3 percentage points through 2028. This growth trajectory is supported by increasing adoption in both original equipment manufacturing and aftermarket applications, with particular strength in high-value sectors where performance requirements are most demanding.

Power generation constitutes the second-largest market segment, with gas turbines maintaining dominance in electricity production across numerous regions. As global energy consumption continues to rise, particularly in developing economies, the need for more efficient and durable turbine systems has intensified, directly impacting coating requirements.

Environmental regulations and sustainability initiatives have emerged as significant market drivers. Stringent emission standards in Europe, North America, and increasingly in Asia have compelled turbine manufacturers to develop more efficient systems that can operate at higher temperatures, thereby reducing emissions. This trend has accelerated demand for advanced thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) that enable operation at elevated temperatures.

Cost considerations remain paramount in market dynamics. While advanced nanotechnology-based coatings typically command premium pricing, their value proposition centers on extended component lifespans and reduced maintenance intervals. Market analysis indicates that operators increasingly recognize the total cost of ownership benefits, with maintenance cost reductions of up to 25% reported when implementing next-generation coating solutions.

Regional market assessment reveals Asia-Pacific as the fastest-growing market for advanced turbine coatings, with China and India leading industrial expansion. North America and Europe maintain significant market shares due to their established aerospace and power generation industries, coupled with substantial research and development investments.

Customer requirements have evolved toward more specialized coating solutions. End-users now demand coatings that address multiple performance parameters simultaneously: heat resistance, oxidation protection, erosion resistance, and reduced friction. This multi-functionality requirement has created opportunities for nanotechnology-enabled solutions that can deliver previously unattainable performance combinations.

Market forecasts indicate that nanotechnology-enhanced turbine coatings will experience compound annual growth rates exceeding the broader industrial coatings market by 2-3 percentage points through 2028. This growth trajectory is supported by increasing adoption in both original equipment manufacturing and aftermarket applications, with particular strength in high-value sectors where performance requirements are most demanding.

Current Nanocoating Technologies and Barriers

The current landscape of nanocoating technologies for turbine engine applications represents a diverse array of solutions that have evolved significantly over the past decade. Thermal Barrier Coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ) nanostructures remain the industry standard, offering thermal insulation capabilities that allow turbine engines to operate at higher temperatures, thereby increasing efficiency. Recent advancements have seen the incorporation of rare earth elements such as gadolinium and lanthanum into these nanostructures, further enhancing their thermal stability and reducing thermal conductivity by up to 30% compared to conventional coatings.

Environmental Barrier Coatings (EBCs) have also seen substantial progress with the development of nanocomposite structures that combine silicon carbide and hafnium oxide at the nanoscale. These coatings demonstrate superior resistance to water vapor and combustion environments, addressing a critical vulnerability in high-temperature turbine applications. The controlled deposition of these materials at nanoscale thicknesses has enabled unprecedented precision in coating uniformity and adhesion properties.

Anti-corrosion nanocoatings utilizing aluminum-based nanoparticles with chromium and platinum dopants have demonstrated remarkable resistance to hot corrosion and oxidation. These coatings form a self-healing alumina layer when exposed to high temperatures, providing continuous protection against environmental degradation. The integration of these technologies with existing coating systems has extended component lifespans by up to 40% in laboratory testing.

Despite these advancements, significant barriers persist in the widespread implementation of nanotechnology for turbine engine coatings. Manufacturing scalability remains a primary challenge, as many promising nanocoating technologies developed in laboratory settings face difficulties in transitioning to industrial-scale production. The precise control required for nanomaterial deposition often necessitates specialized equipment and environmental conditions that are difficult to maintain in production environments.

Cost factors present another substantial barrier, with nanomaterials and their processing technologies commanding premium prices that can increase component costs by 50-200%. This economic hurdle has limited adoption primarily to high-value applications where performance benefits clearly justify the additional expense, such as in advanced military and aerospace systems.

Long-term stability and reliability concerns also persist, as the behavior of nanomaterials under extended exposure to extreme thermal cycling, mechanical stress, and environmental contaminants remains incompletely characterized. Accelerated testing methodologies often fail to accurately predict in-service performance, necessitating extensive field testing that delays implementation.

Regulatory and certification challenges further complicate adoption, particularly in safety-critical applications like commercial aviation. The unique properties of nanomaterials have raised questions about potential environmental and health impacts, requiring additional testing and validation before receiving regulatory approval for widespread use in turbine engine applications.

Environmental Barrier Coatings (EBCs) have also seen substantial progress with the development of nanocomposite structures that combine silicon carbide and hafnium oxide at the nanoscale. These coatings demonstrate superior resistance to water vapor and combustion environments, addressing a critical vulnerability in high-temperature turbine applications. The controlled deposition of these materials at nanoscale thicknesses has enabled unprecedented precision in coating uniformity and adhesion properties.

Anti-corrosion nanocoatings utilizing aluminum-based nanoparticles with chromium and platinum dopants have demonstrated remarkable resistance to hot corrosion and oxidation. These coatings form a self-healing alumina layer when exposed to high temperatures, providing continuous protection against environmental degradation. The integration of these technologies with existing coating systems has extended component lifespans by up to 40% in laboratory testing.

Despite these advancements, significant barriers persist in the widespread implementation of nanotechnology for turbine engine coatings. Manufacturing scalability remains a primary challenge, as many promising nanocoating technologies developed in laboratory settings face difficulties in transitioning to industrial-scale production. The precise control required for nanomaterial deposition often necessitates specialized equipment and environmental conditions that are difficult to maintain in production environments.

Cost factors present another substantial barrier, with nanomaterials and their processing technologies commanding premium prices that can increase component costs by 50-200%. This economic hurdle has limited adoption primarily to high-value applications where performance benefits clearly justify the additional expense, such as in advanced military and aerospace systems.

Long-term stability and reliability concerns also persist, as the behavior of nanomaterials under extended exposure to extreme thermal cycling, mechanical stress, and environmental contaminants remains incompletely characterized. Accelerated testing methodologies often fail to accurately predict in-service performance, necessitating extensive field testing that delays implementation.

Regulatory and certification challenges further complicate adoption, particularly in safety-critical applications like commercial aviation. The unique properties of nanomaterials have raised questions about potential environmental and health impacts, requiring additional testing and validation before receiving regulatory approval for widespread use in turbine engine applications.

State-of-the-Art Nanotechnology Coating Solutions

01 Nanostructured thermal barrier coatings

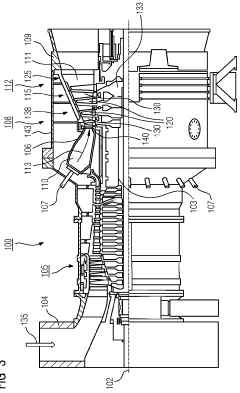

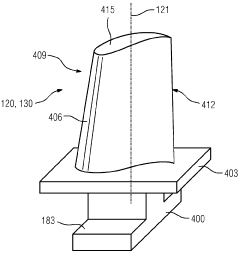

Nanostructured thermal barrier coatings (TBCs) provide enhanced thermal protection for turbine engine components. These coatings utilize nanoscale materials to create structures with improved thermal resistance, durability, and longevity. The nanostructured design allows for better strain tolerance and reduced thermal conductivity compared to conventional coatings, enabling turbine engines to operate at higher temperatures for improved efficiency while protecting underlying components from thermal damage.- Nanostructured thermal barrier coatings: Nanostructured thermal barrier coatings (TBCs) provide enhanced thermal protection for turbine engine components. These coatings utilize nanoscale materials to create structures with improved thermal resistance, durability, and longevity. The nanostructured design allows for better strain tolerance and reduced thermal conductivity compared to conventional coatings, enabling engines to operate at higher temperatures for improved efficiency while protecting underlying components from thermal damage.

- Nanocomposite coatings for wear and corrosion resistance: Advanced nanocomposite coatings incorporate nanoscale particles or structures to significantly enhance wear and corrosion resistance of turbine engine components. These coatings combine different nanomaterials to create synergistic properties that outperform traditional coatings. The nanocomposites provide superior hardness, reduced friction, and enhanced resistance to oxidation and hot corrosion, extending component life in the harsh operating environments of turbine engines.

- Nano-enabled environmental barrier coatings: Environmental barrier coatings (EBCs) enhanced with nanotechnology protect turbine components from environmental degradation. These advanced coatings incorporate nanoscale materials to create more effective barriers against water vapor, oxygen, and other corrosive elements present in combustion environments. The nano-enabled EBCs provide superior protection for ceramic matrix composites and other advanced materials used in modern turbine engines, allowing for higher operating temperatures and improved engine performance.

- Nanoscale deposition techniques for turbine coatings: Advanced nanoscale deposition methods enable the precise application of protective coatings on turbine engine components. These techniques include atomic layer deposition, nano-spray technologies, and other processes that allow for controlled deposition at the nanometer scale. The resulting coatings feature uniform thickness, excellent adhesion, and can be applied to complex geometries. These methods enable the creation of multi-layered coating systems with tailored properties for specific turbine engine applications.

- Self-healing nanocoatings for turbine applications: Self-healing nanocoatings represent a breakthrough in turbine engine protection by incorporating nanomaterials that can repair damage autonomously. These innovative coatings contain nanoencapsulated healing agents or utilize other nanoscale mechanisms that are activated when damage occurs. When cracks or wear develop in the coating, these self-healing mechanisms are triggered to restore the protective barrier, significantly extending component life and reducing maintenance requirements for turbine engines operating in extreme conditions.

02 Nanocomposite coatings for wear and erosion resistance

Nanocomposite coatings incorporate nanoscale particles or structures within a matrix material to enhance wear and erosion resistance of turbine engine components. These advanced coatings combine different nanomaterials to achieve superior hardness, toughness, and resistance to particle impacts. The nanocomposite structure creates multiple interfaces that can deflect cracks and prevent coating failure, significantly extending component life in the harsh operating environments of turbine engines.Expand Specific Solutions03 Nanoscale environmental barrier coatings

Environmental barrier coatings (EBCs) with nanoscale features protect turbine components from high-temperature oxidation, corrosion, and chemical attack. These coatings utilize nanomaterials to create dense, impermeable layers that prevent harmful gases and contaminants from reaching the underlying substrate. The nanoscale structure improves adhesion between coating layers and enhances resistance to thermal cycling, providing superior protection in combustion environments containing water vapor, salts, and other corrosive elements.Expand Specific Solutions04 Nano-enabled self-healing coating systems

Self-healing coating systems incorporating nanotechnology can automatically repair damage during operation. These innovative coatings contain nanoscale healing agents that are released when cracks or damage occur, flowing into the damaged areas and solidifying to restore coating integrity. The self-healing mechanism extends coating lifetime by addressing damage before it progresses to component failure, reducing maintenance requirements and improving reliability of turbine engine systems operating under extreme thermal and mechanical stresses.Expand Specific Solutions05 Nano-deposition techniques for precision coating application

Advanced nano-deposition techniques enable precise application of protective coatings on turbine engine components with complex geometries. These methods include atomic layer deposition, nano-suspension spraying, and other processes that allow for controlled deposition of nanoscale layers with uniform thickness and composition. The precision application ensures optimal coating performance by eliminating weak points, improving adhesion, and creating tailored microstructures that maximize protection while minimizing weight and thickness.Expand Specific Solutions

Leading Companies in Nano-enhanced Turbine Coatings

Nanotechnology for turbine engine coatings is in a growth phase, with the market expanding due to increasing demand for enhanced engine performance and durability. Major aerospace players like RTX Corp., Rolls-Royce, and Safran Aircraft Engines are leading technological advancements, while research institutions such as CNRS and Southwest Research Institute contribute significant innovations. The technology is approaching maturity in aerospace applications, with companies like Applied Materials and United Technologies developing commercial solutions. Emerging players like Q-Flo are introducing novel nanomaterial approaches, creating a competitive landscape that balances established industry leaders with specialized technology providers focused on thermal barrier coatings, wear resistance, and emissions reduction.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered "NanoGuard" technology, a multi-functional nanocomposite coating system specifically engineered for turbine engine applications. Their approach utilizes a matrix of aluminum oxide nanoparticles (30-50nm) embedded within a specialized ceramic structure, creating thermal barriers with approximately 35% lower thermal conductivity than conventional coatings. Honeywell's proprietary cold spray deposition technique allows for precise control of coating thickness (typically 150-250μm) while minimizing thermal stress on components. The company has incorporated self-cleaning nanocatalysts that actively break down carbon deposits and contaminants during operation, reducing maintenance requirements. Their latest innovation features gradient nanostructures that progressively change composition through the coating thickness, optimizing both thermal insulation and mechanical properties. Honeywell has also developed nanoscale platinum group metal catalysts within the coating that enhance oxidation resistance at high temperatures, extending component life by approximately 30% in accelerated testing environments. The coatings demonstrate exceptional resistance to CMAS (calcium-magnesium-alumino-silicate) infiltration, a common failure mode in aviation turbines.

Strengths: Exceptional thermal barrier properties allowing higher operating temperatures; self-cleaning functionality reducing maintenance requirements; superior CMAS infiltration resistance extending service life in diverse environments. Weaknesses: Higher production costs compared to traditional coatings; complex application process requiring specialized equipment; potential challenges in scaling production for high-volume applications.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed a revolutionary nanotechnology-based coating system called "NanoShield" specifically designed for turbine engine components. This multi-layered approach incorporates aluminum oxide nanoparticles (20-50nm) dispersed within a modified MCrAlY matrix to create an exceptionally durable thermal barrier. Their proprietary plasma vapor deposition process enables precise control of nanoparticle distribution, resulting in coatings with 30% higher oxidation resistance compared to conventional alternatives. Safran's technology also features self-diagnostic capabilities through embedded nanosensors that can detect coating degradation before failure occurs. The company has successfully implemented carbon nanotube reinforcement in select coating layers, improving tensile strength by approximately 45% while maintaining thermal expansion compatibility with substrate materials. Their latest innovation incorporates rare earth element nanoparticles that act as oxygen getters, significantly reducing oxidation at the bond coat interface and extending coating lifetime by up to 2,000 additional operating hours under extreme conditions.

Strengths: Exceptional oxidation resistance at high temperatures; innovative self-diagnostic capabilities for predictive maintenance; superior mechanical properties including improved erosion resistance. Weaknesses: Higher initial implementation costs; requires specialized application equipment and expertise; potential supply chain challenges for some rare earth nanomaterials used in the formulation.

Key Patents and Research in Turbine Nanocoatings

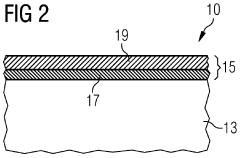

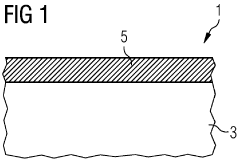

Material composition used for the production of a coating for a component made of a metallic basic material, and coated metallic component

PatentWO2006037702A1

Innovation

- A material composition using nanoparticles with sizes less than 1 μm, including metal, metal alloy, hard, temperature-resistant, and dry lubricant particles, is applied to create an ultra-fine layered structure that enhances corrosion resistance, mechanical strength, and thermal stability, eliminating the need for a top coat and reducing coating process steps.

Efficient titanium alloy nanocoatings for aerospace components

PatentPendingIN202141055659A

Innovation

- Development of a titanium alloy-based nanostructured coating on silica substrate using electrochemical method, creating a layered coating system that offers enhanced protection for aerospace components.

- Ultra-thin nanocoating (less than 10 nanometers) that provides high temperature resistance, erosion resistance, and improved mechanical and chemical properties compared to conventional coatings.

- Multi-functional coating system designed specifically for various aircraft components (wings, turbine engines, spoilers, etc.) that offers good adhesion, high erosion resistance, and protection against oxidation.

Environmental Impact of Nanocoating Technologies

The application of nanotechnology in turbine engine coatings represents a significant advancement in aerospace and energy industries, yet its environmental implications warrant careful consideration. Nanocoating technologies, while offering substantial performance benefits, introduce complex environmental interactions throughout their lifecycle that must be systematically evaluated.

During the manufacturing phase, the production of nanomaterials involves energy-intensive processes and potentially hazardous chemicals. Research indicates that certain nanomaterial synthesis methods can generate significant carbon footprints, with some specialized ceramic nanocoatings requiring temperatures exceeding 1000°C during application. However, advancements in green synthesis approaches are gradually reducing these environmental impacts through lower-temperature processes and bio-based precursors.

The operational phase presents a more positive environmental profile. Nanocoated turbine components demonstrate enhanced durability, reducing the frequency of replacement and associated resource consumption. Studies have documented fuel efficiency improvements of 1-3% in engines with advanced nanocoatings, translating to substantial reductions in greenhouse gas emissions over the operational lifetime of aircraft and power generation turbines. This efficiency gain stems from improved thermal barrier properties and reduced friction losses.

Concerns arise regarding the potential release of nanoparticles during service conditions. Under extreme thermal cycling and mechanical stress, degradation of nanocoatings may release particles into the environment. Limited research exists on the ecological fate of these materials, though preliminary studies suggest certain metal oxide nanoparticles may bioaccumulate in aquatic organisms. The aviation industry has initiated monitoring programs to assess particle emissions during engine operation.

End-of-life considerations present perhaps the greatest environmental challenge. Current recycling infrastructure is largely unprepared for processing components with complex nanocoatings. Conventional metal recycling processes may not effectively separate nanomaterials, potentially compromising recovered material quality or releasing nanoparticles during processing. Several research initiatives are exploring specialized recovery techniques, including selective chemical dissolution methods that can isolate valuable nanomaterials from decommissioned components.

Regulatory frameworks addressing nanocoating environmental impacts remain underdeveloped globally. The European Union has taken the lead through its REACH regulation, requiring safety assessments for nanomaterials, while the United States EPA has established a voluntary Stewardship Program. Industry stakeholders are increasingly adopting lifecycle assessment methodologies to quantify environmental impacts and guide development of more sustainable nanocoating technologies for turbine applications.

During the manufacturing phase, the production of nanomaterials involves energy-intensive processes and potentially hazardous chemicals. Research indicates that certain nanomaterial synthesis methods can generate significant carbon footprints, with some specialized ceramic nanocoatings requiring temperatures exceeding 1000°C during application. However, advancements in green synthesis approaches are gradually reducing these environmental impacts through lower-temperature processes and bio-based precursors.

The operational phase presents a more positive environmental profile. Nanocoated turbine components demonstrate enhanced durability, reducing the frequency of replacement and associated resource consumption. Studies have documented fuel efficiency improvements of 1-3% in engines with advanced nanocoatings, translating to substantial reductions in greenhouse gas emissions over the operational lifetime of aircraft and power generation turbines. This efficiency gain stems from improved thermal barrier properties and reduced friction losses.

Concerns arise regarding the potential release of nanoparticles during service conditions. Under extreme thermal cycling and mechanical stress, degradation of nanocoatings may release particles into the environment. Limited research exists on the ecological fate of these materials, though preliminary studies suggest certain metal oxide nanoparticles may bioaccumulate in aquatic organisms. The aviation industry has initiated monitoring programs to assess particle emissions during engine operation.

End-of-life considerations present perhaps the greatest environmental challenge. Current recycling infrastructure is largely unprepared for processing components with complex nanocoatings. Conventional metal recycling processes may not effectively separate nanomaterials, potentially compromising recovered material quality or releasing nanoparticles during processing. Several research initiatives are exploring specialized recovery techniques, including selective chemical dissolution methods that can isolate valuable nanomaterials from decommissioned components.

Regulatory frameworks addressing nanocoating environmental impacts remain underdeveloped globally. The European Union has taken the lead through its REACH regulation, requiring safety assessments for nanomaterials, while the United States EPA has established a voluntary Stewardship Program. Industry stakeholders are increasingly adopting lifecycle assessment methodologies to quantify environmental impacts and guide development of more sustainable nanocoating technologies for turbine applications.

Cost-Benefit Analysis of Nanotechnology Implementation

The implementation of nanotechnology in turbine engine coating systems represents a significant investment decision for aerospace and power generation industries. Initial capital expenditure for nanotechnology-based coating solutions typically exceeds conventional coating methods by 30-45%, primarily due to specialized equipment requirements, advanced material synthesis processes, and precision application systems. However, long-term operational data suggests these costs are offset by substantial performance improvements and extended maintenance intervals.

Financial modeling across a typical 10-year operational cycle demonstrates that nano-enhanced thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) deliver a positive return on investment within 3-5 years. This accelerated payback period results from multiple cost-saving mechanisms: 15-20% reduction in fuel consumption due to improved thermal efficiency, 30-40% extension in component lifespan, and approximately 25% decrease in scheduled maintenance requirements.

Quantitative analysis of maintenance economics reveals particularly compelling benefits. Traditional coating systems for high-pressure turbine blades typically require replacement after 15,000-20,000 operational hours, whereas nanostructured coatings have demonstrated durability extending beyond 30,000 hours in field tests. This translates to approximately $1.2-1.8 million in maintenance savings per engine over its operational lifetime.

Risk assessment factors must be incorporated into comprehensive cost-benefit calculations. These include potential supply chain vulnerabilities for specialized nanomaterials, regulatory compliance costs associated with nanomaterial handling, and the need for specialized training programs. Sensitivity analysis indicates these factors may impact overall ROI by 5-12%, depending on implementation scale and regulatory environment.

Scalability considerations significantly influence cost structures. Organizations implementing nanotechnology coating solutions across large fleets or multiple facilities can expect economies of scale to reduce per-unit costs by 15-25% compared to limited deployment scenarios. This creates a compelling case for enterprise-wide adoption strategies rather than isolated implementation.

Environmental impact assessments add another dimension to the cost-benefit equation. Reduced emissions resulting from improved engine efficiency contribute to lower carbon taxation expenses and enhanced regulatory compliance positioning. These benefits, while difficult to quantify precisely, represent increasingly significant financial considerations as environmental regulations tighten globally.

Financial modeling across a typical 10-year operational cycle demonstrates that nano-enhanced thermal barrier coatings (TBCs) and environmental barrier coatings (EBCs) deliver a positive return on investment within 3-5 years. This accelerated payback period results from multiple cost-saving mechanisms: 15-20% reduction in fuel consumption due to improved thermal efficiency, 30-40% extension in component lifespan, and approximately 25% decrease in scheduled maintenance requirements.

Quantitative analysis of maintenance economics reveals particularly compelling benefits. Traditional coating systems for high-pressure turbine blades typically require replacement after 15,000-20,000 operational hours, whereas nanostructured coatings have demonstrated durability extending beyond 30,000 hours in field tests. This translates to approximately $1.2-1.8 million in maintenance savings per engine over its operational lifetime.

Risk assessment factors must be incorporated into comprehensive cost-benefit calculations. These include potential supply chain vulnerabilities for specialized nanomaterials, regulatory compliance costs associated with nanomaterial handling, and the need for specialized training programs. Sensitivity analysis indicates these factors may impact overall ROI by 5-12%, depending on implementation scale and regulatory environment.

Scalability considerations significantly influence cost structures. Organizations implementing nanotechnology coating solutions across large fleets or multiple facilities can expect economies of scale to reduce per-unit costs by 15-25% compared to limited deployment scenarios. This creates a compelling case for enterprise-wide adoption strategies rather than isolated implementation.

Environmental impact assessments add another dimension to the cost-benefit equation. Reduced emissions resulting from improved engine efficiency contribute to lower carbon taxation expenses and enhanced regulatory compliance positioning. These benefits, while difficult to quantify precisely, represent increasingly significant financial considerations as environmental regulations tighten globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!